基于生命周期评价的我国原铝生产的环境影响评估

来源期刊:中国有色金属学报(英文版)2019年第8期

论文作者:杨毅 郭尧琦 朱文松 黄健柏

文章页码:1784 - 1792

关键词:原铝;环境影响;生命周期评价;减排潜力

Key words:primary aluminum; environmental impact; life cycle assessment; emission reduction potential

摘 要:在当前生态文明建设的背景下,对原铝生产过程中的物料消耗、环境影响进行评估和核算,是进行环境外部性计量和促进铝行业绿色发展的基础性工作。为此,本文作者利用生命周期评价理论,采用拜耳法制备氧化铝工艺,根据不同发电方式分别对原铝生命周期内的环境影响进行评估,并分析4种主要环境影响类型的来源和分布。结果表明:(1) 铝工业的负面环境影响一般来自于氧化铝冶炼、碳阳极制备和电解工艺,尤其是电解和氧化铝工艺。初级能源消耗(PED)、水资源消耗(WU)、温室效应(GWP)和淡水富营养化(FEP)是主要的环境影响类型。(2) 火力发电模式生产原铝产生的环境负荷明显高于水力发电模式(前者温室气体排放系数为21800 kg CO2 eq/t (Al),后者为4910 kg CO2 eq/t (Al))。(3) 反映能源结构的发电方式和反映技术水平的直接排放所占比重揭示中国铝行业巨大的节能减排潜力,可制定发展清洁发电、提高能源效率和促进技术进步等相关的政策和措施。

Abstract: Assessing and accounting for material consumption and environmental impact are necessary to measure environmental externalities of the aluminum industry and to construct an ecological civilization. In this research, life cycle assessment (LCA) theory was used to assess the environmental impact of primary aluminum based on the lime soda Bayer process and different power generation modes, and the sources and distributions of the four selected impact categories were analyzed. The results show that, (1) Negative environmental impact of aluminum industry generally occurs from alumina extraction, carbon anode fabrication and electrolysis, particularly electrolysis and alumina extraction. Primary energy demand (PED), water use (WU), global warming potential (GWP) and freshwater eutrophication potential (FEP) are main environmental impact categories. (2) The environmental load with thermal power is higher than that with hydropower, e.g., for the former, the greenhouse gas emission coefficient of 21800 kg CO2 eq/t (Al) will be generated, while for the latter, 4910 kg CO2 eq/t (Al) will be generated. (3) Both power mode methods reflect the energy structure, whereas direct emissions reflect the technical level, indicating the potential for large energy savings and emission reductions, and some policies, related to clean power, energy efficiency and technological progress, should be made for emission reduction.

Trans. Nonferrous Met. Soc. China 29(2019) 1784-1792

Yi YANG1, Yao-qi GUO2,3, Wen-song ZHU2, Jian-bai HUANG1,3

1. School of Business, Central South University, Changsha 410083, China;

2. School of Mathematics and Statistics, Central South University, Changsha 410083, China;

3. Institute of Metal Resources Strategy, Central South University, Changsha 410083, China

Received 10 September 2018; accepted 21 May 2019

Abstract: Assessing and accounting for material consumption and environmental impact are necessary to measure environmental externalities of the aluminum industry and to construct an ecological civilization. In this research, life cycle assessment (LCA) theory was used to assess the environmental impact of primary aluminum based on the lime soda Bayer process and different power generation modes, and the sources and distributions of the four selected impact categories were analyzed. The results show that, (1) Negative environmental impact of aluminum industry generally occurs from alumina extraction, carbon anode fabrication and electrolysis, particularly electrolysis and alumina extraction. Primary energy demand (PED), water use (WU), global warming potential (GWP) and freshwater eutrophication potential (FEP) are main environmental impact categories. (2) The environmental load with thermal power is higher than that with hydropower, e.g., for the former, the greenhouse gas emission coefficient of 21800 kg CO2 eq/t (Al) will be generated, while for the latter, 4910 kg CO2 eq/t (Al) will be generated. (3) Both power mode methods reflect the energy structure, whereas direct emissions reflect the technical level, indicating the potential for large energy savings and emission reductions, and some policies, related to clean power, energy efficiency and technological progress, should be made for emission reduction.

