文章编号:1004-0609(2016)-12-2605-08

QBe1.9铜合金Ti-N等离子复合渗及其摩擦磨损性能

刘 琳,申航航,刘小镇,郭 麒,孟天旭,王振霞,刘小萍

(太原理工大学 表面工程研究所,太原 030024)

摘 要:对QBe1.9铜合金进行双辉等离子渗Ti及后续离子氮化复合处理,在其表面制备TiN(Ti2N)/Ti合金层以改善其摩擦磨损性能。采用扫描电镜、能谱、辉光放电光谱仪、X射线衍射仪等手段观察分析Ti-N复合渗合金层的组织、成分及相结构,对合金层硬度及导电性进行了分析,并利用往复球盘摩擦磨损试验机研究QBe1.9基材及其Ti-N复合渗后的摩擦磨损性能。结果表明:经过Ti-N复合处理后,在QBe1.9铜合金表面形成厚度为27 μm的复合渗层,该渗层包括表面富TiN(Ti2N)合金层和Ti-Be-Cu扩散过渡层;QBe1.9铜合金经Ti-N复合渗后,表面硬度达964 HV,比基材的硬度明显提高;摩擦因数和比磨损率分别仅为未处理基材的30%和1.38%,达到减摩耐磨效果。表面高硬氮化物的形成是Ti-N复合渗改善QBe1.9铜合金表面性能的主要原因。

关键词:QBe1.9铜合金;等离子渗Ti;离子氮化;导电性;摩擦;磨损

中图分类号:TG174.445 文献标志码:A

铍铜合金属于时效析出强化的铜基合金,经淬火时效处理后具有高弹性极限、耐蚀、导电导热性好以及色彩鲜亮等一系列优点,被广泛用于航空航天、石油化工、电子电器等多种领域,已经成为国民经济建设中不可缺少的重要工业材料[1-4]。QBe1.9铜合金是一种常见的铍铜合金,常用于制造齿轮、测试探针、弹片等器件。然而由于QBe1.9铜合金的硬度较低,耐磨性较差,当这些器件在摩擦磨损比较严重的环境中工作时,常因磨损严重而失效,致使使用寿命大大缩短[5-7]。热处理是目前提高QBe1.9铜合金性能的主要方法。例如,对QBe1.9铜合金弹性针进行800 ℃淬火以及(300 ℃, 2.5 h)时效热处理,可以使针头的显微硬度得到提高[8]。但受QBe1.9铜合金成分、结构等的限制,其硬度提高幅度较小,对耐磨性的改善作用不大。表面处理作为常用的改善材料表面性能的有效方法,可以在保持基体性能的基础上提高其表面性能。对于QBe1.9铜合金,通常采用在其表面形成薄膜的方式来提高其表面强度。例如,通过在QBe1.9铜合金测试针表面进行Ni化学镀和Au磁控溅射复合处理形成Au/Ni复合镀层来改善其表面耐磨性,进而延长其使用寿命[9]。然而,Au/Ni复合镀层表面硬度较低,复合镀层之间以及膜基间结合力较弱,探针在不断摩擦过程中易因磨损或剥落而报废。QBe1.9铜合金的表面耐磨性还可以通过Ti沉积及离子氮化处理在其表面制备Cu-Ti-N复合层来提高[6]。但是Ti薄膜与基体间的结合强度较低仍然是QBe1.9铜合金摩擦磨损失效的一个关键因素。

双层辉光等离子表面冶金技术是一种通过向基体材料渗入特定元素,在基体材料表面形成合金层的表面改性新方法。相比于微弧氧化、离子注入、激光表面处理等其他表面处理方法[10-12],双辉技术具有渗速快、节约能源、合金层成分基本可控等优点。利用该技术形成的表面合金层成分、组织与性能呈梯度变化,与基体结合牢固,具有典型梯度材料的特征[13]。TiN具有高硬度、低摩擦因数以及良好的耐磨性和耐腐蚀性[14-16],是常用的表面薄膜材料。但是,由于TiN薄膜通常在低温下制备,与基体间的结合力较弱,而且对铍铜合金来说,基体较软更是难以支撑其上的硬质TiN薄膜。

