文章编号:1004-0609(2007)12-2065-09

基于综合工况评判模型的铅锌烧结过程操作参数优化方法

王春生,吴 敏,徐辰华

(中南大学 信息科学与工程学院,长沙 410083)

摘 要:针对铅锌烧结过程中复杂的过程优化控制问题,提出基于综合工况评判模型的铅锌烧结过程操作参数优化方法。在基于机理分析的基础上,综合运用主元分析、神经网络和模糊理论等方法,建立综合工况评判模型;并根据当前的操作参数和综合工况评判模型结果,采用基于模糊C均值聚类的匹配优化算法获得最优的操作参数,从而为现场操作人员提供科学的操作指导。结果表明:该方法可显著改善工况波动、提高烧结块的产量和质量,较好地解决铅锌烧结过程的优化控制问题。

关键词:铅锌烧结过程;操作参数;透气性预测模型;产量质量预测模型;工况评判模型;模糊C均值聚类;匹配优化算法

中图分类号:TP 273 文献标识码:A

Optimization method of operating parameters for lead-zinc sintering process based on comprehensive status evaluation model

WANG Chun-sheng, WU Min, XU Chen-hua

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: An optimization method of operation parameter based on comprehensive status evaluation model was proposed on the background of optimization control problem for lead-zinc sintering process. Based on the sintering process mechanism analysis, the comprehensive status evaluation model was proposed, which synthesizes a lot of intelligent technique, including principle components analysis, neural network, fuzzy theory and so on. Then according to the current operating parameters and the result of comprehensive status evaluation model, the optimum operation parameters were calculated by using matching optimization algorithm based on fuzzy C-means clustering. The results show that the fluctuation of status can be meliorated efficiently and the output and quality of agglomerate is improved, so the problem of optimization control for lead-zinc sintering process can be resolved.

Key words: lead-zinc sintering process; operating parameters; permeability prediction model; output-quality prediction model; status evaluation model; fuzzy C-means clustering; matching optimization algorithm

密闭鼓风炉铅锌熔炼ISP工艺(Imperial smelting process)包括烧结和熔炼两大工艺[1]。由于这种方法的优势在于在同一冶炼过程中冶炼铅锌两种金属,因而成为近代火法冶炼铅锌的主要方法之一。烧结过程工艺流程长,生产用原料和过程反应机理复杂,生产边界条件变化剧烈,是一个具有强非线性、强耦合性和时变时滞性的不确定复杂工业过程,仅凭经验对操作参数进行调节随意性较大,易造成生产工况的波动,进而降低烧结机的结块率和烧结块的质量。因此,需要从优化控制角度寻求对策和方法,以达到稳定工艺过程,实现整个烧结生产过程稳顺运行和优质高产的目的。

目前,国内外关于烧结过程控制的研究大多集中在铁矿石烧结控制领域,主要以抽风烧结方式为主,所建立的模型和控制方法仅解决烧结过程中的局部参数优化问题。密闭鼓风铅锌烧结与铁矿石抽风烧结相比工艺更为复杂,对其过程优化控制的技术要求更高。针对铅锌烧结过程的优化控制问题,一些学者进行了有益的研究[2-5],这些方法大多集中在状态参数和综合指标参数的优化控制上。如何通过对烧结过程的综合状况进行评判,并根据当前烧结过程综合工况的实际情况,给出相应的操作指导,对烧结过程的操作参数做出相应调整,进而使烧结状态参数和指标参数达到最优,这是一个亟待解决的实际问题。

本文作者针对上述问题,结合某冶炼厂的实际生产状况,在对铅锌烧结过程工艺和机理进行分析的基础上,建立烧结过程综合工况评判模型,该模型包括如下几个方面:基于BP神经网络的烧结综合透气性预测模型、结合主元分析和神经网络的烧结块产量、含铅量、含硫量的神经网络模型。在综合工况评判模型的基础上,提出基于综合工况评判模型的聚类分析参数优化算法,最后对烧结过程可操作参数实际采样值与优化值、实际工况与优化工况的状态进行了对比分析。

1 铅锌烧结过程机理分析

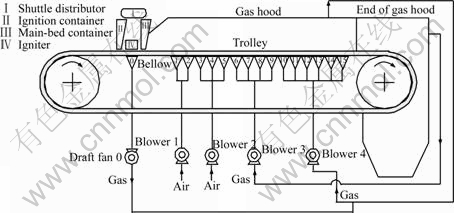

铅锌烧结过程作为铅锌火法冶炼过程的第一道工序,其目的是生产出具有较大强度、孔隙度和还原性且满足鼓风还原熔炼条件的烧结块。烧结过程通常在DL(Dwight-Liyod)型移动带式烧结机中进行,如图1所示。

