Trans. Nonferrous Met. Soc. China 22(2012) s491-s495

Characterization of TiAl-based alloy with high-content Nb by powder metallurgy

SUN Hong-fei1, LI Xue-wen1, FENG Jie1, FANG Wen-bin1,2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China

Received 28 August 2012; accepted 25 October 2012

Abstract: Powders with nominal composition of Ti-45Al-10Nb (mole fraction, %) were prepared by mechanical ball milling and were then consolidated by hot-pressed sintering in vacuum atmosphere. The microstructures of 12 h-milling composite powders and sintered bulk materials were characterized by OM, XRD, SEM and EDX. The results showed that the composite powders were completely homogeneous, and fine-grained Ti/Al/Nb composite powders were made. The microstructure of the consolidated alloy was composed of fine equiaxed grains with large pure Nb particles. And the results also indicated that the compressive strength and ductility of the sintered TiAl-based bulk material at RT could be improved effectively by adding 10% Nb element. The yield strength (σ0.2) and fracture strength (σb) of the alloy were 842 MPa and 1314 MPa, respectively, and the compressive ductility (δp) was 12.4%.

Key words: TiAl-based alloy; powder metallurgy; particle size; composites; sintered bulk

1 Introduction

As promising candidate materials, high temperature strength and environmental stability were required for engineering applications. Attractive properties such as low densities and high temperature capabilities were displayed by TiAl-based intermetallics, and made them exhibit great potential for specific applications, particularly in turbine engines where steels or nickel-based alloys could be replaced [1,2]. At present, TiAl alloys are mostly fabricated by ingot metallurgy (IM) process, which was initially pursued for preparation of these alloys and sometimes followed by hot isostatic pressing (HIP) to eliminate porosities of TiAl alloys before thermo-mechanical processing at high temperatures [3,4].

However, the processing of TiAl components was complicated because of the low ductility of TiAl-based intermetallic at room temperature [5,6], and the poor oxidation resistance above 750 °C [7,8]. And it was indicated that ingot metallurgy route had some disadvantages, such as, coarse grains, difficult-to-deform lamellar structure, distinct segregation effects and poor reproducibility. Meanwhile, the ingots had to be deformed at high temperatures in order to refine alloy microstructures and improve its mechanical properties [9].

Recently, studies showed that powder metallurgy (PM) technique could give good structural homogeneity of TiAl alloy and a relatively low temperature was required in its deformation processing [10-12]. And adding alloy elements including Cr, Nb, V, Ta, Si and etc was considered to be the most beneficial for improving the workability and ductility of TiAl-based intermetallic, especially adding Nb [13-15]. Therefore, it is significant to survey the fabrication and deformation of TiAl-based alloy with high-content Nb via PM-route.

In this study, TiAl alloys with high-content Nb were prepared by elemental powder metallurgy method. And then the microstructures and tensile properties of the composite powders and the sintered bulk materials were characterized by means of OM, XRD, SEM and EDX.

2 Experimental

Powders of Ti (average particle size of 48 μm, purity>99.5%), Al (average particle size of 48 μm, purity>99.7%) and Nb (average particle size of 45 μm, purity>99.5%) were used in this experiment. The mechanical ball milling of the mixture was carried out in a planetary ball mill (QM-2SP12) with stainless steel milling container and balls. The milling process consisted of high-energy ball milling of the Ti/Al powders for 10 h with a high rotation speed of 300 r/min, and subsequently low-energy mechanical milling of the Ti/Al/Nb powder mixture for 2 h with a low rotation speed of 150 r/min. The milling machine was paused for 15 min after every 20 min milling to let the device cool to room temperature in the course of Ti/Al powder ball milling.

Sintering process of the mixture powder was divided into two steps: pre-sintering and high- temperature sintering. Pre-sintering was conducted in argon atmosphere under a pressure of 30 MPa at 600 °C, and then sample was sintered at high temperature (~1200 °C) for 2 h to homogenize its microstructure and eliminate the porosity.