本文作者结合双辉技术的特点以及TiN的优良性能,对QBe1.9铜合金进行双辉等离子渗Ti及离子氮化复合处理,并分析QBe1.9铜合金Ti-N复合处理后组织、成分分布和相结构,研究未处理的QBe1.9基材及Ti-N复合处理后的表面硬度和导电性能,并通过比较两种试样的摩擦磨损行为,研究其摩擦磨损机制。

1 实验

基体材料选用QBe1.9铜合金,尺寸为d 34 mm×4 mm,经过水洗砂纸打磨,金刚石粉抛光,丙酮清洗,干燥后备用。靶材为90 mm×50 mm×4 mm的纯Ti板。等离子渗Ti处理在自制的LS-450型双层辉光等离子渗金属炉中进行,其中,Ti靶作为源极悬于QBe1.9试样上方。渗Ti工艺参数为:温度800 ℃,保温时间2 h;工件为阴极,所加电源为脉冲电源,占空比0.8,电压300~450 V,源极电源为直流电源,电压580~650 V;放电气压35 Pa,极间距18 mm,工作气体为氩气。渗Ti完成后进行后续离子氮化处理,采用NH3作为氮原子供给源,渗氮温度为600 ℃,时间为10 h,阴极电压为700 V,阴极电流为25 A。

试样经Ti-N复合处理完成后,分别用TESCAN-MIRA3型扫描电子显微镜、GDOES750型辉光放电光谱仪、Rigaku X射线衍射仪观测并分析其渗层组织、成分及结构。采用Shimadzu HMV-2T型显微硬度仪检测QBe1.9基材及Ti-N复合处理试样的表面硬度。用Lucas-signatone pro4-4000型四探针电阻测试仪检测经Ti-N复合渗后QBe1.9的导电性,并与未处理的QBe1.9基材作对比分析。

摩擦磨损实验在MFT-R4000型往复摩擦磨损试验机上进行,摩擦配副为直径5 mm的GCr15钢球,硬度为62HRC。实验参数为:载荷5 N,频率2 Hz,摩擦长度5 mm,摩擦时间20 min,环境温度(25±2) ℃,相对湿度RH=(50±5)%。磨痕形貌采用附带能谱仪的Nano SEM 430扫描电镜进行观察,用Nikon C2 plus激光共聚焦显微镜测量磨痕的三维轮廓。

