DOI:10.19476/j.ysxb.1004.0609.2018.10.13

Nb-Ti-Co氢分离合金优化设计和渗氢性能:I. 合金相图和渗氢成分区域构建

黄浩然1,闫二虎1,闵若男1,朱坤军2,赵光伟3,李新中2,徐 芬1,孙立贤1

(1. 桂林电子科技大学 材料科学与工程学院,桂林 541004;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

3. 三峡大学 机械与动力学院,宜昌 443002)

摘 要:基于CALPHAD方法和Thermo-Calc软件构建了Nb-Ti-Co三元合金富Nb角相图,而后结合微观偏析统一模型研究58种合金的凝固路径,探讨固相反扩散系数和冷却速率对凝固路径的影响规律,并利用Bridgman定向凝固实验对其验证,最后通过SEM和XRD观察上述合金的微观结构,并与数值模拟计算结果进行比较,建立了Nb-Ti-Co相图中的渗氢成分区域。结果表明:1) Nb-Ti-Co三元合金相图富Nb角存在两个三元四相平衡反应,分别为L+α-Nb→TiCo+Co6Nb7 (1225.35 ℃)和L+TiCo→α-Nb+Ti2Co (1099.06 ℃);2) Nb相区中至少存在四种不同的凝固路径,分别为(L+α-Nb)、(L+α-Nb)→(L+α-Nb+Co6Nb7)→(L+α-Nb+Co6Nb7+TiCo)、(L+α-Nb)→ (L+α-Nb+TiCo)和(L+α-Nb)→(L+α-Nb+TiCo)→(L+α-Nb+TiCo+Ti2Co);3) 冷却速率(Rf)对渗氢区域内合金凝固路径影响较小,相反,固相反扩散系数(Ф)对其凝固路径影响较大;4) 渗氢区域内合金显微组织中初生α-Nb相体积分数随着Nb含量和Ti/Co比率的增加而增加,相反,两相共晶体积分数随之而降低。

关键词:Nb-Ti-Co合金;CALPHAD;凝固路径;渗氢区域

文章编号:1004-0609(2018)-10-2058-12 中图分类号:TG139 文献标志码:A

近年来,由于化石能源的濒临枯竭和日益凸显的环境等问题使得开发清洁、无毒、无污染的可再生新能源成为世界各国的能源战略重点。氢能由于具有以上一系列特征以及在石油化工行业、航空航天和燃料电池等诸多领域的广阔应用使其备受关注[1-3]。目前,H2的生产主要来自化石原料的转换,如煤的气化和裂化石油气等[2, 4-5]。由于煤的杂质含量较高,在气化生产过程中会伴随许多副产品,如CO、CO2、N2、H2S、NH3和H2O(gas)等,因此,如何将H2从上述混合气体中分离出来是制取纯氢的一个重要环节[6-8]。在该种背景下,氢分离技术应运而生。该技术利用膜对特定气体组分(H2)具有选择渗透性和扩散特性来实现气体分离和纯化的目的[9-10]。膜材料是发展膜分离技术的关键问题之一。与传统的陶瓷膜和有机膜相比,金属膜由于具有较高的机械强度和良好的高温韧性而被广泛应用在氢分离膜材料中。过去几十年,钯及其合金(如Pd-Ag)得到了深入广泛的研究,成为了目前应用于氢分离领域唯一商业化的合金膜[11-15]。然而,钯资源十分稀缺、价格昂贵,不适合大规模工业化应用,亟待开发廉价、高渗氢性能的无钯或少钯的新型氢分离金属膜材料。

为了解决上述问题,氢渗透性能更高的5B族金属(Nb、V和Ta等)很快引起了全球各国学者的重点关注[16-19]。然而,上述纯金属及其单相合金在渗氢过程中引发的氢脆问题十分严重,无法应用于氢分离过程[17, 20]。因此,围绕5B族金属开发同时具有抗氢脆和高渗氢性能的新型膜材料仍是当今氢能源领域的重要研究方向之一。2006年,日本学者HASHI等[21]首次发现,由初生固溶体α-Nb相和共晶相(α-Nb+TiCo)构成的Nb-Ti-Co系合金(膜)具有较高的氢渗透和抗氢脆性能。其中固溶体α-Nb相是氢的主要扩散通道,但该相在氢扩散之后脆性较大,而共晶相(α-Nb+TiCo)的存在恰恰解决了氢脆问题。基于此,HASHI等提出了“多相构成,功能分担”的渗氢膜设计理念。另外,HASHI等[21]指出完全由共晶(α-Nb+TiCo)相构成的Nb30Ti35Co35合金在400 ℃时具有最大的氢渗透性,为2.64×10-8 mol/(m·s·Pa0.5)。此外,澳大利亚DOLAN等[22]、韩国MAGNONE等[23]、日本ISHIKAWA等[24]、美国KAMAKOTI等[25]以及LUO等[26]和王仲民[27]等陆续对Nb基和V基三元合金(膜)开展了大量的研究,发现具有初生α-Nb相和共晶(α-Nb+ TiCo)相构成的Nb60Ti21Co19合金具有更高的渗氢性能,约为相同试验条件下Nb30Ti35Co35合金的1.5倍,并且氢渗透系数随初生α-Nb相体积分数的增加而增大,完全由共晶(α-Nb + TiCo)相构成的合金氢渗透系数最小。另外,文中还指出,为了获取渗氢性能和抗氢脆性能最佳组合的合金成分,迫切需要掌握Nb-Ti-Co合金整体相图信息,尤其是初生α-Nb相和共晶(α-Nb+TiCo)相构成的合金成分区域(该区域成分最终应用于渗氢合金,简称“渗氢成分区域”)。尽管上述众多学者对Nb-Ti-Co合金系开展了大量实验研究,但迄今国内外对于“渗氢成分区域”在Nb-TiCo相图中的位置仍不明确,渗氢区域内是否存在更高渗氢性能的合金成分也是未知的,渗氢性能和抗氢脆性能最佳的合金成分仍旧存在众多争议,严重制约了该系合金膜的设计与开发[21, 26]。另外,由于Nb-Ti-Co相图的缺失以及高温平衡相数据的匮乏,各国学者前期研究中不得不采用“实验测定法[21]”来探寻该系合金中具有上述双相结构的合金成分,也就是说,在准二元Nb-TiCo相图位置处首先围绕可能出现上述结构的合金成分开展相关实验研究,根据实验结果再次优选合金成分,异常繁琐且具有一定的盲目性,如何更好地绘制出该合金体系的三元相图,并有效地应用于合金成分、工艺和渗氢性能的设计显得尤为关键。

