文章编号:1004-0609(2013)S1-s0035-06

TiNbTaZr钛合金的组织演变及弹性行为

王玉会,李 野,张旺峰,颜孟奇,李 艳

(北京航空材料研究院,北京100095)

摘 要:研究Ti35Nb2Ta3Zr0.3O合金在冷变形过程的组织结构及弹性行为。结果表明:随着冷变形的进行,合金的显微组织交织更加剧烈,并出现与旋锻轴向平行的<110>丝织构,使该方向的弹性模量下降;冷变形合金无应力诱发α"马氏体产生,β相具有较强的稳定性,无伪弹性变形特征;随冷变形量的增加,合金衍射峰变宽,亚晶数量增多,缺陷密度增大,也致使弹性模量下降;强冷变形合金在拉伸过程不断产生孪晶,缺陷密度持续增大,导致合金的非线弹性特征。

关键词:钛合金;冷变形;显微组织;弹性行为;弹性模量

中图分类号:TG146.2 文献标志码:A

Microstructure evolution and elastic behaviors of TiNbTaZr titanium alloy

WANG Yu-hui, LI Ye, ZHANG Wang-feng, YAN Meng-qi, LI Yan

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The microstructure and elastic behaviors of Ti35Nb2Ta3Zr0.3O alloy during cold working were investigated. The results show that the microstructure is highly distorted, and the <110> texture along the swaging axis is produced with the cold working, which results in the decrease in the elastic modulus along the direction. Stress-induced α"-phase is not observed, β phase is of strong stability in cold worked alloy, and no pseudo-elastic deformation occurs. With the increase of cold deformation rate, the diffraction peak broadens, the number of subgrains increases, the defect density increases accordingly, and the elastic modulus decreases. Twins are generated constantly, and defect density increases in severely worked alloy during the tensile test, which results in non-linear elasticity characteristics of the alloy.

Key words: titanium alloy; cold working; microstructure; elastic behavior; elastic modulus

2001年,日本丰田中央研究所SAITO等[1-4]研制出一组以Ti35Nb2Ta3Zr0.3O合金为代表的新型多功能Ti-Nb基亚稳态β钛合金(Gum metal),该合金具有超弹性、室温超塑性、低加工硬化率,并且经历超过90%的冷旋锻变形后具有高强度、非线弹性、恒弹和恒胀等独特的性能。2003年SAITO研究组在《Science》上首次报道该合金之后即引起轰动,多个国家的研究者对此展开了研究[2-9]。

因该合金具有比普通金属高1个数量级的弹性变形能(2.5%),因此其弹性行为及机理尤其得到国内外学者的广泛关注,但目前争议也最多。并且,随冷加工过程的进行,该合金在室温下的弹性模量及弹性变形能发生较大变化。因此,通过系统研究冷加工过程的组织结构演变来揭示合金的弹性行为就显得十分必要。此外,对该问题的研究,可为制备新型Ti-Nb基超弹性合金提供有价值的参考。

由于含有大量高熔点组元Nb,大多数研究者采用粉末冶金法制备该合金,但粉末冶金法需要特殊的粉体,成本高;另外,也难以制备大尺寸构件。本文作者采用低成本的真空自耗熔炼法制备化学成分均匀的Ti35Nb2Ta3Zr0.3O铸锭,并在此基础上深入研究该合金在冷变形过程中的组织演变,探讨其对弹性性能的影响,为Ti-Nb基弹性合金的组织与弹性行为控制提供依据。

1 实验

实验原料采用海绵Ti、Ta-Zr中间合金、粉末烧结Nb条和TiO2粉末等。采用真空自耗电弧炉熔炼3~5次,以得到化学成分均匀的铸锭,铸锭质量为36 kg,实测的化学成分见表1。铸锭经开坯锻造后,在800 ℃热轧得到d 15 mm棒材,对d 15 mm棒材进行石英管真空封装,固溶处理(1 000 ℃,1 h,15%NaCl溶液)后,冷旋锻至d 3 mm。

在MTS810-15液压伺服拉伸机上进行力学性能测试,采用LEICA DMI3000 M型光学显微镜及JEOL JEM-2100F型透射电子显微镜进行显微组织观察,用XRD-6000X型X射线衍射仪进行相成分分析。

