超弹TiNi合金机敏摩擦学特性的有限元研究

王立民1, 2, 徐久军1, 严 立1, 杨 钢2, 刘正东2

(1. 大连海事大学 材料工艺研究所, 大连 116026;

2. 钢铁研究总院 结构材料研究所, 北京 100081)

摘 要: 采用有限元法、 Vickers压痕和滑动磨损实验研究超弹TiNi合金在法向载荷作用下的机敏摩擦学特性。 结果表明: 超弹TiNi合金的弹性恢复量大于奥氏体不锈钢, 在载荷为0.98N时, 其弹性恢复量是不锈钢的1.30倍, 在本实验条件下, 其滑动磨损量是奥氏体不锈钢的0.14倍; 综合有限元计算结果、 Vickers压痕以及滑动磨损实验结果, 超弹TiNi合金的机敏摩擦学特性是其塑性变形临界载荷和最大弹性应变增加、 塑性区域面积减小以及应力增加速度减缓的综合体现。 这种机敏摩擦学特性是TiNi合金具有良好耐磨性的主要原因。

关键词: 有限元法; 超弹TiNi合金; 机敏摩擦学特性; 磨损机理 中图分类号: TG139; O241.82

文献标识码: A

FEM study of smart tribological properties of pseudo-elastic TiNi alloys

WANG Li-min1, 2, XU Jiu-jun2, YAN Li2, YANG Gang1, LIU Zheng-dong1

(1. Institute of Material and Technology, Dalian Marimetime University,Dalian 116026, China;

2. Institute for Structural Materials, Central Iron and Steel Research Institute,Beijing 100081, China)

Abstract: A finite element method (FEM) and Vickers indentation and sliding wear were used to study the smart tribological properties of pseudo-elastic TiNi alloys. The elastic recovery of TiNi alloys is higher than that of austenitic stainless steel, under the normal load of 0.98N, the elastic recovery of the former is 1.30 times of that of the latter. The volume loss of the TiNi alloy is only 0.14 times of that of the austenitic steel under the sliding wear. Considering the results of FEM and Vickers indentation and sliding wear, the smart tribological properties of pesudo-elastic TiNi alloys are integrative embodiments as follows: increasing plastic deformation critical load and maximum elastic strain, decreasing the plastic deformation region and slowing the stress increasing trend. This smart tribological property is the main reason of high wear resistance of TiNi alloys.

Key words: finite element method; pseudo-elastic TiNi alloys; smart tribological properties; wear mechanism

近年来的研究表明, 形状记忆合金(SMAs)除了具有形状记忆效应外, 在特定的条件下, 还表现出良好的耐磨性。 金嘉陵等[1]研究了TiNi 合金、 Co45以及经过氮化的38CrMoAl的磨损性能, 把TiNi合金具有较好耐磨性归因于它的超弹性、 晶体结构、 以及高阻尼特性。 Singh和Alpas[2] 把Ti50Ni47Fe3 合金与SAE52100 轴承钢对磨, 发现Ti50Ni47Fe3合金的磨损率只有SAE52100的2%~5%, 他们认为在该合金氧化层下面生成的指状加工硬化层是其具有良好耐磨性的原因。 王红卫等[3, 4] 研究了Cu-26Zn-4Al(质量分数, %) 形状记忆合金的干摩擦磨损特性, 用裂纹尖端的钝化机制来解释其磨损机理。 除了形状记忆效应之外, 形状记忆合金还具有另外一独特的力学特性—超弹性, 这是应力诱发马氏体相变及其逆相变的结果。 随着对SMAs耐磨性研究的不断深入, 越来越多的学者认为超弹性是形状记忆合金具有良好耐磨性的原因, 持这种观点的有Liang [5], Li[6-11], Shida和Sugimoto[12], 以及Rong Liu等[13]。

