齿宽系数对面齿轮齿根弯曲应力的影响

靳广虎,朱如鹏,李政民卿,鲍和云

(南京航空航天大学 江苏省精密与微细制造技术重点实验室,江苏 南京,210016)

摘要:根据面齿轮传动的啮合原理,给出面齿轮齿根弯曲应力计算的三齿几何模型。采用正交试验法,确定面齿轮的计算参数。通过有限元分析,计算面齿轮齿根弯曲应力;将面齿轮当量成齿条,分析弯曲应力比值与齿宽系数的关系,获得面齿轮齿根弯曲应力的拟合计算公式。研究结果表明:面齿轮最大弯曲应力位于齿根部位;沿齿根最大弯曲应力的齿宽方向,其弯曲应力近似呈抛物线分布;面齿轮弯曲应力的比值与齿宽系数近似呈线性分布,平均相对误差为6.17%;齿根弯曲应力对面齿轮的齿宽系数和齿数较敏感,在使用本文给出的拟合计算公式,且当面齿轮齿数小于90且齿宽系数小于3时,计算结果可适当放大5%,以减小齿宽系数和齿面曲率对齿根弯曲应力的影响。

关键词:齿轮传动;面齿轮;弯曲应力;有限元

中图分类号:TH132.4 文献标志码:A 文章编号:1672-7207(2011)05-1303-07

Impact of coefficient of tooth width on bending stress of face gear

JIN Guang-hu, ZHU Ru-peng, LI Zheng-min-qing, BAO He-yun

(Jiangsu Key Laboratory of Precision and Micro-Manufacturing Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: Based on engagement theory of face gear drive, the three-teeth geometric model of face gear was developed to calculate the bending stress. The design parameters were confirmed using orthogonal experiment method, and the bending stress of face gear was calculated by finite element analysis (FEA). Regarding the face gear as a rack, the expression of bending stress of face gear and the relationship between bending stress ratio and coefficient of tooth width were obtained. The results show that the maximum bending stress location is in tooth root, and the distribution of bending stress is parabolic line approximately along the tooth width of the maximum bending stress location. The relationship between the ratio of bending stress and the coefficient of tooth width is approximately linear and the mean relative error is 6.17%. The coefficient of tooth width and teeth number affect the bending stress greatly. In order to diminish the effect of coefficient of tooth width and teeth number on the bending stress, the results appropriately magnifies by 5% in application of the expression of bending stress of face gear when the teeth number is less than 90 and the coefficient of tooth width is less than 3.

Key words: gear drive; face gear; bending stress; finite element

面齿轮传动是一种圆锥齿轮与圆柱齿轮相啮合的传动,圆锥齿轮(面齿轮)采用直齿渐开线齿轮刀具经范成加工而成。面齿轮传动以其体积小、质量轻、无需防错位设计以及精确的分流传动性能成为直升机主减传动系统的重点研究方向之一[1-2],被西方发达国家称之为“21世纪旋翼机传动之希望所在”。Litvin等[3-4]研究了面齿轮传动的啮合原理和设计方法;Handschuh等[5-6]开展了面齿轮传动的试验研究;Zhang等[7-10]分析了主要参数对面齿轮承载能力的影响;朱如鹏 等[11-13]就面齿轮传动的啮合特性开展了研究;杨连顺等[14-16]分析了面齿轮传动的弯曲强度及承载能力;李政民卿等[17-18]研究了面齿轮的切磨齿加工方法;靳广虎等[19]就面齿轮传动的动力学特性进行了理论分 析;沈云波等[20]还就斜齿面齿轮的齿宽设计开展了研究。但是,有关面齿轮传动的齿根弯曲强度的研究还不够深入,至今尚无有关点接触面齿轮传动齿根弯曲应力的工程计算方法。在此,本文作者根据面齿轮传动的啮合特性,提出了面齿轮传动的弯曲应力计算模型,依据传动系统常用的传动比、模数、压力角,采用正交试验法,给出面齿轮有限元计算分析的参数,获得面齿轮弯曲应力的分布规律,以便为面齿轮弯曲应力的工程计算提供参考依据。

