DOI:10.19476/j.ysxb.1004.0609.2019.02.17

TA1钛薄板激光冲击成形实验及数值模拟

张青来1,彭新成1,韩伟东2,石海洋1

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 宝鸡市博信金属材料有限公司,宝鸡 721013)

摘 要:采用最大输出激光脉冲能量为12.5 J的Thales Laser激光器,对TA1纯钛薄板进行激光冲击成形,并运用激光共聚焦扫描显微镜、透射电镜和有限元模拟等方法对冲击表层的残余应力和微观结构进行分析。结果表明:功率密度为6.11 GW/cm2时,单次冲击成形效果更好;多次冲击工艺更适合于较小的功率密度3.06 GW/cm2。冲击断口由大量的韧窝、少量的撕裂棱和层裂组成,断口呈韧性断裂,破裂表现为减薄机制和层裂机制。冲击层存在大量的孪晶、位错墙、周期性波纹等结构。激光冲击使钛薄板表面引入高幅值的残余压应力,呈“W”形分布,多次冲击中心区易形成残余拉应力。

关键词:TA1钛薄板;激光冲击成形;残余压应力;微观结构; 破裂机制;数值模拟

文章编号:1004-0609(2019)-02-0350-11 中图分类号:TN249;TG146.2 文献标志码:A

激光冲击成形(Laser shock forming, 即LSF)是一种新兴的冷成形技术,是集材料改性强化和成形于一体的复合成形技术。WIELAGE等[1]对铝箔、铜和不锈钢进行了激光冲击微拉伸成形实验,这些材料均表现出良好的高应变速率成形性;其中,在铝箔成形实验中,对不同厚度的铝箔进行单点多次激光冲击成形实验,研究了冲击波压力随时间、板厚和冲击次数的变化情况。NAGARAJAN等[2-3]对铜箔柔性垫激光冲击成形展开了一系列研究,特别是柔性垫厚度、约束层、约束层厚度对铜箔成形结果的影响,并借助高速相机研究了等离子体形成过程,分析了铜箔截面厚度分布和硬度变化。本文作者[4-5]前期对AZ31薄板和脆性材料钼带的激光冲击成形及其破裂行为进行了实验研究。

纯钛常用于制作微产品,该类产品具有小批量、多品种、更新换代快等特点,相关的微塑性成形技术应运而生。众多学者[6-12]进行了纯钛激光冲击成形实验及其理论研究。WANG等[8]研究了激光冲击成形/冲裁制造金属箔微小零件的复合工艺,通过激光驱动橡胶柔性垫作用于钛箔,研究了不同激光能量下工件的表面粗糙度、成形深度和力学性能等。LIU等[9]研究了纯钛激光冲击成形性能,在高应变速率响应及惯性作用的双重效应下,塑性成形能力显著提高,同时晶粒发生细化,探讨了晶粒细化机制。

板料激光冲击成形过程复杂,影响因素众多,通过实验进行分析和验证,不仅工作量巨大,而且实验经费高。随着数值模拟技术快速发展,利用有限元方法模拟板料的激光冲击变形过程,成为行之有效的研究手段。ARIF[13]利用有限元法模拟激光诱导冲击波的冲击效应,并对冲击后金属板料的塑性变形和残余应力进行了分析。LI等[14]通过数值模拟技术,利用Johnson-Cook本构模型与损伤模型模拟铝箔在达到成形极限后的失效行为。

本文以TA1纯钛薄板为研究对象,在不同激光功率密度下对其进行连续多次冲击,直至钛薄板发生破裂。通过实验与数值模拟技术相结合,研究纯钛在不同激光功率密度和冲击次数下的组织性能变化规律、残余应力分布和破裂特性。

1 实验

本试验材料为交叉轧制的0.26 mm厚的TA1薄板。沿薄板最后的轧制方向(纵向)和垂直于轧制方向(横向)取样测力学性能,其拉伸曲线如图1所示。TA1薄板的横向和纵向抗拉强度分别为788 MPa和774 MPa,伸长率分别为24%和26%,表明薄板具有良好的各向同性。

图1 不同取向下交叉轧制纯钛薄板拉伸曲线

Fig. 1 Tensile curves of cross rolled pure titanium sheet in different sampling directions

激光冲击成形试验在江苏大学激光技术研究所的法国产脉冲Thales Laser激光器上进行,其最大输出脉冲能量为12.5 J、频率为10 Hz、波长为1.06 μm,光斑直径选为5 mm。冲击成形过程中靶材连同模具夹持在工作台上,用流动的水为约束层,选用厚度为100 μm的美国3M公司专用铝箔作为吸收层。激光冲击成形试验装置示意图如图2所示。