Key words: primary aluminum; environmental impact; life cycle assessment; emission reduction potential

1 Introduction

Since the beginning of this century, China’s aluminum industry has witnessed a 10-year period of rapid growth due to urbanization and industrialization. The primary aluminum output increased rapidly from 5.55×106 t in 2003 to 22.06×106 t in 2013, with an average annual growth rate of approximately 15.2%, which is far higher than the global average for this sector. In 2017, China reported an output of 53.78×106 t of 10 kinds of nonferrous metals, an increase of 3%, and China has been the top global producer of nonferrous metals for consecutive 16 years. According to this report, the aluminum output was 32.27×106 t, accounting for 60% of the total amount of these kinds of 10 nonferrous metals. Therefore, China is the most important global economy regardless of the absolute demand for aluminum metal or consumption increase. However, the processes utilized by the aluminum industry, e.g., bauxite mining, alumina extraction, anode fabrication, electrolysis and ingot casting, require high energy consumption and produce large quantities of harmful substances and high emissions. In recent years, China has continued to improve its aluminum industry technologies, although the negative environmental impact of the aluminum industry remains difficult to eliminate, resulting in a national situation when thermal power is used as the main energy source.

In the current context of constructing an ecological civilization, continuous progress has been made in analyzing resources and the environment. However, an important and urgent problem that needs to be solved is how to account for material consumption and the environmental impact and to assess the environmental and economic impact of the development and utilization of nonferrous metal resources. According to existing studies, the environmental impact of the aluminum industry process flow has been assessed to some extent. For example, the European Aluminum Association (EAA) collected life cycle index data on aluminum production and manufacturing enterprises in major European countries in 1992 and released the first ecological profile report in 1996 [1]. The International Aluminum Institute issued the life cycle inventory of the worldwide aluminum industry with regard to energy consumption and emission of greenhouse gases (section 1: automobiles in 2000) [2], the life cycle assessment (LCA) of aluminum: inventory data for the worldwide primary aluminum industry in 2003 and an updated version of the report in 2007 [3]. Moreover, the EAA published the environmental profile report for the European aluminium industry in 2008 [4]. These research reports were based on questionnaire survey data from the aluminum industry in 27 EU countries, North American countries and member states of other economic cooperation organizations. In academic research, LCA of aluminum and its application can be found throughout the international literature. TAN and KHOO [5] used the LCA method to conduct a quantitative analysis on the environmental impact of different processes in Australia. ZARE and IZADIKHAH [6] compared the potential environmental impact of three categories of aluminum in Iran: primary aluminum ingot, secondary aluminum ingot and mixed aluminum ingot. However, most researches have been limited to a specific process, such as bauxite mining [7], casting [8] and recycling [9-11]. Some studies discussed the feasibility of using aluminum material for applications or as a substitute for other materials, e.g., vehicles [12] and packaging [13,14].

LCA on the environmental impact of China’s aluminum industry has generally focused on specific processes and recycling [15], alloys and transportation applications [16,17], resource management [18,19], and greenhouse gas (GHG) emissions [20,21]. LIU and MüLLER [22] summarized some notable features and trends in aluminum LCA studies, including the limited scope and differentiated system boundaries, the common practice of using industry-wide generic inventory data, challenges of allocation for aluminum recycling, and the predominant focus on energy and GHG emissions as environmental metrics. In particular, ZHANG et al [23] evaluated the environmental impact of aluminum production in China, including primary aluminum and secondary aluminum, via LCA. This study is quite comprehensive and representative, although the alumina extraction and power structure were not clearly described.

China’s aluminum industry is a key sector facing increasing pressure to reduce emissions. Thus, China- focused LCA is and will be always important and required for reducing energy usage and implementing effective policies. This research, combining field surveys from specific enterprises based on the literature and other information, attempted to comprehensively evaluate process flows and material input/output for the LCA of China’s aluminum industry. Moreover, owing to the prior usage of LCA that focused on global average conditions in China, China’s Life Cycle Database (CLCD) was used to further study the environmental impact of thermal power and hydropower into the LCA of the aluminum industry. This evaluation will allow a more complete and updated life cycle impact assessment (LCIA) of China’s aluminum industry.

2 Assessment objective definition

In accordance with the research objectives and scope requirements and to guarantee the integrity of important processes and data, effective classification and division of system boundaries are beneficial to the subsequent inventory analysis and assessment interpretation. The selected rules are as follows.

(1) Inputs from fixed assets, such as machine rooms, factory buildings and personnel-related consumption, are not included.

(2) When the weight of the common material is <1% or the weight of the material containing rare or high-purity components is <0.1% of the product weight, the upstream production data are ignored, although the total weight of the material ignored is no more than 5%.

(3) The main pollutants (see the relevant industrial standard) and pollutants with a contribution of >1% should be included, although it is not necessary to reject those with a contribution of <1%.