1 面齿轮齿根弯曲应力计算几何模型

1.1 点接触面齿轮传动的啮合原理

正交面齿轮加工示意图如图1所示。面齿轮2用直齿渐开线齿轮刀具,经范成加工而成。当传动中采用的圆柱齿轮与刀具齿数相同时,面齿轮传动是线接触传动。由于各种误差的存在,这种线接触传动在实际工作中不能实现,从而产生偏载现象。为避免这一现象, 实际参加啮合传动的圆柱齿轮齿数要比加工面齿轮的刀具齿数少1~3个,实现点接触传动。假设插齿刀齿面(ΣS)、圆柱齿轮齿面(Σ1)和面齿轮齿面(Σ2)是相互啮合的。由加工原理可知:齿面ΣS和Σ2是线接触,设其瞬时齿面接触线为LS2、传动瞬轴线为IS2;齿面ΣS和Σ1的啮合为假想的内啮合情形(见图2(a)),其中,心距b取决于齿数差Δ,啮合的瞬轴线IS1为2个基圆柱的公切面与通过两齿轴心线平面的交线,它们的瞬时齿面接触线LS1平行于刀具和圆柱齿轮的轴心线。接触线LS1和LS2在空间是不重合的,它们的交点即为瞬时齿面接触点P,也是传动瞬轴线IS1和IS2的交点(见图2(b))。

1.2 面齿轮齿宽的选择

面齿轮的齿面很复杂,在面齿轮的加工中,面齿轮的内径处会出现根切,外径处会发生齿顶变尖的现象[21],面齿轮的齿宽受到限制;沿齿高方向各截面形

图1 正交面齿轮加工示意图

Fig.1 Schematic of generation of face gear

图2 点接触正交面齿轮传动原理

Fig.2 Schematic plan of point contact of face gear drives

状也不相同,因此,必须就面齿轮的齿宽进行选择。

根据面齿轮啮合传动的啮合原理,其啮合轨迹为通过节点P且沿齿顶方向的1条近似直线。为避免面齿轮啮合传动中发生偏载现象,面齿轮的齿宽以节点P为中心选取。根据设计参数,分别计算出面齿轮内径处出现根切和外径处发生齿顶变尖时离节点P的长度,选取两者最小值作为齿宽的一半,从而确定出整个齿宽,作为考察面齿轮弯曲应力计算的齿宽选择 基准。

1.3 面齿轮计算模型的参数选择

为获得齿根弯曲应力的分布规律,必须正确选定分析模型的参数。齿轮的设计参数很多,且每种因素又有多种变化,如果开展全面的试验,试验量非常大,不经济、不现实;因此,在参数的选择中,采用正交试验法确定模型的设计参数,它可以大幅度减少试验次数,而且并不会降低试验可信度。

在直升机主减传动系统中,具有面齿轮传动的分扭机构一般置于输入级,齿轮模数一般选为2~5 mm;为增强齿轮的抗弯能力,航空齿轮传动中的压力角一般为22.5°和25°左右,为此,压力角取为20°~27°;结合航空齿轮的应用情况看,其速比一般为3~6,圆柱齿轮的齿数一般不小于17个;综合考虑齿轮传递的功率、转速以及齿轮的几何参数确定法向载荷。通过四因素四水平正交试验法建立计算模型的设计参数,再根据正交表依次确定面齿轮的齿数。正交试验的因素水平如表1所示。

表1 试验因素及水平

Table 1 Experimental factors and levels

1.4 面齿轮几何模型的选择

目前,现代设计、分析方法很多,尤其是大型商业软件的普及,为开展齿轮弯曲应力的分析提供了基础。因此,从实际情况出发,选择仿真试验的方法,不仅可以节约成本,同时可保证分析的精确性。