表1 Ti35Nb2Ta3Zr0.3O合金的主要化学成分

Table 1 Main chemical compositions of Ti35Nb2Ta3Zr0.3O alloy (mass fraction, %)

2 结果与讨论

2.1 Ti35Nb2Ta3Zr0.3O合金的弹性性能

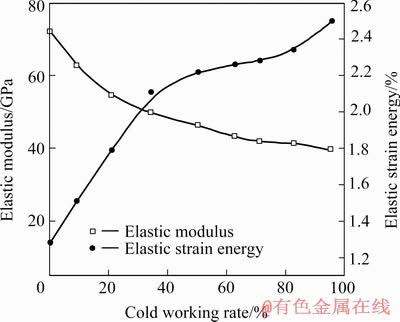

图1所示为在不同冷变形量下合金的弹性模量与弹性变形能曲线。由图1可见,随着冷变形的进行,合金的弹性模量E下降,弹性变形能增大。其中,超过50%的冷变形以后,随着冷变形的进行,弹性模量降低的趋势减小,超过90%形变量后的弹性模量可低至约40 GPa;同时,超过50%的冷变形以后,弹性变形能增加的趋势也有所降低,但其超过90%以上的冷变形后,弹性变形能增加迅速,达到约2.5%。

图1 Ti35Nb2Ta3Zr0.3O合金在不同冷变形量下的弹性性能

Fig. 1 Elastic properties of Ti35Nb2Ta3Zr0.3O alloy at different cold deformation rates

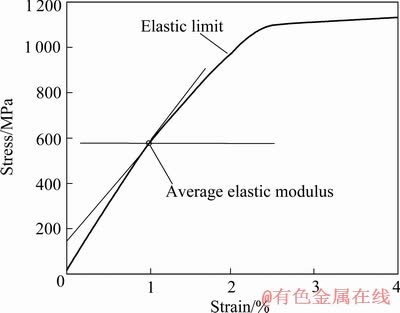

图2 96%冷旋锻后Ti35Nb2Ta3Zr0.3O合金的弹性性能

Fig. 2 Elastic properties of 96% cold-swaged Ti35Nb2Ta3- Zr0.3O alloy

研究发现,该合金在固溶态及冷变形态(尤其是超过90%冷变形后),表现出非线弹性现象,即达到拉伸弹性极限前弹性模量非一定值。图2所示为96%冷变形后丝材的拉伸应力—应变曲线,其达到弹性极限前的线段为曲线段。因此,将处于拉伸弹性极限强度值1/2处曲线的切线斜率看作平均弹性模量。图1所表示的弹性模量即全部为平均弹性模量。

综上所述,Ti35Nb2Ta3Zr0.3O合金具有超弹性及非线弹性特征。Ti35Nb2Ta3Zr0.3O合金的这种超弹性行为除了化学成分因素外,其独特的弹性性能还与合金在变形过程中的组织结构演变密切相关。

2.2 组织结构及其对弹性行为的影响

2.2.1 显微组织及织构

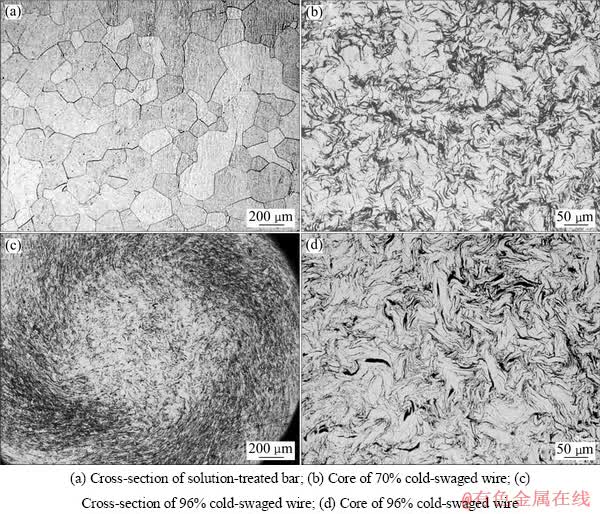

Ti35Nb2Ta3Zr0.3O合金d 15 mm棒材在1 000 ℃、1 h、15%NaCl溶液中固溶及经历70%与96%冷变形的d 8 mm和d 3 mm丝材的显微组织见图3。由图3可见,经固溶处理后的棒材组织为单一的粗大β等轴晶粒;冷变形70%后,丝材横截面组织已变成由细小纤维交织而成的螺旋状;而冷变形96%后,细小显微组织交织更加剧烈,呈现出黑色大理石纹状组织特征。

