文章编号:1004-0609(2012)07-2061-08

石煤钒矿硫酸活化常压浸出提钒工艺

居中军,王成彦,尹 飞,杨永强,李敦钫

(北京矿冶研究总院 冶金研究设计所,北京 100070)

摘 要:研究石煤钒矿的硫酸活化提钒方法。分别考察矿石粒度、硫酸浓度、活化剂用量、催化剂用量、反应温度、反应时间和浸出液固比等因素对钒浸出率的影响。结果表明:石煤提钒的优化条件为矿石粒度小于74 μm的占80%、硫酸浓度150 g/L、活化剂CaF2用量(相对于矿石)60 kg/t、催化剂R用量20 g/L、反应温度90 ℃、反应时间6 h、液固比(体积/质量,mL/g)2:1,在此优化条件下,钒浸出率可达94%以上;在优化条件下,采用两段逆流浸出,可有效减少活化剂CaF2以及浸出剂硫酸的消耗量;经过两段逆流浸出-萃取-反萃-氧化水解工艺,全流程钒资源总回收率可达86.9%;V2O5产品纯度高于99.5%。

关键词:石煤;钒;活化酸浸;活化剂;浸出率

中图分类号:TF841.3 文献标志码:A

Process of vanadium extraction from stone coal vanadium ore by activated sulfuric acid leaching at atmospheric pressure

JU Zhong-jun, WANG Cheng-yan, YIN Fei, YANG Yong-qiang, LI Dun-fang

(Research and Design Institute of Metallurgy, Beijing General Research Institute of Metal and Metallurgy, Beijing 100070, China)

Abstract: The method of activated sulfuric acid leaching of stone coal vanadium ore was studied. The effects of the ore particle sizes, sulfuric acid concentration, amount of active agent and catalyst agent, reaction temperature, reaction time and liquid to solid ratio on the leaching rate of vanadium were investigated, respectively. The results show that the optimal conditions of leaching vanadium from stone coal are as follows: stone coal with size less than 74 μm accounting for 80%, sulfuric acid concentration 150 g/L, dosage of active agent (relative to ore) CaF2 60 kg/t, dosage of catalyst R 20 g/L, reaction temperature 90 ℃, reaction time 6 h and liquid to solid ratio (volume/mass, mL/g) 2:1. Under the best condition, the leaching rate of vanadium can be higher than 94%. Under the optimum condition, the two-stage counter-current leaching process was employed, and the dosages of sulfuric acid and active agent CaF2 can be saved. The total recovery rate of vanadium is 86.9% throughout the whole process of two-stage counter-current leaching-solvent extraction-stripping-oxydrolysis. The purity of product V2O5 is higher than 99.5%.

Key words: stone coal; vanadium; activated acid leaching; active agent; leaching rate

自然界中钒矿主要有钒钛磁铁矿和石煤钒矿,我国拥有丰富的石煤钒矿资源,主要集中在四川、湖南、湖边、甘肃和贵州等地,全国石煤储量为618.8亿t,蕴藏于石煤中的V2O5储量为11 797万t,其中V2O5品位≥0.5%的资源储量为7 707.5万t,是我国钒钛磁铁矿中V2O5储量的2.7倍[1]。以上数据显示,我国的石煤钒矿具有很高的工业价值。

目前,应用较广的石煤钒矿提钒工艺主要是采用钠化焙烧-水浸-铵盐沉钒工艺流程[2-4],该工艺首先在氯化钠存在的条件下于800~850 ℃焙烧2~2.5 h,使石煤钒矿中的V(Ⅲ)及V(Ⅵ)转化为可溶性的钒酸钠,焙砂经过水浸得到钒酸钠溶液,然后采用铵盐沉钒的方式得到钒酸氨渣,煅烧钒酸铵渣可得到粗V2O5产品。钠化焙烧工艺中钒的总回收率一般只有45%左右,且生产成本高、工艺流程复杂、操作条件差、劳动强度大,焙烧过程会产生大量Cl2和HCl气体,对生产设备腐蚀严重,同时对环境危害也很大。为克服钠化焙烧工艺的诸多缺点,研究人员开发了钙化焙烧工艺[3-4],钙化焙烧温度一般为900~950 ℃,焙烧时间为2~3 h,矿石中的钒在焙烧过程中被氧化并与石灰作用生成钒酸钙,焙砂采用稀酸浸出,可实现钒的提取。钙化焙烧工艺中石灰石在焙烧过程中有固硫作 用,因此,生产过程中产生的气体主要为CO2,无有害气体,对大气没有污染。但生产实践显示,钙化焙烧工艺V2O5的总收率也只有55%~70%,回收效果不够理想。