基于此,本工作首先利用CALPHAD(Calculation of phase diagrams)方法和Thermo-Calc软件构建了Nb-Ti-Co三元合金富Nb角相图,得出相图中三元四相平衡反应等重要信息;而后结合本文作者前期提出的微观偏析统一模型,研究该相图α-Nb相区内58种合金的凝固路径,着重探讨固相反扩散系数和冷却速率对凝固路径的影响规律,并利用Bridgman定向凝固实验对其验证;最后借助SEM和XRD系统研究上述合金的微观结构,并与数值模拟计算结果进行比较,最终建立了渗氢成分区域。本研究一方面可解决国际上众多学者在实验初期渗氢成分选择时的盲目性与复杂性等问题,另一方面可补充完善国际上尚不明确的Nb-Ti-Co合金相图并构建渗氢成分区域,为该系合金渗氢膜的设计与开发提供理论依据。

1 实验方法与数值模型

1.1 实验方法

在Nb-Ti-Co合金相图中的α-Nb固溶体相区优选58种合金成分,并依次编号为1#~58#,具体成分及其位于相图中的位置如图1所示,其中Ti和Co的变化梯度均为5%(摩尔分数)。实验用原材料为99.9%纯度(质量分数)Nb棒、99.99%纯度Ti棒和99.9%纯度Co棒,利用氩气保护气氛下电弧炉熔炼制备合金样品。熔炼时试样翻转3次并加电磁搅拌,以确保合金成分均匀。锭质量约为30 g。从纽扣锭的中间部位取样,样品尺寸为直径16 mm,厚度0.7 mm。Brigman定向凝固实验用合金样品采用水冷铜坩埚冶炼制备,样品尺寸为直径50 mm,高120 mm。而后利用线切割技术围绕中心轴线位置切取直径和高分别为3 mm和120 mm的棒材进行实验,实验方法详见文献[28]。所有试样依次经打磨、抛光和超声波清洗备用。采用带能谱(EDS)的扫描电子显微镜(SEM, HITACHI S-4700)观察合金的显微组织形貌并进行成分分析,利用X射线衍射仪(Cu Kα,2θ范围:20°~90°,扫描速度:8 (°)/min)分析合金的相构成,利用Image-Pro Plus软件测量显微组织内部各相体积分数。

1.2 数值模型和算法

本文模型在作者前期模型基础上进行了延伸,主要是从原有的二元合金体系扩展至三元合金体系,并在后期计算程序中耦合了三相共晶及包共晶凝固计算。另外,本文模型的求解和推导过程中也将“几何权重平均技术”[29-30]引入,并构建五种基本形貌[30](圆柱状、板状、球状、内向圆柱形和内向球形)来描述合金凝固过程中时刻变化的枝晶形态,并综合考虑任意固相反扩散效应,最终得出本文数值模型计算式为:

(1)

(1)

式中:cn0 (n=1, 2)代表合金中组元n的初始浓度,即合金中Ti和Co的初始含量; 代表综合微观固相反扩散参数,可涵盖诸多因素,如枝晶几何形貌、冷却速率和固相扩散系数等。当合金凝固过程中忽略固相扩散(DS=0),本文模型可以简化为严格的Scheil-Gulliver方程,即

代表综合微观固相反扩散参数,可涵盖诸多因素,如枝晶几何形貌、冷却速率和固相扩散系数等。当合金凝固过程中忽略固相扩散(DS=0),本文模型可以简化为严格的Scheil-Gulliver方程,即 ;当假定凝固各相中充分固相扩散(DS→∞)时,模型可以简化为lever-rule模型,即:

;当假定凝固各相中充分固相扩散(DS→∞)时,模型可以简化为lever-rule模型,即:

(2)

(2)

式中:cL和c0分别为液相和初始成分;fL为液相体积分数,k为溶质分配系数。

实际上,本文数值模型与上述两种模型均具有统一的函数形式,所不同的只是参数 取值各异。式(1)中,

取值各异。式(1)中, 的表达式为

的表达式为

(3)

(3)

式中: 和

和 分别代表凝固枝晶间隙液相成分对固相反扩散效应的敏感性参数和枝晶凝固过程中形貌变化的溶质扩散Fourier数,各自表达式为

分别代表凝固枝晶间隙液相成分对固相反扩散效应的敏感性参数和枝晶凝固过程中形貌变化的溶质扩散Fourier数,各自表达式为

(4)

(4)

(5)

(5)

式中:几何权重系数矢量 与基本几何体素矢量A2N的点积

与基本几何体素矢量A2N的点积 代表了凝固枝晶几何形貌对微观偏析的影响,详细推导过程和参数定义/取值详见文献[31]。

代表了凝固枝晶几何形貌对微观偏析的影响,详细推导过程和参数定义/取值详见文献[31]。

合金凝固路径模拟计算过程中,首先需要利用Fortran软件搭建TQ 6.0接口程序,并耦合Thermo- Calc软件,用来获取凝固过程中的相关参数信息,如:溶质分配系数、凝固结晶温度、凝固过程中平衡相的个数和相名称等。计算过程中,初生相及两相共晶凝固阶段的迭代计算以fS(固相体积分数)作为控制变量,三相共晶凝固阶段的迭代计算以 (温度梯度)作为控制变量,详细算法见文献[31]。

