Bulk Al/SiC nanocomposite prepared by ball milling and hot pressing method

GU Wan-li(谷万里)

School of Mechanical Engineering, Shandong University of Technology, Zibo 255049, China

Received 10 April 2006; accepted 25 April 2006

Abstract: Nano-sized Al/SiC powders were prepared by mechanical alloying method. Two sorts of SiC particle, i.e., nano-sized and popular micron-sized SiC were utilized. The particle size and microstructure of the milled powder were characterised. Effects of the particle size and agglomerate state of SiC, as well as the microstructure of Al/SiC nanocomposite were studied by SEM and TEM. The results show that nano-sized SiC particles is dispersed in aluminium uniformly after ball milled for only 2 h, whereas the similar process need about 10 h for popular micron-sized SiC particle. The bulk Al/SiC nanocomposite can be fabricated by hot pressing the nano-sized Al/SiC powders at temperature about 723 K under pressure of 100 MPa.

Key words: nanocomposite; aluminium; SiC; Al/SiC nanocomposite; mechanical alloying; hot pressing

1 Introduction

Aluminium based composite has been widely used in many fields owing to its excellent properties. It is generally prepared by dispersion of high temperature resistant ceramic particle like SiC, Si3N4, Al2O3 or TiC in Al matrix and the most commonly used particle is SiC. Many methods have been studied to prepare aluminium based composite. In the liquid methods, particles are added to liquid aluminium by stirring before casting. However, the difference in thermal expansion coefficients between these two constituents and the poor wettability between molten Al and SiC become an obstacle to the liquid method used for synthesizing Al/SiC composite. In addition, liquid metallurgy may lead to an undesirable reaction between SiC and molten Al, producing brittle phase of Al3C4 and Si [1]. Another way of producing the fine and homogenous distribution of these hard particles is by solid method. In the preparation method, mechanical alloying (MA) is a simple and useful technique to synthesize both equilibrium and nonequilibrium material from initial powder. It is used to refer to the process using a ball-milling technique for preparing homogenous composite particles with intimately dispersed uniform internal structure. The process often consists of repeated fracture, mixing and cold welding of a fine blend of initial powders. As a nonequilibrium processing method, it can be utilized to produce large quantities of material at relatively low cost.

Recently, more and more evidence shows that the mechanical properties of metal matrix composites can be enhanced significantly by adding nano-sized ceramic particle. Although a small scale homogeneity can be obtained using gel-dry route, the relative high cost of some reactants and the difficulty to control the gel-drying become drawback of the method’s application. Compared with this method, mechanical alloying has a relatively low cost and simple technique and it is fit for fabricating composite in a large scale. It has been well known as a valuable technique to produce new material such as amorphous alloy[2-4] and nanocomposite[5-7]. Up till now, this method has been used to produce nanocomposite in many systems such as Cu/ Al2O3[8], Al3Ti/Al2O3[9], Fe70Al30[10] and Al2O3/SiC[11].

In the preparation of nanocomposite, the main problem comes from the large surface-to-volume ratio of nanoscaled reinforcements that makes chemical reactions and diffusion occur easily, moreover, the agglomeration becomes severe. The nanosized reinforcements always prevent composites from densification. In the present work, Al/SiC nanocomposite was prepared by mechanical alloying technique. In order to consolidate the as-milled powder into bulk samples, the pressure and temperature effects on the hot pressing process were investigated. It is suggested that the microstructure of Al/SiC composite has a close relationship with the hot pressing condition. Nanosized SiC particle will disperse homogenously in Al matrix under a relatively high pressure 100 MPa and low temperature 723 K. Compared with the other methods, the present technique provides an effective approach for synthesizing bulk Al based nanocomposite.

2 Experimental

In order to investigate the ball milling behaviours of the mixture affected by the difference of the SiC particle size, two kinds of SiC particle were utilized to mix with aluminium powder and then ball was milled. One was ordinary particle with a size less than 45 μm and purity higher than 99%, the mixture of it with Al was called Al/SiC mixture; another one was nano-sized SiC particle with a size about 20-50 nm and purity higher than 99%, the mixture was called Al/SiCN mixture. All the volume fraction of SiC particles in the mixture was 10% and omitted in later fraction. The initial mixed powders were then charged and sealed in an agate vial together with 60 agate balls. The ball-milling experiments were performed in a high energy planetary ball mill (QM-1SP2) at a rotation speed of 5 s-1 in argon atmosphere with a ball-to-powder mass ratio of 20∶1. No lubricant solution was added to the charge. The ball milling experiments were stopped periodically (every 0.5 h) and then resumed when the temperature of the vial decreased to about 300 K. The final product of the ball milled powder (10 h) was put into superalloy mould and hot pressed in argon atmosphere in a temperature range from 723 to 873 K under a pressure range from 10 to 100 MPa.

The density of the consolidated samples was determined by ARCHIMEDE’s principle. The morphologies of mixed powder ball milled for different times and the microstructure of hot pressed bulk composite were characterised by field-emission scanning electron microscopy (FE-SEM, FEI Sirion200) and more detailed by Electron transmission microscopy (TEM, JEM-2000 Ex, 200 KV).