用一垂直于圆柱齿轮轴线的平面剖切圆柱齿轮和面齿轮的啮合齿面,其剖面图如图3所示。剖切平面与圆柱齿轮齿面的交线为渐开线,与面齿轮齿面的交线可近似地认为是直线。首先,从加工时的运动情况可知:圆柱齿轮剖面上的渐开线齿廓作定轴转动,而面齿轮作近似的直线移动,根据范成运动的原理,面齿轮的齿面与剖面的交线应为一直线齿廓;其次,研究结果表明,相对于渐开线齿面的法曲率,面齿轮的齿面法曲率较小[21],因此,其与剖面的交线可近似地认为是直线,齿面可近似为平面,从而可以把面齿轮近似为齿条。在齿根的弯曲应力分析中,为降低边界条件对分析结果的影响,需要定义模型的大小。根据文献[22],对直齿圆柱齿轮模型,当齿根距离约束面的高度不小于1.5m(m为模数),模型的端面长度不小于3m时,则边界位移点上的位移都小于齿轮最大位移的3%,考虑到齿轮腹板对面齿轮齿根弯曲应力的影响,面齿轮弯曲应力的分析模型选择实心式三齿 模型。

图3 渐开线圆柱齿轮与面齿轮啮合的剖面图

Fig.3 Section of spur gear and face gear

2 面齿轮齿根弯曲应力的有限元计算分析

2.1 面齿轮的有限元模型

根据面齿轮传动的啮合理论,开发了面齿轮传动的设计、切齿加工仿真软件,将模型导入ANSYS计算软件,可对几何模型进行分析。图4所示为面齿轮的有限元模型,该模型应用四面体单元通过映射的方法划分网格。假设啮合处于理想状态,啮合点位于齿顶;模型的边界约束条件是限制三齿模型的2个侧面及底面的法向位移。经过多次试算发现:单元棱长在