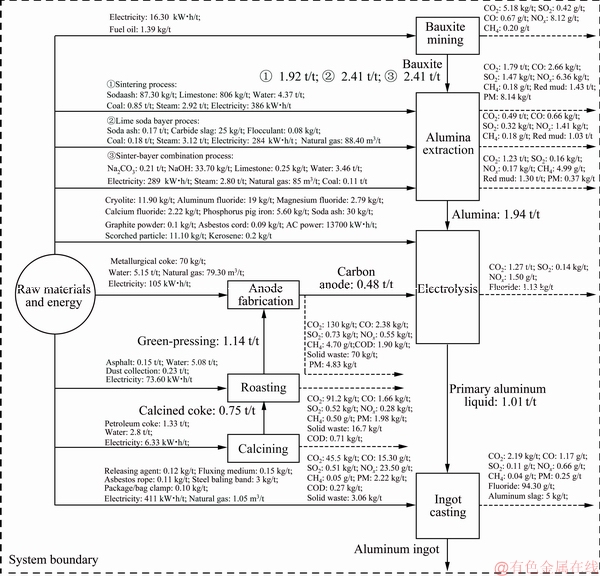

Using the above criteria as a basis, this work did not consider the environmental impact caused by transportation due to differences in regional distances and conditions. Instead, this work covered the process flows, such as bauxite mining, alumina extraction, carbon anode fabrication, electrolysis and ingot casting (from cradle to gate) because of their absolute resource and energy consumption and pollution domination. Alumina extraction was analyzed based on the lime soda Bayer process, and prebaked carbon anode fabrication provided auxiliary raw materials for electrolysis; the input consisted of raw material and energy inputs, and the output mainly included gaseous effluents, liquid waste, solid waste, byproducts and products. Waste pollutants were discharged both directly and indirectly; the emissions of the material flow inventory shown in Fig. 1 were all direct emissions, while indirect emissions were referred to in the CLCD and the online LCA and database development tool eFootprint of IKE Environmental Technology Co., Ltd.

Fig. 1 Material and energy input intensity of system boundaries (PM: Particulate matter)

3 Material flow inventory of primary aluminum

A field survey of actual production situations in aluminum enterprises found that the main fuels involved in the aluminum smelting process are fuel oil, coal, natural gas, kerosene and coke. Figure 1 shows the input and emission intensity to obtain 1 t of the next main product. Using fuel consumption and corresponding gaseous pollutant emission coefficients obtained or calculated by the relevant parameters from IPCC (Intergovernmental Panel on Climate Change), the direct emissions of gaseous pollutants from fuel use in a relevant process flow can be calculated. The gaseous effluents from fuel combustion mainly include CO2, CO, SO2, NOx and CH4. Production data for primary aluminum were obtained from the China Nonferrous Metals Industry Yearbook. Inputs for bauxite mining, alumina extraction, carbon anode fabrication, electrolysis and ingot casting were collected in 2017, and those for other materials and energy, such as fuel oil, electricity, soda ash, carbide slag, flocculant, coal, steam, natural gas, water, metallurgical coke, asphalt, petroleum coke, aluminum fluoride, cryolite, graphite powder, AC power, scorched particle, and kerosene, were obtained from the CLCD-China-ECER 0.8, representing the industry average in 2013. Direct emissions of fluoride, SO2, solid waste and liquid waste were obtained from monitoring reports.

Bauxite is the main raw material of primary aluminum, and China obtains bauxite mainly through strip mining and imports from other countries. After ignoring bauxite quality differences and environmental impact transfer factors and carrying out a survey of aluminum enterprises, the bauxite mining material flow inventory is sorted. Gaseous effluents are expressed by direct emission data for the process, i.e., mainly from fuel oil combustion, and can be determined by calculating the emission coefficients listed in Table 1 and other parameters, such as the fuel oil heat value.

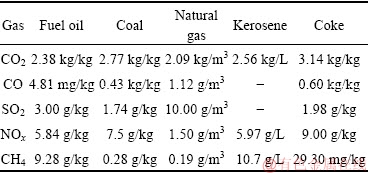

Table 1 Gaseous emission coefficients of different fuels

The sintering process, the lime soda Bayer process and the sinter-Bayer combination process are available for alumina production. China has established a production process highlighting the lime soda Bayer process with the development of alumina techniques. Therefore, in this work, an analysis is conducted based on the lime soda Bayer process.

Both a self-baked anode (anode paste) and a prebaked anode can be used as carbon anodes in an aluminum electrolytic tank based on certain differences in the used modes. Prebaked anodes feature low voltage, low pollution, convenient mechanical operation, advanced processes and suitability for high-capacity electrolytic tanks; thus, most aluminum enterprises currently have used prebaked anodes. A prebaked anode is made from petroleum coke, asphalt and metallurgical coke raw materials, and natural gas is used as the main fuel. The production process includes the calcining, roasting and carbon anode fabrication, and results in the discharge of solid waste, chemical oxygen demand (COD) and granule particulates in addition to gaseous emissions of CO2, CO, SO2, NOx and CH4. The data for the raw material input, energy input and environmental emission data are taken from Ref. [24].