图3 Ti35Nb2Ta3Zr0.3O合金的显微组织

Fig. 3 Microstructures of Ti35Nb2Ta3Zr0.3O alloy

事实上,在冷旋锻Ti35Nb2Ta3Zr0.3O合金中所观察到的细小纤维交织而成的大理石纹状组织与钨、铁和铌等普通体心立方金属经过大变形量旋锻或拉拔处理后形成的螺旋状组织(见图4)十分相似[10]。这种螺 旋状组织的形成是由于体心立方金属在张应力主导的外加应力作用下,晶粒处于平面应变状态(见图5)。

图4 金属Nb拉丝后的显微组织

Fig. 4 Microstructure of transverse section of drawn niobium wire

当晶体的[110]晶向平行于旋锻(拉伸)轴时,晶体有可能沿4个<111>晶向滑移,其中,[111]和 是优先滑移方向。沿这两个晶向滑移导致晶粒沿平行于[110]的方向伸长,并在平行[001]的方向收缩,而在

是优先滑移方向。沿这两个晶向滑移导致晶粒沿平行于[110]的方向伸长,并在平行[001]的方向收缩,而在 方向长度没有变化。即晶体的变形被局限在

方向长度没有变化。即晶体的变形被局限在 晶面上。相反地,沿

晶面上。相反地,沿 和

和 两个晶向滑移将导致晶粒在[100]方向伸长,在

两个晶向滑移将导致晶粒在[100]方向伸长,在 方向收缩,但这两个方向与[110]晶向垂直,所以沿着这两个方向的滑移不可能发生。在进行冷旋锻(拉拔)变形的多晶体中,在一个晶粒伸长的同时,与之相邻的具有不同取向的晶粒为了协调变形会产生扭曲旋转,进而发展成[110]晶向平行于旋锻(拉伸)轴向的变形组织,因而合金的横截面就出现了涡旋状变形组织并且沿合金冷旋锻轴向出现了强烈的<110>丝织构。沿旋锻轴向<110>丝织构的形成,使Ti35Nb2Ta3Zr0.3O合金弹性模量各向异性,导致沿该方向的弹性模量最低。

方向收缩,但这两个方向与[110]晶向垂直,所以沿着这两个方向的滑移不可能发生。在进行冷旋锻(拉拔)变形的多晶体中,在一个晶粒伸长的同时,与之相邻的具有不同取向的晶粒为了协调变形会产生扭曲旋转,进而发展成[110]晶向平行于旋锻(拉伸)轴向的变形组织,因而合金的横截面就出现了涡旋状变形组织并且沿合金冷旋锻轴向出现了强烈的<110>丝织构。沿旋锻轴向<110>丝织构的形成,使Ti35Nb2Ta3Zr0.3O合金弹性模量各向异性,导致沿该方向的弹性模量最低。

图5 体心立方(BCC)金属中晶粒的平面应变方式

Fig. 5 Representation of position of <111> slip directions in BCC metal

2.2.2 相成分

图6所示为固溶态及不同程度冷变形后Ti35Nb2Ta3Zr0.3O合金的XRD谱。由图6可见,该合金固溶态除β相外,还存在微量的α″相;经历不同程度冷变形后,只有β相的衍射峰。也即,该合金基本是由单一的β相构成,而且变形过程无应力诱发α″马氏体等亚稳定组织。说明该合金中β相具有较强的稳定性。而合金中较高的氧含量(0.3%)对抑制应力诱发α″马氏体的产生发挥重要作用[11]。另外,具有<110>丝织构的棒丝材,因经历过剧烈变形,增加了α″的弹性能,也会抑制β→α″转变[12]。