图4 面齿轮三齿有限元模型

Fig.4 Three teeth element model of face gear

0.1~0.2 mm时计算结果趋于收敛;因此,在计算分析时,单元棱长取为0.2 mm。面齿轮材料的弹性模量为2.10×105 MPa,泊松比为0.3。

2.2 面齿轮齿根弯曲应力的分布

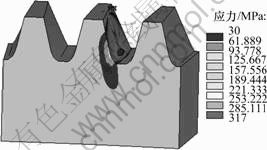

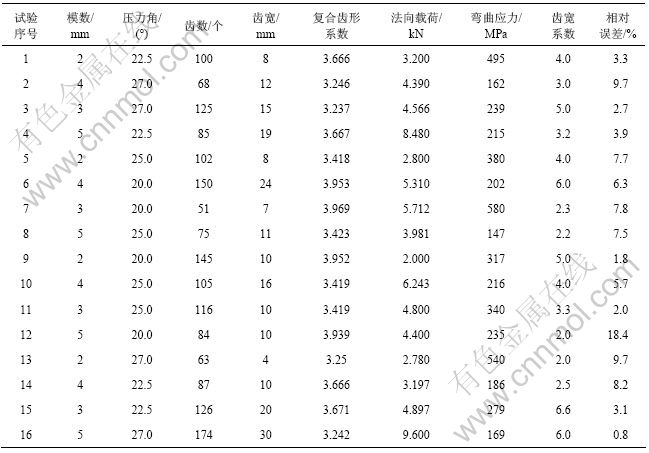

根据以上分析,对16组模型进行有限元分析,计算结果如表2所示。图5所示为典型面齿轮齿根弯曲应力云图。

图5 面齿轮齿根弯曲应力云图

Fig.5 Bending stress images of face gear

从图5可以看出:加载点附近和齿根部位弯曲应力最大。根据圣维南原理,加载点附近的应力不能作为齿轮的最大弯曲应力,因此,远离加载区域的齿根弯曲应力最大,且该点所处的截面(沿齿高方向)和加载位置位于同一个平面。过齿根最大弯曲应力位置沿齿宽方向取1条直线,提取该线上的相应等值线应力发现:应力基本上是对称分布的,中心应力较大;且中心区域的应力梯度变化大,离齿宽中心距离越远,弯曲应力越小。面齿轮齿根弯曲应力分布如图6所示,其齿根弯曲应力的分布规律和Jaramillo等[23-24]的研究结果很相似,说明有限元分析结果以及把面齿轮当量成齿条是合理的。

图6 面齿轮齿根弯曲应力分布

Fig.6 Bending stress distribution along tooth root of face gear

2.3 面齿轮齿根弯曲应力的计算结果分析

集中载荷作用下的齿轮齿根弯曲应力的计算一直是一个难点,目前没有理论解。自内切抛物线法的齿轮弯曲强度计算公式被提出以来,科研工作者就齿轮的弯曲应力开展了大量的研究工作。Jaramillo[23]采用广义积分的方法给出了集中载荷下无限长悬臂板固定端的弯矩分布和应力分布,但是,求解方法十分复杂; Wellauer等[24]根据Jaramillo理论,采用“弯矩影象法”,给出了集中载荷下齿根弯矩的分布规律,进而提出了半经验法的齿根弯曲应力计算方程,与试验结果比较吻合,在工程应用中具有足够高的精度。

当悬臂板宽度过大时,固定端远离加载位置的弯矩为0,且固定端的弯矩分布只与加载作用点到固定端的相对距离、悬臂薄板的相对宽度以及相对厚度有关,加载作用点区域的应力梯度变化大[23];因此,本文提出这样一个假设:点接触的正交面齿轮传动中,齿轮的弯曲应力与加载作用点到齿根的相对距离、齿轮的相对宽度以及危险截面的相对厚度有关;点加载和全齿宽加载条件下的齿根弯曲应力之间存在一定的关系。可以参考现有齿轮弯曲应力的方法,找出点加载和全齿宽加载条件下齿根弯曲应力之间的联系,从而获得适用于实际工程强度计算的设计方程:

(1)

(1)

式中: 为全齿加载条件下齿根的最大弯曲应力,此处把面齿轮当量成齿条,其载荷与集中载荷相等;

为全齿加载条件下齿根的最大弯曲应力,此处把面齿轮当量成齿条,其载荷与集中载荷相等; 为集中载荷下面齿轮齿根的最大弯曲应力,采用有限元计算获得;A和B为常数;

为集中载荷下面齿轮齿根的最大弯曲应力,采用有限元计算获得;A和B为常数; 为齿宽系数。

为齿宽系数。

在全齿加载条件下,其相对加载位置和相对齿厚都在一定程度上反映在复合齿形系数中,没有相对齿宽问题。因此,在假设中,本文提出齿宽系数 用于考察齿宽对面齿轮齿根弯曲应力的影响。齿宽系数

用于考察齿宽对面齿轮齿根弯曲应力的影响。齿宽系数 定义为:

定义为:

(2)

(2)

式中:b为面齿轮的宽度;m为面齿轮的模数。

根据全齿加载条件下的面齿轮齿根弯曲应力和集中载荷条件下采用有限元法计算的面齿轮齿根弯曲应力,引入齿宽系数,获得了16组不同参数、不同齿宽系数分布,结果如表2所示。采用最小二乘法,弯曲应力比值与齿宽系数的拟合曲线如图7所示,其中,横坐标为齿宽系数 ,纵坐标为集中载荷和全齿加载条件下的面齿轮齿根最大弯曲应力的比值

,纵坐标为集中载荷和全齿加载条件下的面齿轮齿根最大弯曲应力的比值 。从图7可以看出:各数值点基本上分布在拟合曲线的周围。集中载荷和全齿加载条件下的面齿轮齿根最大弯曲应力的比值