利用图3所示的自制测试装置测量激光冲击的钛薄板厚度。测量选点过程如下:预先标记出冲击凹坑的中心和边缘,从冲击中心点到冲击边缘沿任意直径方向选取5个测试点,每个测试点测量3组数据,取其算术平均值作为最终测试点的壁厚。

采用日本OLYMPUS公司生产的LEXT OLS4100激光共聚焦扫描显微镜对激光冲击后留下的凹坑表面形貌进行测量及微观组织分析。JEM-2100(HR)型高分辨率透射电子显微镜(TEM)对冲击区微观结构进行观察。冲击断口形貌分析在JEOL JSEM -7001F热场发射高分辨率电镜上进行。

图2 激光冲击试验装置示意图

Fig. 2 Schematic of laser shock testing apparatus

图3 试件壁厚测试装置

Fig. 3 Test device for wall thickness of specimen

2 结果与分析

2.1 LSF实验

图4所示为不同功率密度下1~7次激光冲击试样照片。在光斑直径为5 mm、不同能量的激光束下对试样进行单点连续多次冲击,圆形靶材经激光冲击后在冲击背面中心区域形成趋于半球形的凸起状。随着激光能量的增加,参与变形的靶材的面积越大,成形深度亦随之增大,这是作用于靶材的冲击波压力随激光能量增加而提高的结果。在相同的激光能量下,随着连续冲击次数的增加,靶材的成形深度与成形面积因多次冲击累计而变大。

表1所列为靶材连续激光冲击成形实验结果。当功率密度为3.06 GW/cm2时,形成的激光冲击波压力相对较小,靶材在连续冲击12次后而未发生宏观破裂;当功率密度增至4.58 GW/cm2时,激光冲击波压力也相应增加,靶材在连续冲击12次后,达到自身成形极限,发生破裂;当功率密度增至6.11 GW/cm2时, 激光冲击波压力更大,靶材在连续冲击11次后即发生破裂。

图4 激光冲击成形试样

Fig. 4 LSF specimens

表1 TA1薄板连续激光冲击成形实验结果

Table 1 Experimental results of TA1 pure titanium sheet by continuous LSF

2.2 成形件壁厚分析

减薄率是衡量工件成形性能的一个重要标准,一般情况下,工件的局部减薄率不应超过板厚的30%[15]。若工件出现局部过度减薄,成形性能会受到影响。以下探讨激光功率密度和冲击次数对靶材厚度的影响。

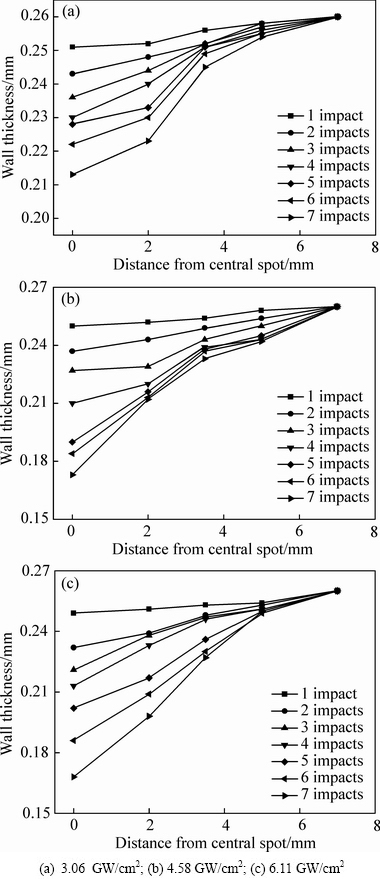

图5和6所示分别为不同激光功率密度下连续冲击1~7次成形区域中心位置及其壁厚的减薄率情况。由图5可见,在功率密度为3.06 GW/cm2下冲击1次时,冲击中心位置减薄了3.5%,随着冲击次数增加,试样不断减薄,最大减薄处依然位于试样中心位置,连续冲击7次后中心位置的最大减薄率达到18.1%;当功率密度为4.58 GW/cm2时,冲击中心位置减薄率由冲击1次后的3.8%增至连续冲击7次后的33%;当功率密度为6.11 GW/cm2时,随着冲击次数由1次增加到7次,中心位置最大减薄率由4.2%增加到35.3%。同时发现,冲击次数不变条件下,最大减薄率并不一定随功率密度的增加而增加,例如当连续冲击次数达到4~6次时,功率密度为4.58 GW/cm2时最大减薄率反而比功率密度为6.11 GW/cm2时高。