The material inputs for electrolysis include carbon anodes, cryolite, soda ash, calcium fluoride, electrolyte blocks, graphite and scorched particles. Of these materials, cryolite is a solvent, and calcium fluoride is mainly used for mending electrolytic tanks. Electrolytes include magnesium fluoride, aluminum fluoride and alumina. Scorched particles have a sulfur content of no more than 0.6%, and phosphorus pig iron has a sulfur content of no more than 0.2%. When converting AC power to DC power with a converter and connecting the DC power to electrolytic tanks for electrolysis, the cathode produces liquid aluminum, and the anode generates gas.

Gaseous pollutants from the electrolysis process include CO2, CO, SO2, NOx and CH4 from electrolysis and fuel combustion, and other GHGs and perfluoro- carbon gases, mainly CF4 and C2F6, are generated from molten salt electrolysis with a generation proportion of approximately 10:1. The fluorine content in the emitted gases is calculated to be 0.835 kg/t (Al) [25]. In the electrolysis process, the consumption of graphite powder and asbestos cord is so low that we can ignore their environmental load in compliance with the selected rules.

Currently, the aluminum ingot casting process uses primarily natural gas and electric power for energy. A releasing agent and a flux medium are used for the degassing and deslagging treatments, respectively, and asbestos rope, steel baling bands and package/bag clamps are used for packaging. Except for primary aluminum liquid, the limited materials that are consumed can be ignored. The pure aluminum loss is 0.4%-0.5% in the casting process, and this work uses 0.5% as a standard.

4 Environmental impact assessment results and analysis

4.1 Selection of environmental impact categories

This work considers the product environmental footprint (PEF) for green product assessment. The PEF methodology, released based on LCA theory by the European Commission in 2013 and widely applied in EU countries, analyzes 13 categories of environmental impact, namely, the global warming potential (GWP), primary energy demand (PED), abiotic depletion potential (ADP), water use (WU), acidification potential (AP), freshwater eutrophication potential (FEP), respiratory inorganics (RI), ozone depletion potential (ODP), photochemical ozone formation potential (POFP), human toxicity-cancer effects (HT-cancer), human toxicity-noncancer (HT-noncancer), ecotoxicity (ET), and ionizing radiation potential-human health effects (IRP).

4.2 Characterization

Characterization is the assessment of the magnitude of the potential impact of each inventory flow based on the corresponding environmental impact (e.g., modeling the potential impact of carbon dioxide and methane on global warming). Characterization factors are commonly referred to as equivalency factors and provide a way to directly compare the LCI results within each category [26].

Two LCA models of primary aluminum based on the lime soda Bayer process are established according to different electric power generation modes used for energy inputs, namely, LCA-Al-TP (with thermal power) and LCA-Al-HP (with hydropower), for comparison and analysis.