(温度梯度)作为控制变量,详细算法见文献[31]。

2 结果和讨论

2.1 Nb-Ti-Co三元合金相图和渗氢成分区域

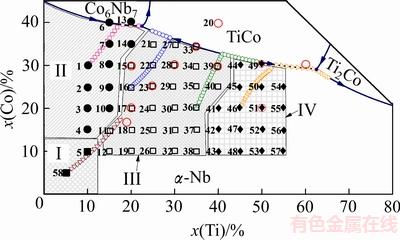

图1所示为利用CALPHAD方法[29-31]和Thermo-Calc软件计算的Nb-Ti-Co三元合金富Nb角液相面投影图,并在α-Nb固溶体相区内划分出了渗氢成分区域。相图中存在两个三元包共晶点Nb38.5Ti22.4Co39.1和Nb8.4Ti62.4Co29.2,该处合金凝固时发生三元包共晶反应,分别为L+α-Nb→TiCo+Co6Nb7 (1225.35 ℃)和L+TiCo→α-Nb+Ti2Co (1099.06 ℃)。围绕上述两个包共晶点周围有4个相,分别为α-Nb、Co6Nb7、TiCo和Ti2Co相。另外,相图中还包含有6个二元共晶线和4个液相面。为了全面分析α-Nb固溶体相区内合金的凝固特性并能够精确确定渗氢成分区域在相图中的位置,本文选取的58种合金既包含位于两个包共晶反应位置附近处的成分,也包含二元共晶沟(L→Nb+TiCo)位置处的成分,还有位于高Nb含量(>80%,摩尔分数)的合金成分,可以近似认为,此58种合金成分涵盖了Nb-Ti-Co相图中α-Nb相区内几乎所有可能发生的凝固路径。根据合金的XRD谱、SEM像和凝固路径模拟计算结果(后文详细讨论),将上述58合金划分为四个区域,分别记为Ⅰ、Ⅱ、Ⅲ和Ⅳ,如图1所示。

图1 Nb-Ti-Co富Nb角相图和四区域(分别记为Ⅰ、Ⅱ、Ⅲ和Ⅳ)内典型合金的凝固路径

Fig. 1 Nb-Ti-Co phase diagram in Nb-rich region calculated by using microsegregation model coupled with Thermo-Calc and calculated solidification paths for typical alloys in four sub-regions (denominated by ‘Ⅰ’ , ‘Ⅱ’, ‘Ⅲ’ and ‘Ⅳ’)

2.2 相结构和显微组织分析

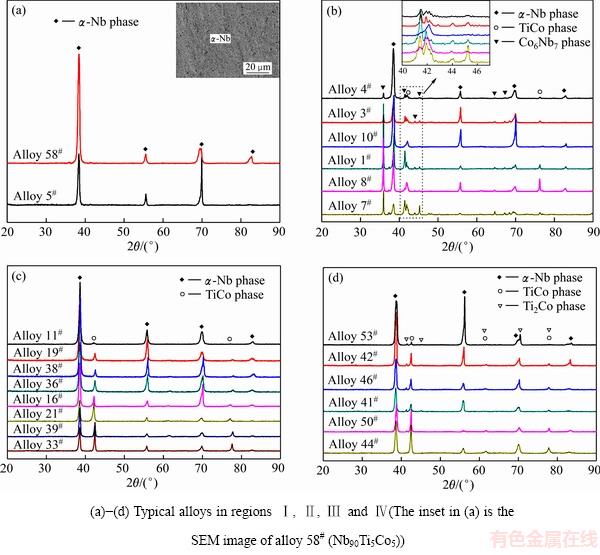

图2所示为上述各区域内典型合金的XRD谱。从图2(a)中可看出,区域Ⅰ中的合金(58#和5#)仅包含一相α-Nb,右上角的插图(SEM像)也证实了该单一相的存在。上述结果说明该区域内部合金凝固时仅涉及一个单相凝固反应L→α-Nb,直至凝固结束。区域Ⅱ中典型合金的XRD谱如图2(b)所示,合金中共包含三相:α-Nb、TiCo和Co6Nb7相,且合金成分距离三元包共晶点(Nb38.5Ti22.4Co39.1)越近(4#→10#→7#),Co6Nb7相的含量越大。图2(c)列出了区域Ⅲ中8种合金的相组成,可以看出,此区域的合金仅包含两相,分别为α-Nb和TiCo相,而区域Ⅳ中合金的相组成为α-Nb、TiCo和Ti2Co(见图2(d)),且距离二元共晶沟(L→Nb+TiCo)和三元包共晶点Nb8.4Ti62.4Co29.2越近,Ti2Co相含量随之增加。为了进一步分析上述各区域内合金的凝固行为,对其凝固试样进行了SEM分析。