由图6可见,与冲击中心距离不同,减薄率也不尽不同。壁厚减薄率发生的最大位置位于激光冲击中心,越接近冲击边缘区域,壁厚变化越小。靶材的实际减薄区域面积大于激光冲击区域,在距离光斑中心5 mm(光斑直径为5 mm)处,靶材的壁厚依然存在减薄,直至距离光斑中心7 mm处。

图7所示为相同冲击次数和不同激光功率密度下成形件壁厚分布情况。经过1次和2次冲击后,壁厚随功率密度的增加而减小,如图7(a)和(b)所示。经过3次和4次冲击后,减薄率并不随功率密度增加而规律性地增加,如在4.58 GW/cm2的功率密度下冲击的成形件壁厚减薄率反而大于6.11 GW/cm2时的减薄率,如图7(c)和(d)所示。分析认为,大功率密度下成形件减薄率降低可能是由于冲击力越大回弹越大,而对于小功率密度下的冲击成形件来说,冲击回弹相对较小,使得逐次减薄率相对均匀,即出现小功率密度冲击成形件的减薄率更大。

图5 不同功率密度和不同次数激光冲击中心位置的最大减薄率

Fig. 5 Maximum wall thickness reduction in central location after different impacts with different power densities

图6 不同冲击次数下试样壁厚分布

Fig. 6 Distribution of wall thickness of specimens with different shock times and different power densities

图7 不同激光功率密度下试样壁厚分布

Fig. 7 Distribution of wall thickness of specimens with different laser power densities

图8 成形区域应变分布

Fig. 8 Theoretical strain distribution of formed region

基于凹模的钛薄板激光冲击成形后,未冲击变形区域与冲击变形区域的应变状态不同,如图8所示。图中A为激光冲击变形区域,B为光斑外部变形区域,C为压边区域。

激光冲击成形属于拉胀变形,在冲击波压力的作用下,A区靶材依靠材料的减薄而发生塑性变形。由于材料的连续性,光斑外部B区域的靶材也被径向拉伸流入凹模腔内。A与B处材料在变形过程中的理论应变状态不同:A区域材料在冲击波压力直接作用下,呈双向拉伸状态,沿径向和环向均形成拉应变,且冲击中心处为双向等拉伸状态;B区域材料因相邻冲击区域材料流动而向凹模内部流动补充,径向拉伸,环向因尺寸缩小而呈现受压状态[9]。因此,冲击区域因冲击波压力的高斯分布与双向拉伸应变状态的影响,钛薄板壁厚减薄程度远大于光斑外围区域,且冲击中心处减薄量最大。

2.3 成形深度

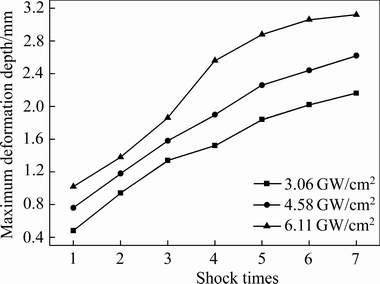

图9 不同冲击参数下试样最大成形深度

Fig. 9 Maximum deformation depth of specimens with different shock parameters

图9所示为不同功率密度下1~7次冲击成形件的最大成形深度。由图可知,TA1钛薄板表现出良好的高应变速率激光冲击成形效果,且最大成形深度随激光功率密度和冲击次数的增加而增加。钛薄板在连续多次激光冲击成形过程中,出现连续动态响应,成形效果不断叠加,凹坑的最大成形深度随之增大。关于激光冲击成形深度提高幅度在后续冲击过程中逐次减小,可能原因如下:1) 靶材在冲击后会发生加工硬化现象,后续冲击在前一次冲击的基础上完成,更加难以发生塑性变形;2) 在第一次冲击后,靶材表面难以继续保持清洁,会有残留物产生,从而影响冲击效果;3) 实验过程中采用去离子水作为约束层,伴随前一次冲击凹坑深度增加,水流入凹坑后使冲击区域的约束水层加厚,从而使激光冲击效果逐次减弱。

