DOI:10.19476/j.ysxb.1004.0609.2019.03.01

微量Ce和Ca对AZ31组织演变及成形性能的影响

黄 伦1, 2,黄光胜1, 2, 3,邓钱元1, 2,汤爱涛1, 2, 3,蒋 斌1, 2, 3,潘复生1, 2, 3

(1. 重庆大学 机械传动国家重点实验室,材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金工程技术研究中心,材料科学与工程学院,重庆 400044;

3. 重庆先进材料研究中心,重庆科学技术研究院,重庆 401123)

摘 要:研究微量(0.2%,质量分数)Ce和Ca对AZ31合金组织演变和成形性能的影响,期望通过改善组织和织构开发低成本高成形性能的镁合金。结果表明:Ce和Ca可以使挤压态AZ31板材再结晶晶粒更加均匀细小;Ce和Ca可以弱化轧制退火态板材的基面织构,Ca会使AZ31板材的基面织构基极向横向发散,同时,Ce和Ca还能使AZ31板材的r值和各向异性降低;Ce和Ca可以大幅提高AZ31合金板材的室温成形性能,Mg-3Al-1Zn-0.2Ce-0.2Ca合金薄板的基面织构强度为3.2,r值为1.05,△r值为0.04,其Erichsen值达到6.0 mm。织构的改善主要是由于合金元素引起的滑移系的改变,板材各向异性的降低与其织构的改善密切相关,室温成形性能的提高可以归因于织构的改善、较小的r值和较大的n值。

关键词:镁合金;组织演变;成形性能;织构;微合金化

文章编号:1004-0609(2019)-03-0429-10 中图分类号:TG146.2 文献标志码:A

镁合金具有低密度、较高的比强度和比刚度等优点,近年来受到了越来越多的关注,在汽车、航空航天、医疗、轻量化等领域的应用日渐广泛[1-4]。然而,镁合金较差的室温成形性能限制了其商业应用[5-6]。镁合金具有密排六方结构,在室温下其非基面滑移系启动所需的临界剪切应力(CRSS)较大,在室温变形时非基面滑移系难以启动,基面滑移系是主要的可激活滑移系[7-8]。此外,基面滑移系无法协调沿c轴方向的变形,也无法满足Von-Mises准则所要求的多晶体塑性变形所需要的5个以上独立滑移系[9]。因此,在室温下镁合金的塑性和成形性能较差。而且,普通的热轧镁合金板材具有强烈的基面织构,降低板材的室温成形性能,还导致板材具有强烈的各向异性,进一步限制了镁合金的应用[10-11]。

镁合金板材的室温成形性能与其基面织构密切相关,改善织构类型和弱化织构强度均可以改善镁合金的成形性能[12-14]。合金化是一种有效改善镁合金织构、提高镁合金的室温成形性能的方法。LIU等[15]的研究证明了稀土元素Y、Ce和Gd(0.2%)可以有效地弱化镁合金板材的基面织构,并显著提高了板材的室温伸长率。CHINO等[16]的研究表明,Mg-0.2Ce合金具有比纯镁更弱的基面织构和更好的成形性能。然而,稀土元素大多价格昂贵,成本较高。Ce是一种较为廉价的轻稀土元素,可以有效地弱化镁合金织构[17]。Ca元素成本低廉,研究表明,虽然Ca元素与稀土元素的物理特性差别很大,但镁合金中添加少量的Ca元素对镁合金轧板织构的影响却可以表现出与稀土元素相似的特性[18-19]。KIM等[20]的研究发现,加入Ca元素后,镁合金板材的基面织构显著减弱,具有较高的屈服强度和成形性能。因此,本实验设计了AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca(质量分数,%) 3种微合金含量的镁合金,研究Ce和Ca元素对AZ31镁合金组织演变和成形性能的影响,开发低成本高成形性能的镁合金。