Microstructures of the powder particles and sintered sample were observed by X-ray diffractometry (XRD) (Philips X-Pert system with Cu Kα radiation), scanning electron microscopy (SEM) (Hitachi S4700 SEM equipped with an energy dispersive spectrometer) and energy dispersive spectroscopy(EDS). XRD was applied to characterizing the constituent of the mixture. For SEM examination, the polished surfaces of the sintered bulk samples were etched with Kroll solution (5%HNO3+ 10%HF+85%H2O in volume fraction).

3 Results and discussion

3.1 Micrograph and phase composition of composite powders

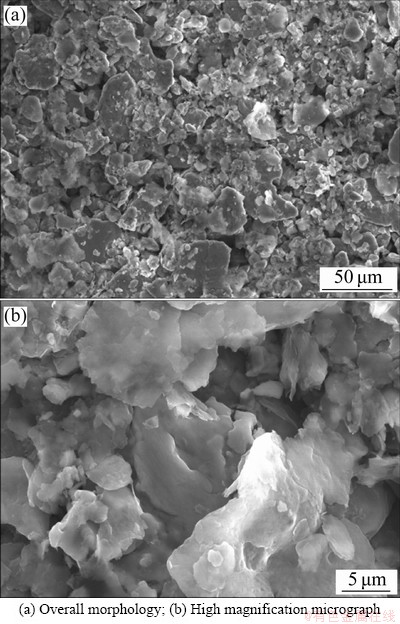

Qualitative investigation on the particle morphology and size of the Ti/Al/Nb composite powder after 12 h milling was carried out by SEM. Figure 1 shows the morphologies of some selected powder mixture. It was clearly indicated that the particle size of composite powder was considerably reduced by 12 h-milling, compared with the as-received elemental powder. And even nanometer particles were found in Fig. 1(a). Such effective particle refinement might be attributed to the relatively hard titanium powders which promoted the crushing of all particles during ball milling. At the same time, many agglomerates were observed in Fig. 1(b). It was suggested that the cold welding occurred in Ti/Al/Nb composite powders in the course of ball milling. Those agglomerations (<10 μm) were mainly composed of much smaller particles with size of ~1 μm. The analysis of agglomeration was conducted and it was found that large area of grain boundary and short diffusion pathway which is beneficial to accelerating the sintering process were formed in these fine particles after ball milling because each particle had a tendency to be round in shape during ball milling.

Fig. 1 SEM images of composite powders after 12 h milling

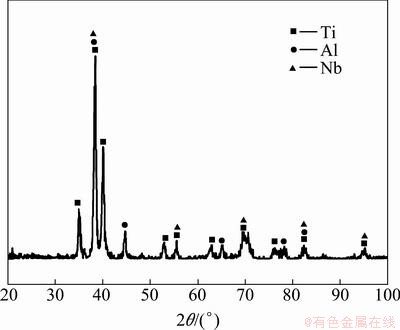

The XRD pattern of the powder mixtures after milling for 12 h is shown in Fig. 2. It was indicated that the Ti, Al and Nb phases (Ti, Al and Nb) were presented as major peaks for Ti/Al/Nb composite powder after 12 h and two-step mechanical milling. So a conclusion was obtained that the reaction among Al, Ti and Nb phases during ball milling was negligible. It was also noted that the diffraction peaks of these three phases gradually became wide but their intensities decreased as a result of the reduction of grain size and/or the accumulation of mechanical stress, which suggested that the milled mixture particles containing Al(Ti) and Ti(Al) solutions were formed by the interdiffusion between Al and Ti phases in the process of ball milling.