作为一种机敏材料, TiNi合金具有感知和执行双重功能, 当应力达到应力诱发马氏体相变临界点时, 发生应力诱发马氏体相变, 合金的弹性性能大幅度增强, 对外界产生的驱动力增加, 而表现出机敏特性。 在摩擦磨损过程中, 同样存在应力诱发马氏体相变的条件, 合金也会感知外界应力的变化, 内部结构进行自动调整, 合金接触表面的微凸体也会发生适应性的改变, 从而表现出机敏摩擦学特性。 本文作者从TiNi合金独特的力学特性出发, 采用有限元法对其在法向载荷下所表现出的机敏摩擦学特性进行研究, 进而对其磨损机理进行探讨。

1 TiNi合金的超弹性及双线性应变强化模型

图1所示为采用MTS800在室温下测得的超弹态TiNi(Ti-50.2%Ni, 摩尔分数)合金的拉伸应力—应变曲线。 可以看出, 超弹TiNi合金与不同金属材料不同之处在于它的弹性阶段由两部分组成: 一部分是线弹性阶段, 如图1中的OA段所示, 在该段应变与应力成正比, 并遵守胡克定律; 另一部分应变与应力不再成正比, 如图中AD段所示, 在此阶段卸载, 应力与应变仍能回到原点, 但已不按原路返回, 有较大的弹性滞后。 由于第二部分的弹性是由可逆的应力诱发马氏体相变产生的, 所以这部分弹性被称为伪弹性或超弹性。 实验中在D点卸载时, 有0.0032的残余应变产生, 由于实验中很难判断材料的真正屈服点, 所以把曲线中的C点作为其室温下的屈服点, 该点的残余应变约为0.002, 并把该点对应的应力700MPa作为下面有限元计算中的屈服应力, 把该点对应的应变称为其弹性极限εy, 实际上该弹性极限由材料的线弹性应变极限

图1 超弹TiNi合金拉伸应力—应变曲线

Fig.1 Tensile stress—strain curves of pseudo-elastic TiN alloy

加上伪弹性应变极限组成(εy=εs+εpE)。 从图1中可以看出, TiNi合金的力学特性有两个特殊表现: 一个是较低的伪弹性模量(AC段斜率), 另一个是较高的弹性极限; 图1中的弹性极限约为0.05, 为普通金属材料(0.002)的25倍。 这两点是TiNi合金机敏特性的重要表现, 本文的有限元研究即是以这两点为基础来分析合金在法向载荷作用下所表现出的机敏摩擦学特性。

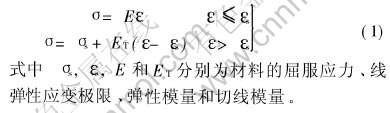

图2所示为双线性应变强化模型。 图中的OF和FG分别表示材料的线弹性阶段和屈服之后的应变硬化阶段。 该模型的本构方程为

在有限元计算中, 把该模型中的屈服点(F点)和切线模量(ET)作为超弹TiNi合金的应力诱发马氏体相变点和伪弹性模量来处理, 从而在固定屈服应力下, 通过改变伪弹性模量的大小可以得到不同的弹性极限, 进而研究弹性极限和伪弹性模量对合金接触特性的影响。

图2 双线性应变强化模型简图

Fig.2 Scheme of bilinear strain hardening law

2 有限元模型

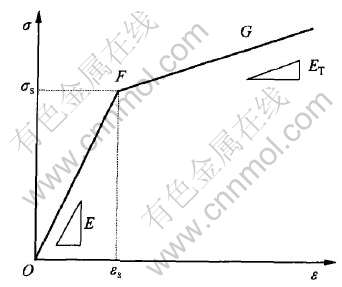

图3所示为二维有限元模型。 上部半圆形模拟金刚石磨粒或微凸体, 其半径为10μm, 弹性模量为1120GPa, 泊松比为0.07。 下部为待分析材料, 尺寸为50μm×50μm。 采用平面应变8节点单元划分网格, 对接触区进行了局部细化, 接触区单元边长为模型边界单元边长的2%。 接触单元175个, 目标单元320个, 分别附着在ACB线和DE线上。 由于在法向载荷下, 摩擦系数产生的影响可以忽略[14, 15], 所以计算中假设两接触体之间无摩擦。 FG线x方向和y方向的位移为零, 载荷均匀作用在AB线上, 大小为60kN。 全部载荷分100个载荷步施加, 即每个载荷步施加6kN。