2 结果与讨论

2.1 Ti-N复合渗层组织与成分

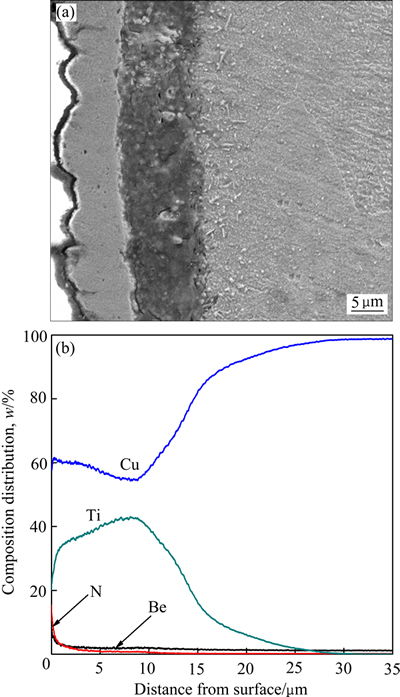

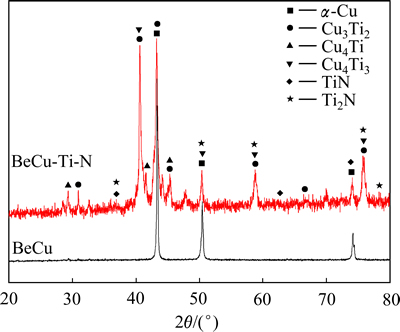

图1所示为QBe1.9铜合金经(800 ℃, 2 h)等离子渗Ti及(600 ℃, 10 h)离子氮化复合处理后合金层的截面组织及相应的成分分布。由图1可见,QBe1.9基材经过Ti-N复合渗后,在表面形成厚约27 μm的合金层,其组织致密且与基体结合牢固。结合其组织特点及GDS成分分布可知,合金层从表及里分为Ti-N-Cu-Be合金层/Ti-Cu-Be扩散过渡层,其中Ti-N-Cu-Be合金层较薄,厚度约为3 μm。合金层形成的前提条件是渗入元素与基体元素具有一定的固溶度。对于所研究的铍铜合金,800 ℃时Ti在Cu中的固溶度为4%[17],经高温渗Ti后,与基体中Cu形成置换固溶体,当渗入的Ti含量超过其固溶度时,Ti元素将以第二相的形式析出。图2所示为Ti-N复合渗后合金层的XRD谱。由图2可看出,合金层中除了包括Cu3Ti2、Cu4Ti、Cu4Ti3等Cu-Ti化合物外,还有TiN、Ti2N相。Ti是一种强氮化物形成元素,即使在较低的反应温度下与N也有较高的反应活性[18]。因此,在随后的离子氮化过程中,合金层中的Ti易与N发生反应形成Ti的氮化物,说明经过Ti-N复合渗QBe1.9铜合金表面生成了TiN(Ti2N)/Ti复合渗层。从图1所示的成分分布图还可以看出,Ti-N复合处理得到的合金层表面Be的含量很高,其原因有待于今后进一步研究,但表面高的Be浓度有益于合金层导电性的改善。

图1 QBe1.9经Ti-N复合渗后的截面组织及成分分布

Fig. 1 Cross-section morphology(a) and composition distribution(b) of QBe1.9 after Ti-N duplex treatment

图2 QBe1.9基材及Ti-N复合渗后的XRD谱

Fig. 2 XRD patterns of untreated and Ti-N duplex-treated QBe1.9 alloy

2.2 导电性及表面硬度

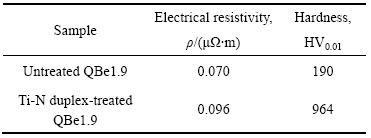

QBe1.9铜合金经Ti-N复合渗后电阻率有所增加。未处理的基材及Ti-N复合处理试样的电阻率分别为0.070和0.096 μΩ·m (见表1)。这是由于合金层中引入Ti和TiN的电阻率分别为0.42和0.25 μΩ·m,均高于Cu(0.017 μΩ·m)和Be(0.040 μΩ·m)的电阻率值。但是合金层表面含有大量低电阻率的Be元素,并且含氮化物表层较薄,因此,Ti-N复合渗对QBe1.9铜合金的导电性能影响较小。

硬度是影响摩擦学性能的一个主要因素。由表1可知,Ti-N复合渗合金层的表面硬度约964 HV,明显高于基材硬度(190 HV)。硬度的提高主要是由于合金层表面形成硬质的TiN和Ti2N。合金层中Cu-Ti金属间化合物的析出也是硬度提高的一个原因[19]。此外,基体Cu的晶格由于Ti的进入发生畸变,阻碍了位错运动,对合金层也起到固溶强化的作用[20]。除了组织变化导致的硬化效果,在表层与基体之间的Ti过渡层增加了金刚石压头压入时产生的形变抗力,也有助于表面硬度的提高。

表1 QBe1.9基材及其Ti-N复合渗后表面电阻率及硬度

Table 1 Electrical resistivity and hardness of untreated and Ti-N duplex-treated QBe1.9

