Trans. Nonferrous Met. Soc. China 22(2012) 1457-1461

Intelligent method to develop constitutive relationship of Ti-6Al-2Zr-1Mo-1V alloy

SUN Yu1, ZENG Wei-dong1, ZHAO Yong-qing2, HAN Yuan-fei1, MA Xiong1

1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China

Received 28 July 2011; accepted 26 December 2011

Abstract: The isothermal compression tests were carried out in the Thermecmastor-Z thermo-simulator at temperatures of 800, 850, 900, 950, 1000 and 1050 ℃ and the strain rates of 0.01, 0.1, 1 and 10 s-1. The influence of deformation temperature and strain rate on the flow stress of Ti-6Al-2Zr-1Mo-1V alloy was studied. Based on the experimental data sets, the high temperature deformation behavior of Ti-6Al-2Zr-1Mo-1V alloy was presented using the intelligent method of artificial neural network (ANN). The results indicate that the predicted flow stress values by ANN model is quite consistent with the experimental results, which implies that the artificial neural network is an effective tool for studying the hot deformation behavior of the present alloy. In addition, the development of graphical user interface is implemented using Visual Basic programming language.

Key words: Ti-6Al-2Zr-1Mo-1V alloy; artificial neural network; constitutive relationship; deformation behavior

1 Introduction

The constitutive relationship of materials describes the basic correlation of flow stress with hot processing parameters, which presents the dynamic behavior of materials during hot deformation at the elevated temperature [1-3]. In general, it is quite significant to control the value of flow stress in which it is the premise of the equipment selection and the critical mark to the hot workability of materials. Additionally, the optimal processing parameters would be achieved with the help of good and deep understanding regarding the characterization of hot deformation of materials. Therefore, it is fairly meaningful to investigate the high temperature deformation behavior of titanium alloys in terms of controlling the microstructure and determining the optimal processing parameters. Conventionally, the flow stresses were obtained under various deformation conditions in the isothermal compression testing, and the constitutive relationship was developed at a steady state or certain strain using regressing analysis approach based on the classical sine hyperbolic equation [4,5]. Nevertheless, the internal of the metals and alloys presents the extremely complicated dynamic response, and the affecting factors of flow stress possess the characteristic of highly non-linear relationship. Thus, the actual deformation circumstances cannot be accurately elaborated by the conventional method, which restricts the application range of constitutive relationship model.

Ti-6Al-2Zr-1Mo-1V alloy, a type of near α titanium alloy, has excellent welding performance and thermal stability, high strength and exceptional resistance to creep. It has been extensively applied to the engineering fields of aerospace to use as some key components, including compressor disks and aero engine blades [6,7]. However, the Ti-6Al-2Zr- 1Mo-1V alloy is difficult to be deformed and processed due to its low plasticity and narrow processing window. Hence, it is necessary to study its high temperature deformation behavior of the present alloy. The constitutive relationship equation of Ti-6Al-2Zr-1Mo- 1V alloy has ever been established using regression method by SHU et al [7] at a certain strain rate of 0.01 s-1 instead of the whole range of deformation condition. By contrast, the intelligent technique of artificial neural network (ANN) is able to acquire the potential correlation and complex non-linear relationship of objectives without any explicit mathematical model or physical knowledge of the deformation mechanism [8,9]. In recent years, a great number of beneficial efforts have been made regarding various kinds of materials throughout the world due to the advantages of ANN [10-14]. For instance, LIU et al [11] proposed an intelligent technique of artificial neural networks combined with genetic algorithms in order to analyze and optimize the correlation between heat treatment parameters and properties for Cu-Cr-Sn-Zn lead frame alloy. SUN et al [12,13] established the constitutive relationship and processing map of Ti40 alloy using the technique of artificial neural network. GENEL et al [14] predicted the wear rate and friction coefficient of alumina fiber reinforced zinc-aluminum composites on the basic of artificial neural network. However, it can be suggested that there are limited reports regarding the Ti-6Al-2Zr-1Mo-1V alloy, and the technology of visual interface is not applied in the ANN model. Therefore, in the present work, the research on the deformation behavior of Ti-6Al-2Zr-1Mo-1V alloy at high temperature was conducted using ANN with a back-propagation (BP) learning rule. Also, a graphical user interface was designed and implemented using the Visual Basic programming language in order to make users operate conveniently.