因焙烧工艺存在诸多缺点,石煤钒矿的直接浸出工艺越来越受到重视。魏昶等[5-8]研究了加压酸浸工艺,在硫酸浓度为200 g/L及180 ℃条件下,一段浸出率为76%,两段浸出率可达90%,但加压酸浸需要特种设备,操作条件苛刻。冯其明等[9]研究了以HF为浸出剂的工艺,钒浸出率高达97.91%,浸出效果理想,但浸出剂HF浓度为3.5 mol/L,而HF具有高挥发性和高毒性。HE等[10]研究了在稀硫酸中加入NaF或CaF2为浸出剂的工艺,在90 ℃下浸出12 h,钒浸出率约为83%,较传统工艺提升有限。因此,为综合利用我国的石煤钒矿资源,开发环保、经济且高效的提钒工艺具有重要的经济价值和战略意义。

本文作者针对贵州某地低品位石煤钒矿进行硫酸活化浸出工艺研究,并对浸出液进行萃取-反萃,反萃液采用氧化水解沉钒-钒渣焙烧处理,得到高纯V2O5产品,全流程钒回收率较高。本研究工艺具有以下优点:避免焙烧环节,因此无污染气体排放;采用少量CaF2作为活化剂,可避免高浓度HF的污染;在常压下浸出,操作简单,对设备要求较低;浸出液后处理部分未采用铵盐沉钒,钒渣煅烧时仅排放清洁的水蒸气,无铵盐沉钒所得钒渣煅烧时所产生的氨气 污染。

1 实验

1.1 样品成分

实验所用样品取自贵州某石煤钒矿,其化学成分如表1所列。

表1 石煤钒矿主要元素的化学成分

Table1 Main chemical components of stone coal vanadium ore (mass fraction, %)

1.2 实验方法

浸出实验在2 L烧杯中进行,控温和搅拌系统分别采用电子继电器控温和机械搅拌装置。实验所用H2SO4为98%分析纯硫酸,活化剂CaF2和催化剂R均为分析纯,CaCO3为工业级。

本研究主要考察矿石粒度、浸出温度、浸出时间、硫酸浓度、液固比、催化剂用量以及活化剂用量对钒浸出率的影响,实验过程中搅拌桨直径以及搅拌强度均保持一致(转速为600 r/min)。

浸出反应:先将水与硫酸按所需比例配好,搅拌下缓慢将矿石加入烧杯内,加热至所需温度并在 10 min内缓慢加完活化剂CaF2,1 h内缓慢加完催化剂R。两段逆流浸出方法:二段浸出液返回一段浸出,与原矿接触,一段浸出液作为成品液进入下一环节;一段浸出渣进入二段浸出,在二段浸出过程加入硫酸、活化剂CaF2以及催化剂R,二段浸出渣经过滤、洗涤后排放。

浸出液预处理与溶剂萃取:取一段浸出液在常温下用CaCO3中和至一定pH值,同时加入还原铁粉还原溶液中的Fe3+;经中和还原的浸出液用5%P204+ 95%磺化煤油为有机相进行6级逆流萃取。