2.4 表面形貌

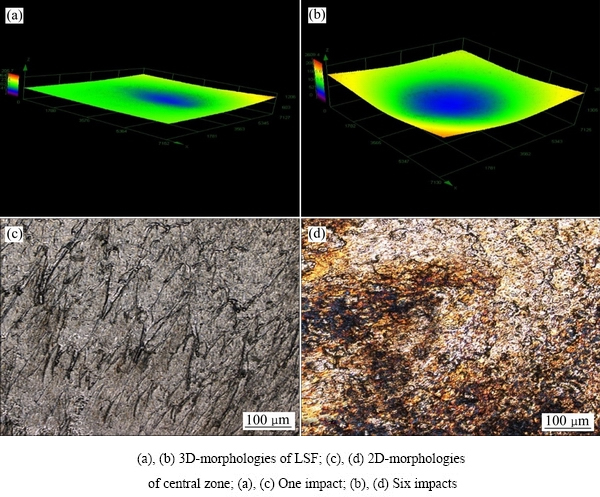

以3.06 GW/cm2功率密度下的单次和6次冲击成形件为例,利用激光共聚焦显微镜对其表面形貌进行测试和分析。

图10 激光功率密度为3.06 GW/cm2时激光冲击形貌

Fig. 10 Laser shock morphologies with power density of 3.06 GW/cm2

图10所示为3.06 GW/cm2功率密度下冲击1次与6次的激光冲击成形整体3D形貌和冲击中心区域2D形貌。靶材经激光冲击后,在冲击中心区域形成圆形凹坑,蓝色区域代表向下凹陷的区域,单次冲击后的成形区域面积远小于6次冲击,如图10(a)和(b)所示。由于靶材表面未加涂层,表面均出现不同程度的热损伤,例如1次冲击成形件中心区域出现舌状烧蚀痕迹,而6次冲击后则烧蚀程度加剧,但表面均未出现烧蚀坑。这是因为在激光作用于材料表面,表层材料吸收大部分能量以熔融气化形成等离子体冲击波,仍会有剩余能量传递到次表层,该表面形貌是剩余能量与冲击波共同作用的结果。

2.5 微观结构

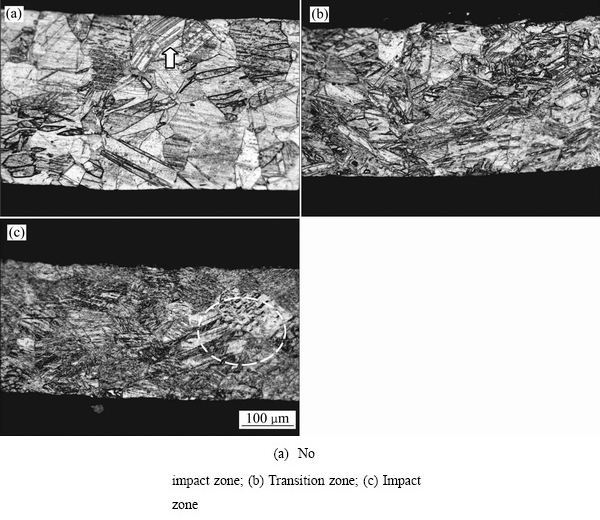

以4.58 GW/cm2功率密度下6次激光冲击成形件为例,利用光学显微镜和透射电镜对冲击区域材料的微观结构进行分析和讨论,其金相组织和TEM像如图11和12所示。

由图11可见,未冲击区等轴晶内存在大量的带状和透镜状孪晶、少量的滑移带(箭头所指);过渡区域形变孪晶和层状滑移结构数量均随变形量增加而增加,且部分孪晶跨越晶界而破碎,局部区域孪晶相互交错后形成“孪晶栅”;冲击中心区剧烈塑性变形后,层状滑移结构布满晶粒内部,标记区域发现尺寸极其微小的形变孪晶。

图11 激光功率密度为4.58 GW/cm2时冲击6次的试样金相组织

Fig. 11 Metallographic structures of specimen by six times of impacts with power density of 4.58 GW/cm2

图12 功率密度为4.58 GW/cm2时冲击6次的试样TEM像

Fig. 12 TEM images of specimen by six times of impacts with powder density of 4.58 GW/cm2

由图12(a)和(b)可观察到,激光冲击诱发了高密度的位错塞积,形成了胞块状的形变亚结构,胞壁由大量堆积的位错构成,且比内部位错密度更大。

从图12(c)中的TEM像及其选区电子衍射花样中可见,高应变速率形变过程中,具有HCP结构的α-钛位错滑移模式仍依赖于3个 柱面、6个

柱面、6个 锥面和

锥面和 基面3种滑移面以及

基面3种滑移面以及 的滑移方 向[16],在常温下通常需要形变孪晶来激活滑移系以协调c轴方向的变形,而激光诱导的冲击波压力达到GPa级,使得孪生变形更容易发生。在晶粒内部还观察到块状超细亚晶粒,多次冲击后达到一定变形量时,位错亚结构中的位错在密度达到一定值后发生湮灭、重排,形成亚晶界,晶粒内部位错密度较低。