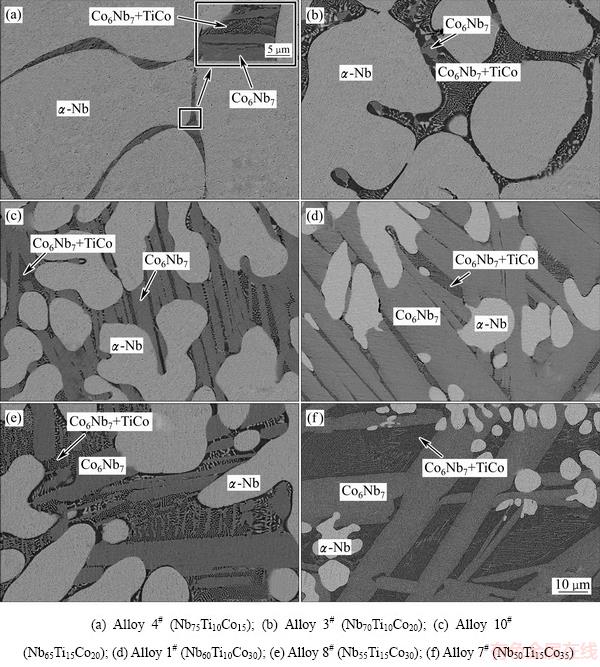

图3所示为区域Ⅱ内典型合金的SEM像,可以看出,所有合金显微组织中均包含呈初生枝晶状的α-Nb相、粗大板条状Co6Nb7相和包共晶(Co6Nb7+ TiCo)相。其中,细小的包共晶相随机地分布在Co6Nb7相的周围,如图3(a)右上角插图所示。随着合金成分向包共晶点(Nb38.5Ti22.4Co39.1)偏移(4#→10#→8#→7#),显微组织中初生α-Nb相体积分数迅速减少,相反,板条状的Co6Nb7相和包共晶(Co6Nb7+TiCo)相逐渐增多。结合Nb-Ti-Co相图(见图1)可发现,造成上述变化的主要原因是由于合金凝固过程中越来越多的液相参与了包共晶反应L+α-Nb→TiCo+Co6Nb7,生成了包共晶(Co6Nb7+TiCo)相。由于该区域合金显微组织中的脆性Co6Nb7相会降低合金的抗氢脆性能,所以区域Ⅱ内合金不适合选用在氢渗透过程中。

图2 四区域内典型合金的XRD谱

Fig. 2 XRD patterns of typical alloys in four regions

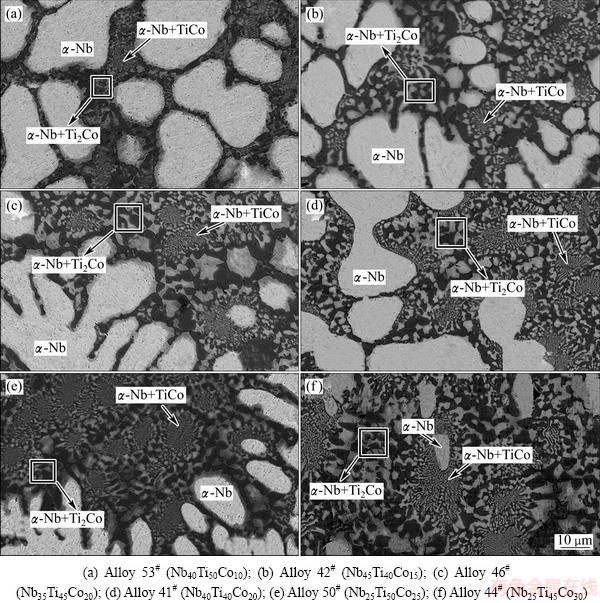

图4所示为区域Ⅲ内典型合金的SEM像,可以看出,所有合金的显微组织中均由初生α-Nb相和共晶(α-Nb+TiCo)相构成。当合金成分Ti/Co比率为cTi/cCo=1时(即位于Nb-TiCo准二元合金相图位置处),例如11#合金(Nb70Ti15Co15),其凝固结束后合金内部会形成上述双相组织,与LUO等[26]研究结果相一致。另外,当合金中原始成分Ti/Co比率低(或高)于1时,合金内部也会形成同种双相组织,上述结果表明,偏离Nb-TiCo准二元合金相图位置的合金成分也会形成初生α-Nb相和共晶(α-Nb和TiCo)相组织,这也是HASHI等[21]和LUO等[26]前期研究发现的Nb29Ti40Co31和Nb60Ti21Co19合金氢渗透性能相对较好的原因。根据“多相构成,功能分担”的渗氢膜设计理念,该区域内部的双相合金适用于氢渗透过程。

图5所示为区域Ⅳ内典型合金的SEM像,可以看出,所有合金均由初生α-Nb相、二元共晶(α-Nb+TiCo)相和包共晶(α-Nb+Ti2Co)相构成,其中,初生α-Nb相呈树枝晶状,包共晶相包裹在二元共晶相的周围,呈“离异共晶”状。随着合金成分中Nb含量的逐渐降低,显微组织中初生α-Nb相随之降低,如共晶沟附近的44#合金(Nb25Ti45Co30)显微组织中初生α-Nb相体积分数仅为3.2%,几乎完全由共晶相构成。该区域内合金凝固过程中由于生成了脆性Ti2Co相[21],严重制约了其在氢渗透过程中的应用。图3~5所示的SEM结果与图2所示的XRD结果相互吻合。

图3 区域Ⅱ内典型合金的SEM像

Fig. 3 SEM images of typical alloys in region Ⅱ

值得关注的是,上述四个区域内部的58种合金的XRD谱和SEM像(图2~5)均是在非平衡凝固条件下获取的,因为上述试样均采用电弧炉熔炼制备(冷却速率高达200 K/s)。但是,本工作模拟计算的Nb-Ti-Co合金相图是在平衡凝固条件获取,两种凝固条件下四个区域内合金的凝固行为是否一致值得尤为关注,凝固条件(如冷却速率)的改变是否会有新相的析出进而改变合金原有的凝固路径也是未知的。因此,下文研究了不同冷却速率和固相反扩散系数对合金凝固路径的影响规律,并模拟计算了四个区域内58种合金的凝固路径,最后利用Bridgman定向凝固实验对模拟结果进行验证。