2 Experimental

The experimental material employed in the present study was provided as the form of bar with diameter of 209 mm. The testing specimens of Ti-6Al-2Zr-1Mo- 1V alloy from the bar, which was forged at 955 ℃, were machined into cylinder with 8 mm in diameter and 12 mm in length. Both cylinder ends were grooved for retention of the glass lubricants so as to reduce friction. Isothermal compression tests were performed on a Thermecmastor-Z thermo-simulator at various conditions, including the deformation temperatures from 800 to 1050 ℃ with intervals of 50 ℃, and the strain rates of 0.01, 0.1, 1 and 10 s-1. The high reduction of the specimens was 60%. The stress—strain curves were automatically recorded by the experimental equipment.

3 Results and discussion

3.1 Influence of deformation temperature and strain rate on flow stress

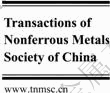

The effect of deformation temperature and strain rate on the flow stress, which is plotted at a strain of 0.5, is shown in Fig. 1. It can be markedly observed from Fig. 1(a) that the variation of flow stress of Ti-6Al-2Zr- 1Mo-1V alloy is significantly affected by the deformation temperature. The magnitude of flow stress decreases with the increase of temperature at a certain strain rate, which is probably associated with the dynamic softening occurring and rapid dislocation annihilation during high temperature. It is important to point out that the trend of flow stress dropping with increasing temperature is obviously smaller at a low strain rate (0.01 s-1) than that at other strain rates. On the other hand, the variation of flow stress with strain rate is exhibited in Fig. 1(b), which suggests that the strain rate has a notable influence on the flow stress of Ti-6Al-2Zr-1Mo-1V alloy. It can be found from this figure that the flow stress rapidly increases with increasing the strain rate. The reason for such behavior is probably that the increase of the dislocation multiplication rate with increasing strain rate and strain contributes to the decrease of flow stress. Based on the mentioned above, it can be considered that Ti-6Al-2Zr-1Mo-1V alloy is a sort of material which is quite sensitive to the strain rate and deformation temperature.

Fig. 1 Effect of deformation temperature (a) and strain rate (b) on flow stress of Ti-6Al-2Zr-1Mo-1V alloy at strain of 0.5

3.2 High temperature deformation behavior using ANN

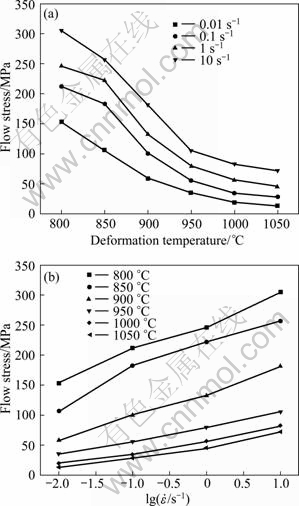

Artificial neural network (ANN) is an intelligent and powerful information treatment system which can establish complex non-linear relationships through the application of many non-linear processing units called neurons. The detailed information about the basic algorithm concerning ANN could be found and systematically understood in Ref. [15]. In this investigation, the input variables of ANN are strain (ε), strain rate ( ) and deformation temperature (T), while the output variable is flow stress (σ). A feed forward neural network model trained with back-propagation (BP) learning algorithm was developed because this kind of learning algorithm is accepted as the most popular method in the field of engineering applications, which is estimated to be more than 90% of the ANN applications adopting the back-propagation learning algorithm [16]. Thus, the ANN model used to research the deformation behavior of Ti-6Al-2Zr-1Mo-1V alloy is shown schematically in Fig. 2. Before training the network, the input and output data must be normalized between 0 and 1 for the ANN learning to prevent a specific factor from dominating the learning. The following equation is used widely for unification:

) and deformation temperature (T), while the output variable is flow stress (σ). A feed forward neural network model trained with back-propagation (BP) learning algorithm was developed because this kind of learning algorithm is accepted as the most popular method in the field of engineering applications, which is estimated to be more than 90% of the ANN applications adopting the back-propagation learning algorithm [16]. Thus, the ANN model used to research the deformation behavior of Ti-6Al-2Zr-1Mo-1V alloy is shown schematically in Fig. 2. Before training the network, the input and output data must be normalized between 0 and 1 for the ANN learning to prevent a specific factor from dominating the learning. The following equation is used widely for unification:

(1)