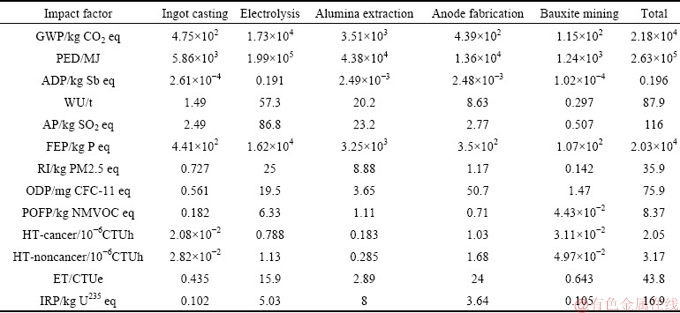

(1) Characterization of LCA-Al-TP

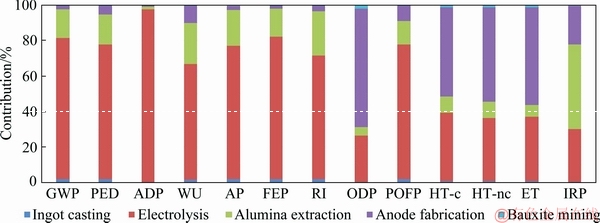

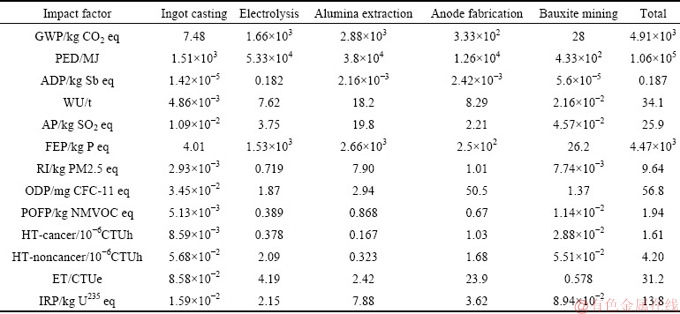

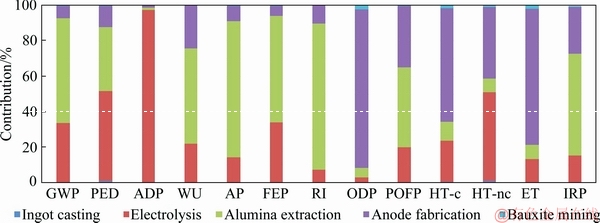

The characterization results and contribution to the environmental impact categories of LCA-Al-TP are shown in Table 2 and Fig. 2, respectively. The electrolysis process has the highest contribution to ADP, FEP, GWP, POFP and PED, with corresponding total values of 0.196 kg Sb eq, 2.03×104 kg P eq, 2.18×104 kg CO2 eq, 8.37 kg NMVOC eq, and 2.63×105 MJ, respectively, and the contribution percentage reaches 97.4% for ADP. In terms of FEP, GWP, POFP and PED, the contribution percentages are close to 80%. Alumina extraction has the highest contribution to IRP, accounting for 47.3%. Carbon anode fabrication has the highest contribution to ODP, HT-cancer, HT-noncancer and ET, and the contribution percentages are 66.8%, 50.2%, 53.0% and 54.8%, respectively. The contribution percentages of the aluminum ingot casting and bauxite mining processes to various environmental impacts are generally no more than 2.2%.

Table 2 Characterization results of LCA-Al-TP

Fig. 2 Contributions to environmental impact categories of LCA-Al-TP

(2) Characterization of LCA-Al-HP

Table 3 and Fig. 3 show the characterization results and contributions to the environmental impact categories of LCA-Al-HP, respectively, which indicate that the electrolysis process has the highest contribution to ADP, PED and HT-noncancer, with total values of 0.187 kg Sb eq, 1.06×105 MJ and 1.61×10-6 CTUh and accounting for 97.3%, 50.3% and 50.1%, respectively. The alumina extraction process has the highest contribution to GWP, WU, AP, FEP, RI, POFP and IRP, and the corresponding contribution percentages reach 58.7%, 53.4%, 76.4%, 60.0%, 82.1%, 44.8% and 57.1%, respectively. Carbon anode fabrication has the highest contribution to ODP, HT-cancer and ET, accounting for 88.9%, 64.1% and 76.6%, respectively. The aluminum ingot casting process and bauxite mining have much lower contribution percentages of no more than 2.4% to various environmental impacts. All of the total impact values in Table 3 are generally smaller than those in Table 2 except for HT-noncancer, which is caused by different power generation modes, suggesting the environmental friendliness of hydropower and the very large energy saving and emission reduction potential of China’s aluminum industry.

The accumulated characterization results for different environmental impact categories from two LCA modes of primary aluminum systems are shown in the “total” columns of Tables 2 and 3. The accumulated values show that the environmental load of primary aluminum for thermal power is higher than that for hydropower. Moreover, GWP, AP, FEP and RI exhibit large differences under different power generation modes. For example, for GHGs, when a unit of primary aluminum is produced under thermal power, 21800 kg CO2 will be generated, while only 4910 kg CO2 will be generated with hydropower.

Table 3 Characterization results of LCA-Al-HP

Fig. 3 Contributions to environmental impact categories of LCA-Al-HP

4.3 Sources and distributions of main environmental impact categories

Normalization is an optional step within LCIA that may be used to assist in the interpretation of life cycle inventory data as well as LCIA results. Normalization transforms the magnitude of the LCI and LCIA results into relative contributions by substance and life cycle impact category [27]. However, normalization in software such as GaBi has gradually been eliminated. Thus, we select 4 of the 13 environmental impact categories based on the characterization results and emissions pollution accuracy, where the latter includes direct solid, liquid, and gaseous emissions in primary aluminum production. Most enterprises may own monitoring equipment for CO2 and sulfide or utilize sophisticated statistical data; however, they lack data for indicators of ODP and HT-(non)cancer. Specifically, PED, WU, GWP and FEP are chosen to analyze the key sources and distributions of the impact categories owing to their relatively small relative errors.