2.3 摩擦磨损

2.3.1 摩擦因数

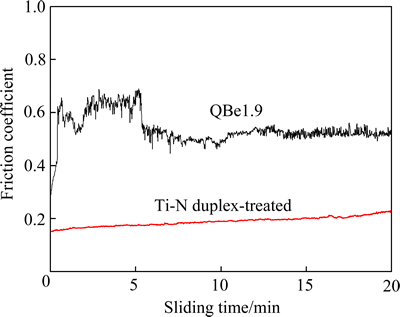

图3所示为QBe1.9基材及Ti-N复合渗试样在5 N载荷下与GCr15对磨后的摩擦因数曲线。由图3可看出,QBe1.9基材在初始摩擦阶段,摩擦表面是硬质粒子或微凸体相互接触,摩擦过程中表面粗糙微凸体发生剧烈破坏和塑性变形。由于初始的表面接触面积较小,摩擦因数也较低,仅0.3左右,随滑动的进行,表面接触面积增加,摩擦因数迅速上升至0.6。经过短时间的磨合,接触表面逐渐被“磨平”,磨损速率开始减缓,摩擦因数趋于稳定,进入稳定磨损阶段[21]。此时,QBe1.9基材摩擦因数稳定在0.5左右,之后围绕该值上下波动直到实验结束。QBe1.9铜合金经Ti-N复合处理后的摩擦因数在整个滑动过程中波动幅度小并且稳定,其平均数值在0.18左右,远低于基体的摩擦因数,说明Ti-N复合处理起到了良好减摩作用。

图3 QBe1.9基材及其Ti-N复合渗试样的摩擦因数

Fig. 3 Friction coefficients of untreated and Ti-N duplex- treated QBe1.9 samples

2.3.2 磨痕形貌

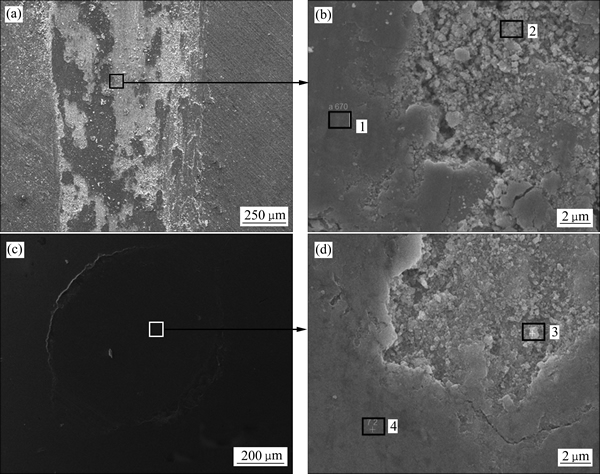

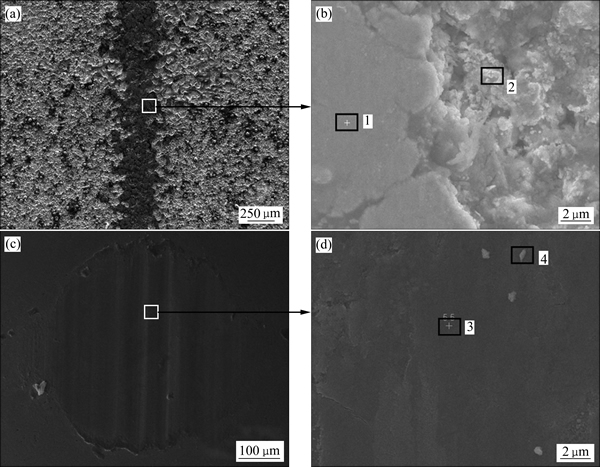

图4所示为QBe1.9基材在5N载荷下与GCr15摩擦配副对磨20 min后试样及其对应摩擦配副表面的磨痕形貌。由图4(a)可见,未处理的QBe1.9基材磨痕范围较大,磨痕宽度约950 μm,在磨痕表面上不仅有明显的局部剥离以及转移物粘着,还有大量的磨屑。图4(c)为对应摩擦配副表面的磨痕形貌,其磨痕直径约为770 μm。图4(b)、(d)分别为QBe1.9基材及对应摩擦配副磨痕表面的局部放大图,其中标记点的成分如表2所列。从表2可以看出,QBe1.9基材磨痕表面不仅有Cu、Be基体元素,同时还有O、Fe元素的存在,摩擦配副磨痕表面除本身元素外也含有QBe1.9基材中的Cu、Be元素,说明摩擦过程中摩擦材料之间发生了物质转移,其中QBe1.9基材表面Fe元素含量较高,并且在对磨球表面观察到明显的凹陷,说明摩擦配副中的Fe元素被转移到QBe1.9基材表面的现象较为严重。GCr15球的硬度为62HRC,而QBe1.9基材硬度较低(190 HV0.01),干摩擦条件下承载能力明显不足[22],造成摩擦过程中对磨球压入深度较大,产生较强烈的塑性变形并发生粘着、撕裂,致使表面温度瞬间升高,发生氧化,生成了氧化物,同时发生对磨球向基体表面的物质转移。伴随塑性变形会产生加工硬化,致使脆性增加,局部应力集中处发生开裂剥离成为磨屑,所以其磨损机制主要为粘着磨损[23]。