图3 有限元模型

Fig.3 Finite element model

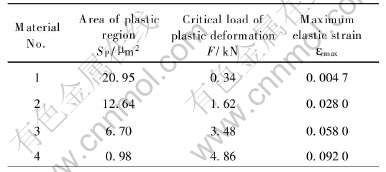

研究中共分析了4种材料, 其力学参数列于表1。 1号材料为对比材料沉淀硬化型奥氏体不锈钢, 根据其室温拉伸性能可大致确定其切线模量为弹性模量的1/10, 作为虚拟伪弹性模量。 2号、 3号和4号材料为具有不同弹性极限和伪弹性模量的超弹TiNi合金, 它们的弹性模量和相变启动应力由图1中得出, 并假设其屈服极限均为700MPa, 弹性极限分别为0.02, 0.04和0.06, 伪弹性模量可以通过图2中的几何关系得出。 每个模型在PⅣ 1.4G PC机上的平均计算时间为120~150min。

3 结果

3.1 有限元计算结果

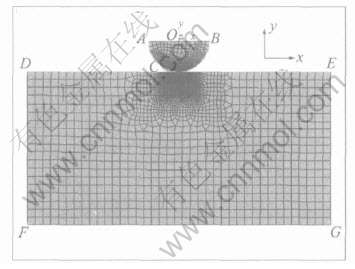

采用塑性区域面积、 塑性变形临界载荷、 最大弹性应变以及最大von Mises 应力来分析不同材料在法向载荷作用下引起的力学响应。 图4为4种材料在载荷为6kN时的塑性区域图, 图中最高的von Mises应力等值线为700MPa, 该等值线内部即为塑性区域。 图4表明, 1号材料的塑性区域最大, 而对于3种TiNi合金, 塑性区域则随着弹性极限的增加而减小。 借助于AUTOCAD软件, 可以测量4种材料在该载荷下塑性区域面积的大小, 所得结果列于表2。 3种超弹TiNi合金的塑性区域面积分别是不锈钢的0.60, 0.32和 0.047倍。

对于不同力学特性的材料, 其发生塑性变形的临界载荷也各不相同。 4种材料的临界塑性变形临界载荷列于表2。 从表中可知, 1号材料最容易发生塑性变形, 弹性极限最高的4号材料的临界塑性变形载荷也最高, 为1号材料的12.49倍。 在该载荷下所得最大弹性应变也列于表2。 不锈钢的弹性变形能力最差, 在载荷为6kN时, 最大弹性应变只有0.0047, 而3种超弹TiNi合金的最大弹性应变都大于不锈钢, 并随着其弹性极限的增加而增加。

表1 4种材料的力学性能

Table 1 Mechanical properties of four materials

图4 4种材料在法向载荷为6kN时von Mises应力等值线图

Fig.4 von Mises stress isolines of four materials under normal loads 6kN

表2 4种材料的有限元结果

Table 2 Finite element results of four materials

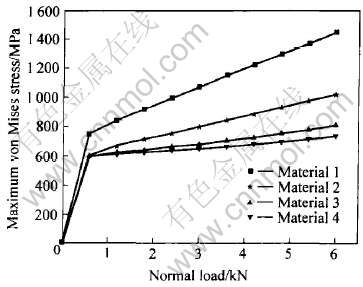

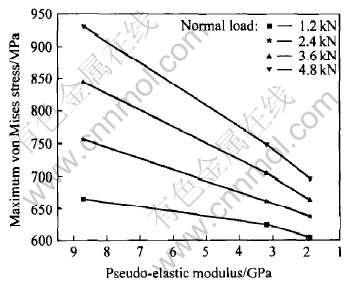

图5所示为4种材料在不同载荷下的最大von Mises应力曲线。 由于3种TiNi合金具有相同的弹性模量, 所以在线弹性阶段其应力均一致, 只有当应力超过其相变启动应力后才发生分离。 在相同载荷下, 最大von Mises应力随伪弹性模量的降低而减小。 图6所示为不同载荷下, 3种TiNi合金的最大von Mises应力与其伪弹性模量之间的关系。 可以看出, 随着伪弹性模量的降低, 一方面最大von Mises应力减小; 另一方面最大von Mises应力随载荷增加而增加的趋势变缓。