的滑移方 向[16],在常温下通常需要形变孪晶来激活滑移系以协调c轴方向的变形,而激光诱导的冲击波压力达到GPa级,使得孪生变形更容易发生。在晶粒内部还观察到块状超细亚晶粒,多次冲击后达到一定变形量时,位错亚结构中的位错在密度达到一定值后发生湮灭、重排,形成亚晶界,晶粒内部位错密度较低。

由图12(d)可见激光冲击成形凹面留下的周期性波纹结构,波纹近似相互平行,其间距约80~120 nm。对多数材料而言,在很大的激光脉冲宽度和波长范围内,激光冲击的表层普遍出现周期性波纹结构,波纹的方向、大小、锐利度等与激光参数和材料物理性能均有关系[17-18]。

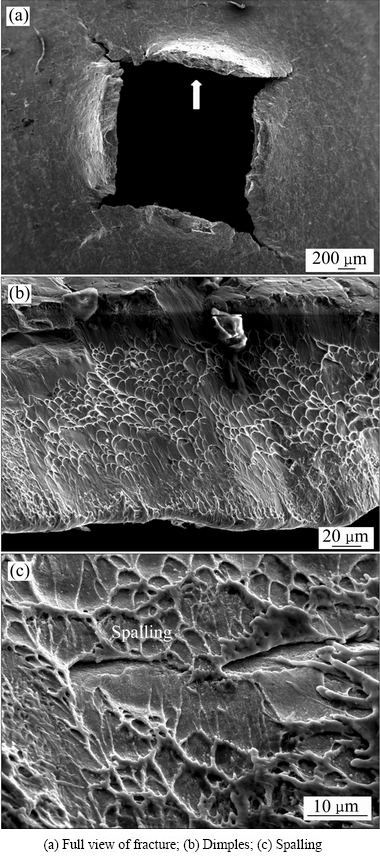

2.6 断口形貌及破裂机制

图13所示为6.11 GW/cm2的功率密度下连续冲击11次后破裂试样的断口形貌。冲击断口内部布满了拉伸状等轴韧窝,呈韧性断裂,韧窝拉伸方向即为激光冲击方向,还存在横向层裂(见图13(c))。层裂是材料在动态载荷加载下常见现象之一,通常发生在激光冲击区域和冲击边缘处。结合壁厚演变可得出,TA1钛薄板破裂行为表现为厚度减薄机制和层裂机制。

3 数值模拟结果与分析

激光冲击成形是一个高应变率、超快冷塑性成形的过程,材料模型既要反应材料变形特点,又要考虑应变率和加工硬化的影响,合理选择材料本构模型是进行激光冲击成形数值模拟的前提,材料模型包括弹性体、弹塑性体和流体,依据激光诱导冲击波压力为几个GPa,属于中等强度载荷,选用弹塑性材料模型。本文采用有限元分析软件ABAQUS模拟纯钛薄板激光冲击成形,ABAQUS中Johnson-Cook损伤模型能够预测由于延性金属内部微孔洞形核、长大、集结形成的损伤,并综合考虑了材料动态失效过程中的应变率、应力状态和温度效应,适用于模拟钛带激光冲击成形失效行为。