1 实验

通过熔炼和半连续铸造得到了AZ31、AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca(质量分数,%) 4组合金铸锭,成分见表1。铸锭经线切割获得长度为150 mm、直径为83 mm的挤压圆坯。挤压圆坯在400 ℃的加热炉中保温2 h之后进行热挤压,挤压比为31.5:1,挤压速度为1.2 m/min,挤压出的板坯宽60 mm,厚度为3 mm。在每道次轧制之前需要将板坯在450 ℃的加热炉中退火20 min,轧制方向 (RD)与挤压方向(ED)相同,每道次轧制压下率为 20%,经过5道次轧制以后板坯减薄到1 mm。轧制完成后,将薄板在300 ℃下最终退火,退火时间为30 min。

合金微观组织采用金相显微镜观察,观察面为RD-ND或ED-ND面(ND为板面法向量方向),通过截线法测量平均晶粒尺寸。宏观织构使用X射线衍射(XRD)测定,测量面为板面中间层。合金的第二相分布和拉伸断裂形貌由装配有能谱仪(EDS)的扫描电子显微镜(SEM)分析。

选取轧制退火态薄板的RD、45°和横向(TD) 3个方向制备拉伸试样,试样标距长度为12 mm,宽度为6 mm。通过拉伸实验测得合金的屈服强度、抗拉强度和断裂伸长率等。室温单向拉伸实验的初始应变速率为1×10-3 s-1,每种样品至少测试3次。合金的应变硬化指数(n值)从真应力-应变曲线的均匀塑性变形区得到。塑性应变比(r)通过拉伸实验测量,应变为10%。ravg为合金在3个方向r值的平均值,定义如下:

ravg=(rRD+2r45°+rTD)/4 (1)

△r表示薄板的平面各项异度,定义如下:

△r=(rRD+rTD)/2-r45° (2)

式中:rRD、r45°和rTD分别表示样品RD、45°方向和TD的r值。合金的成形性能采用室温Erichsen杯突实验测量,杯突实验样品为轧制退火态薄板。

2 结果与讨论

2.1 挤压态板坯的组织演变

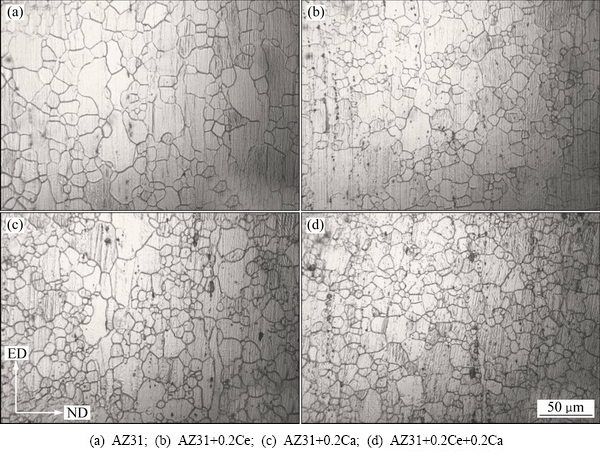

挤压态板坯的金相组织如图1所示。4种合金均发生了明显的动态再结晶,AZ31板坯晶粒尺寸不均匀,与之相比,单独加入Ce或Ca之后,板坯再结晶晶粒尺寸减小,复合加入Ce和Ca的AZ31+0.2Ce+ 0.2Ca板坯再结晶晶粒最为均匀细小。这说明Ce和Ca元素可以促进动态再结晶并细化晶粒。挤压态板坯的基面极图如图2所示,AZ31、AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板坯的基面织构强度分别为23.2、21.3、18.8和10.0。板坯的织构均为沿ED的双峰织构,基面极图为椭圆状(长轴平行于ED),其中AZ31+0.2Ce+0.2Ca板坯的织构强度最低,分布较为发散,这与热挤压变形时滑移系的启动有关。