反萃与氧化水解沉钒:采用4级逆流反萃,反萃剂为氧化水解沉钒后液;反萃液经NaClO3氧化后加热到沸腾,水解沉钒。

钒渣煅烧:首先将炉温升至350 ℃,此时将钒渣放入马弗炉中煅烧,维持1 h,随后升温至550 ℃,煅烧2 h,得到V2O5产品。

2 结果与讨论

2.1 实验条件探索

首先进行一组条件探索实验,实验条件分别如下。

A:硫酸浓度150 g/L,液固比2:1(mL/g),反应温度90 ℃;

B:硫酸浓度150 g/L,液固比2:1(mL/g),活化剂CaF2用量60 kg/t,反应温度90 ℃;

C:硫酸浓度150 g/L,液固比2:1(mL/g),活化剂CaF2用量60 kg/t,催化剂R用量(相对于矿石)40 kg/t,反应温度90 ℃。

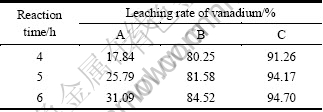

本组实验结果如表2所列。由表2数据可知,在不加活化剂CaF2以及催化剂R的条件下采用硫酸直接浸出,反应6 h钒的浸出率仅为31.09%;而在加入活化剂CaF2的条件下反应6 h,钒的浸出率可以达到84.52%;在此基础上加入催化剂R,钒的浸出率得到了进一步提升,浸出率达到94.70%。因此,常压下浸出石煤钒矿中的钒,活化剂CaF2起到了至关重要的作用,而催化剂R进一步加强了浸出效果,因此在后续实验中,均在活化剂CaF2以及催化剂R存在的条件下进行。

表2 探索实验结果

Table 2 Results of exploring experiments

2.2 矿石粒度对钒浸出率的影响

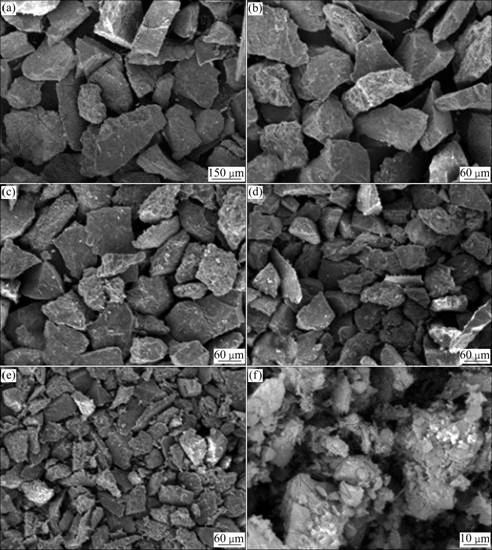

石煤钒矿矿石经过破碎、球磨后筛分为不同粒径矿石,不同粒径矿石的SEM像如图1所示。由图1可知,不同粒径的矿石均呈不规则块状以及不规则片状结构。

图1 不同粒度石煤钒矿矿石的SEM像

Fig. 1 SEM images of stone ore vanadium ore with different particle sizes: (a) Particles with size between 124 μm and 250 μm; (b) Particles with size between 104 μm and 124 μm; (c) Particles with size between 74 μm and 104 μm; (d) Particles with size between 58 μm and 74 μm; (e) Particles with size between 45 μm and 58 μm; (f) Particles with size smaller than 45 μm

矿石粒度影响实验条件:400 g矿样、液固比2:1 (mL/g)、硫酸浓度150 g/L、活化剂CaF2用量60 kg/t、催化剂R浓度 20 g/L、反应温度80 ℃、反应时间6 h。实验结果如图2所示。

图2 矿石粒度对钒浸出率的影响

Fig. 2 Effect of particle size of ore on leaching rate of vanadium

由图2可知,矿物粒度对钒的浸出影响较小,矿物粒度从小于74 μm 占50%提高到85%,浸出渣含钒从0.033%降低到0.021%,渣计浸出率仅提高2.8%,说明在本研究所采用的实验条件下,各种粒径的矿石均可与反应剂充分接触,并发生相应的化学反应。若该工艺用于工业生产,则需综合考虑磨矿的经济性与浸出渣过滤性能等因素,因此,矿物的磨矿粒度应优选小于74 μm颗粒占65%左右。为统一浸出条件、排除矿石粒度的细微影响,本研究中其他条件实验中均采用粒度小于74 μm占80%的矿样。