图1 DL型移动带式鼓风烧结机结构示意图

Fig.1 Schematic structure of Dwight-Liyod sintering machine

铅锌烧结原料经过一次和二次配料以后,粉状混合料经过混料圆筒和制粒圆筒成为具有合适混料水分的混合料料球。混合料料球通过梭式布料机分别送入点火仓和主料仓,点火仓的混合料球布到烧结机的台车上形成约3 cm厚的薄层矿料,称为点火层。点火后的混合料跟随台车一起移动,在烧结机机头后部主料仓再布上混合料,形成约30~40 cm厚的总料层。混合料随台车一起移动,经过烧结过程的如下4个阶段:干燥、加热、反应和烧结过程。混合料料球烧结成为具有一定结构的烧结块料,并在烧结机尾产出。4台风机提供脱硫氧化反应中所需要的氧气和进行必要的热循环。烧结块料经过两级破碎,大小合适的成为烧结块进入熔炼工艺流程;规格不合适的再经过两级破碎成为返粉,重新进入二次配料流程。生成的烟气则由密闭烟罩导出,送制酸系统制酸。

烧结过程的综合工况主要通过烧结料层的透气性、烧结块的产量、烧结块的含硫量和含铅量反映出来。铅锌烧结DL型移动带式烧结机主要有4台鼓风风机对应着15个风箱,1号新鲜风机对应的1号~2号风箱,主要进行物料的干燥和加热,对烧结过程的整体透气性影响较小;2号新鲜风机对应的3号~5号风箱,主要进行物料的氧化脱硫反应,是烧结过程最关键的环节,对整体透气性影响最大;3号返烟风机对应的6号~9号风箱主要进行物料的氧化脱硫和烧结,对整体透气性也有较大的影响;4号返烟风机对应10号~15号风箱,在实际烧结生产中15号风箱没有使用。10号~14号风箱没有支管流量和总管流量检测值,仅有支管压力和总管压力检测值,无法计算对应的透气性,只能获得1号~9号风箱对应位置的透气性。在10号风箱以前,基本上完成烧结过程的干燥、加热、反应和烧结这4个阶段。因此,根据1号~9号风箱位置对应的透气性,可以反映出烧结过程的整体透气性,而3号~9号风箱位置对应的透气性是影响烧结速度、烧结产量质量的最重要因素。

2 基于模型的烧结工况综合评判

烧结工况综合评判模型主要运用智能集成技术[6-7]。首先,结合透气性数学模型建立烧结透气性神经网络模型进行综合透气性预测;然后利用主元分析降维后的变量作为神经网络的输入变量,建立烧结块产量预测模型、烧结块含铅量和含硫量预测模型;最后,通过对大量历史数据的分析处理、结合专家经验确定综合透气性指标、烧结块产量、含铅量、含硫量对烧结工况的加权系数,获得烧结工况综合判断模型,进行工况的整体评判(优、良、中、差),从而确定烧结过程的控制目标函数,为实现智能优化奠定基础。

2.1 综合透气性预测模型

所谓炉料的透气性,是指在烧结机鼓风风箱上,每平方米炉蓖面积每秒钟通过的气体体积(m3)或气体速度(m/s),或者说以单位炉蓖面积上一定厚度的料层在单位时间内通过一定量空气体积时料层的阻力来衡量。在固定风量的条件下,风箱的风压越小,对应的阻力越小,透气性越好。

2.1.1 综合透气性计算公式

反映透气性状况的主要参数有烧结块的产量质量、各风箱位置的风压风量、各位置的烧结温度。烧结块的产量质量不能实时测量,产量每班仅有一个检测数据,烧结块的成分分析每两个小时检测一次。为了反映整个烧结过程透气性状况,引入综合透气性指数的概念。