表1 4种实验合金的成分

Table 1 Compositions of four alloys

图1 挤压态板坯的金相组织

Fig. 1 Optical micrographs of as-extruded magnesium alloy sheets

图2 挤压态合金基面极图

Fig. 2 Pole figures of extruded alloys

图3 挤压退火态合金金相图

Fig. 3 Optical micrographs of extruded and annealed magnesium alloys

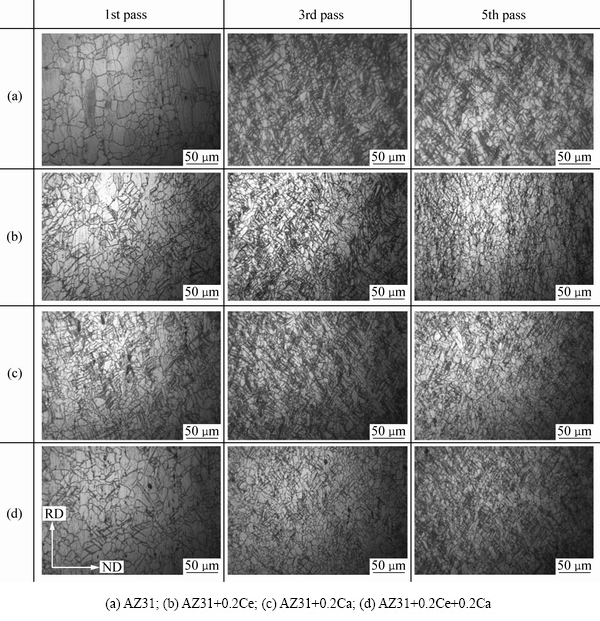

图4 轧制态合金的金相组织

Fig. 4 Optical micrographs of rolled alloys

如图3所示,挤压态板坯经450 ℃退火20 min后晶粒迅速长大。4种合金经第一道次、第三道次和第五道次热轧后的金相组织如图4所示。在第一道次热轧后,4种合金组织中均未发现大量剪切带。随着轧制道次的增加,晶粒逐渐细化。由于组织变形不均匀, AZ31合金组织中形成了大量的剪切带。然而,在同样轧制工艺条件下,经过第三道次的热轧,AZ31+0.2Ce+0.2Ca合金组织中未观察到明显的剪切带。对比不同轧制道次后合金组织中的剪切带,合金化的板材剪切带明显少于AZ31板材的。这说明在热轧中合金化板材的组织变形更为均匀协调。根据Von-Mises准则,在变形过程中至少需要5个独立的滑移系启动才能协调多晶体镁合金的变形。镁合金非基面滑移系启动所需的CRSS较大,在变形时,基面滑移系最容易启动。在AZ31合金的轧制过程中,非基面滑移未能大量启动,位错滑移无法协调沿c轴的变形,因此产生了大量的剪切带。向AZ31合金中加入Ce和Ca元素后,合金层错能降低[21],非基面滑移系启动所需的CRSS降低,非基面滑移系更容易启动,添加Ce和Ca的合金在轧制过程中变形较为均匀,剪切带减少。