图6 Ti35Nb2Ta3Zr0.3O合金在不同状态的XRD谱

Fig. 6 XRD patterns of Ti35Nb2Ta3Zr0.3O alloy under different conditions

该合金在变形过程中无应力诱发马氏体相变,从而使其弹性变形区别于普通弹性合金的伪弹性变形,属于真正的弹性变形行为(见图2),因而其屈服强度也高于普通弹性合金。

由图6可知,冷变形状态与固溶态相比,合金的衍射峰宽化,这是因为经过强烈的塑性变形后,合金中出现了大量细小的亚晶粒,同时材料经强塑性变形产生不均匀的形变所引起的。

2.2.3 形变亚结构

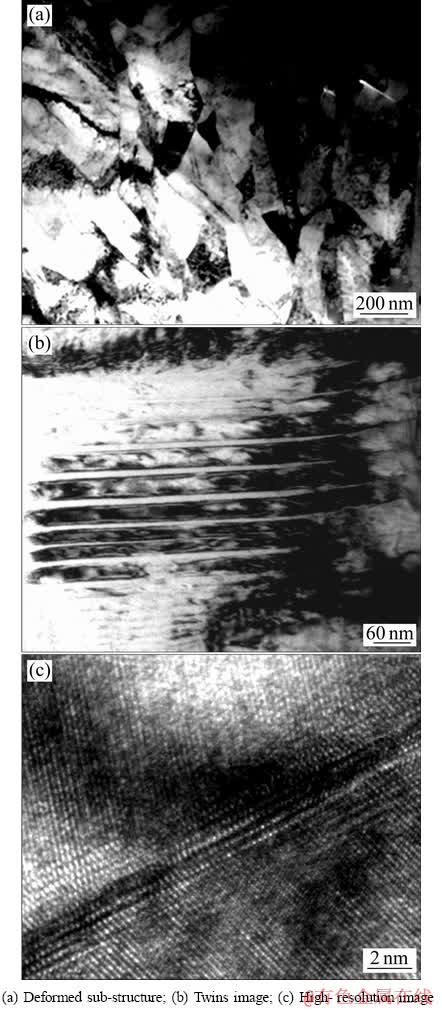

冷变形96%的d 3 mm丝材TEM像如图7所示。

与冷变形之前的固溶态(见图3(a))相比,晶粒已发生明显碎化(变形亚结构的TEM像见图7(a))。同时,在d 3 mm拉伸丝材中发现了大量孪晶,其形貌如图7(b)所示,高分辨TEM像如图7(c)所示。

图7 96%冷旋锻Ti35Nb2Ta3Zr0.3O合金的TEM像

Fig. 7 TEM images of 96% cold swaged Ti35Nb2Ta3Zr0.3O alloy

一般来说,小角度晶界的比例与应变几乎呈线性关系[13],小角度晶界比例的增加意味着合金内部应变的增加,同时也意味着合金中出现了大量的亚晶粒。郭文渊[14]曾详细研究了冷变形与小角度晶界数量的关系,研究结果表明,固溶态合金中小角度晶界所占的比例不到5%;而经过1.6%的小塑性变形后,合金中的小角度晶界比例迅速增加并超过20%;在变形量为50.4%的合金中,小角度晶界所占的比例增加到40%以上;当合金的变形量超过90%时,小角度晶界所占的比例达到约90%。

随冷变形量增加,缺陷密度明显增加。而较高的缺陷密度,会致使合金弹性模量降低[15]。例如,非晶合金具有极低的弹性模量(钛基非晶合金的弹性模量可低至58 GPa),其根源在于它的结构无序性(其所具有的无定形结构也可以认为是连续的缺陷)[16]。

由图7可知,孪生在该合金冷变形后期的变形机制中发挥重要作用。因高铌含量的合金层错能较低,极易发生孪生,而且在拉伸过程中还可不断产生孪晶,并且由于该基体的塑性极好,其孪生现象可以一直延续到断裂。在强冷塑性变形下,合金的缺陷密度不断提高,从而使其弹性模量不断下降,伴随着弹性模量的不断降低,冷变形丝材的拉伸过程出现非线弹性特征(见图2)。

3 结论

1) 随着冷变形的进行,Ti35Nb2Ta3Zr0.3O合金横截面的显微组织交织更加剧烈,且出现与旋锻轴向平行的<110>丝织构,使该方向的弹性模量下降。

2) 合金冷变形过程无α"马氏体产生,β向具有较强的稳定性,使其弹性行为区别于普通合金的伪弹性变形。

3) 随着冷变形量的增加,合金衍射峰变宽,亚晶数量增加,缺陷密度相应增大,弹性模量下降。

4) 强冷变形合金在拉伸过程中不断产生孪晶,缺陷密度也不断提高,导致合金的非线弹性特征。

REFERENCES

[1] SAITO T, FURUTA T, HWANG J H, KURAMOTO S, NISHINO K, SUZUKI N, CHEN R, YAMADA A, ITO K, SENO Y, NONAKA T, IKEHATA H, NAGASAKO N, IWAMOTO C, IKUHARA Y, SAKUMA T. Multifunctional alloys obtained via adislocation-free plastic deformation mechanism [J]. Science, 2003, 300(18): 464-467.