图5 最大von Mises应力与法向载荷的关系

Fig.5 Curves of maximum von Mises stress—normal load

图6 最大von Mises应力与伪弹性模量的关系

Fig.6 Curves of maximum von Mises stress and pseudo-elastic modulus

3.2 Vickers压痕实验结果

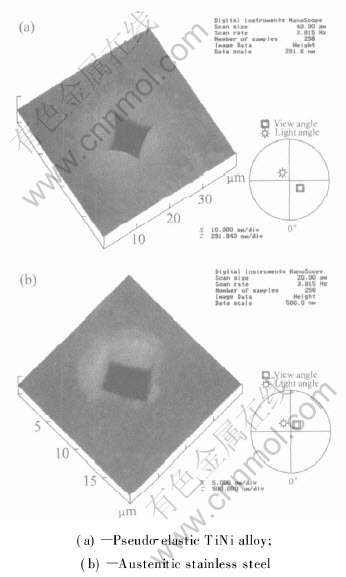

对d1.4mm的超弹TiNi合金丝和奥氏体不锈钢丝在型号为MH-6型显微维氏硬度计上进行Vickers压痕实验, 载荷为0.98N, 加载时间10s。 用NanoscopeⅢ型原子力显微镜(AFM)对压痕的形貌及尺寸进行观察、 测量, 结果如图7所示。 对于TiNi合金, 在接触变形过程中能够发生应力诱发马氏体转变而呈现出超弹性, 使变形部位以及附近的材料产生很高的弹性变形, 载荷卸除后, 弹性变形得以恢复, 而使4个侧面出现向压痕中心凸起的趋势。 与TiNi合金相比, 奥氏体不锈钢的弹性变形能力很小, 变形主要为塑性变形, 因而导致4个侧面产生的压痕边缘接近直线。 测量结果表明, 虽然在同样载荷下, 超弹TiNi合金压痕对角线长度大于奥氏体不锈钢(20.09μm和19.73μm), 但其压痕深度却比不锈钢小(1.62μm 和2.10μm), 大致可以估算出压头尖端TiNi合金的弹性恢复量约为不锈钢的1.30倍。

图7 不锈钢与TiNi合金Vickers压痕的AFM图

Fig.7 Vickers indentation AFM pictures of TiNi alloy and stainless steel (load of 0.98N)

3.3 滑动磨损实验结果

对超弹TiNi合金和奥氏体不锈钢的滑动磨损性能进行了比较。 图8所示为2种材料在法向载荷为200N、 磨损时间为12min时的磨损表面形貌, 配对副为高速钢。 可以看出, 由于高速钢表面微凸体对材料的破坏作用, 2种材料的主要磨损形式均为磨粒磨损。 但超弹TiNi合金较高的伪弹性应变使其弹性变形能力大大增强, 可以以较大的弹性变形来缓解磨粒的磨削, 磨粒滑过后, 弹性变形恢复, 产生的犁沟浅而窄, 磨损轻微。 而不锈钢抵抗塑性变形能力较差, 导致材料表面在磨粒作用下产生的变形以塑性变形为主, 破坏严重, 在不锈钢试样表面以这种浅而宽且底部有犁皱现象的塑性磨损形貌居多。 由于磨粒磨损带来材料的塑性破坏是普遍的, 而且非常严重, 这是其耐磨性低于TiNi合金的主要原因。 在本实验条件下, 奥氏体不锈钢的体积磨损量为9.60mm3, 而TiNi合金的体积磨损量只有1.32mm3, 是奥氏体不锈钢0.14倍。