图4 QBe1.9基材与GCr15摩擦配副表面的磨痕形貌及局部放大图

Fig. 4 Wear surface and partial enlarged detail of QBe1.9((a), (b)) and GCr15 ball((c), (d))

表2 图4(b)和(d)中标记1,2,3,4处成分

Table 2 Composition of analyzed areas 1, 2, 3, 4 show in Figs. 4(b) and (d)

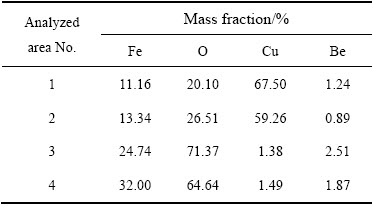

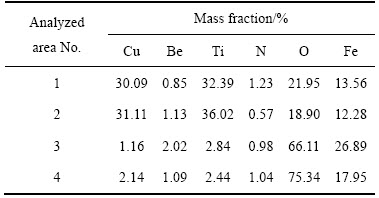

图5所示为Ti-N复合渗试样及对应GCr15摩擦配副表面的磨痕形貌。由图5(a)可以看出,Ti-N复合渗试样表面的磨痕宽度较窄,约为530 μm。磨痕表面光滑,未出现犁沟、塑性流动等特征,未发生磨损的原表面依然可见,只发生了轻微磨损,其磨损机制主要是微切削磨损。图5(b)所示为其磨痕形貌的局部放大图,从图中可以看到片状平整表面,这是由于摩擦过程中复合渗层表面微凸体被压平所致。图5(c)所示为对应摩擦配副表面的磨痕形貌,其磨痕直径约为460 μm,明显小于与QBe1.9基材对磨的GCr15摩擦配副表面磨痕尺寸,磨痕边缘处磨屑较少,图5(d)所示为其磨痕局部放大图。图5(b)和(d)中标记点的成分如表3所示。从表3中可以看出,Ti-N复合渗QBe1.9和摩擦配副磨痕表面不仅均含有O,而且有对磨材料元素,说明在摩擦过程中摩擦表面温度升高,发生了氧化,并且产生了磨屑,分布在Ti-N复合渗试样与摩擦配副表面。Ti-N复合渗后表面发生变化,在改性层中形成了TiN和Ti2N等硬质化合物相,这些化合物的存在不仅限制了磨损表面塑性变形的产生,还减小了其磨损量。Ti-N复合渗后QBe1.9表面硬度提高,摩擦过程中产生的磨屑硬度与摩擦表面硬度相近,在滑动摩擦过程中起到了一定的润滑作用。另外,基材和Ti-N表层之间的Ti过渡层对硬质表面合金层提供充足的机械支撑。由此可以知道,通过Ti-N复合处理在QBe1.9铜合金表面制备的Ti-N改性层能有效地改善其摩擦磨损性能。

图5 Ti-N复合渗试样及GCr15摩擦配副表面的磨痕形貌及局部放大图

Fig. 5 Wear surface and partial enlarged morphologies of Ti-N duplex-treated QBe1.9((a), (b)) and GCr15 ball((c), (d))

表3 图5(b)和(d)中标记处成分

Table 3 Composition of area shown in Figs. 5(b) and (d)