(1)

where X is the original data; X′ is the unified data of the corresponding X; Xmin and Xmax are the minimum and maximum values of X, respectively. Additionally, the complexity of neural network and precision of predicted values depend on the number of hidden-layer units. With the help of trail-and-error approach from 5 to 20, it was found that when the hidden-layer neurons were 12, the ANN model performed a desired prediction accuracy which was quantitatively evaluated by the term of mean square error (MSE) shown as Eq. (2):

(2)

(2)

where  and

and  are the desired and output values of ANN model, and n is the patterns presented. Basically, this procedure of minimizing the MSE is considered the training of the ANN model. Once the MSE reaches the goal error, the weight matrix is saved so as to predict the outputs corresponding to the given input variable.

are the desired and output values of ANN model, and n is the patterns presented. Basically, this procedure of minimizing the MSE is considered the training of the ANN model. Once the MSE reaches the goal error, the weight matrix is saved so as to predict the outputs corresponding to the given input variable.

Fig. 2 Schematic diagram of ANN model for constitutive relationship of Ti-6Al-2Zr-1Mo-1V alloy

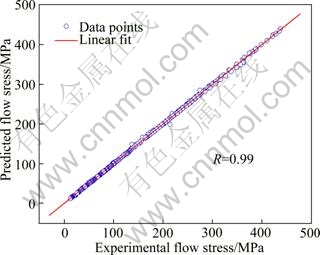

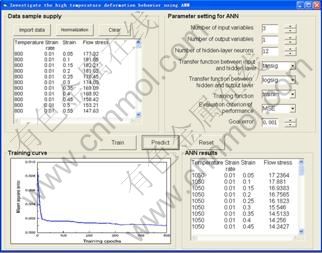

The normalized data set at 1050 ℃ were taken as testing set and the others were chosen as training set for ANN model. After the training procedure, the model is tested to check whether the predicted results agree with the experimental results. The plot of experimental value of flow stress and predicted flow stress by ANN model is shown in the Fig. 3. It can be shown that the correlation coefficient (R) for the training data set is 0.99. This means that a good correlation between the hot processing parameters and flow stress of Ti-6Al-2Zr-1Mo-1V alloy has been achieved. Figure 4 shows the comparison of the flow stress predicted by the ANN model and the experimental results. It can be obviously seen that the accuracy of the predicted flow stress based on the ANN model fits well with the experimental data. The mean absolute error between predicted and experimental data is only 0.286 MPa. Therefore, the developed neural network, with good performance and network architecture, is in a good agreement with the experimental data. More important, it is necessary to emphasize that the steady state of flow stress of Ti-6Al-2Zr-1Mo-1V alloy is also exhibited even if there are only limited experimental data, implying that the ANN method is beneficial to present the high temperature deformation behavior of Ti-6Al-2Zr-1Mo- 1V alloy, such as combined working hardening and flow softening. A graphical user interface (Fig. 5) about modeling the correlation between processing parameters and flow stress of Ti-6Al-2Zr- 1Mo-1V alloy using ANN was created based on the Visual Basic programming language so that it is convenient for users to operate.

Fig. 3 Comparison of experimental flow stress and predicted stress by ANN

Fig. 4 Correlation coefficient between flow stress predicted by ANN and experimental value at 1050 ℃

Fig. 5 Interface developed by Visual Basic based on established ANN model

4 Conclusions

1) Hot processing parameters (strain, strain rate and deformation temperature) have remarkable effects on the flow stress, which decreases with an increase of the deformation temperature and a decrease of strain rate.

2) An intelligent ANN model is applied efficiently to developing the correlation of processing parameters and flow stress of Ti-6Al-2Zr-1Mo-1V alloy. The value of predicted flow stress indicates that the ANN with structure of 3-12-1, which is trained by back-propagation learning algorithm, possesses excellent generalization performance.

3) On the basis of established ANN model and Visual Basic programming language, the graphical user interface is also developed so that this proposed advanced model will be utilized for an industrial practice.

References

[1] PARK S S, GARMESTANI H, BAE G T, KIM N J, KRAJEWSKI P E, KIM S, LEE E W. Constitutive analysis on the superplastic deformation of warm-rolled 6013 Al alloy [J]. Mater Sci Eng A, 2006, 435-436: 687-696.

[2] LEE B H, REDDY N S, YEOM J T, LEE C S. Flow softening behavior during high temperature deformation of AZ31 Mg alloy [J]. J Mater Process Technol, 2007, 187-188: 766-769.