The emission sources are divided into direct emissions that occur in chemical reactions in owned or controlled process equipment, such as alumina extraction and electrolysis, and indirect emissions that come from the materials and energy used in the production of primary aluminum, such as emissions at the facility where purchased electricity is generated and emissions from the extraction and production of purchased materials.

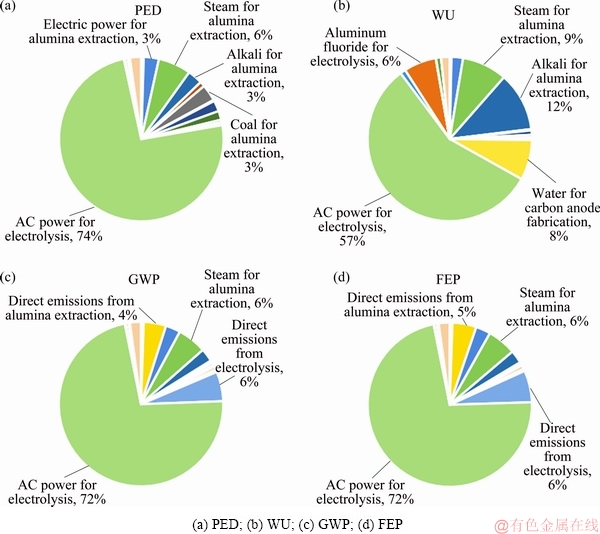

(1) Source and distribution of main impact categories in LCA-Al-TP

As shown in Fig. 4, the key factors influencing PED are AC power, with a proportion of 74% used in AC power for electrolysis, and steam, alkali, coal and electricity used in alumina extraction, approximately 15% (Fig. 4(a)). The WU mostly comes from AC power and aluminum fluoride in the electrolysis process, accounting for as much as 63%. Secondly, alkali and steam in alumina extraction account for 12% and 9% of WU, respectively, and carbon anode fabrication consumes 8% (Fig. 4(b)). AC power used in electrolysis produces 72% of the GWP, and direct emissions of electrolysis and alumina extraction generate about 10% (Fig. 4(c)). FEP is similar to GWP. Direct emissions of electrolysis and alumina extraction account for about 11% of the FEP (Fig. 4(d)). Overall, these four impact categories are still dominated by indirect emissions, and emissions from thermal power account for a significant proportion.

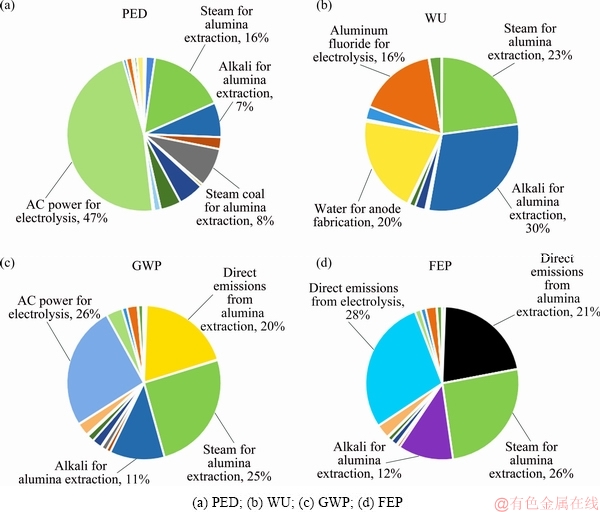

(2) Sources and distribution of main impact categories in LCA-Al-HP

The AC power used in electrolysis is still the main source of PED since it accounts for less than 47%. Steam, coal and alkali in alumina extraction produce 16%, 8% and 7% of the PED, respectively (Fig. 5(a)). The key factors influencing the WU are alkali and steam in the alumina extraction process, accounting for 53% in total. Electrolysis and carbon anode fabrication also make significant contributions (Fig. 5(b)). GWP mainly results from indirect emissions generated by AC power for electrolysis (26%) as well as steam (25%) and alkali (11%) for alumina extraction, and direct emissions from alumina extraction account for 20% (Fig. 5(c)). More than 59% of the FEP is generated during the alumina extraction process, nearly half of FEP is related to direct emissions, accounting for up to 49% when combined with that of the electrolysis process (Fig. 5(d)).

These four environmental impact categories selected for China’s aluminum industry are dominant in electrolysis and alumina extraction. Moreover, the environmental impact of bauxite mining and ingot casting is smaller. Different power generation modes result in a large gap in the environmental impact, which is caused by the requirement for more resources and energy consumption for thermal power. However, the situation in China is that thermal power still accounts for more than 80% of production. These results urge the transition to clean power generation modes, including hydropower, wind power or nuclear power, at larger scales. Additionally, direct emissions from electrolysis and alumina extraction with hydropower still have a substantial environmental impact (e.g., more than 20% of the GWP and nearly 47% of the FEP), indicating that there is room for technological progress. Both methods of generating electric power, which reflect the energy structure, and the proportion of direct emissions, which reflect the technical level, reveal a very large potential for energy savings and emission reductions in China’s aluminum industry.