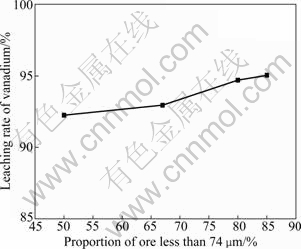

2.3 温度对钒浸出率的影响

实验条件:400 g矿样,液固比2:1(mL/g),硫酸浓度150 g/L,活化剂CaF2用量60 kg/t,催化剂R浓度 20 g/L,反应温度分别为95、90、80、70、60、50和40 ℃,反应时间为6 h。实验结果如图3所示。

由图3可知,钒浸出率随温度升高而增大,40 ℃时钒浸出率仅为34%,而80 ℃时钒浸出率高达95.04%。由Arrhenius公式:ln k=-E/(RT )+B可知,反应速率常数k随温度的升高而增大,在低温条件下,由于反应速度很慢,因此,6 h反应时间之内钒浸出率较低,而温度到达80 ℃以上时钒浸出率变化趋缓,90 ℃时钒浸出率达到最高,为95.25%,这是由于在80 ℃以上,反应速率已经很快,足以在6 h反应时间内浸出95%以上的钒。从温度实验可知,浸出温度至少应在80 ℃以上,以保证在较短反应时间内达到高浸出率的目的。

图3 反应温度对钒浸出率的影响

Fig. 3 Effect of reaction temperature on leaching rate of vanadium

2.4 活化剂CaF2用量对钒浸出率的影响

实验条件:400 g矿样,液固比2:1(mL/g),硫酸浓度150 g/L,催化剂R浓度 20 g/L,活化剂CaF2用量分别取0、20、30、40、50、60和88 kg/t,反应温度80 ℃,反应时间6 h。实验结果如图4所示。

图4 活化剂CaF2用量对钒浸出率的影响

Fig. 4 Effect of dosage of CaF2 on leaching rate of vanadium

由图4可知,钒的浸出率随活化剂CaF2用量的增加而显著增大,无活化剂CaF2时,反应6 h钒浸出率仅为30%左右,而当活化剂CaF2用量为60 kg/t时钒浸出率则高达95.04%。在此基础上,继续增加活化剂CaF2用量至88 kg/t,钒的浸出率增加不明显,考虑到工艺的经济性,选择活化剂CaF2用量为60 kg/t。

2.5 催化剂R浓度对钒浸出率的影响

实验条件:400 g矿样,液固比2:1(mL/g),硫酸浓度150 g/L,催化剂R浓度分别选择0、5、7.5、10、15和20 g/L,活化剂CaF2用量60 kg/t,反应温度80 ℃,反应时间6 h。实验结果如图5所示。

图5 催化剂R浓度对钒浸出率的影响

Fig. 5 Effect of concentration of catalyst R on leaching rate of vanadium

由图5可知,钒浸出率随催化剂R浓度增加而增大,不使用催化剂R时,浸出反应进行6 h,钒浸出率约为85%,当催化剂R浓度达到20 g/L时钒浸出率则可达95.04%,在0~20 g/L浓度范围内,催化剂R对钒浸出率影响显著,继续增加催化剂R浓度,钒浸出率不再增加,因此,选择催化剂R的浓度为20 g/L。

2.6 浸出剂硫酸浓度对钒浸出率的影响

硫酸作为浸出剂,其浓度对钒浸出率具有重要影响,同时硫酸作为主要浸出试剂,其消耗量直接关系到本工艺的经济性,因此本节着重研究硫酸浓度对钒浸出率的影响。

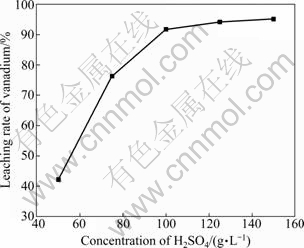

实验条件:400 g矿样,液固比2:1(mL/g),硫酸浓度分别为50、75、100、125、150 g/L,催化剂R浓度20 g/L,活化剂CaF2用量60 kg/t,温度80 ℃,反应时间6 h。实验结果如图6所示。