图13 激光功率密度为6.11 GW/cm2冲击下断口形貌

Fig. 13 Fracture morphologies by laser shock with 6.11 GW/cm2

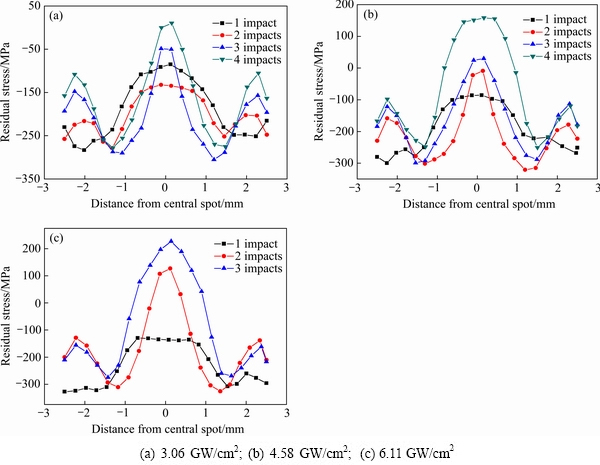

3.1 残余应力

以云图冲击区域过中心的直径上各节点的残余应力值作曲线,不同功率密度下冲击残余应力分布曲线如图14所示。由图14可观察到,冲击残余应力分布曲线均呈“W”形,不同激光功率密度下多次冲击表面残余应力分布变化趋势有所不同。在3.06 GW/cm2与4.58 GW/cm2的激光冲击下,残余压应力随冲击次数先增加再减小,分别在4次和3次冲击后出现残余拉应力;在6.11 GW/cm2的激光冲击下,两次冲击后即出现残余拉应力。由此得出,在3.06 GW/cm2的功率密度下进行2~3次冲击,在材料表面可以引入更高幅值的残余压应力。

3.2 成形极限

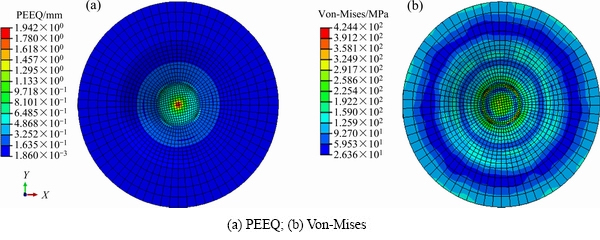

断裂是成形件常见的失效形式,实验方法难以观察到动态冲击破裂过程。以下以6.11 GW/cm2的激光冲击为例,通过数值模拟技术观察TA1钛薄板在达到成形极限后的失效过程,预测其失效破裂位置。预测结果为钛薄板在第15次冲击后发生破裂,比实验中多了3次,这与J-C损伤模型不能完全反应激光冲击破裂特点有关。

图15给出了钛薄板在破裂前第14次冲击后达到成形极限状态下的等效塑性应变PEEQ和Von Mises应力云图。14次冲击后累积的塑性应变分布状况与激光能量分布不均相对应,中心位置塑性应变最大,达到1.9。应力分布图中,冲击区域的应力明显大于光斑外围的应力,且光斑中心与光斑边缘应力值最大。因此,综合应力与应变结果,光斑边缘与冲击中心属于易破裂区域。

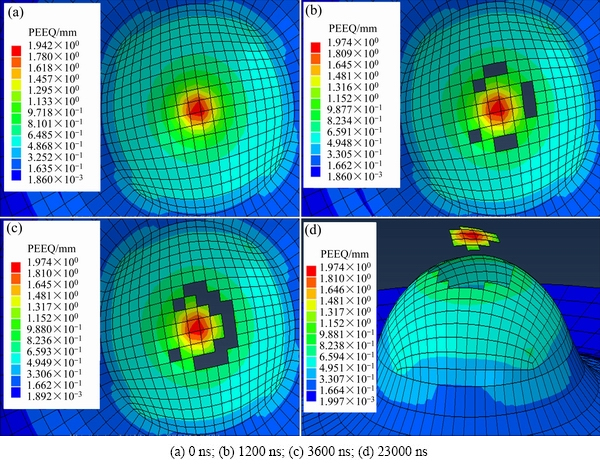

以等效塑性应变为考量的钛薄板第15次动态冲击破裂演化过程如图16所示。连续14次冲击后,钛薄板达到成形极限,在载荷的再一次加载下,部分单元损伤因子D达到1,单元删除。由图16中可以观察到,时间为1200 ns时材料发生失效,被删除单元呈不连续环状围绕冲击中心;在3600 ns时,有更多的单元失效,钛薄板破裂加剧;在动态冲击结束后,中心处的单元完全脱落,形成冲击断口。

图14 不同激光功率密度下多次冲击残余应力模拟曲线

Fig. 14 Simulated curves of residual stress of multiple impacts with different laser power densities

图15 在14次冲击后应力与应变分布模拟云图

Fig. 15 Simulated contours of stress and strain distribution after 14 impacts

图16 钛薄板激光冲击失效过程模拟云图

Fig. 16 Simulated contours of failure progress of titanium sheet after LSF

比较图13(a)与16(d),二者基本吻合,但实验中的裂口由中心扩展,且未有材料脱落,这与所采用的损伤模型和累积失效准则有关。分析认为,在第15次冲击初始,中心的等效塑性应变因达到极限而增加缓慢,而其邻近单元的塑性应变继续增加,损伤因子D率先达到1,发生失效。虽然最终模拟结果与实验结果存在一定偏差,但模拟结果仍能够粗略地预测成形件连续冲击后破裂次数和破裂位置,为研究纯钛薄板激光冲击失效行为提供参考数据。