2.2 轧制退火态板材的组织

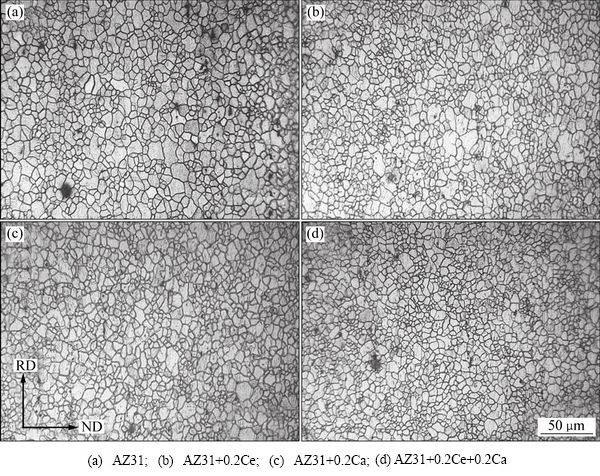

图5 轧制退火态板材的金相组织

Fig. 5 Optical micrographs of rolled and annealed magnesium alloys

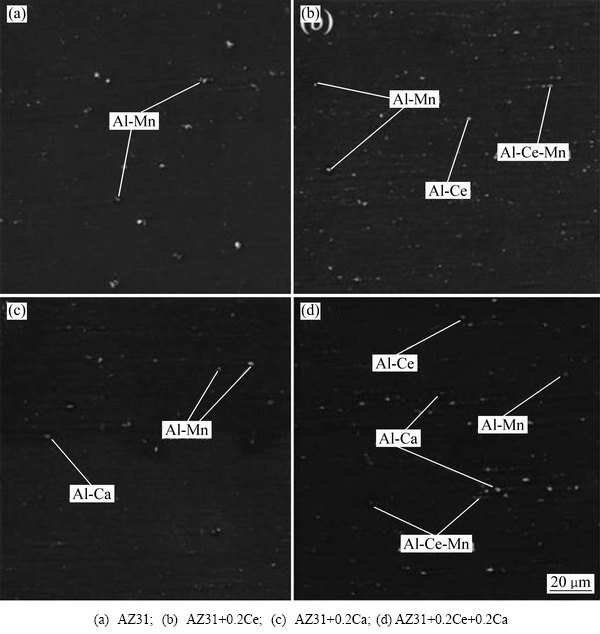

图6 轧制退火态板材中第二相分布图

Fig. 6 Second phase particles distribution of rolled and annealed alloys

轧制退火态板材的金相组织如图5所示。在最终退火之后,4种板材的晶粒均为完全再结晶的等轴晶粒。AZ31、AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+ 0.2Ca板材的平均晶粒尺寸分别为7.1、5.9、5.8和5.0 μm。合金元素Ce和Ca可以促进动态再结晶晶粒形核,并抑制晶粒长大,从而细化晶粒。轧制退火态板材的第二相粒子分布如图6所示。部分Ce和Ca原子固溶进入Mg基体造成晶格畸变,未固溶的合金元素会形成Al8Mn5、Al2Ca、Al11Ce3和Al8CeMn4等第二相。如Al2Ca等第二相粒子促进形核(PSN),大量新生成的再结晶晶粒具有随机取向[22],会改变退火态板材的织构。而且,Ce和Ca元素的加入会引起合金滑移系和孪晶系的改变,其总体织构特征发生改变。

图7所示为轧制退火态板材的基面极图,AZ31、AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板材的基面织构强度分别为6.3、5.7、3.5和3.2。4种合金板材的织构均为沿RD的双峰织构,其中,AZ31和AZ31+0.2Ce板材织构分布为椭圆状,长轴为RD。与之相比,AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板材织构强度较弱并且基极向TD发散。这说明微量的Ce和Ca可以有效地弱化AZ31合金基面织构,复合添加Ce和Ca的合金弱化效果最明显。AZ31+0.2Ca板材的织构强度比AZ31+0.2Ce的更弱,但是这并不意味着Ca元素弱化织构的效果更强。在高温下,AZ31合金中的Al会与Ce元素发生反应生成合金化合物,消耗掉部分的Ce。部分研究[23-24]认为,Ce和Ca合金化可以降低Mg合金的c/a轴比,从而弱化基面织构。但是,这些研究中c/a轴比的改变很小,通常在0.001左右,数值如此微小的改变是否为织构明显弱化的主要原因值得进一步的研究。MACKENZIED等[25]的研究表明粒子诱导形核可以弱化镁合金挤压织构。合金元素形成的第二相粒子促进动态再结晶形核,新生成的再结晶晶粒不具有明显的择优取向,可以弱化基面织构。本实验中加入的Ce和Ca极少,形成的第二相粒子也较少,织构改变主要是由于合金元素引起的滑移系的改变。Ce和Ca会降低AZ31合金的层错能,在变形过程中,非基面滑移系更容易启动,从而弱化基面织构。轧制态金相组织(见图4)中存在大量的孪晶,滑移系以及孪晶系的启动都会对织构产生影响,各种滑移系以及孪晶会诱导织构向特定方向偏转。AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板材织构基极向TD发散与其棱柱面滑移系的启动有关。