图8 TiNi合金(a)和奥氏体不锈钢(b)在相同载荷和时间下的磨损形貌

Fig.8 Wear scar of TiNi alloy(a) and austenitic stainless steel(b) under same load and time

4 讨论

超弹TiNi合金可以定量地感知外界应力, 当应力达到临界值时(应力诱发马氏体相变临界应力), 材料内部发生适应性的结构调整, 发生应力诱发马氏体相变[1, 7], 导致伪弹性模量大幅度下降, 弹性极限相应增加(比普通材料高大约1~2个数量级), 从而在摩擦接触过程中改善材料表面接触状态, 表现出机敏摩擦学特性。 综合本文的有限元计算结果以及Vickers压痕以及滑动磨损实验结果可知, 这种机敏摩擦学特性具体表现为: 随着合金弹性极限的增加以及伪弹性模量的减小, 材料产生的塑性区域面积得到抑制; 发生塑性变形所需的临界载荷提高; 最大弹性应变大幅度增强, 弹性恢复量明显增加; 产生的最大von Mises应力降低, 而且伪弹性模量的降低减缓了该应力随载荷增加而增加的幅度。 即超弹TiNi合金的机敏摩擦学特性是增加合金的塑性变形临界载荷、 减小塑性区域面积、 弹性变形能力增强以及减缓应力增加速度的综合体现。

借助于超弹TiNi合金的机敏摩擦学特性, 对其磨粒磨损及疲劳磨损机理探讨如下。 在磨粒磨损当中, 磨粒的塑性嵌入以及后续的犁削作用对材料的磨损量起着至关重要的作用, TiNi合金发生塑性变形所需的临界载荷值较高, 磨粒在合金表面滑过时使合金产生塑性变形就更加困难, 减小了磨粒发生塑性嵌入的可能, 进而在滑动过程中减轻磨粒的犁削作用; 塑性变形区域的减小降低了材料在磨粒作用下发生塑性变形的范围, 在随后的循环载荷作用下, 塑性变形的累计效应较弱, 一方面减轻了磨粒对材料的破坏程度, 另一方面可以减弱犁沟两侧以及沟底材料的硬化, 从而减少了三体磨粒磨损的发生; 弹性变形能力的加强, 能够把磨粒的动能转化为自身的弹性变形能, 当磨粒滑过后, 贮存的弹性能得到释放[1, 6-11], 残留的塑性变形较小, 减少了磨粒对材料表面犁沟作用的形成。 许多学者[10, 16]和本文作者都观察到了TiNi合金的这种良好的耐磨粒磨损特性。 根据Suh的疲劳磨损理论, 材料内部的位错运动以及应力状态决定其磨损量, 而TiNi合金塑性变形临界载荷的提高表明材料内部位错的运动及相互作用必须在较高载荷下发生, 可以延缓裂纹在材料内部的形成, 进而推迟裂纹的扩展及磨屑的产生; 塑性变形区域的减小保证了材料内部位错的运动在较小的范围内发生, 随着循环载荷的增加, 位错的塞积效应以及与材料中夹杂物和第二相质点相互作用的区域减小, 从而大大限制了裂纹形成的范围; von Mises应力的降低使材料表面在磨损过程中处于有利地位, 可以降低裂纹扩展的动力, 对裂纹的扩展起到阻碍作用。 Clayton[17]在实验中观察到了TiNi合金具有较好的耐疲劳磨损特性。

5 结论

1) 有限元计算结果表明, 随着弹性极限的升高以及伪弹性模量的降低, 在法向载荷下, 超弹TiNi合金的塑性变形临界载荷和最大弹性应变增加, 塑性区域面积减小, 最大von Mises应力随载荷增加而增加的幅度减缓。

2) Vickers压痕实验结果表明, 超弹TiNi合金的弹性恢复量大于奥氏体不锈钢, 在载荷为0.98N时, 其弹性恢复量约为不锈钢的1.30倍; 在本实验中的滑动磨损实验条件下, TiNi合金的磨损量是奥氏体不锈钢的0.14倍。

3) 综合有限元计算和Vickers压痕实验结果, 超弹TiNi合金的机敏摩擦学特性是增加合金的塑性变形临界载荷、 减小塑性区域面积、 弹性变形能力增强以及减缓应力增加幅度的综合体现。

REFERENCES

[1]金嘉陵, 王宏亮. Ni-Ti合金耐磨性研究[J]. 金属学报, 1988, 24(1): A66-A69.