Fig. 4 Source distribution of impact categories selected in LCA-Al-TP

Fig. 5 Source distribution of impact categories selected in LCA-Al-HP

5 Conclusions

(1) Negative environmental impact of China’s aluminum industry is generally related to alumina extraction, carbon anode fabrication and electrolysis, particularly electrolysis and alumina extraction. The characterization results show that the normalized values of PED, WU, GWP and FEP are higher than those of the other categories.

(2) The environmental contamination of primary aluminum production using thermal power is greater than that using hydropower. A significant environmental impact discrepancy exists in GWP, AP, FEP and RI under different power generation modes; pollution comes mainly from indirect emissions, and direct emissions from hydropower only contribute a limited proportion (e.g., more than 20% of the GWP and nearly 47% of the FEP) as well.

(3) Both methods of generating electric power, which reflects the energy structure, and the proportion of direct emissions, which reflects the technical level, indicate a very large potential for energy savings and emission reductions in China’s aluminum industry. The results encourage corresponding policies and measures, such as developing clean power generation (such as hydropower, wind power or nuclear power), improving energy efficiency and promoting technological progress.

References

[1] European Aluminium Association. Ecological profile report for the European aluminium industry [R]. Brussels: European Aluminium Association, 1996.

[2] IPAI Life Cycle Working Committee. Life cycle inventory of the worldwide aluminum industry with regard to energy consumption and emissions of greenhouse gases [R]. London: International Aluminium Institute, 2000.

[3] SAUR K. Life cycle assessment of aluminum: inventory data for the worldwide primary aluminium industry [R]. London: International Aluminium Institute, 2003.

[4] European Aluminium Association. Environmental profile report for the European aluminium industry [R]. Brussels: European Aluminium Association, 2008.

[5] TAN R B H, KHOO H H. An LCA study of a primary aluminum supply chain [J]. Journal of Cleaner Production, 2005, 13(6): 607-618.

[6] ZARE R, IZADIKHAH M. Multi-criteria decision making methods for comparing three models of aluminum ingot production through life cycle assessment [J]. Applied Ecology and Environmental Research, 2017, 15(3): 1697-1715.

[7] NORGATE T, HAQUE N. Energy and greenhouse gas impacts of mining and mineral processing operations [J]. Journal of Cleaner Production, 2010, 18(3): 266-274.

[8] KOLTUN P, THARUMARAJAH A, GRANDFIELD J F. Greenhouse emissions in primary aluminium smelter cast houses e a life cycle analysis [J]. Materials Science Forum, 2010, 630: 27-34.

[9] OLIVIERI G, ROMANI A, NERI P. Environmental and economic analysis of aluminium recycling through life cycle assessment [J]. International Journal of Sustainable Development & World Ecology, 2006, 13(4): 269-276.

[10] DAMGAARD A, LARSEN A W, CHRISTENSEN T H. Recycling of metals: Accounting of greenhouse gases and global warming contributions [J]. Waste Management & Research, 2009, 27(8): 773-780.

[11] PARASKEVAS D, KELLENS K, DEWULF W, DUFLOU J R. Environmental modelling of aluminium recycling: A life cycle assessment tool for sustainable metal management [J]. Journal of Cleaner Production, 2015, 105: 357-370.

[12] DAS S. Life cycle energy and environmental assessment of aluminum-intensive vehicle design [J]. SAE International Journal of Materials and Manufacturing, 2014, 7(3): 588-595.

[13] NIERO M, NEGRELLI A J, HOFFMEYER S B, OLSEN S I, BIRKVED M. Closing the loop for aluminum cans: life cycle assessment of progression in cradle-to-cradle certification levels [J]. Journal of Cleaner Production, 2016, 126: 352-362.

[14] STOTZ P M, NIERO M, BEY N, PARASKEVAS D. Environmental screening of novel technologies to increase material circularity: A case study on aluminium cans [J]. Resources, Conservation and Recycling, 2017, 127: 96-106.

[15] HONG Jian-ping, WANG Jun, CHEN Hai-yan, SUN Bao-de, LI Jia-jing, CHEN Chong. Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2155-2161.

[16] HONG Jing-min, ZHOU Jing, HONG Jing-lan, XU Xu. Environmental and economic life cycle assessment of aluminum- silicon alloys production: A case study in China [J]. Journal of Cleaner Production, 2012, 22(1): 11-19.