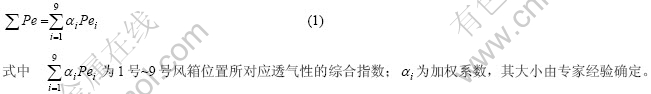

定义:烧结过程透气性综合指数为 ,它反映出整个烧结过程透气性状况,即

,它反映出整个烧结过程透气性状况,即

在实际的生产过程中,操作人员往往主要根据2号风机位置对应3号~5号风箱的风压来判定当前烧结过程的透气性。如果烧结混和料的透气性较差,对应位置的料层阻力增大,即对应位置的风箱压力增大,可由此判定烧结过程透气性的好坏。由上述烧结机理分析可知:1号~2号风箱对烧结过程的整体透气性影响较小,3号~5号风箱影响最大,6号~9号风箱影响较大。考虑到各风箱位置的透气性对整个烧结过程的不同影响程度,综合工艺机理分析和专家经验确定加权系数,采用以下公式计算综合透气性指数,即

根据式(2)就可以求得烧结过程综合的透气性指数,进而建立烧结过程综合透气性指数与工况指数之间的关系。

2.1.2 综合透气性指数的神经网络模型

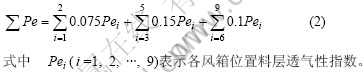

由于神经网络具有以任意精度逼近非线性映射的能力,在工业过程建模中得到广泛应用[8-11]。由于透气性能反映整个烧结过程的状况,为了使现场操作人员及时了解、掌握烧结运行状态,从而及时适度调整操作参数、防止或抑制烧结工况的波动,因此,需要建立综合透气性指数神经网络预测模型,预测下一时刻的综合透气性指数,为参数优化操作指导提供参考。综合透气性指数神经网络预测模型的结构示意图如图2所示。

图2 综合透气性指数神经网络预测模型

Fig.2 Neural network prediction model of integrated permeability index

由图2可知神经网络的输入变量共7个,分别为I1,I2,???,I7。其中I1为前一时刻的综合透气性指数值,I1= ;

; 为1号风机的风量

为1号风机的风量 ;

; 为2号风机的风量

为2号风机的风量 ;

; 为点火温度

为点火温度 ;

; 为台车速度v;

为台车速度v; 精矿返粉比Pro;

精矿返粉比Pro; 为混合料水分

为混合料水分 。7个输入变量对应7个神经元,隐层神经元15个,输出神经元1个(

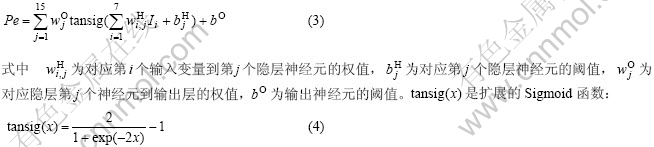

。7个输入变量对应7个神经元,隐层神经元15个,输出神经元1个( )。根据多次训练的结果确定学习速率为0.005。输入层到输出层的激励函数采用tansig函数,隐层到输出层的激励函数采用purelin线性函数,综合透气性指数神经网络预测模型可以表示为

)。根据多次训练的结果确定学习速率为0.005。输入层到输出层的激励函数采用tansig函数,隐层到输出层的激励函数采用purelin线性函数,综合透气性指数神经网络预测模型可以表示为

综合透气性神经网络预测模型采用下式表示:

2.2 烧结块产量质量预测模型

通过对现场数据的分析,影响生产工况和烧结块产量质量的因素很多,为减少建模的复杂性,采用机理分析和主元分析以降低输入变量维数。

通过机理分析得到影响烧结块产量质量的主要因素有:混合料含铅量、含锌量、含硫量、二氧化硅含量、氧化钙含量、含水量、1号新鲜风机风量、2号新鲜风机风量、3号返烟风机风量、4号返烟风机风量、台车速度、精矿流量和返粉流量。

主元分析[12-13]是将研究对象的多个相关变量转化为少数几个不相关变量的一种多元统计分析方法,被视为一种数据减维和揭示变量之间线性相关关系的工具。在机理分析的基础上,通过计算对应的主元矩阵、相关系数矩阵和荷载矩阵,在保证特征抽取率的基础上取前3个主元对输入变量进行相关性分析,最终确定烧结块产量质量模型的输入变量为:混合料含铅量( )、混合料含锌量(