从图6可知,硫酸浓度对钒浸出率影响显著,当硫酸浓度为50 g/L时,钒浸出率不足45%;而当硫酸浓度达到150 g/L时,钒浸出率达到最大值95.04%,若继续增加硫酸浓度,势必会大量增加硫酸消耗以及浸出液游离酸浓度,同时,浸出液后续处理时中和碱耗也会相应增加,因此,应选择150 g/L的硫酸浓度作为浸出酸度。

图6 硫酸浓度对钒浸出率的影响

Fig. 6 Effect of concentration of H2SO4 on leaching rate of vanadium

2.7 浸出液固比对钒浸出率的影响

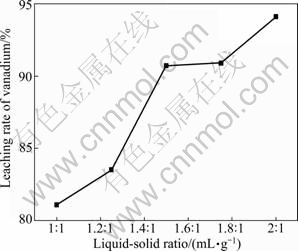

实验条件:400 g矿样,液固比(mL/g)分别为1:1、1.25:1、1.5:1、1.75:1和2:1,硫酸浓度150 g/L,催化剂R浓度20 g/L,活化剂CaF2用量60 kg/t,反应温度80 ℃,反应时间6 h。实验结果如图7所示。

图7 液固比对钒浸出率的影响

Fig. 7 Effect of liquid-solid ratio on leaching rate of vanadium

由图7可知,钒浸出率随液固比的增大而增加,这是由于随着浸出反应的进行,溶液中离子浓度会越来越高,在低液固比条件下,同离子效应使得矿物中的元素难以进入溶液。另外,溶液中离子浓度过高会增加溶液黏度,影响搅拌效果,从而使得被浸出金属离子停留在固体颗粒表面,难以扩散至溶液内部,抑制了浸出反应的进行。当液固比达到2:1时钒浸出率可达94.11%。

2.8 反应时间的影响

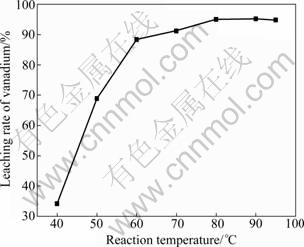

实验条件:400 g矿样,液固比2:1(mL/g),硫酸浓度150 g/L,催化剂R浓度20 g/L,活化剂CaF2用量60 kg/t,反应温度80 ℃,反应总时间8 h,从第4 h开始取样。实验结果如表3所列。

表3 反应时间对钒浸出率的影响

Table 3 Effect of reaction time on leaching rate of vanadium

由表3可知,钒浸出率随反应时间的延长而增加,当反应进行到6 h时钒浸出率可达94.70%,而到6 h以后钒浸出率则增长缓慢,因此,考虑到工艺的能耗,将浸出时间选择为6 h。

2.9 二段逆流循环实验

由于该工艺采用较高酸度浸出,因此,浸出液中含有较高的游离酸,为综合利用浸出液中的游离酸、催化剂R以及减少活化剂CaF2的消耗量,工业设计可采用分两段逆流浸出,一段浸出为中和反应,利用原矿中和浸出液中的游离酸。

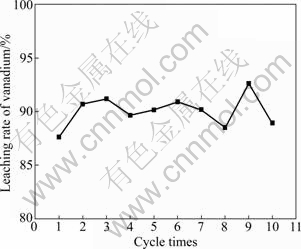

两段逆流实验流程如图8所示,一段浸出为中和段,即原矿与二段浸出液接触,中和二段浸出液中的游离酸,一段浸出液作为低酸成品液进入后续处理步骤;二段浸出为高酸、高温浸出阶段,在二段浸出中加入硫酸和催化剂R,并补充活化剂CaF2,为钒浸出阶段。经10次循环实验分析得,一段浸出成品液的平均游离硫酸浓度为37.05 g/L,二段浸出液平均游离硫酸浓度为100.03 g/L,因此,采用二段浸出流程,可有效利用溶液中的残余硫酸,使进入下一环节的浸出液中硫酸浓度有效降低,既减少了硫酸的消耗,又减少了后续环节中浸出液预中和的碱耗。