2.3.3 磨损体积及比磨损率

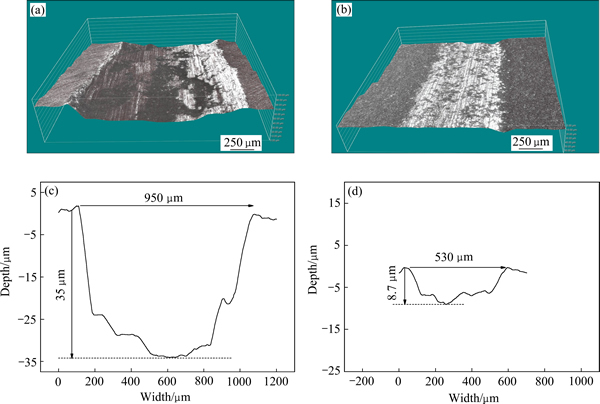

为了进一步研究耐磨性能,利用激光共聚焦显微镜观察QBe1.9基材及其Ti-N复合处理试样表面磨痕的三维形貌,分别如图6(a)和(b)所示。Ti-N复合处理后试样表面的磨痕(见图6(b))明显比基材(见图6(a))的窄且浅。根据图6(c)和(d)所示的磨痕轮廓曲线,QBe1.9基材的磨痕宽度约为950 μm,磨痕深度约为35 μm;Ti-N复合渗试样的磨痕宽度约为530 μm,磨痕深度约为8.7 μm。由此计算QBe1.9基材及Ti-N复合渗试样比磨损率[24]分别为92.46×10-5和1.28×10-5 mm3/(N·m),即Ti-N复合渗后的比磨损率为基材的1.38%,说明QBe1.9铜合金Ti-N复合处理后,抗磨损性能得到了明显改善。这是由于QBe1.9铜合金的硬度在Ti-N复合处理后明显提高,磨损量降低,耐磨性能得到了明显提高。同时,硬度提高还可以减少合金表面与摩擦配副之间的实际接触面积,避免较严重的塑性变形。除此之外,较硬的表面增加了膜基接触面的屈服强度,有效减少了切线应力和界面应力。

图6 QBe1.9基材和Ti-N复合渗QBe1.9表面三维磨痕形貌和磨痕轮廓曲线

Fig. 6 Three-dimensional topographies of wear scar and wear profile of untreated((a), (c)) and Ti-N duplex-treated((b), (d)) QBe1.9

3 结论

1) 通过等离子渗Ti和离子氮化复合处理,在QBe1.9铜合金表面制备厚约27 μm的复合改性层: 富Ti-N表层/Ti-Cu-Be过渡层。Ti-N表层主要包含TiN和Ti2N,Ti-Cu-Be过渡层主要包括Cu2Ti、Ti2Cu3和Cu3Ti等Cu-Ti金属间化合物。

2) Ti-N复合渗试样的表面电阻率为0.096 μΩ·m,略高于QBe1.9基材的。由于Ti-N复合渗层较薄且表面Be元素含量较高,渗层中高电阻率的Ti和TiN对试样整体导电性影响较小。

3) Ti-N改性层表面硬度达964 HV,明显高于基材硬度。表面硬质氮化钛、Cu-Ti化合物以及Ti的固溶强化是复合渗后铍铜表面硬化的主要原因。

4) Ti-N复合渗后摩擦因数仅为0.18(基材摩擦因数约0.5),同时,比磨损率是基材的1.38%,磨损机制为微切削磨损。Ti-N复合渗所引起的减摩和耐磨效果主要与渗层硬度增加有关,此外,Ti-N表层与基体之间所形成的Ti过渡层的机械支撑作用也起到一定作用。

REFERENCES

[1] HU Jing, DONG Chao-fang, LI Xiao-gang, XIAO Kui. Effects of applied magnetic field on corrosion of beryllium copper in NaCl solution[J]. Journal of Materials Science & Technology, 2010, 26(4): 355-361.

[2] ESMATI K, OMIDVAR H, JELOKHANI J, NADERI M. Study on the microstructure and mechanical properties of diffusion brazing joint of C17200 Copper Beryllium alloy[J]. Materials and Design, 2014, 53: 766-773.

[3] ATABAKI M M. Characterization of transient liquid-phase bonded joints in a copper-beryllium alloy with silver-base interlayer[J]. Journal of Materials Engineering and Performance, 2012, 21(6): 1040-1045.