。从图7可以看出:各数值点基本上分布在拟合曲线的周围。集中载荷和全齿加载条件下的面齿轮齿根最大弯曲应力的比值 与齿宽系数

与齿宽系数 近似满足以下关系,即

近似满足以下关系,即

(3)

(3)

则由式(3)和圆柱齿轮弯曲应力计算方程可知集中载荷条件下面齿轮齿根弯曲应力 可表示为:

可表示为:

(4)

(4)

式中:K为工况系数;Fn为法向载荷;YS为复合齿形系数。

从表2可以看出:齿宽系数为2的面齿轮齿根弯曲应力相对误差较大,尤其是模数为5 mm时,相对误差达18.4%,齿宽效应影响明显;另外,齿数和齿宽系数较小的面齿轮,其误差也较大,说明面齿轮的弯曲应力对齿面曲率较敏感。因此,考虑到支撑、齿宽效应以及面齿轮齿面曲率的影响,在面齿轮传动的设计中,齿宽系数 应尽量不小于3;当面齿轮齿数

应尽量不小于3;当面齿轮齿数

z<90且齿宽系数小于3时,计算结果可适当放大5%,以减小齿宽系数和齿面曲率对齿根弯曲应力的影响。经计算,16个参数条件下面齿轮齿根弯曲应力的平均相对误差较小,为6.17%,因此,该方法可以作为工程设计阶段面齿轮齿根弯曲应力计算的参考依据。

图7 弯曲应力的比值与齿宽系数的关系

Fig.7 Relationship between bending stress ratio and coefficient of tooth width

表2 面齿轮的设计参数及计算结果

Table 2 Design parameters and calculation results of face gear

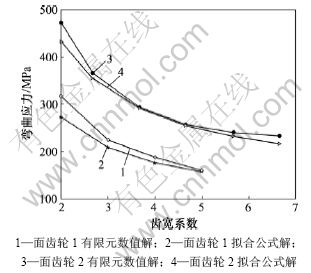

3 齿宽系数对面齿轮弯曲应力的影响

为进一步考察齿宽系数对面齿轮齿根弯曲应力的影响,在划分单元尺寸不变的情况下,分析面齿轮1和2在不同齿宽系数下的弯曲应力。面齿轮1的参数为:模数m=2 mm,压力角 =20?,齿数z=145,法向载荷Fn=1 kN;面齿轮2的参数为:模数m=3 mm,压力角

=20?,齿数z=145,法向载荷Fn=1 kN;面齿轮2的参数为:模数m=3 mm,压力角 =22.5?,齿数z=126,法向载荷Fn=3 897 N。图8所示为面齿轮1和2的弯曲应力与齿宽系数的关系曲线,表3所示为不同齿宽系数下的相对误差。从表3可以看出:当齿宽系数减小至2时,相对误差明显偏大;对面齿轮1,当齿宽系数为2时,相对误差达14.1%。

=22.5?,齿数z=126,法向载荷Fn=3 897 N。图8所示为面齿轮1和2的弯曲应力与齿宽系数的关系曲线,表3所示为不同齿宽系数下的相对误差。从表3可以看出:当齿宽系数减小至2时,相对误差明显偏大;对面齿轮1,当齿宽系数为2时,相对误差达14.1%。

图8 弯曲应力与齿宽系数的关系曲线

Fig.8 Graph of bending stress and coefficient of tooth width

表3 不同齿宽系数下的齿根弯曲应力相对误差

Table 3 Error of bending stress in different coefficients of tooth width

4 结论

(1) 面齿轮的最大弯曲应力位于齿轮的根部;沿齿根最大弯曲应力的齿宽方向取弯曲应力的等值线图可发现齿根弯曲应力近似呈抛物线分布。

(2) 齿根弯曲应力的比值和齿宽系数近似呈线性分布,平均相对误差为6.17%。

(3) 齿根弯曲应力对面齿轮的齿宽系数和齿数较敏感,在使用本文给出的拟合计算公式,且当面齿轮齿数z<90且齿宽系数小于3时,计算结果可适当放大5%,以减小齿宽系数和齿面曲率对齿根弯曲应力的影响。

参考文献:

[1] Heath G F, Bossler R B. Advanced rotorcraft transmission (ART) program-final Report[R]. Cleveland: Lewis Research Center, 1993: 1-2.