2.3 凝固路径模拟计算和验证

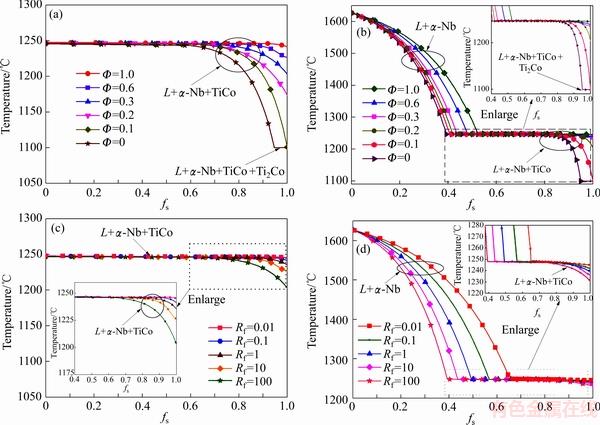

从式(1)可看出,当参数Ф取极限值0和1时,本文模型可以简化为严格的Scheil-Gulliver方程和lever-rule模型,两模型分别代表了合金凝固过程时固相反扩散程度为零和无限大,即DS=0和DS→∞。当式(1)中Ф值逐渐变大时,说明合金凝固过程中固相反扩散程度随之变大,进而可能影响合金的凝固行为,尤其是各相的结晶顺序和最终的凝固路径。因此,为了获取与上文实验结果相互匹配的凝固参数Ф,本文尝试计算了6种不同固相反扩散系数(Ф=0, 0.1, 0.2, 0.3, 0.6, 1)下渗氢区域内典型合金(33#和36#)的凝固路径,如图6所示。可以看出,当参数Ф由1逐渐过渡到0时,两种合金凝固路径发生了较大的变化,例如,当Ф=1时,33#合金的凝固路径为(L→α-Nb+TiCo)(见图6(a)),相应的36#合金的凝固路径为(L→α-Nb)→ (L→α-Nb+TiCo)(见图6(b));而当Ф=0时,两种合金凝固后期均会经历新的三元包共晶反应(L+TiCo→ α-Nb+Ti2Co)。另外,随着Ф的降低,两种合金显微组织中初生相(或两相共晶体积分数)变小,三相共晶体积分数变大。当Ф=0.3时,两种合金的凝固路径和各相体积分数与实验结果吻合较好。除固相反扩散系数,图6(c)和(d)还分别给出了33#和36#合金在5种不同冷却速率下(Rf = 0.01, 0.1, 1, 10, 100 K/s)的凝固路径。可以看出,两种合金的凝固路径在在5种不同冷却速率下均保持一致,也就是说冷却速率对合金的凝固路径基本没有影响,例如,33#合金在每一种冷却速率下均仅经历了两相共晶凝固(L→α-Nb+TiCo),直至凝固结束。但是,冷却速率对显微组织中各相体积分数具有一定的影响,伴随着冷却速率的逐渐降低,显微组织中初生相体积分数减少,而两相共晶体积分数增多。当Rf =0.1时,两种合金的凝固路径和各相体积分数与实验结果吻合较好。综合上述结果表明:与固相反扩散系数相比,合金凝固路径受冷却速率影响相对较小,在非(或近)平衡条件下合金的凝固路径类型相互一致。

图4 区域Ⅲ内典型合金的SEM像

Fig. 4 SEM images of typical alloys in region Ⅲ

图5 区域Ⅳ内典型合金的SEM像

Fig. 5 SEM images of typical alloys in region Ⅳ

图6 不同固相反扩散系数和冷却速率下33#合金和36#合金凝固路径计算结果

Fig. 6 Calculated solidification path for 33# alloy((a), (c)) and 36# alloy((b), (d)) with different solid back diffusion coefficients Ф and solidification rates Rf

为了验证上述规律,对33#合金(Nb30Ti35Co35)进行了两种速率(1和10 μm/s)下的Brigman定向凝固实验,重点关注上述合金的凝固路径和显微组织随抽拉速率的变化规律。为了避免合金熔体中的Ti与Al2O3陶瓷管(Brigman定向凝固时需用陶瓷管装样品)在高温下反应,采用“模壳法”[28]对合金熔体进行保护。图7所示为定向凝固33#合金在1和10 μm/s抽拉速率下的SEM像,可以看出,两种抽拉速率下合金显微组织中均包含α-Nb和TiCo两相。在凝固组织中可观察到清晰的淬火界面,如图7(a)和(b)所示,淬火界面下方为两相(α-Nb+TiCo)共晶,暗示出合金凝固过程中仅发生了如下共晶反应(L→Nb+TiCo),与模拟结果(见图6)相一致。另外,在抽拉速率为1 μm/s时,共晶组织中的两相与生长方向相互平行且呈棒状生长,这是由于Nb相在共晶组织中的体积分数约为25%,低于共晶层状生长的临界体积分数值30%。当抽拉速率增大至10 μm/s时,共晶组织呈现出胞状共晶生长,并且胞状中间的Nb相平行于生长方向,靠近边缘处的Nb相和TiCo相变得粗化、分散。上述结果表明:随着抽拉速率(晶体生长速率)的增加,定向凝固淬火界面发生“平→胞”转变,即:平界面失稳并逐渐向胞状或胞状枝晶转化,但合金的凝固类型保持不变。

图7 定向凝固33# (Nb30Ti35Co35)合金SEM像

Fig. 7 SEM images of DS 33# (Nb30Ti35Co35) alloy at different growth rates

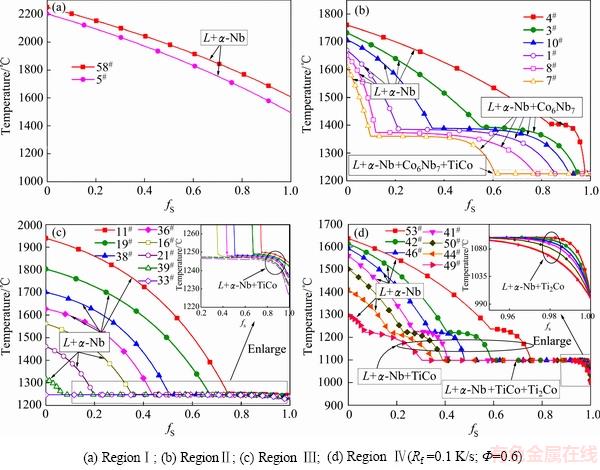

图8 四区域内典型合金的温度-固相体积分数关系曲线

Fig. 8 Solid volume fractions as function of temperature for typical alloys in four regions