4 结论

1) 激光冲击后形成圆形凹坑,受激光能量高斯分布影响,中心区减薄量和成形深度最大;随冲击次数的增加,壁厚减薄量与最大成形深度增加;随功率密度增加,成形深度增加,而壁厚呈不规律变化。功率密度为6.11 GW/cm2时,单次冲击成形效果更好;多次冲击工艺更适合于较小的功率密度3.06 GW/cm2。

2) 冲击断口内部发现了大量的韧窝、少量的撕裂棱和层裂现象,断口呈韧性断裂,破裂表现为减薄机制和层裂机制。

3) 激光冲击的TA1薄板是在孪生和滑移两种方式共同作用下发生塑性变形,形成孪晶、滑移带共存的高密度组织,以及位错墙和位错胞等位错亚结构,表层存有周期性波纹结构。

4) 模拟结果表明,激光冲击成形残余压应力场呈“W”形分布,且压应力的值随激光功率密度增加而增加,随冲击次数的增加而先增加后减小,中心在多次冲击后容易形成残余拉应力。

REFERENCES

[1] WIELAGE H, VOLLERTSEN F. Investigations of forming behaviour in laser shock forming[J]. Steel Research International, 2010, 80(5): 323-328.

[2] NAGARAJAN B, WANG Z, CASTAGNE S, ZHENG H. Investigation of laser-induced plasma evolution in flexible pad laser shock forming with high speed camera[J]. Applied Surface Science, 2014, 308: 221-229.

[3] NAGARAJAN B, CASTAGNE S, WANG Z K. Investigation of copper foil thinning behavior by flexible-pad laser shock forming[J]. Key Engineering Materials, 2013, 535/536: 306-309.

[4] 张青来, 陈 骏, 冯甜甜, 姜银方, 韩伟东. 激光冲击冷轧钼带的微观结构和性能[J]. 材料研究学报, 2012, 26(5): 545-550.

ZHANG Qing-lai, CHEN Jun, FENG Tian-tian, JAING Yin-fang, HAN Wei-dong. Property and microstructures of cold rolled molybdenum strip by laser shock processing[J]. Chinese Journal of Materials Research, 2012, 26(5): 545-550.

[5] 张青来, 王 荣, 洪妍鑫, 吴铁丹, 钱 阳, 张永康. 金属板料激光冲击成形及其破裂行为研究[J]. 中国激光, 2014, 41(4): 0403010.

ZHANG Qing-lai, WANG Rong, HONG Yan-xin, WU Tie-dan, QIAN Yang, ZHANG Yong-kang. Study on laser shock forming and fracture behavior of metal sheet[J]. Chinese Journal of Lasers, 2014, 41(4): 0403010.

[6] 杨建阳, 左敦稳, 黎向锋, 张永康, 王 珉. 激光冲击成形TA2钛合金板的变形与残余应力[J]. 南京航空航天大学学报, 2005, 37(B11): 31-35.

YANG Jian-yang, ZUO Dun-wen, LI Xiang-feng, ZHANG Yong-KANG, WANG Min. Deformation and residual stresses of titanium alloy TA2 sheet after laser shock forming[J]. Journal of Nanjing University of Aeronautics &Astronautics, 2005, 37(B11): 31-35.

[7] WANG F, YAO Z Q, HU J, DENG Q L. Experimental research and numerical simulation of laser shock forming of TA2 titanium sheet[J]. Acta Metallurgica Sinica, 2006, 19(5): 347-354.

[8] WANG X, ZHANG D, GU C X, SHEN Z B, MA Y J, GU Y X, QIU T B, LIU H X. Micro scale laser shock forming of pure copper and titanium sheet with forming/blanking compound die[J]. Optics & Lasers in Engineering, 2015, 67: 83-93.

[9] LIU H X, HU Y, WANG X, SHEN Z B, LI P. Grain refinement progress of pure titanium during laser shock forming (LSF) and mechanical property characterizations with nanoindentation[J]. Materials Science and Engineering A, 2013, 564: 13-21.

[10] 罗新民, 赵广志, 杨 坤, 陈康敏, 张晓柠. 工业纯钛板激光冲击形变的特征微结构[J]. 中国激光, 2012, 39(6): 0603001.