[17] YI Qiu-ping, TANG Chang-ping. Environmental impact assessment of magnesium alloy automobile hub based on life cycle assessment [J]. Journal of Central South University, 2018, 25(8): 1870-1878.

[18] YUE Qiang, WANG He-ming, LU Zhong-wu, ZHI Sheng-ke. Analysis of anthropogenic aluminum cycle in China [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1134-1144.

[19] DING Ning, YANG Jian-xin, LIU Jing-ru. Substance flow analysis of aluminum industry in mainland China [J]. Journal of Cleaner Production, 2016, 133: 1167-1180.

[20] LIU Zhe, GENG Yong, ADAMS M, DONG Liang, SUN Li-na, ZHAO Jing-jing, DONG Hui-juan, WU Jiao, TIAN Xu. Uncovering driving forces on greenhouse gas emissions in China’s aluminum industry from the perspective of life cycle analysis [J]. Applied Energy, 2016, 166: 253-263.

[21] GAO Feng, NIE Zuo-ren, WANG Zhi-hong, LI Hong-mei, GONG Xian-zheng, ZUO Tie-yong. Greenhouse gas emissions and reduction potential of primary aluminum production in China [J]. Science in China Series E: Technological Sciences, 2009, 52(8): 2161-2166.

[22] LIU Gang, MüLLER D B. Addressing sustainability in the aluminum industry: A critical review of life cycle assessments[J]. Journal of Cleaner Production, 2012, 35: 108-117.

[23] ZHANG Yan-lu, SUN Ming-xing, HONG Jing-lan, HAN Xiao-fei, HE Jing, SHI Wen-xiao, LI Xiang-zhi. Environmental footprint of aluminum production in China [J]. Journal of Cleaner Production, 2016, 133: 1242-1251.

[24] ZHANG Ping. The application of life cycle assessment in the cleaner production in a carbon enterprise [D]. Zhengzhou: Henan Agricultural University, 2008. (in Chinese)

[25] TANG Chang-ting, JIANG Hai-tao, ZHOU Ping. Calculation of aluminum fluoride consumption in aluminum reduction production [J]. Light Metals, 2016(2): 28-33. (in Chinese)

[26] ROY P, NEI D, ORIKASA T, XU Q Y, OKADOME H, NAKAMURA N, SHIINA T. A review of life cycle assessment (LCA) on some food products [J]. Journal of Food Engineering, 2009, 90(1): 1-10.

[27] BARE J, GLORIA T, NORRIS G. Development of the method and US normalization database for life cycle impact assessment and sustainability metrics [J]. Environmental Science & Technology, 2006, 40(16): 5108-5115.

杨 毅1,郭尧琦2,3,朱文松2,黄健柏1,3

1. 中南大学 商学院,长沙 410083;

2. 中南大学 数学与统计学院,长沙 410083;

3. 中南大学 金属资源战略研究院,长沙 410083

摘 要:在当前生态文明建设的背景下,对原铝生产过程中的物料消耗、环境影响进行评估和核算,是进行环境外部性计量和促进铝行业绿色发展的基础性工作。为此,本文作者利用生命周期评价理论,采用拜耳法制备氧化铝工艺,根据不同发电方式分别对原铝生命周期内的环境影响进行评估,并分析4种主要环境影响类型的来源和分布。结果表明:(1) 铝工业的负面环境影响一般来自于氧化铝冶炼、碳阳极制备和电解工艺,尤其是电解和氧化铝工艺。初级能源消耗(PED)、水资源消耗(WU)、温室效应(GWP)和淡水富营养化(FEP)是主要的环境影响类型。(2) 火力发电模式生产原铝产生的环境负荷明显高于水力发电模式(前者温室气体排放系数为21800 kg CO2 eq/t (Al),后者为4910 kg CO2 eq/t (Al))。(3) 反映能源结构的发电方式和反映技术水平的直接排放所占比重揭示中国铝行业巨大的节能减排潜力,可制定发展清洁发电、提高能源效率和促进技术进步等相关的政策和措施。

关键词:原铝;环境影响;生命周期评价;减排潜力

(Edited by Wei-ping CHEN)

Foundation item: Projects (71633006, 71403298) supported by the National Natural Science Foundation of China; Projects (14YJCZH045, 15YJCZH019) supported by the Ministry of Education of Humanities and Social Science, China

Corresponding author: Yao-qi GUO; Tel: +86-13787798224; E-mail: guoyaoqi@csu.edu.cn

DOI: 10.1016/S1003-6326(19)65086-7