图8所示为位于α-Nb固溶体相区典型合金的温度-固相体积分数关系曲线。为了便于讨论,将模拟结果按照区域Ⅰ、Ⅱ、Ⅲ和Ⅳ进行了划分。可以看出,区域Ⅰ内的合金(58#和5#)自凝固起始至终仅经历一个转变L→α-Nb,与其铸态凝固组织相一致(见图2(a)插图)。相反,区域Ⅱ内的合金凝固时经历了三种不同的凝固阶段,分别为初生α-Nb相的析出(L→α-Nb),两相共晶凝固(L→α-Nb+Co6Nb7)和最后的包共晶凝固(L+α-Nb→Co6Nb7+TiCo),模拟计算结果与图3中的铸态组织相吻合。区域Ⅲ内的合金凝固时经历了以下两个阶段:L→α-Nb和L→α-Nb+TiCo,而区域Ⅳ内的合金凝固时要额外经历一个新的凝固反应,L+TiCo→α-Nb+Ti2Co,如图8(d)和(e)所示。上述凝固路径模拟计算结果与图4和5的凝固组织相吻合。此外,利用Image-Pro Plus软件,对合金显微组织内部的各相表面体积分数进行了测量,并与模拟计算结果进行了对比,为了便于分析讨论,各区域内分别精选了一种合金,如图9所示。由图9可看出,各区域内合金的模拟计算结果与实验结果相差较小,其中,区域Ⅱ内的7#合金中的初生Nb相和Co6Nb7相体积分数测量值与模拟计算值相差为0.8%和1.3%,造成上述差值的主要原因可能是本文模型构建过程中忽略了晶体形核、孔洞形成和枝晶复杂形貌等因素。另外,尽管7#合金显微组织中每一相的测量值与模拟计算值具有细小的差别,但将所有相综合起来分析,即将初生相、两相共晶和三相包共晶体积分数综合考虑,可发现测量值与模拟计算值之和差值几乎为0,说明合金整个凝固过程中的测量值与模拟计算值相互吻合。

图9 四区域内典型合金(5#、7#、11#和41#)各相表面体积分数模拟计算结果和测量结果对比

Fig. 9 Comparison of volume fractions of solidified phases between calculated and measured results for typical alloys (Ⅰ—5#, Ⅱ—7#, Ⅲ—11# and Ⅳ—41#) in four regions

综合考虑上述实验和模拟计算结果,可以发现,Nb-Ti-Co合金相图中存在由初生α-Nb相和共晶(α-Nb+TiCo)相构成的合金成分区域,即图1中区域Ⅲ,该区域内合金在较宽的凝固冷却速率范围下均能结晶出上述双相组织,并且,合金原始成分中的Nb含量和Ti/Co比均影响最终显微组织构成。因此,可以通过调节该区域内合金中的原始成分,进而调控合金的显微组织构成,最终平衡合金的氢渗透性能、抗氢脆性能和持久性能。区域Ⅰ内的合金仅由初生α-Nb相构成,虽然氢渗透性能较高,但由于存在严重的氢脆问题不能应用于氢渗透过程[26]。区域Ⅱ和Ⅳ内的合金由于凝固组织中分别包含脆性Co6Nb7和Ti2Co相,因此也不能应用于氢渗透过程。

本工作探寻了Nb-Ti-Co合金相图中由初生α-Nb相和共晶(α-Nb+TiCo)相构成的合金成分区域,并给出了一个较宽的渗氢合金成分设计区间范围;同时突破了传统的关于Nb-Ti-Co渗氢合金设计时的限制,即“渗氢合金成分仅位于Nb-TiCo准二元合金相图位 置[26]”。

3 结论

1) Nb-Ti-Co三元合金相图富Nb角存在两个三元四相平衡反应,分别为:L+α-Nb→TiCo+Co6Nb7和L+TiCo→α-Nb+Ti2Co,此外,Nb相区中至少存在四种不同的凝固路径,分别为:(L+α-Nb),(L+α-Nb)→ (L+α-Nb+Co6Nb7)→(L+α-Nb+Co6Nb7+TiCo),(L+α-Nb) → (L+α-Nb+TiCo)和(L+α-Nb)→(L+α-Nb+TiCo)→(L+α-Nb+ TiCo+Ti2Co);

2) 冷却速率(Rf)对渗氢区域内合金的凝固路径影响较小,相反,固相反扩散系数(Ф)对其影响较大,随着Ф的逐渐降低,合金显微组织中初生相和两相共晶体积分数变小,而三相共晶体积分数变大,当Ф取极限值0时,合金凝固后期伴随着新的凝固反应生成。

3) 随着抽拉速率的增加(1→10 μm/s),33#合金定向凝固过程中的平直淬火界面发生弯曲,规则的棒状共晶组织转化为胞状共晶组织,但合金的凝固类型保持不变,两种抽拉速率下合金的凝固路径均为L→α-Nb+TiCo。

4) Nb-Ti-Co合金相图中存在由初生α-Nb相和共晶(α-Nb+TiCo)相构成的合金成分区域,即图1中区域Ⅲ,该区域内部合金显微组织中初生相体积分数随着Nb含量和Ti/Co比的增加而增加,相反,两相共晶体积分数随之而降低。

REFERENCES

[1] 朱 敏. 先进储氢材料导论[M]. 北京: 科学出版社, 2015: 62-68.

ZHU Min. Introduction to advanced hydrogen storage materials[M]. Beijing: Science Press, 2016: 62-68.

[2] 宋永臣, 宁亚东, 金东旭. 氢能技术[M]. 北京: 科学出版社, 2009: 5-11.