JIN Jia-ling, WANG Hong-liang. Wear resistance of Ni-Ti alloy[J]. Acta Metall Sinica, 1988, 24(1): A66-A69.

[2]Singh J, Alpas A T. Dry sliding wear mechanism in a Ti50Ni47 intermetallic alloy[J]. Wear, 1995, 181-183: 302-311.

[3]WANG Hong-wei, YANG Da-zi. Friction and wear unlubricated copper-based CuZnAl shape memory alloys[J]. Wear, 1991, 148: 113-121.

[4]王红卫, 吴望子, 王凤庭, 等. Cu基形状记忆合金干滑动磨损研究[J]. 金属学报, 1991, 27(6): 444-448.

WANG Hong-wei, WU Wang-zi, WANG Feng-ting, et al. Friction and wear unlubricated copper-based CuZnAl shape memory alloys[J]. Acta Metall Sinica, 1991, 27(6): 444-448.

[5]Liang Y N, Li S Z, Jin Y B, et al. Wear behavior of a TiNi alloy[J]. Wear, 1996, 198: 236-241.

[6]Li D Y. Wear behaviour of TiNi shape memory alloys[J]. Scripta Mater, 1996, 34:195-200.

[7]Li D Y. TiNi-based pseudo-elastic tribomaterials[J]. Materials and Design, 2000, 21: 551-555.

[8]Li D Y, Ma X. Variation in wear resistance of a novel triboalloy-pseudo-elastic TiNi alloy-with respect to its pseudo-elasticity and hardness[J]. Journal of Material Science and Technology, 2001, 17: 45-47.

[9]Li D Y. A new type of wear-resistant material: pseudo-elastic TiNi alloy[J]. Wear, 1998, 221: 116-123.

[10]Li D Y. Exploration of TiNi shape memory alloy for potential application in a new area: tribological engineering[J]. Scripta Material Structure, 2000, 9: 717-726.

[11]Li D Y, LIU Rong. The mechanism responsible for high wear resistance of pseudo-elastic TiNi alloy- a novel tribo-material[J]. Wear, 1999, 225-229: 777-783.

[12]Shida Y, Sugimoto Y. Water jet erosion behavior of TiNi binary alloys[J]. Wear, 1991, 146: 219-228.

[13]LIU R, LI D Y. A finite element method study on wear resistance of pseudo-elastic TiNi alloy[J]. Mater Sci Eng A, 2000, A277: 169-175.

[14]Bhattacharya A K, Nix W D. Analysis of elastic and plastic deformation associated with indentation testing of thin films on substrates[J]. Int J Solids Structures, 1988, 24(12): 1287-1298.

[15]Bhattacharya A K, Nix W D. Finite element simulation of indentation experiments[J]. Int J Solids Structures, 1988, 24(9): 881-891.

[16]ZHANG Tian-cheng, Li D Y. An exprimental study on the erosion behavior of pseudo-elastic TiNi alloy in dry sand and in aggressive media[J]. Mater Sci Eng A, 2000, A293: 208-214.

[17]Clayton P. Tribological behavior of a titanium-nickel alloy[J]. Wear, 1993, 162: 202-209.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(59905003)

收稿日期: 2005-04-21; 修订日期: 2005-07-15

作者简介: 王立民(1971-), 男, 工程师, 博士

通讯作者: 王立民, 工程师; 电话: 010-62183615; E-mail: wanglimin@nercast.com