[4] YANG L, ZHANG F Y, YAN M F, ZHANG M L. Microstructure and mechanical properties of multiphase layer formed during thermo-diffusing of titanium into the surface of C17200 copper-beryllium alloy[J]. Applied Surface Science, 2014, 292: 225-230.

[5] BEHJATI P, VAHID DASTJERDI H, MAHDAVI R. Influence of ageing process on sound velocity in C17200 copper-beryllium alloy[J]. Journal of Alloys and Compounds, 2010, 505: 739-742.

[6] ESMATI K, OMIDVAR H, JELOKHANI J, NADERI M. Study on the microstructure and mechanical properties of diffusion brazing joint of C17200 copper beryllium alloy[J]. Materials and Design, 2014, 53: 766-773.

[7] YAN M F, ZHU Y D, ZHANG C S, ZHANG Y X, WANG Y X, YANG L. Microstructure and mechanical properties of copper-titanium-nitrogen multiphase layers produced by a duplex treatment on C17200 copper-beryllium alloy[J]. Materials and Design, 2015, 84: 10-17.

[8] 蓝玉荣. 铍铜弹性针热处理工艺研究[J]. 机电元件, 2004, 12(4): 35-37.

LAN Yu-rong. Heat treatment technology of Beryllium copper elastic[J]. Electromechanical Components, 2004, 12(4): 35-37.

[9] Tronic Company Switch probes[EB/OL]. [2016-04-10]. http://www.tronic- elec.com.

[10] NEUPANE M P, PARK I S, LEE M H. Surface characterization and corrosion behavior of micro-arc oxidized Ti surface modified with hydrothermal treatment and chitosan coating[J]. Thin Solid Films, 2014, 550: 268-271.

[11] AN Quan-zhang, FENG Kai,  He-ping, CAI Xun, SUN Tie-tun, CHU P K. Effects of Al and N plasma immersion ion implantation on surface microhardness, oxidation resistance and antibacterial characteristics of Cu[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1944-1949.

He-ping, CAI Xun, SUN Tie-tun, CHU P K. Effects of Al and N plasma immersion ion implantation on surface microhardness, oxidation resistance and antibacterial characteristics of Cu[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1944-1949.

[12] 刘建弟, 张述泉, 王华明. 激光熔覆WC颗粒增强复合涂层的组织及耐磨性[J]. 中国有色金属学报, 2012, 22(9): 2600-2607.

LIU Jian-di, ZHANG Shu-quan, WANG Hua-ming. Microstructure and wear resistance of laser cladding WC particles reinforced composite coatings[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2600-2607.

[13] 宁来元. 双层辉光等离子渗金属法硬质合金金刚石涂层刀具过渡层制备技术研究[D]. 太原: 太原理工大学, 2014: 11-12.

NING Lai-yuan. Sunthesis of metal interlayer of diamond-coated cemented carbide cutting tools by double glow plasma surface alloying technique[D]. Taiyuan: Taiyuan University of Technology, 2014: 11-12.

[14] ZHOU Lan-ying, ZHOU Huan-lei, JIA Qing-lian. Heat resistance of TiN coated HSS tools[J]. Journal of Beijing Institute of Technology, 2003, 12(2): 176-179.

[15] MA Jing, YAN Dong-qing, HU Jian-wen, ZHANG Xin, LI Yang. Reactive HVOF sprayed TiN-matrix composite coating and its corrosion and wear resistance properties[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1011-1018.

[16] HONG Xiang, TAN Ye-fa, WANG Xiao-long, TAN Hua, XU Ting. Effects of nitrogen flux on microstructure and tribological properties of in-situ TiN coatings deposited on TC11 titanium alloy by electrospark deposition[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3329-3338.

[17] NAGASAKI S, HIRABAYASHI M. Binary alloy phase- diagrams[M]. Beijing: Metallurgical industry press, 2004: 144.

[18] ROZWADOWSKA J, KIDA K, SANTOS E C, HONDA T, KOIKE H, KASHIMA Y, KANEMASU K. Wear resistance improvement of titanium bearings by laser gas nitriding[J]. Advanced Materials Research, 2011, 217/218: 988-993.