2.3 轧制退火态合金板材的力学性能

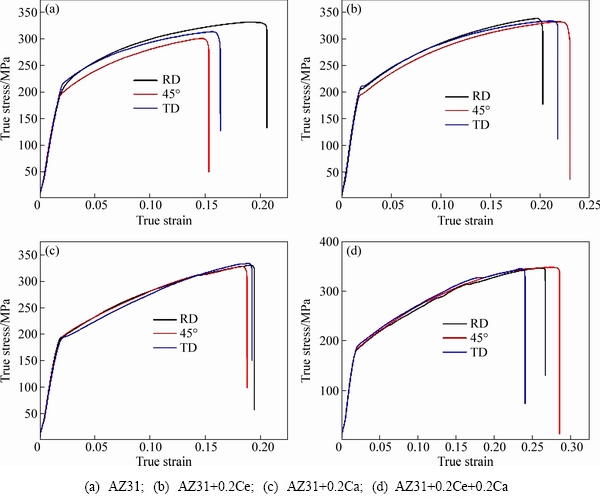

图8所示为4种轧制退火态合金板材的真实应 力-应变曲线,其中1、2和3分别代表沿RD、与RD成45°方向和沿TD的试样,其力学性能见表2。Ce和Ca微合金化后,板材的抗拉强度明显提高,复合添加Ce和Ca板材的抗拉强度提高了约40 MPa。复合添加Ce和Ca的合金板材塑性最好,其断裂伸长率在45°方向上达到了28%。添加微量Ce和Ca后,合金板材的n值略微增加。n值是表征合金板材抵抗塑性失稳的重要参数,n值越大,材料抵抗缩颈的能力越强,均匀伸长率越高。4种合金板材的r值和△r值大小关系为:AZ31>AZ31+0.2Ce>AZ31+0.2Ca>AZ31+0.2Ce+0.2Ca。可以看出,随着Ce和Ca的微合金化,板材的r值和各向异性显著降低,AZ31+0.2Ce+0.2Ca合金的△r值由AZ31合金的0.37降低到了0.04。板材的r值与织构强度密切相关,通常织构越弱,r值越小,板材的织构分布越发散,其各向异性越弱。

图7 轧制退火态板材基面极图

Fig. 7 Pole figures of rolled and annealed alloys

图8 轧制退火态板材的真实应力-应变曲线

Fig. 8 True stress-true strain curves of rolled and annealed alloys

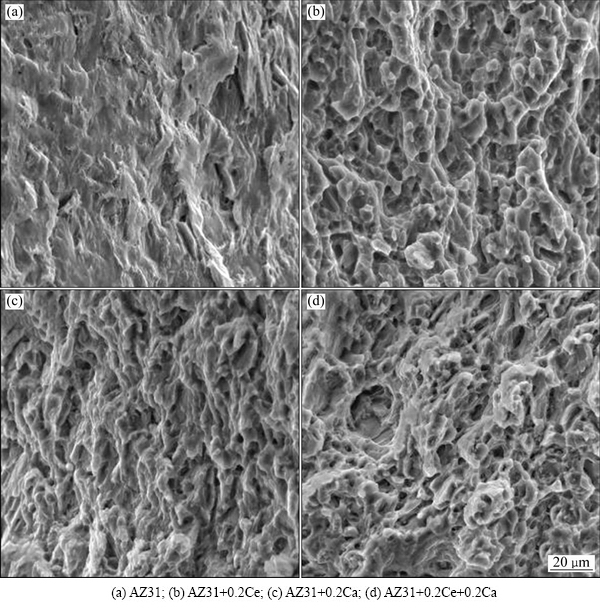

表2 轧制退火态板材的力学性能

Table 2 Mechanical properties of rolled and annealed alloy sheets

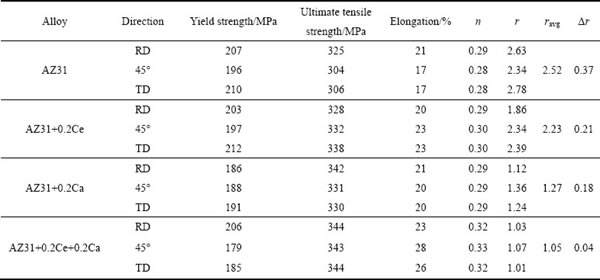

样品拉伸断裂形貌的SEM像如图9所示。通过断裂形貌的对比可以明显地观察到4种板材塑性的差异。AZ31板材断口有很多光滑的小平面,相比之下,Ce和Ca合金化后断口变得粗糙,观察到较多的韧窝,不同的合金化板材韧窝的大小和深度有差异。这是因为板材的断裂机理不同,AZ31为准解理断裂,其他3种合金为塑性断裂。AZ31+0.2Ce板材韧窝深度和粗糙程度比AZ31+0.2Ca板材的高,AZ31+0.2Ce+0.2Ca板材韧窝最深,其塑性也最好。