Fig. 2 XRD pattern of powder mixtures after 12 h milling

3.2 Phase composition and microstructure of bulk sample

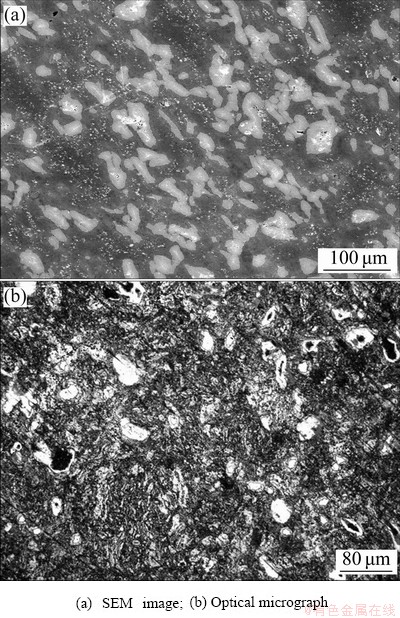

As presented in Fig. 3, the microstructures of Ti/Al/Nb sintered bulk sample were obviously formed by solid-state interdiffusion among Ti, Al and Nb. The SEM image indicated that dark-gray Nb particles which appeared in Fig. 3(a) were evidently visible in the inhomogeneous primary phase. It was clearly that the grain size of TiAl matrix was very fine, even did not exceed 1 μm in Fig. 3(b). However, the grain size of additional Nb in the sintered sample was larger than that of the matrix and small grains with irregular grain boundaries were observed.

Fig. 3 Microstructures of sintered bulk

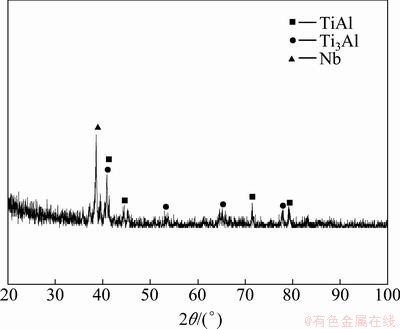

Figure 4 shows X-ray diffraction pattern of high- temperature sintered Ti/Al/Nb bulk, which was sintered at 1200 °C for 2 h. Not only γ-TiAl, α2-Ti3Al but also Nb phase were detected in the sintered bulk. It was concluded that most Nb powders in the Ti/Al/Nb sintered bulk were still in the form of single phase.

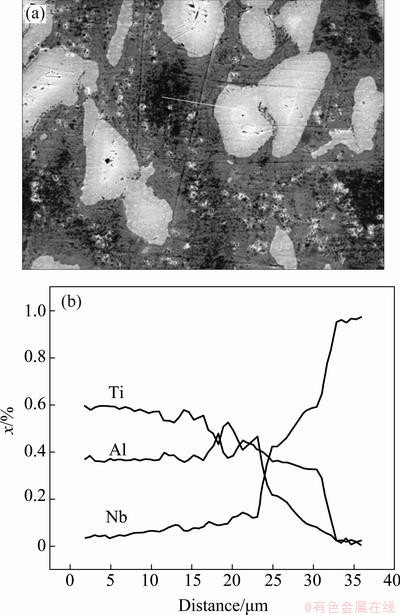

Both SEM and EDS were applied to analyzing a sintered Ti-45Al-10Nb sample surface. The elemental distribution including Ti, Al and Nb in the sintered bulk is clearly shown in Fig.5. A comparison of the phases identified in the XRD measurements with the phases contrasts observed in SEM allowed us to establish that the white regions were Nb powders, black regions were γ-TiAl and α2-Ti3Al phases.

Fig. 4 XRD pattern of sintered bulk

Fig. 5 Backscattered electron image (a) and EDS profiles (b) of bulk sample after sintering at 1200 °C