)、混合料含锌量( )、混合料含硫量(

)、混合料含硫量( )、混合料含水量(

)、混合料含水量( )、1号新鲜风机风量(

)、1号新鲜风机风量( )、2号新鲜风机风量(

)、2号新鲜风机风量( )、3号返烟风机风量(

)、3号返烟风机风量( )、台车速度(v)、精矿流量(

)、台车速度(v)、精矿流量( )和返粉流量(

)和返粉流量( )。

)。

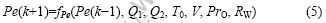

为减小模型的复杂程度,提高网络的收敛速度,统一采用与2.1.2节类似的三层BP神经网络结构(其中输入变量为10个,隐层神经元为23个,输出变量为1个)。令

根据铅锌烧结过程的工艺要求,确定如下约束条件:

将对应于x(RS, RW, QJK, QFF, Q1, Q2, Q3, v)的函数值M称为烧结过程的操作参数优化度,它反映出在操作参数x条件下烧结综合工况的优化程度。

2.3 烧结工况综合评判模型

建立烧结工况综合评判模型,对烧结工况进行综合评判,是实现烧结过程全局优化控制的关键。烧结工况的评判是根据综合透气性、烧结块产量质量来综合判断烧结工况是否正常,并给出操作优化指导,确保烧结过程的稳顺进行。

综合评判是对受到多个因素制约的事物或对象做出一个总的评价,由于从多方面对事物进行评价难免模糊性和主观性,采用模糊数学的方法进行综合评判一一模糊综合评判,将使结果尽量客观,从而取得更好的实际效果。

将综合透气性输出 、烧结块产量预测模型输出

、烧结块产量预测模型输出 、烧结块含铅量预测模型输出

、烧结块含铅量预测模型输出 以及烧结块含硫量预测模型输出

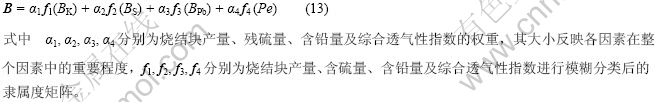

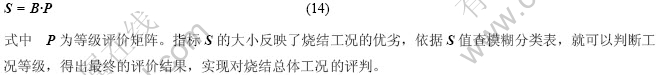

以及烧结块含硫量预测模型输出 作为评价因子,采用模糊综合评判法,按照下式计算反映烧结工况状态的评价向量B,即

作为评价因子,采用模糊综合评判法,按照下式计算反映烧结工况状态的评价向量B,即

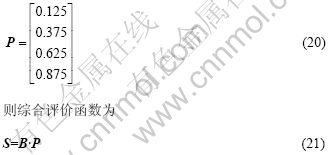

根据评价向量B,计算工况综合评价函数S:

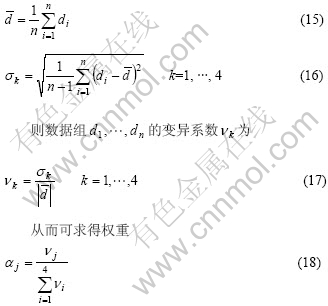

因此,在模糊综合评判中,关键是确定权重分配A = (α1, α2, α3, α4)以及建立单因素评判矩阵F = [f1, f2, f3, f4]T。烧结工况模糊综合评判中参数A,F,B、P及S的计算步骤分别如下所示。

步骤1:确定模糊权重向量A。

本模拟采用变异系数法确定模糊权重向量A,本文共有4个评价指标:烧结块产量、烧结块残硫量、烧结块含铅量和综合透气性指数,因此,需要确定相应的4个权重αi,i=1, 2, 3, 4。对于每个指标数据d1,???, dn,记

步骤2:评语集与隶属函数的确定。

对于每一个评价因素,确定评语集U={差,中,良,优}和隶属函数,以确定各评价因素对评语的隶属度。根据每个评价因素的实际情况,采用三角形隶属函数。

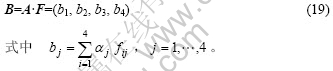

步骤3:模糊评价向量B的生成。

由各指标对评语的隶属度构建模糊评价向量B,即

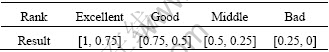

步骤4:建立综合评价函数S。

为了便于得到一个精确的评价结果,设变量数值的范围为:0~0.25(差),0.25~0.5(中),0.5~0.75(良),0.75~1.0(优)。计算各组的中值即可得到如下等级评价矩阵:

再根据S的大小,对照表1得到相应的评语等级,该评语即为烧结综合工况的最终结果。

表1 评价结果与评语等级对照表

Table 1 Contrast between evaluation results and remark ranks

3 基于聚类分析的参数匹配优化算法

在建立烧结过程综合工况评判模型的基础上,获取操作参数进行烧结工况预测,判断当前工况状态是否处于较优的状态,如果当前工况不处于“优”,则调用参数优化算法,给出具体的参数优化值作为优化操作指导,通过调整参数值使当前非“优”的工况趋于较为优化和稳定的状态。