2.4 合金板材的室温成形性能

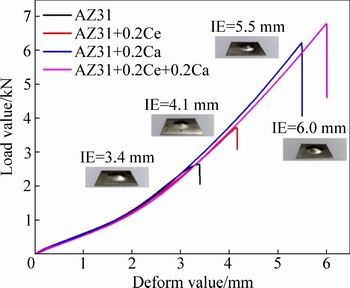

图10所示为4种合金板材的室温Erichsen杯突实验结果。AZ31、AZ31+0.2Ce、AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板材的Erichsen值(IE)分别为3.4、4.1、5.5和6.0 mm。微量Ce和Ca显著地提高了AZ31合金的室温成形性能。众所周知,较大的n值可以抵抗板材塑性失稳,增强塑性成形能力。CHINO等[26]的研究表明,轧制态AZ31板材具有较小的r值时,板材在厚度方向上变形更容易。根据杯突实验结果,4种板材Erichsen值的大小关系与基面织构强度的关系一致。其中AZ31+0.2Ce+0.2Ca板材的基面织构强度最弱,织构基极向TD发散,其Erichsen值最高,达到6.0 mm。值得注意的是,只加入极少量的合金元素(0.2%)板材的室温成形性能就显著增强。因此,室温成型性能的提高可以归因于织构的改善、较小的r值和较大的n值,Ce和Ca原子在形成独特织构的过程中起着重要作用。

图9 板材的拉伸断裂表面形貌

Fig. 9 SEM images of tensile fracture surface

图10 轧制退火态板材室温 Erichsen 杯突实验结果

Fig. 10 Erichsen tests of rolled and annealed magnesium alloys at room temperature

3 结论

1) Ce和Ca元素可以促进动态再结晶形核,使挤压态板材的再结晶晶粒更加均匀细小,并弱化挤压态板材的基面织构。

2) Ce和Ca可以弱化轧制退火态板材的基面织构, AZ31+0.2Ce+0.2Ca合金的基面织构最弱,基面织构强度为3.2,AZ31+0.2Ca和AZ31+0.2Ce+0.2Ca板材的基面织构基极向TD发散,织构的改善主要是由于合金元素引起的滑移系和孪晶系的改变。

3) Ca和Ce使AZ31板材的r值和各向异性降低,其中AZ31+0.2Ce+0.2Ca板材的各向异性最弱,其r值为1.05,△r值为0.04,板材各向异性的降低与其织构改善密切相关。

4) Ce和Ca大幅提高了AZ31合金板材的室温成形性能,其中AZ31+0.2Ce+0.2Ca板材的Erichsen值最大,达到6.0 mm。室温成型性能的提高可以归因于织构的改善、较小的r值和较大的n值。

REFERENCES

[1] SUNIL B R, GANESH K V, PAVAN P, VADAPALLI G, SWARNALATHA C, SWAPNA P, BINDUKUMAR P, PRADEEP KUMAR REDDY G. Effect of aluminum content on machining characteristics of AZ31 and AZ91 magnesium alloys during drilling[J]. Journal of Magnesium and Alloys, 2016, 4(1): 15-21.

[2] XIONG H, YU K, YIN X, DAI Y, YAN Y, ZHU H. Effects of microstructure on the electrochemical discharge behavior of Mg-6wt%Al-1wt%Sn alloy as anode for Mg-air primary battery[J]. Journal of Alloys and Compounds, 2017, 708: 652-661.

[3] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004.

[4] 李树新, 杨 巍. 生物可降解镁合金支架在冠状动脉血管中应用进展[J]. 医学综述, 2015, 21(2): 193-195.

LI Shu-xin, YANG Wei. Advancement of application of bioabsorbable magnesium stents in coronary artery[J]. Medical Recapitulate, 2015, 21(2): 193-195.