3 Results and discussion

Mechanical alloying process consists of deforma- tion, cold welding and fracture of powder particles. The process depends on intrinsic property of constituents and the process parameters. For the present Al/SiC system, the particle size often increases initially and then reduces continuously from the largest size about 30-50 μm to a few microns. On the other hand, the size of SiC particle often has a significant influence on the ball milling process.

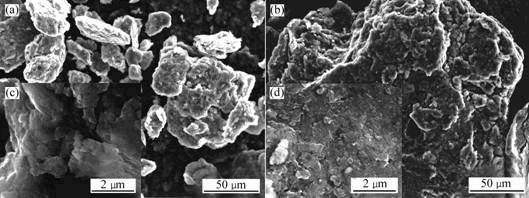

The SEM technique was used to describe the characteristics of the powders during the several stages of ball milling. The morphology and size of alloyed Al/SiC and Al/SiCN powders after a selected ball milling duration was investigated. As shown in Figs.1(a)-(d), the early stage of mechanical alloying (2 h) results in the formation of powder agglomerates which have a wide range in size (from 5 to 200 μm). The particles agglomerate as a result of the repeated welding during milling. By comparing Figs.1(a) with (b), it is obvious that the particle size of Al/SiCN is larger than that of Al/SiC. Furthermore, in the higher magnifie image, it is observed that large quantity of particles with a size approximately 20-50 nm dispersed in Al matrix homogeneously in Fig.1(d). The difference of these figures implies that nano-sized SiC particle is more easily embedded in aluminium powder and beneficial to cold welding of Al powder.

The SEM images of Al/SiC and Al/SiCN mixture ball milled for 10 h are shown in Fig.2. As shown in Figs.2(a) and 2(b), the particle sizes of Al/SiC and Al/SiCN, as well as those shown in Figs.2(c) and 2(d), the detail morphology of these two mixtures are similar.

Fig.1 SEM images of Al/SiC and Al/SiCN mixture ball milled for 2 h, respectively: (a) Al/SiC; (b) Al/SiCN; (c) Al/SiC; (d) Al/SiCN

This result implies that after 10 h of milling, these two mixtures have a less difference than that after 2 h. The figure also shows that the agglomerated powder particles are subjected to a continuous disintegration with fragment to form finer powder with extremely wide particle size distribution. Particularly, large quantity of nano-sized particles can be observed in Figs.2(c) and (d), which is similar to SHERIF’s results[12]. Generally, further milling often leads to deformation increase and the agglomerated powders disintegrate into fragments producing finer particles[13].

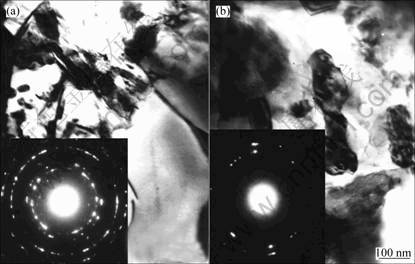

In order to investigate the change of microstructure during the ball milling more detailedly, TEM image and the selected area diffraction pattern (SADP) for these two mixtures ball milled for 10 h are shown in Fig. 3. It is confirmed again that SiC particle disperses in aluminium matrix uniformly. The SADP shows a sharp ring-spot pattern that is the characteristic of the simultaneous diffracting polycrystalline β-SiC (f.c.c.) and Al (f.c.c.). More diffraction ring-spots can be observed in Al/SiCN (Fig.3(a)) than in Al/SiC(Fig.3(b)), which implies that the particle of SiC in Al/SiCN has a smaller size. Furthermore, highly streaked diffraction spots in SADP suggest extensively strained crystallites. The formation of shear bands in the shock-densified compacts is considered to be induced by non-homogeneous deformation at high strain rate, which is similar to the milling process of NiAl powder reported by CHEN et al[14].

The uniformly dispersed SiC particle in aluminum matrix provides a condition to fabricate bulk homogeneous nanocomposite. The microstructure of composite has a close relationship with hot pressing temperature and pressure. The reinforced ceramic particle in aluminium will agglomerate under an ordinary powder metallurgy condition such as hot pressing at 873 K and 10 MPa. However, for a relatively lower hot pressing temperature about 723 K and higher pressure 100 MPa, the reinforced ceramic phase in composite will remain a size of less than 50 nm and homogenously distribution in aluminium matrix. Fig.4 shows the SEM morphology of Al/SiC milled for 10 h (a) and Al/SiCN

Fig.2 SEM images of Al/SiC and Al/SiCN mixture ball milled for 10 h, respectively: (a) Al/SiC; (b) Al/SiCN; (c) Al/SiC, 10 000×; (d) Al/SiCN

Fig.3 TEM images and selected area diffraction patterns (SADP) of mixed Al/SiCN (a) and Al/SiC (b) powders ball milled for 10 h

Fig.4 SEM morphologies of bulk composite hot pressed at 723 K and 100 MPa for 600 s: (a) Al/SiC, 10 h; (b) Al/SiCN, 2 h; (c) Al/SiCN, 10 h

milled for 2 h (b) and 10 h (c) hot pressed at 723 K under pressure of 100 MPa for 600 s, respectively. It is clear that the morphologies of Al/SiC and Al/SiCN are similar, which implies that the initial difference of SiC in size can be eliminated during a long time milling. This result has a great significance because the Al/SiC nanocomposite can be fabricated using relatively cheap popular SiC particle. On the other hand, a shorter milling time will be needed if the nano-sized SiC is utilized.