图9所示为两段循环过程中钒浸出率的变化情况。由图9可知,经过10次循环实验后,钒的平均浸出率为90%,且无下降趋势,因此,该两段浸出流程对于这种矿石的浸出效果具有很高的稳定性,可用于工业生产。

活化剂在浸出过程中起到的作用是破坏矿物硅酸盐结构,使钒暴露在浸出剂硫酸之中,从而加速浸出过程,其反应方程式为[9]

CaF2+H2SO4=CaSO4+2HF (1)

K(Al,V)(AlSi3O10)(OH)3+12HF+9H+=

K++2Al3++VO2++12H2O+3SiF4 (2)

图8 全流程示意图

Fig. 8 Schematic diagram of whole process

图9 钒浸出率随循环次数变化情况

Fig. 9 Change of leaching rate of vanadium with cycle times

此处仅考虑HF对于Si的反应,由反应(1)和(2)可知,活化剂CaF2之所以具有活化作用,是由于通过反应(1)生成了HF,而HF可与硅酸盐反应,反应(2)的产物SiF4在水中会立即水解生成HF和H4SiO4[11],HF溶于浸出液中,由于采用两段浸出工艺,氟元素可随二段浸出液返回浸出体系中,使得活化剂CaF2实际消耗量仅为5.0 kg/t,有效地降低了试剂成本。

2.10 含钒浸出液的处理

硫酸活化酸浸所得浸出液化学成分如表4所示。

表4 一段浸出液主要成分

Table 4 Main components of first-stage leachate (g/L)

由表4可知,浸出液中钒含量仅为1.69 g/L,且有大量其他杂质存在,如Al3+和Fe3+等金属离子,因此,处理该浸出液不宜采用重结晶或直接沉淀法。本研究采用5%P204+95%磺化煤油为有机相的溶剂萃取法进行处理。

2.10.1 浸出液预处理

P204对钒的萃取最佳pH值为2.2左右[12-14],因此,需要将浸出液中和至pH值为2.2左右。浸出液 中含有一定量的Fe3+,而Fe3+与P204有极强的结合能力,因此,Fe3+的存在将影响P204对钒的萃取效率,需要提前将其还原为Fe2+,还原剂采用还原铁粉,控制最终还原电位在-150 mV。浸出液预处理环节钒的收率为99.01%。

2.10.2 萃取

萃取实验条件:有机相为5%P204+95%(体积分数)磺化煤油,水相为经中和还原预处理后的一段浸出液,采用6级逆流萃取,萃取相比V(O):V(A)=1:1,接触时间7 min,萃取温度35 ℃,平均分相时间5 min。钒的萃取率大于98.5%,水相中钒含量低于0.025 g/L。

2.10.3 反萃与氧化-水解沉钒

反萃实验条件:反萃剂为150 g/L H2SO4,采用4级逆流反萃,反萃相比V(O):V(A)=8:1,反萃接触时间5 min,反萃温度为室温。经反萃后的有机相中含钒低于3 mg/L,因此,钒的反萃率大于99.0%。

氧化-水解沉钒实验条件:反萃液用1.05倍理论量的NaClO3氧化后,加热至沸腾,水解2 h,得到钒渣以及沉钒后液。沉钒后液直接返回用作反萃剂,因此,水解沉钒过程钒不发生损失。

反萃-氧化-水解沉钒的反应方程式如下:

VO(P204)2+H2SO4=VOSO4+2H-P204 (3)

从反应方程式(3)可知,反萃过程消耗的硫酸与钒的物质的量相同。

氧化沉钒反应方程式如下:

6VOSO4+NaClO3+3H2O=3(VO2)2SO4+NaCl+3H2SO4 (4)