[2] Heath G F, Filler R R, TAN Jie. Development of face gear technology for industrial and aerospace power transmission[R]. Mesa: The Boeing Company, 2002: 1-3.

[3] Litvin F L, Zhang Y, Wang J C, et al. Design and geometry of face-gear drives[J]. ASME Journal of Mechanical Design, 1992, 114(4): 642-647.

[4] Litvin F L, Wang J C, Bossler Jr R B, et al. Application of face-gear drives in helicopter transmissions[J]. ASME Journal of Mechanical Design, 1994, 116(3): 672-676.

[5] Handschuh R F, Lewicki D G, Bossler R. Experimental testing of prototype face gears for helicopter transmissions[J]. Journal of Aerospace Engineering, 1994, 208(2): 129-135.

[6] Lewicki D G, Handschuh R F, Heath G F. Evaluation of carburized and ground face gears[C]//American Helicopter Society 55th Annual Forum, Montreal, 1999: 1-9.

[7] Zhang Y, Litrin F L, Maruyama N, et al. Computerized analysis of meshing and contact of gear real tooth surfaces[J]. Journal of Mechanical Design, 1994, 116(3): 677-682.

[8] Barone S, Borgianni L, Forte P. Evaluation of the effect of misalignment and profile modification in face gear drive by a finite element meshing simulation[J]. Transactions of the ASME, 2004, 126(9): 916-924.

[9] Litvin F L, Fuentes A, Zanzi C, et al. Design, generation, and stress analysis of two versions of geometry of face-gear drives[J]. Mechanism and Machine Theory, 2002, 37(10): 1179-1211.

[10] Guingand M, de Vaujany J P, Jacquin C Y. Quasi-static analysis of face gear under torque[J]. Computer Methods in Applied Mechanics and Engineering, 2005, 194(39/41): 1-8.

[11] 朱如鹏, 高德平. 在面齿轮设计中避免根切和齿顶变尖的设计方法研究[J]. 中国机械工程, 1999, 10(11): 1274-1276.

ZHU Ru-peng, GAO De-ping. Study on the methord of avoiding dedendum undercutting and addendum pointing in face gear design[J]. China Mechanical Engineering, 1999, 10(11): 1274-1276.

[12] 朱如鹏, 潘升材, 高德平. 正交面齿轮传动中齿宽设计的研究[J]. 机械科学与技术, 1999, 18(4): 566-567.

ZHU Ru-peng, PAN Sheng-cai, GAO De-ping. Study of the design of tooth width of right shaft-angle face-gear drive[J]. Mechanical Science and Technology, 1999, 18(4): 566-567.

[13] 贺鹏, 刘光磊. 面齿轮传动安装误差特性研究[J]. 机械科学与技术, 2008, 27(1): 92-95.

HE Peng, LIU Guang-lei. Tooth contact analysis of face fear meshing[J]. Mechanical Science and Technology, 2008, 27(1): 92-95.

[14] 杨连顺, 朱如鹏, 曾英. 正交面齿轮弯曲应力的分析[J]. 机械科学与技术, 2001, 20(5): 708-714.

YANG Lian-sun, ZHU Ru-peng, ZENG Ying. Analysis of bending stress in perpendicular face gear[J]. Mechanical Science and Technology, 2001, 20(5): 708-714.

[15] 郭辉, 赵宁, 方宗德, 等. 基于接触有限元的面齿轮传动弯曲强度研究[J]. 航空动力学报, 2008, 23(8): 1438-1442.