[2] IKEHATA H, NAGASAKO N, FURUTA T, FUKUMOTO A, MIWA K, SAITO T. First-principles calculations for development of low elastic modulus Ti alloys [J]. Physical Review B, 2004, 70(17): 174113: 1-8.

[3] IKEHATA H, NAGASAKO N, KURAMOTO S, SAITO T. Designing new structural materials using density functional theory: The example of gum metal [J]. MRS Bulletin, 2006, 31(9): 688-692.

[4] KURAMOTO S, FURUTA T, HWANG J H, NISHINO K, SAITO T. Plastic deformation in a multifunctional Ti-Nb-Ta- Zr-O alloy [J]. Metallurgical and Materials Transactions A, 2006, 37A(3): 657-662.

[5] GUTKIN M Y, ISHIZAKI T, KURAMOTO S, OVIDKO I A. Nanodisturbances in deformed gum metal [J]. Acta Materialia, 2006, 54(9): 2489-2499.

[6] TALLING R J, DASHWOOD R J, JACKSON M, DYE D, Compositional variability in gum metal [J]. Scripta Materialia, 2009, 60(11): 1000-1003.

[7] 杨 义, 李阁平, 吴松全, 李玉兰, 杨 柯. Gum metal钛合金研究进展[J]. 材料研究学报, 2011, 25(1): 1-6.

YANG Yi, LI Ge-ping, WU Song-quan, LI Yu-lan, YANG Ke. Progress in research of gum metal [J]. Chinese Journal of Materials Research, 2011, 25(1): 1-6.

[8] YANG Y, LI G P, CHENG G M, WANG H, ZHANG M, XU F, YANG K. Stress-introduced α" martensite and twinning in a multifunctional titanium alloy [J]. Scripta Materialia, 2008, 58(1): 9-12.

[9] HUPALO M F, PADILHA A F, SANDIM H R Z, KLIAUGA A M. Cold swaging, recovery and recrystallization of oligocrystalline INCOLOY MA 956—Part I: Deformed state [J]. ISIJ International, 2004, 44(11): 902-1910.

[10] HOSFORD W. Microstructural changes during deformation of [011] fiber-textured metals [J]. Trans TMS—AIME, 1964, 230(1): 12-15.

[11] TALLING R J, DASHWOOD R J, JACKSON M, DYE D. On the mechanism of superelasticity in gum metal [J]. Acta Materialia, 2009, 57: 1188-1198.

[12] MORRIS JR J W, HANULUMYUANG Y, SHERBURNE M, WITHEY E, CHRZAN D C, KURAMOTO S, HAYASHI Y, HARA M. Anomalous transformation-induced deformation in <110> textured gum metal [J]. Acta Materialia, 2010, 58: 3271- 3280.

[13] RANDLE V. Application of electron backscatter diffraction to grain boundary characterization [J]. Int Mater Rev, 2004, 49(1): 1-11.

[14] 郭文渊. 亚稳β型Ti-Nb-Ta-Zr-O合金的显微组织与性能[D]. 上海: 上海交通大学, 2008: 45-48.

GUO Wen-yuan. Microstructure and properties of a new metastable b type Ti-Nb-Ta-Zr-O alloy [D]. Shanghai: Shanghai Jiao Tong University, 2008: 45-48.

[15] 潘金生, 田民波. 材料科学基础[M]. 北京: 清华大学出版社, 2000: 300-314.

PAN Jin-sheng, TIAN Min-bo. Materials science and engineering [M]. Beijing: Tsinghua University Press, 2000: 300- 314.

[16] 惠希东, 陈国良. 块体非晶合金[M]. 北京: 化学工业出版社, 2007: 155-158.

HUI Xi-dong, CHEN Guo-liang. Bulk amorphous alloys [M]. Beijing: Chemical Industry Press, 2007: 155-158.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2007CB613803)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王玉会,高级工程师,博士;电话: 010-62496627;E-mail: wyhnoah@126.com