LUO Xin-min, ZHAO Guang-zhi, YANG Kun, CHEN Kang-min, ZHANG Xiao-ning. Deformation microstructure characteristics of commercial pure titanium sheet induced by laser shock forming[J]. Chinese Journal of Lasers, 2012, 39(6): 0603001.

[11] 张永康, 高 立, 杨超君. 激光冲击TA2板料变形的理论分析和实验研究[J]. 中国激光, 2006, 33(9): 1282-1287.

ZHANG Yong-kang, GAO Li, YANG Chao-jun. Theoretical analysis and experiment on deformation of TA2 sheet under laser shock[J]. Chinese Journal of Lasers, 2006, 33(9): 1282-1287.

[12] 王 霄, 邱唐标, 顾宇轩, 张 迪, 马友娟. 激光间接冲击下钛箔的微成形特性[J]. 光学精密工程, 2015, 23(3): 632-638.

WANG Xiao, QIU Tang-biao, GU Yu-xuan, ZHANG Di, MA You-juan. Micro-forming, properties of Ti foil under laser indirect shock[J]. Optics and Precision Engineering, 2015, 23(3): 632-638.

[13] ARIF A F M. Numerical prediction of plastic deformation and residual stresses induced by laser shock processing[J]. Journal of Materials Processing Technology, 2003, 136(1/3): 120-138.

[14] LI J, GAO H, CHENG G J. Forming limit and fracture mode of microscale laser dynamic forming[J]. Journal of Manufacturing Science & Engineering, 2010, 132(6): 061005.

[15] 张 迪, 刘立华, 郭 华, 陈志澜. 激光间接冲击直接制造微零件的实验及模拟[J]. 激光与光电子学进展, 2016, 53: 081404.

ZHANG Di, LIU Li-hua, GUO Hua, CHEN Zhi-lan. Experiment and simulation of manufacturing microparts by laser indirect shocking[J]. Laser & Optoelectronics Progress, 2016, 53: 081404.

[16] CONRAD H. Effect of interstitial solutes on the strength and ductility of titanium[J]. Progress in Materials Science, 1981, 26(2/4): 123-403.

[17] YOUNG J F, PRESTON J S, VAN DRIEL H M, SIPE J E. Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass[J]. Physical Review B, 1983, 27(2): 1155-1172.

[18] 张永康, 裴 旭, 陈菊芳, 顾永玉, 任爱国. 脉冲激光冲击镁合金表面产生周期性波纹结构的现象及分析[J]. 光学学报, 2010, 30(9): 2613-2619.

ZHANG Yong-kang, FEI Xu, CHEN Ju-fang, GU Yong-yu, REN Ai-guo. Phenomenon and analysis of periodic ripple structure on magnesium alloy surface induced by laser shock processing[J]. Acta Optica Sinica, 2010, 30(9): 2613-2619.

Experiment and numerical simulation on laser shock forming of TA1 pure titanium sheet

ZHANG Qing-Lai1, PENG Xin-cheng1, HAN Wei-dong2, SHI Hai-yang1

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. Baoji Boxin Metal Materials Ltd, Baoji 721013, China)

Abstract: The TA1 pure titanium sheet was laser shocked by the Thales Laser with the maximum output laser pulse energy for the 12.5 J, and the residual stress and microstructure on the shocked layer were analyzed by confocal laser scanning microscope (CLSM), transmission electron microscope (TEM) and finite element simulation. The results show that the laser with power density of 6.11 GW/cm2 is used to single impact titanium sheet with better formation; multiple impact process is more suitable for small power density of 3.06 GW/cm2. The fracture is composed of a large number of dimples, a small amount of tearing ridges and spallation, which is ductile fracture. The fracture mechanism is the thinning and spallation. A large amount of deformed twins, dislocation tangles and periodic corrugated structure are gained. High amplitude residual compressive stress is gained on the surface of titanium sheet, which is in distribution shape of “W”, the residual tensile stress generates in the central zone after multiple impacts gradually.

Key words: TA1 titanium sheet; LSF; compressive residual stress; microstructure; rupture mechanism; numerical simulation

Foundation item: Project(51175231) supported by the National Natural Science Foundation of China

Received date: 2017-11-03; Accepted date: 2018-01-24

Corresponding author: ZHANG Qing-lai; Tel: +86-511-88797783; E-mail: zhangql196210@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51175231)

收稿日期:2017-11-03;修订日期:2018-01-24

通信作者:张青来,教授,博士;电话:0511-88797783;E-mail:zhangql196210@163.com