[5] PARK S H, HONG S G, LEE C S. Enhanced stretch formability of rolled Mg-3Al-1Zn alloy at room temperature by initial  twins[J]. Materials Science and Engineering A, 2013, 578(9): 271-276.

twins[J]. Materials Science and Engineering A, 2013, 578(9): 271-276.

[6] 吴泽宏, 古文全, 于云峰, 梁 寅, 李 英, 吴 健, 郭光平. 镁合金板材室温成形性能影响因素及改善措施[J]. 热加工工艺, 2015, 44(17): 6-9.

WU Ze-hong, GU Wen-quan, YU Yun-feng, LIANG Yin, LI Yin, WU Jiang, GUO Guang-ping. Influencing factors and improving methods of room temperature formability of magnesium alloy sheet[J]. Hot Working Technology, 2015, 44(17): 6-9.

[7] SHI Z Z, ZHANG Y, WAGNER F, JUAN P A, BERBENNI S, CAPOLUNGO L, LECOMTE J S, RICHETON T. On the selection of extension twin variants with low Schmid factors in a deformed Mg alloy[J]. Acta Materialia, 2015, 83: 17-28.

[8] QIAO H, AGNEW S R, WU P D. Modeling twinning and detwinning behavior of Mg alloy ZK60A during monotonic and cyclic loading[J]. International Journal of Plasticity, 2015, 65: 61-84.

[9] KOIKE J, KOBAYASHI T, MUKAI T, WATANABE H, SUZUKI M, MARUYAMA K, HIGASHI K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Materialia, 2003, 51(7): 2055-2065.

[10] XIN R, LIU D, SHU X, LI B, YANG X, LIU Q. Influence of welding parameter on texture distribution and plastic deformation behavior of as-rolled AZ31 Mg alloys[J]. Journal of Alloys and Compounds, 2016, 670: 64-71.

[11] ZENG Z R, BIAN M Z, XU S W, DAVIES C H J, BIRBILIS N, NIE J F. Texture evolution during cold rolling of dilute Mg alloys[J]. Scripta Materialia, 2015, 108: 6-10.

[12] HUANG X, SUZUKI K, CHINO Y, MABUCHI M. Texture and stretch formability of AZ61 and AM60 magnesium alloy sheets processed by high-temperature rolling[J]. Journal of Alloys and Compounds, 2015, 632: 94-102.

[13] MILLER V M, BERMAN T D, BEYERLEIN I J, JONES J W, POLLOCK T M. Prediction of the plastic anisotropy of magnesium alloys with synthetic textures and implications for the effect of texture on formability[J]. Materials Science and Engineering A, 2016, 675: 345-360.

[14] 胡水平, 王 哲. 织构和晶粒尺寸对AZ31镁合金薄板成形性能的影响[J]. 中国有色金属学报, 2012, 22(9): 2424-2429.

HU Shui-ping, WANG Zhe. Effects of texture and grain size on press formability of AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2424-2429.

[15] LIU P, JIANG H, CAI Z X, KANG Q, ZHANG Y. The effect of Y, Ce and Gd on texture, recrystallization and mechanical property of Mg-Zn alloys[J]. Journal of Magnesium & Alloys, 2016, 4(3): 188-196.

[16] CHINO Y, KADO M, MABUCHI M. Enhancement of tensile ductility and stretch formability of magnesium by addition of 0.2 wt%(0.035 at%)Ce[J]. Materials Science and Engineering A, 2008, 494(1/2): 343-349.

[17] LANGELIER B, NASIRI A M, LEE S Y, GHARGHOURI M A, ESMAEILI S. Improving microstructure and ductility in the Mg-Zn alloy system by combinational Ce-Ca microalloying[J]. Materials Science and Engineering A, 2015, 620: 76-84.

[18] DU Y, ZHENG M, QIAO X, WANG D B, PENG W Q, WU K, JIANG B L. Improving microstructure and mechanical properties in Mg-6 mass% Zn alloys by combined addition of Ca and Ce[J]. Materials Science and Engineering A, 2016, 656: 67-74.

[19] CHINO Y, HUNG X, SUZUKI K, MABUCHI M. Enhancement of stretch formability at room temperature by addition of Ca in Mg-Zn alloy[J]. Materials Transactions, 2010, 51(4): 818-821.