从反应方程式(4)可知,氧化过程产生的硫酸为钒的物质的量的1/2。

(VO2)2SO4+2H2O=2HVO3+H2SO4 (5)

从反应方程式(5)可知,水解过程中产生的硫酸为钒的物质的量的1/2。

综合反应(4)和(5)可知,钒氧化-水解过程中产生的硫酸与钒的物质的量之比为1:1。所以反萃-氧化-水解沉淀全过程中硫酸消耗与产生恰好相抵消,反萃-氧化-水解沉淀过程不需要补充酸,相对于传统铵盐沉钒工艺,可大量降低酸耗以及中和所需要的碱耗,同时能避免含铵废水的排放。

2.11 钒渣煅烧

将水解沉钒所得到的钒渣在高温下煅烧可使其失水得到高纯V2O5产品,其反应方程式如下:

2HVO3=H2O+V2O5 (6)

钒渣煅烧条件如下:取水解沉钒得到的钒渣在马弗炉中煅烧,首先将炉温升至350 ℃,此时钒渣入炉,维持1 h,随后升温至550 ℃,煅烧2 h,得到V2O5产品,纯度高于99.5%。本工艺未采用传统的铵盐沉钒方式[15-16],因此,煅烧过程中无氨气放出,对环境不会造成不良影响。本工艺全流程示意图如图9所示,V2O5的总回收率可达86.9%。

3 结论

1) 采用硫酸活化常压浸出石煤提钒的优化工艺条件如下:80%的矿石粒度小于74 μm,硫酸浓度150 g/L,活化剂CaF2用量60 kg/t,催化剂R浓度 20 g/L,液固比(mL/g) 2:1,反应温度90 ℃,反应时间6 h。

2) 在优化工艺条件下钒的浸出率可达94%以上,比传统提钒工艺的提高20%。采用二段逆流浸出实验经过10次循环,平均浸出率可达90%,证实该工艺具有较高的稳定性。在此工艺条件下,采用浸出液返回的两段浸出方式可实现浸出液游离酸的综合利用,降低后续中和环节碱的消耗。

3) 在反萃-氧化-水解沉钒过程可以实现硫酸循环利用,不需要额外补充硫酸,沉淀过程不需要中和,降低了碱耗。

4) 矿石中的钒资源经过浸出-萃取-反萃-水解沉钒工艺,总回收率可达86.9%,相对于传统工艺有很大提高。

5) 整个工艺过程无有害气体排放,是一种经济、环保、高效的石煤提钒工艺,具有很高的工业应用 价值。

REFERENCES

[1] ZHANG Yi-min, BAO Shen-xu, LIU Tao, CHEN Tie-jun, HUANG Jing. The technology of extracting vanadium from stone coal in China: History, current status and future prospects [J]. Hydrometallurgy, 2011, 109: 116-124.

[2] 刘景槐, 谭爱华. 我国石煤钒矿提钒现状综述[J]. 湖南有色金属, 2010, 26(5): 11-14.

LIU Jing-huai, TAN Ai-hua. Status review on technologies of extracting vanadium from stone coal vanadium ore [J]. Hunan Nonferrous Metals, 2010, 26(5): 11-14.

[3] 潘 勇, 于吉顺, 吴红丹. 石煤提钒的工艺评价[J]. 矿业快报, 2007, 23(4): 10-12.

PAN Yong, YU Ji-shun, WU Hong-dan. Process evaluation of vanadium extraction from stone coal [J]. Express Information of Mining Industry, 2007, 23(4): 10-12.

[4] 别 舒, 王兆军, 李清海, 张衍国. 石煤提钒钠化焙烧与钙化焙烧工艺研究[J]. 稀有金属, 2010, 34: 291-297.

BIE Shu, WANG Zhao-jun, LI Qing-hai, ZHANG Yan-guo. Review of vanadium extraction from stone coal by roasting technique with sodium chloride and calcium oxide [J]. Chinese Journal of Rare Metals, 2010, 34: 291-297.