3.3 Tensile and compression properties of sintered bulk

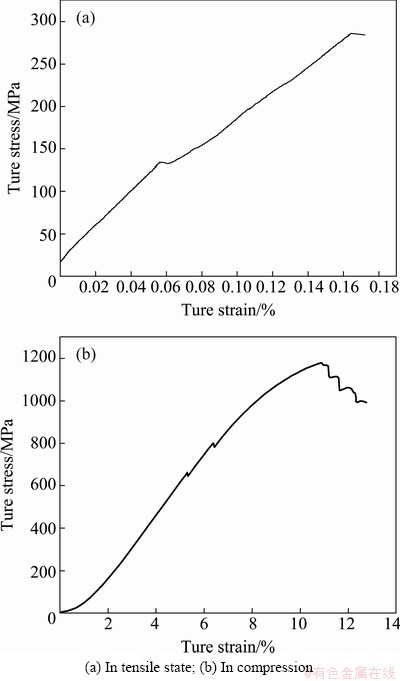

The room temperature ductility of materials synthesized in the present work was illustrated by typical true stress—strain curves (both in compression and in tensile) in Fig. 6. The results showed that the ultimate tensile strength (UTS) of Ti/Al/Nb sintered bulk was 286 MPa(in Fig. 6(a)) and the compression intensity was up to 1200 MPa, which was higher than UTS. The actual mechanical properties of Ti/Al/Nb sintered bulk obtained from the compression experiment were yield strength (YS) of 842 MPa, ultimate compressive strength of 1314 MPa, plastic elongation to fracture of 12.4%, respectively (in Fig.6 (b)). It can be evidenced that TiAl-based composite reinforced with 10% Nb was much more ductile than conventional TiAl [16]. The excellent ductility of TiAl-based composite with high-content Nb could be attributed to the toughening effect of Nb on the TiAl matrix.

Fig. 6 Representative room temperature true stress—strain curves of sintered bulk

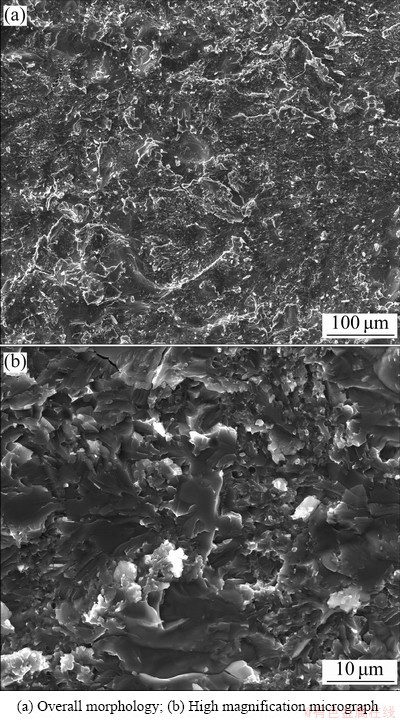

Fracture surface micrographs of Ti/Al/Nb sintered bulk sample after compression test are shown in Fig. 7. Brittle fracture for TiAl-based composite was exhibited because of no trace of plastic deformation and a combination of trans- and inter-crystalline crack growth.

4 Conclusions

1) The morphologies of Ti/Al/Nb composite powder after 12 h milling became regular and the average grain size was less than 10 μm, even nanometer particles were found.

Fig. 7 SEM images of fracture surfaces after compression tests

2) No new phase in Ti/Al/Nb composite powder was formed in the course of mechanical ball milling.

3) γ-TiAl, α2-Ti3Al and Nb phases were observed in Ti/Al/Nb sintered bulk sample, and most Nb powders in the Ti/Al/Nb sintered bulk were still in the form of single phase.

4) Both tensile strength and compressive strength of Ti-45Al-10Nb(mole fraction, %) are increased by adding Nb. The compressive strength of the Ti/Al/Nb sintered bulk was ~1314 MPa and the elongation to failure was up to 12.4%.

References

[1] BOYER R R. An overview on the use of titanium in the aerospace industry [J]. Materials Science and Engineering A, 1996, 213(1-2): 103-114.

[2] WU X H. Review of alloy and process development of TiAl alloys [J]. Intermetallics, 2006, 14(10-11): 1114-1122.

[3] WANG Y, LIU Y, YANG G Y, LI H Z, TANG B. Microstructure of cast γ-TiAl based alloy solidified from β phase region [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 215-222.