GUO Hui, ZHAO Ning, FANG Zong-de, et al. Research on bending strength of face-gear transmission based on contact finite element method[J]. Journal of Aerospace Power, 2008, 23(8): 1438-1442.

[16] 赵宁, 郭辉, 方宗德, 等. 直齿面齿轮修形及承载接触分析[J]. 航空动力学报, 2008, 23(11): 2142-2146.

ZHAO Ning, GUO Hui, FANG Zong-de, et al. Modification and loaded contact analysis of spur face gears[J]. Journal of Aerospace Power, 2008, 23(11): 2142-2146.

[17] 李政民卿, 朱如鹏. 面齿轮插齿加工中过程包络面和理论齿廓的干涉[J]. 重庆大学学报, 2007, 30(5): 55-58.

LI Zheng-min-qing, ZHU Ru-peng. Process method of face gear drive with spur involute pinion with the shaping machine[J]. Journal of Chongqing University, 2007, 30(5): 55-58.

[18] 李政民卿, 朱如鹏. 面齿轮滚磨刀具基蜗杆研究[J]. 机械科学与技术, 2009, 28(1): 98-101.

LI Zheng-min-qing, ZHU Ru-peng. A study of worm of hobbing or grinding wheel for face gear[J]. Mechanical Science and Technology, 2009, 28(1): 98-101.

[19] 靳广虎, 朱如鹏, 朱自冰, 等. 正交面齿轮传动系统的耦合振动分析[J]. 机械科学与技术, 2009, 28(1): 124-132.

JIN Guang-hu, ZHU Ru-peng, ZHU Zi-bing, et al. Analysis of the coupling vibration of a face gear transmission system[J]. Mechanical Science and Technology, 2009, 28(1): 124-132.

[20] 沈云波, 方宗德, 赵宁, 等. 斜齿面齿轮齿宽的设计[J]. 航空动力学报, 2008, 23(4): 754-758.

SHEN Yun-bo, FANG Zong-de, ZHAO Ning, et al. The design of tooth face width of the face-gear drives with helical pinion[J]. Journal of Aerospace Power, 2008, 23(4): 754-758.

[21] 靳广虎. 正交面齿轮传动齿面温升的计算机辅助分析[D]. 南京: 南京航空航天大学机电学院, 2002: 26-28.

JIN Guang-hu. An investigation on the meshing characteristics of face gear drives[D]. Nanjing: Nanjing University of Aeronautics & Astronautics. College of Mechanical Engineering, 2002: 26-28.

[22] 周延泽, 吴继泽. 直齿锥齿轮齿根应力的有限元分析[J]. 北京航空航天大学学报, 1996, 22(1): 88-93.

ZHOU Yan-ze, WU Ji-ze. Finite element analysis of tooth stress of straight bevel gear[J]. Journal of Beijing University of Aeronautics and Astronautics, 1996, 22(1): 88-93.

[23] Jaramillo T J. Deflection and moments due to a concentrated load on a cantilever plate of infinite length[J]. Journal of Applied Mechanics, 1950, 17(5): 67-72.

[24] Wellauer E J, Seireg A. Bending strength of gear teeth by cantilever-pltae theory[J]. Journal of Engineering for Industry, Transactions of ASME, 1960, 23(8): 213-222.

(编辑 赵俊)

收稿日期:2010-03-30;修回日期:2010-07-28

基金项目:国家自然科学基金资助项目(50775108);江苏省自然科学基金资助项目(BK2007194);航空科技创新基金资助项目(08B52004);精密与微细制造技术江苏省重点实验室资助项目(JSPM200701)

通信作者:朱如鹏(1959-),男,江苏建湖人,教授,博士生导师,从事机械传动、结构强度、机械CAD及自动化研究;电话:025-84892500;E-mail: rpzhu@nuaa.edu.cn