[20] KIM D W, SUH B C, SHIM M S, BAE J H, KIM D H, KIM N J. Texture evolution in Mg-Zn-Ca alloy sheets[J]. Metallurgical and Materials Transactions A, 2013, 44(7): 2950-2961.

[21] MOITRA A, KIM S G, HORSTEMEYER M F. Solute effect on the dislocation nucleation mechanism in magnesium[J]. Acta Materialia, 2014, 75: 106-112.

[22] JIANG M G, XU C, NAKATA T, YAN H, CHEN R S, KAMADO S. Development of dilute Mg-Zn-Ca-Mn alloy with high performance via extrusion[J]. Journal of Alloys and Compounds, 2016, 668: 13-21.

[23] 丁汉林, 王天一, 徐成志, 李殿凯. Ca 添加及变形条件对 Mg-Zn 合金组织与织构的影响[J]. 中国有色金属学报, 2015, 25(5): 1142-1152.

DING Han-lin, WANG Tian-yi, XU Cheng-zhi, LI Dian-kai. Effects of Ca addition and deformation conditions on microstructure and texture of Mg-Zn alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1142-1152.

[24] COTTAM R, ROBSON J, LORIMER G, DAVIS B. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development[J]. Materials Science and Engineering A, 2008, 485(1/2): 375-382.

[25] MACKENZIE L W F, DAVIS B, HUMPHREYS F J, LORIMER G W. The deformation, recrystallisation and texture of three magnesium alloy extrusions[J]. Materials Science and Technology, 2013, 23(10): 1173-1180.

[26] CHINO Y, SASSA K, KAMIYA A, MABUCHI M. Enhanced formability at elevated temperature of a cross-rolled magnesium alloy sheet[J]. Materials Science and Engineering A, 2006, 441(1/2): 349-356.

Effects of trace Ce and Ca on microstructure evolution and formability of AZ31 alloys

HUANG Lun1, 2, HUANG Guang-sheng1, 2, 3, DENG Qian-yuan1, 2, TANG Ai-tao1, 2, 3, JIANG Bin1, 2, 3, PAN Fu-sheng1, 2, 3

(1. State Key Laboratory of Mechanical Transmission, College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys,Chongqing University, Chongqing 400044, China;

3. Chongqing Research Center for Advanced Materials, Chongqing Academy of Science & Technology, Chongqing 401123, China)

Abstract: The effects of trace (0.2%, mass fraction) Ce and Ca on microstructure evolution and formability of AZ31 alloys were investigated desiring to develop low-cost and high-formability magnesium alloys by improving the microstructure and texture. The results reveal that Ce and Ca can make the recrystallize grains of the extruded AZ31 sheets more uniform and smaller. Ce and Ca can weaken the basal texture of the rolled and annealed sheet, Ca can cause the basal pole of AZ31 sheets to spread towards TD, Ce and Ca also decrease the r value and anisotropy of AZ31 sheets. Ce and Ca greatly improve the room temperature formability of AZ31 alloy sheets, the basal texture of Mg-3Al-1Zn-0.2Ce-0.2Ca sheets is 3.2, r value is 1.05, △ r value is 0.04, and its Erichsen value is 6.0 mm. The modified texture is mainly due to the change of the slip systems caused by the alloying elements, the reduction of sheet anisotropy is closely related to the modified texture, and the improvements at room temperature formability of the alloys can be attributed to the modified texture, smaller r values and larger n values.

Key words: magnesium alloy; microstructure evolution; formability; texture; microalloying

Foundation item: Project(2016YFB0301104) supported by the National Key Research and Development Plan of China; Projects(51671041, 51531002) supported by the National Natural Science Foundation of China

Received date: 2018-01-24; Accepted date: 2018-05-02

Corresponding author: HUANG Guang-sheng; Tel: +86-23-65112239; E-mail: gshuang@cqu.edu.cn

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2016YFB0301104);国家自然科学基金资助项目(51671041,51531002)

收稿日期:2018-01-24;修订日期:2018-05-02

通信作者:黄光胜,教授,博士;电话:023-65112239;E-mail:gshuang@cqu.edu.cn