[3] SUN Y, ZENG W D, ZHAO Y Q, QI Y L, MA X, HAN Y F. Development of constitutive relationship model of Ti600 alloy using artificial neural network [J]. Comput Mater Sci, 2010, 48: 686-691.

[4] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation [J]. Acta Metall, 1966, 14: 1136-1138.

[5] LIN Y C, CHEN X M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working [J]. Mater Des, 2011, 32: 1733-1759.

[6] ZHAO Yong-qing, XI Zheng-ping, QU Heng-lei. Current situation of titanium alloy materials used for national aviation [J]. Journal of Aeronautical Materials, 2003, 23(S): 215-219. (in Chinese)

[7] SHU Ying, ZENG Wei-dong, ZHOU Jun, ZHOU Yi-gang, ZHOU Lian. A study of hot deformation behavior for BT20 alloy [J]. Materials Science & Technology, 2005, 13(1): 66-69. (in Chinese)

[8] DONG Chang-hong. Artificial neural network and application with MATLAB [M]. Beijing: National Defense Industry Press, 2005: 21-25. (in Chinese)

[9] SAIDA P K, GREGORY G A, OLENA P, GOLAM M N. Biocompatibility assessment of next generation materials for brain implantable microelectrodes [J] Mater Lett, 2011, 65: 876-879.

[10] BHADESHIA H K D H, DIMITRIU R C, FORSIK S, PAK J H, RYU J H. Performance of neural networks in materials science [J]. Mater Sci Technol, 2009, 25: 504-510.

[11] LIU P, SU J H, DONG Q M, LI H J. Optimization of aging treatment in lead frame copper alloy by intelligent technique [J]. Mater Lett, 2005, 59: 3337-3342.

[12] SUN Y, ZENG W D, ZHAO Y Q, ZHANG X M, SHU Y, ZHOU Y G. Modeling constitutive relationship of Ti40 alloy using artificial neural network [J]. Mater Des, 2011, 32: 1537-1541.

[13] SUN Yu, ZENG Wei-dong, ZHAO Yong-qing, ZHANG Xue-min, MA Xiong, HAN Yuan-fei. Constructing processing map of Ti40 alloy using artificial neural network [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 159-165.

[14] GENEL K, KURNAZ S C, DURMA M. Modeling of tribological properties of alumina fiber reinforced zinc-aluminum composites using artificial neural network [J]. Mater Sci Eng A, 2003, 363: 203-210.

[15] SWINGLER K. Applying neural networks: A practical guide [M]. California: Morgan Kaufman Publishers, Inc, 1996: 22-58.

[16] FU R Q, XU T W, PAN Z X. Modelling of the adsorption of bovine serum albumin on porous polyethylene membrane by back- propagation artificial neural network [J]. J Membrane Sci, 2005, 251: 137-144.

应用智能方法建立Ti-6Al-2Zr-1Mo-1V合金的本构关系

孙 宇1,曾卫东1,赵永庆2,韩远飞1,马 雄1

1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 西北有色金属研究院,西安 710016

摘 要:利用Thermecmastor-Z热模拟机进行Ti-6Al-2Zr-1Mo-1V钛合金在不同工艺参数(变形温度800, 850, 900, 1000, 1050 ℃,应变速率0.01, 0.1, 1, 10 s-1)条件下的热模拟压缩试验,研究变形温度和应变速率对Ti-6Al-2Zr-1Mo-1V钛合金流变应力的影响。以试验数据为基础,应用BP神经网络算法原理,建立该合金的高温流动应力与变形温度、应变和应变速率对应关系的高温本构关系预测模型。结果表明,运用神经网络方法建立的Ti-6Al-2Zr-1Mo-1V钛合金本构关系模型具有较高的预测精度,与试验结果吻合良好。此外,运用Visual Basic可视化编程语言设计并开发了具有神经网络功能的用户界面。

关键词:Ti-6Al-2Zr-1Mo-1V合金; 人工神经网络; 本构关系; 变形行为

(Edited by LI Xiang-qun)

Foundation item: Project (2007CB613807) supported by the National Basic Research Program of China; Project (35-TP-2009) supported by the Fund of the State Key Laboratory of Solidification Processing in NWPU, China; Project (51075333) supported by the National Natural Science Foundation of China

Corresponding author: ZENG Wei-dong; Tel/Fax: +86-29-88494298; E-mail: zengwd@nwpu.edu.cn

DOI: 10.1016/S1003-6326(11)61341-1