[4] CHEN G L, XU X J, TENG Z K, WANG Y L, LIN J P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale [J]. Intermetallics, 2007, 15(5-6): 625-631.

[5] HU D, HUANG A J, NOVOVIC D, WU X. The effect of boron and alpha grain size on the massive transformation in Ti-46Al-8Nb-xB alloys [J]. Intermetallics, 2006, 14(7): 818-825.

[6] IMAYEV R M, IMAYAV V M, OEHRING M, et al. Alloy design concepts for refined gamma titanium aluminide based alloys [J]. Intermetallics, 2007, 15(4): 451-460.

[7] JIANG H R, WANG Z L, MA W S, FENG X R, DONG Z Q, ZHANG L, LIU Y. Effects of Nb and Si on high temperature oxidation of TiAl [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 512-517.

[8] SCHUMACHER G, DETTENWANGER F,  M, HORNAUER U, RICHTER E. Microalloying effects in the oxidation of TiAl materials [J]. Intermetallics, 1999, 7(10): 1113-1120.

M, HORNAUER U, RICHTER E. Microalloying effects in the oxidation of TiAl materials [J]. Intermetallics, 1999, 7(10): 1113-1120.

[9] ZHANG W J, CHEN G L, APPEL F, NIEH T G, DEEVI S C. A preliminary study on the creep behavior of Ti-45Al-10Nb alloy [J]. Materials Science and Engineering, A, 2001, 315(1-2): 250-253.

[10] ZHANG W, LIU Y, LIU B, LI H Z, TANG B. Deformability and microstructure transformation of PM TiAl alloy prepared by pseudo-HIP technology[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 547-552.

[11] THOMAS M, RAVIART J L, POPOFF F. Cast and PM processing development in gamma aluminides [J]. Intermetallics, 2005, 13(9): 944-951.

[12] LI H Z, ZENG M, LIANG X P, LI Z, LIU Y. Flow behavior and processing map of PM Ti–47Al–2Cr–0.2Mo alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 754-760.

[13] XIANG L L, ZHAO L L, WANG Y L, ZHANG L Q, LIN J P. Synergistic effect of Y and Nb on the high temperature oxidation resistance of high Nb containing TiAl alloys [J]. Intermetallics, 2012, 27: 6-13.

[14] KIM Y W. Effects of microstructure on the deformation and fracture of γ-TiAl alloys [J]. Materials Science and Engineering A, 1995, 192-193(2): 519-533.

[15] CHENG T T, WILLIS M R, JONES I P. Effects of major alloying additions on the microstructure and mechanical properties of γ-TiAl[J]. Intermetallics, 1999, 7: 89-99.

[16] ZHANG W J, DEEVI S C, CHEN G L. On the origin of superior high strength of Ti-45Al-10Nb alloys [J]. Intermetallics, 2002, 10(5): 403-406.

粉末冶金法制备高铌TiAl基合金的表征

孙宏飞1,李学问1,冯 杰1,房文斌1, 2

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040

摘 要:利用机械球磨法制备了名义成分为Ti-45Al-10Nb(摩尔分数,%)的复合粉末,采用真空热压烧结工艺对粉末进行固结,利用OM、XRD、SEM、EDX对球磨12 h的粉末及烧结块体材料进行表征。结果表明,所得Ti/Al/Nb复合粉末的成分均匀,晶粒细小。烧结后所得合金的显微组织由细小等轴晶和均匀分散其中的大的纯Nb颗粒组成。增加10%(摩尔分数)的Nb元素,TiAl基合金的室温强度及塑性有显著提高,屈服强度和断裂强度分别为842 MPa和1314 MPa,室温压缩率达到12.4%。

关键词:TiAl基合金;粉末冶金;颗粒尺寸;复合材料;烧结块体

(Edited by YANG Hua)

Corresponding author: LI Xue-wen; Tel: +86-451-86403365; E-mail: lixuewen2000@163.com

DOI: 10.1016/S1003-6326(12)61751-8