SONG Yong-chen, NING Ya-dong, JIN Dong-xu. Hydrogen technology[M]. Beijing: Science Press, 2009: 5-11.

[3] 闫二虎, 李新中, 唐 平, 苏延庆, 郭景杰, 傅恒志. Nb-Ti-Co氢分离合金近共晶点处的显微组织及其渗氢性能[J]. 金属学报, 2014, 50(1): 71-78.

YAN Er-hu, LI Xin-zhong, TANG Ping, SU Yan-qing, GUO Jing-jie, FU Heng-zhi. Microstructure and hydrogen permeation characteristic of near eutectic Nb-Ti-Co hydrogen separation alloy[J]. Acta Metallurgica Sinica, 2014, 50(1): 71-78.

[4] 江 鹏, 袁同心, 于彦东. 加工条件对多相V-Ti-Ni合金的显微组织和氢渗透性能的影响[J]. 金属学报, 2017, 53(4): 433-439.

JIANG Peng, YUAN Tong-xin, YU Yan-dong. Effect of processing conditions on microstructure and property of multiphase V-Ti-Ni alloys for hydrogen purifying[J]. Acta Metallurgica Sinica, 2017, 53(4): 433-439.

[5] CHRISTINA L, IVA B, MARTIN B. Electrochemical methods to study hydrogen production during interaction of copper with deoxygenated aqueous solution[J]. Electrochimica Acta, 2016, 202: 333-344.

[6] WANG M M, SONG J, WU X R, TAN X Y, MENG B, LIU S M. Metallic nickel hollow fiber membranes for hydrogen separation at high temperatures[J]. Journal of Membrane Science, 2016, 509: 156-163.

[7] 谈 萍, 葛 渊, 汤慧萍, 朱纪磊, 康新婷, 汪强兵. 国外氢分离及净化用钯膜的研究进展[J]. 稀有金属材料与工程, 2007, 36(3): 567-570.

TAN Ping, GE Yuan, TANG Hui-ping, ZHU Ji-lei, KANG Xin-ting, WANG Qiang-bing. Progress of studies on palladbranes for hydrogen separating and purifying in foreign countries[J]. Rare Metal Materials and Engineering, 2007, 36(3): 567-570.

[8] BOROGLU M S, YUMRU A B. Gas separation performance of 6FDA-DAM-ZIF-11 mixed-matrix membranes for H2/CH4 and CO2/CH4 separation[J]. Separation and Purification Technology, 2017, 173: 269-279.

[9] KO W S, SHIM J H, JUNG W S, LEE B J. Computational screening of alloying elements for the development of sustainable V-based hydrogen separation membranes[J]. Journal of Membrane Science, 2016, 497: 270-281.

[10] 闫二虎, 孙立贤, 徐 芬, 李新中, 郭景杰. Nb-Ni-Ti三元合金渗氢膜的研究进展[J]. 材料导报, 2015, 29(9): 86-91.

YAN Er-hu, SUN Li-xian, XU Fen, LI Xin-zhong, GUO Jing-jie. Research progress of hydrogen permeation membrane made of Nb-Ni-Ti ternary alloy[J]. Material Review, 2015, 29(9): 86-91.

[11] PATI S, JAT R A, ANAND N S, DEROSE J D, KARN K N, MUKERJEE S K , PARIDA S C. Pd-Ag-Cu dense metallic membrane for hydrogen isotope purification and recovery at low pressures[J]. Journal of Membrane Science, 2017, 522: 151-158.

[12] 陈 军, 朱 敏. 高容量储氢材料的研究进展[J]. 中国材料进展, 2009, 28(5): 2-10.

CHEN Jun, ZHU Min. Progress in research of hydrogen storage materials with high capacity[J]. Materials China, 2009, 28(5): 2-10.

[13] LI H, CARAVELLA A, XU H Y. Recent progress in Pd-based composite membranes[J]. Journal of Materials Chemistry A, 2016, 4: 14069-14094.

[14] PISKIN F, AKYILDIZ H, OZTURK H. Ti modified Pd-Ag membranes for hydrogen separation[J]. International Journal of Hydrogen Energy, 2015, 40: 7553-7558.

[15] LOPEZ A, MELENDEZ M J, COLLINS V. Hydrogen production research in Mexico: A review[J]. International Journal of Hydrogen Energy, 2016, 41: 23363-23379.

[16] LI X Z, HUANG F F, LIU D M, LIANG X, CHEN R R, RETTENMAYR S., SU Y Q, GUO J J, FU H Z. V-Cr-Cu dual-phase alloy membranes for hydrogen separation: An excellent combination of ductility, hydrogen permeability and embrittlement resistance[J]. Journal of Membrane Science, 2017, 524: 354-361.

[17] DOLAN M D. Non-Pd BCC alloy membranes for industrial hydrogen separation[J]. Journal of Membrane Science, 2010, 362: 12-28.

[18] PAGLIERI S N, PAL N K, DOLAN M D, KIM S M, CHIEN W M, LAMB J, CHANDRA D, HUBBARD K M, MORE D P. Hydrogen permeability, thermal stability and hydrogen embrittlement of Ni-Nb-Zr and Ni-Nb-Ta-Zr amorphous alloy membranes[J]. Journal of Membrane Science, 2011, 378: 42-50.

[19] YUKAWA H, TSUKADA C, NAMBU T, MASTUMOTO Y. Hydrogen solubility and permeability of V-W-Mo alloy membrane for hydrogen separation and purification[J]. Journal of Alloys and Compounds, 2013, 580: S386-S390.

[20] BASILE A, IULIANELI A. Advances in hydrogen production, storage and distribution[M]. England: Woodhead Publishing, 2014: 341-352.

[21] HASHI K, ISHIKAWA K, MATSUDA T, AOKI K. Microstructure and hydrogen permeability in Nb-Ti-Co multiphase alloys[J]. Journal of Alloys and Compounds, 2006, 425: 284-290.