[19] 赵冬梅, 董企铭, 刘 平, 金志浩, 康布熙. 高强高导铜合金合金化机理[J].中国有色金属学报, 2001, 11(2): 21-24.

ZHAO Dong-mei, DONG Qi-ming, LIU Ping, JIN Zhi-hao, KANG Bu-xi. Mechanism of alloying of copper alloy with high strength and high electrical conductivity[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 21-24.

[20] 张 翥, 王群骄, 莫 畏. 钛的金属学与热处理[M]. 北京: 冶金工业出版社, 2009: 4-7.

ZHANG Zhu, WANG Qun-jiao, MO Wei. Titanium metallography and heat treatment[M]. Beijing: Metallurgical Industry Press, 2009: 4-7.

[21] 王利捷, 杨军胜. 钛合金表面MoS2/TiN复合涂层的摩擦性能研究[J]. 表面技术, 2010, 39(2): 11-13.

WANG Li-jie, YANG Jun-sheng. The study on tribological properties of MoS2/TiN composite coating on the surface of titanium alloy[J]. Surface Technology, 2010, 39( 2): 11-13.

[22] 薛玉君, 朱 荻, 靳广虎. 电沉积Ni-La 2O3纳米复合镀层的摩擦磨损性能[J]. 摩擦学学报, 2005, 25(1): 1-6.

XUE Yu-jun, ZHU Di, JIN Guang-hu. Friction and wear properties of electrodeposited Ni-La2O3 nanocomposite coatings[J]. Tribology, 2005, 25(1): 1-6.

[23] LI C X, BELL T. Sliding wear properties of active screen plasma nitrided 316 austenitic stainless steel[J]. Wear, 2004, 256: 1144-1152.

[24] BROSZEIT E, MATTHES B, HRRR W, KLOOS K H. Tribological properties of r.f. sputtered Ti-B-N coatings under various pin-on-disc wear test conditions[J]. Surface and Coatings Technology, 1993, 58(1): 29-35.

Tribological property of Ti-N composite layer formed on QBe1.9 by plasma surface Ti-alloying and nitriding

LIU Lin, SHEN Hang-hang, LIU Xiao-zhen, GUO Qi, MENG Tian-xu, WANG Zhen-xia, LIU Xiao-ping

(Research Institute of Surface Engineering, Taiyuan University of Technology, Taiyuan 030024, China)

Abstract: The plasma titanizing and plasma nitriding were applied in QBe1.9 alloy to improve its wear resistance. The microstructure, concentration and phase structure were studied by SEM, SED, GDOES and XRD. The hardness, electrical conductivity and tribological property by reciprocating ball-on-disk test after Ti-N duplex treatment were investigated as well. The results show that, after plasma titanizing and nitriding treatments, a modified layer with thickness of 27 μm forms on QBe1.9 surface, which contains surface TiN(Ti2N)-rich layer and Ti-Be-Cu diffusing layer beneath. The surface hardness after Ti-N duplex treatment reaches 964 HV, higher than that of untreated QBe1.9. The average friction coefficient and wear rate of Ti-N duplex-treated QBe1.9 alloy are only 30% and 1.38% of those of the untreated QBe1.9 alloy, showing good combination of antifriction and wear resistance. The improved properties of QBe1.9 alloy effectively after Ti-N complex treatment is attributed to the hard TiN(Ti2N) forming on the surface.

Key words: QBe1.9 alloy; double glow plasma alloying; plasma nitriding; conductivity; friction; wear

Foundation item: Projects(51474154, 51401141) supported by the National Natural Science Foundation of China; Projects(2012011021-4,2014011015-7) supported by the Natural Science Foundation of Shanxi Province, China

Received date: 2016-05-23; Accepted date: 2016-12-09

Corresponding author: LIU Xiao-ping; Tel: +86-351-6010540; E-mail: liuxiaoping@tyut.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51474154,51401141);山西省自然科学基金资助项目(2012011021-4,2014011015-7)

收稿日期:2016-05-23;修订日期:2016-12-09

通信作者:刘小萍,教授,博士;电话:0351-6010540;E-mail: liuxiaoping@tyut.edu.cn