Previous investigations have shown that the Al/SiC interface becomes reactive at temperature above 933 K and the solid-state reaction between Al matrix and SiC nanoscale particle occures above 873 K[15]. For this reason, lower hot pressing temperatures are beneficial to preventing the agglomerate of the SiC particles and the reaction between Al and SiC. However, the compact composite will not be obtained unless with a higher pressure. The relative density of the hot pressed Al/SiC nanocomposite increases from 95% to 99% as the pressure increases from 10 MPa to 100 MPa.

4 Conclusions

Popular micron ceramic SiC particles can be broken up to less than 100 nm and disperse in aluminium homogenously by ball milling the mixed SiC and Al powder for 10 h. This process needs only 2 h if the popular SiC particle is substituted by nanosized SiC. In the preparation of bulk composite, the reinforced ceramic particle in aluminium will agglomerate under an ordinary powder metallurgy condition such as hot pressing at 873 K and 10 MPa. However, the SiC particle about 20 to 50 nm will be dispersed uniformly in aluminium matrix at a hot pressing temperature of about 723 K under pressure of 100 MPa.

References

[1] LEE J C, BYUN J Y, Oh C S, SEOK H K, LEE H I. Effect of various processing methods on the interfacial reactions in SiCp/2024 Al composites[J]. Acta Metall, 1997, 45(12): 5303-5315.

[2] GU X J, YE F, ZHOU F, LU K. Pressure effect on crystallization of mechanically alloyed amorphous Al85Fe15 alloy[J]. Mater Sci Eng A, 2000, 278(1): 61-65.

[3] JURCZYK M. Hydrogen storage properties of amorphous and nanocrystalline MmNi4.2Al0.8 alloys[J]. J Alloys Comp, 2000, 307(2): 279-282.

[4] HUANG B, ISHIHAHA K N, SHINGU P H. Metastable phases of Al-Fe system by mechanical alloying[J]. Mater Sci Eng A, 1997, 231(1): 72-79.

[5] KRASNOWSKI M, FADEEVA V I, MATYJA H. Nanocomposites produced by mechanical alloying of the Al50Fe25Ti25 powders mixture[J]. Nanostruct Mater, 1999, 12(4): 455-458.

[6] YONG Z, KIYOSHI K, SHIGEOKI S. Effect of Ni addition on formation of amorphous and nanocrystalline phase during mechanical alloying of Al-25 at.% Fe-(5-10) at.% Ni powders[J]. Mater Research Bull, 2002, 37(7): 1307-1313.

[7] FAN G J, GAO W N, QUAN M X, HU Z Q. Preparation and thermal stability of supersaturated nanocrystalline Al-Ti alloys[J]. Mater Lett, 1995, 23(4): 33-37.

[8] FERKEL H. Properties of copper reinforced by laser-generated Al2O3-nanoparticles[J]. Nanostruct Mater, 1999, 11(5): 595-602.

[9] UENISHI K, MATSUBARA T, SHIBUTANI T, KOBAYASHI K F. Wear and oxidation resistance of Al2O3 particle dispersed Al3Ti composite with a nanosyructure prepared by pulsed electric current sintering of mechanically alloyed powders[J]. Intermetallics, 2002, 10(1): 105-111.

[10] JARTYCH E, ZURAWICZ J K, OLESZAK D, PEKALA M, SARZYNSKI J, BUDZYNSKI M. Magnetic properties and structure of nanocrystalline Fe70Al30 alloy prepared by mechanosynthesis[J]. J Magn Magn Mater, 1998, 186(3): 299-305.

[11] CARROLL L, STERNITZKE M, DERBY B. Silicon carbide particle size effects in aluminu-based nanocomposites[J]. Acta Mater, 1996, 44(11): 4543-4552.

[12] SHERIF El-ESKANDARANY M. Mechanical solid state mixing for synthesizing of SiCp/Al nanocomposites[J]. J Alloy Comp, 1998, 279(2): 263-271.

[13] ARIK H. Production and characterization of in situ Al4C3 reinforced aluminum-based composite produced by mechanical alloying technique[J]. Mater Design, 2004, 25(1): 31-40.

[14] CHEN T, HAMPIKIAN J M, THADHANI N H. Synthesis and characterization of mechanically alloyed and shock-consolidated nanocrystalline NiAl internetallic[J]. Acta Mater, 1999, 47(9): 2567-2579.

[15] LIU H Z, WANG L H, WANG A M, LOU T P, DING B Z, HU Z Q. Study of SiC/Al nanocomposite under high pressure[J]. Nanostruc Mater , 1997, 9(2): 225-228.

(Edited by CHEN Can-hua)

Corresponding author: GU Wan-li; E-mail: guwanli@sdut.edu.cn