[22] DOLAN M D, KELLAM M E, MCLENNAN K G, LIANG D, SONG G. Hydrogen transport properties of several vanadium-based binary alloys[J]. International Journal of Hydrogen Energy, 2013, 38: 9794-9799.

[23] MAGNONE E, JEON S, PARK J H, FLEUYR E. Relationship between microstructure and hydrogen permeation properties in the multiphase Ni21Ti23Nb56 alloy membranes[J]. Journal of Membrane Science, 2011, 384: 136-141.

[24] HASHI K, ISHIKAWA K, MATSUDA T, AOKI K. Hydrogen permeation characteristics of multi-phase Ni-Ti-Nb alloys[J]. Journal of Alloys and Compounds, 2004, 368: 215-220.

[25] KAMAKOTI P, SHOLL DS. Towards first principles-based identification of ternary alloys for hydrogen purification membranes[J]. Journal of Membrane Science, 2006, 279: 94-99.

[26] LUO W M, ISHIKAWA K, AOKI K. Highly hydrogen permeable Nb-Ti-Co hypereutectic alloys containing much primary BCC-(Nb, Ti) phase[J]. International Journal of Hydrogen Energy, 2012, 37: 12793-12797.

[27] 刘 菲, 王仲民, 黄贺伟, 邓健秋, 周怀营. Nb-Ti-Ni体系合金的结构及其氢渗透性能[J]. 中南大学学报(自然科学版), 2012, 43(9): 3401-3407.

LIU Fei, WANG Zhong-min, HUANG He-wei, DENG Jian-qiu, ZHOU Huai-ying. Phase structure and hydrogen diffusion properties of Nb-Ti-Ni alloys[J]. Journal of Central South University (Science and Technology), 2012, 43(9): 3401-3407.

[28] YAN E H, LI X Z, LIU D M, SU Y Q, GUO J J, FU H Z. A skull-aided technique for directional solidification of Nb-41Ni-40Ti hydrogen permeable alloy[J]. Journal of Crystal Growth, 2014, 391: 78-84.

[29] XU D M. A unified microscale parameter approach to solidification-transport process-based macrosegregation modeling for dendritic solidification: PartⅠ. Mixture average-based analysis[J]. Metallurgical and Materials Transactions B, 2001, 32: 1129-1141.

[30] XU D M. A unified micro-scale parameter approach to solidification-transport process-based macrosegregation modeling for dendritic solidification: PartⅡ. Numerical example computations[J]. Metallurgical and Materials Transactions B, 2002, 33: 451-463.

[31] YAN E H, LI X Z, RETTENMAYR M, LIU D M, SU Y Q, GUO J J, XU D M, FU H Z. Design of hydrogen permeable Nb-Ni-Ti alloys by correlating the microstructures, solidification paths and hydrogen permeability[J]. International Journal of Hydrogen Energy, 2014, 39: 3505-3516.

Optimum design and hydrogen permeability of Nb-Ti-Co separation alloy: I. Construction of phase diagram and hydrogen permeable component region

HUANG Hao-ran1, YAN Er-hu1, MIN Ruo-nan1, ZHU Kun-jun2, ZHAO Guang-wei3, LI Xin-zhong2, XU Fen1, SUN Li-xian1

(1. School of Materials Science and Engineering, Guilin University of Electronic Technology, Guilin 541004, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

3. College of Mechanical and Power Engineering, Three Gorges University, Yichang 443002, China)

Abstract: In the present work, Nb-Ti-Co phase diagram in the Nb-rich region was constructed by using CALPHAD method and Thermo-calc software, and then the solidification paths of 58 kinds of alloys were studied by using the uniform microsegregation model. The influences of solid back diffusion coefficient and solidification rate on their solidification path were discussed. The microstructure of these alloys was observed by SEM and XRD, which was compared with the numerical simulation results. Finally, the hydrogen permeable component region in the Nb-Ti-Co phase diagram was established. The results show that: (1) Two equilibrium reactions, i.e. L+α-Nb→TiCo+Co6Nb7 and L+TiCo→ α-Nb+Ti2Co, exist in the Nb-Ti-Co phase diagram. (2) There are at least four different solidification paths in the Nb-rich region, as follows, (L+α-Nb), (L+α-Nb)→(L+α-Nb+Co6Nb7)→(L+α-Nb+Co6Nb7+TiCo), (L+α-Nb)→ (L+α-Nb+TiCo) and (L+α-Nb)→(L+α-Nb+TiCo)→(L+α-Nb+TiCo+Ti2Co), respectively. The cooling rates have no obvious effect on the solidification path whereas the solid back diffusion coefficient has a great effect on it. The volume fraction of primary phase increases with the increase of Nb content and Ti/Co ratio, whereas the volume fraction of eutectic phase decreases.

Key words: Nb-Ti-Co alloy; CALPHAD; solidification path; hydrogen permeable component region

Foundation item: Projects(51761009, 51701048, 51371060, 51671062, 51201093) supported by the National Natural Science Foundation of China; Project(2017YJCX116) supported by the Innovation Project of GUET Graduate Education, China; Projects(2016GXNSFAA380166, 2015GXNSFBA139208) supported by the Guangxi Natural Science Foundation, China

Received date: 2017-12 -29 ; Accepted date: 2018- 09-05

Corresponding author: YAN Er-hu; Tel: +07-73-2216607; E-mail: yeh@guet.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51761009,51701048,51371060,51671062,51201093);桂林电子科技大学研究生教育创新计划项目(2017YJCX116);广西自然科学基金资助项目(2016GXNSFAA380166,2015GXNSFBA139208)

收稿日期:2017-12-29;修订日期:2018-09-05

通信作者:闫二虎,副研究员;电话:0773-2216607;E-mail: yeh@guet.edu.cn