[5] 魏 昶, 李存兄, 樊 刚, 李旻廷, 邓志敢. 石煤湿法强化提钒新工艺[J]. 中国有色金属学报, 2008, 18(s1): s80-s83.

WEI Chang, LI Cun-xiong, FAN Gang, LI Min-ting, DENG Zhi-gan. New process of vanadium extraction from black shale by strengthening hydrometallurgy [J]. Chinese Journal of Nonferrous Metals, 2008, 18(s1): s80-s83.

[6] 李存兄, 魏 昶, 李旻廷, 樊 刚, 邓志敢. 石煤氧压酸浸提钒工艺优化[J]. 中国有色金属学报, 2008, 18(s1): s84-s87.

LI Cun-xiong, WEI Chang, LI Min-ting, FAN Gang, DENG Zhi-gan. Process optimization of vanadium extraction from black shale by acidic oxidizing pressure leaching [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(s1): s84-s87.

[7] LI Min-ting, WEI Chang, FAN Gang, LI Cun-xiong. Pressure leaching of black shale for extraction of vanadium [J]. Transaction of Nonferrous Metals Society of China, 2010, 20(s1): s112-s117.

[8] LI Ming-ting, WEI Chang, FAN Gang, LI Cun-xiong, DENG Zhi-gan, LI Xing-bin. Extraction of vanadium from black shale using pressure acid leaching [J]. Hydrometallurgy, 2009, 98: 308-313.

[9] 冯其明, 何东升, 张国范, 欧乐明, 卢毅屏. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2007, 17(8): 1348-1352.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1348-1352.

[10] HE D, FENG Q, ZHANG G, OU L. Study on leaching vanadium from roasted residue of stone coal [J]. Minerals and Metallurgical Processing, 2008, 25(4): 181-184.

[11] 曹忠良, 王珍云. 无机化学反应方程式手册[M]. 长沙: 湖南科学技术出版社, 1982: 105.

CAO Zhong-liang, WANG Zhen-yun. Handbook of inorganic chemical equation [M]. Changsha: Hunan Science and Technology Press, 1982: 105.

[12] LI Xing-bing, WEI Chang, DENG Zhi-gan, LI Min-ting, LI Cun-xiong, FAN Gang. Selective solvent extraction of vanadium over iron from a stone coal/black shale acid leach solution by D2EHPA/TBP [J]. Hydrometallurgy, 2011, 105: 359-363.

[13] RIGGA T, GARNERA J O. Solvent extraction of vanadium from chloride solutions using di-(2-ethylhexyl)-phosphoric acid [J]. Journal of Inorganic and Nuclear Chemistry, 1967, 29(8): 2019-2025.

[14] 胡建锋, 朱 云. P204萃取硫酸体系中钒的性能研究[J]. 稀有金属, 2007, 31(3): 367-370.

HU Jian-feng, ZHU Yun. Extraction of vanadium by P204 from surfuric acid solution [J]. Chinese Journal of Rare Metals, 2007, 31(3): 367-370.

[15] 张 云, 范必威, 彭达平. 从酸浸石煤的萃取液中沉淀多聚钒酸铵[J]. 稀有金属, 2000, 25(2): 157-160.

ZHANG Yun, FAN Bi-wei, PENG Da-pin. Research of precipitation poly-ammonium vandate from extraction solution of acid-leaching bone coal [J]. Chinese Journal of Rare Metals, 2000, 25(2): 157-160.

[16] 鲁兆伶. 用酸法从石煤中提取五氧化二钒的试验研究与工业实践[J]. 湿法冶金, 2002, 21(4): 174-183.

LU Zhao-ling. Investigation and industrial practice on extraction of V2O5 from stone coal containing vanadium by acid process [J]. Hydrometallurgy of China, 2002, 21(4): 174-183.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2007CB613505);国家自然科学基金资助项目(50904009);国家“十二五”科技支撑计划资助项目(2012BAB07B01)

收稿日期:2011-06-03;修订日期:2011-09-27

通信作者:王成彦,教授,博士;电话:010-63299551; E-mail: chywang@yeah.net