聚类方法分为C均值聚类、模糊C均值聚类和递阶聚类等,在样本分类和方法选择方面已经得到广泛应用[14-16]。本文作者根据聚类原理提出基于模糊C均值聚类并行搜索的匹配优化算法,对铅锌烧结过程优化操作数据库进行寻优,以获得操作参数的最优解。

匹配优化算法的思想是:优化样本集中的样本状态是较优和稳定的,如果当前的控制参数能够向相似的一类样本状态逼近,那么过程状态将趋于稳定和优化。首先建立一个自校正的优化参数样本数据库,作为操作参数优化算法的基础。由于该数据库中的数据可在线更新,随着生产过程的进行,数据量会比较大,为了减少寻优过程中系统的运算时间,运用模糊C均值聚类将样本数据库进行分类,确定出若干个聚类中心,在当前工况样本所属类中进行参数匹配,获得最终参数优化值。优化样本集中的样本状态是较优和稳定的,如果当前的控制参数能够向相似的一类样本状态逼近,那么过程状态将趋于稳定和优化。

该优化算法的实现步骤如下所示。

步骤1:建立铅锌烧结过程优化操作专家样本数据库,用于保存历史上典型工况下的优化操作参数样本。数据库中的过程变量为:1号和2号新鲜风机总管压力p1和p2、风量Q1和Q2;3号返烟风机总管压力p3、风量Q3;10号和11号风箱温度T10和T11;台车速度v;点火温度T0;精矿流量QJK;返粉流量QFF;混合料水分RW。

步骤2:确定样本状态变量。

通过机理分析,确定8个样本状态变量为:混合料含铅量RPb、混合料含锌量RZn、混合料SiO2含量 、1号新鲜风机总管压力p1、2号新鲜风机总管压力p2、3号返烟风机总管压力p3、10号风箱温度T10和11号风箱温度T11。以上参数反映出铅锌烧结过程历史上的典型工况。

、1号新鲜风机总管压力p1、2号新鲜风机总管压力p2、3号返烟风机总管压力p3、10号风箱温度T10和11号风箱温度T11。以上参数反映出铅锌烧结过程历史上的典型工况。

步骤3:采用模糊C均值聚类方法,根据聚类数据对优化操作参数库中的样本进行聚类,将优化样本集分为4大类,对应上述过程变量求得4个聚类中心Ck(i),i = 1,???,N;k = 1,???,4,k为聚类中心个数,N为每一类包含样本的个数。

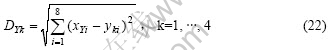

步骤4:计算当前工况样本参数与各类之间的距离,判断当前工况样本所属的类。

设xYi为当前工况样本Y的第i个状态变量,yki为第k类中心相应的状态变量,分别计算Y与第k类的距离DYk:

将DYk排序,记DM = min(DYk)为当前工况样本Y与第k类的最短距离,则当前工况样本应属于距离最短的一类,即 ,i=1,2,???,N)。

,i=1,2,???,N)。

步骤5:在当前工况所在的类中,求取与工况欧氏距离最近的一组样本。

在类 ,i=1,???,N中,计算工况样本Y与该类中第

,i=1,???,N中,计算工况样本Y与该类中第 个样本的欧氏距离DYi,将DYi按照由小到大排序,选取距离最短的样本作为一组优化操作样本:

个样本的欧氏距离DYi,将DYi按照由小到大排序,选取距离最短的样本作为一组优化操作样本:

步骤6:搜寻优化样本。

将 代入综合指标参数优化模型(12)中,可以得到:

代入综合指标参数优化模型(12)中,可以得到:

如果样本 对应的优化度大于当前操作参数的优化度,则可以作为一个优化的操作参数。在遍历搜索优化样本类后,以优化度最高的样本作为最终的优化操作样本,直接作为参数优化操作指导,用于铅锌烧结过程的优化控制。

对应的优化度大于当前操作参数的优化度,则可以作为一个优化的操作参数。在遍历搜索优化样本类后,以优化度最高的样本作为最终的优化操作样本,直接作为参数优化操作指导,用于铅锌烧结过程的优化控制。

4 应用结果与分析

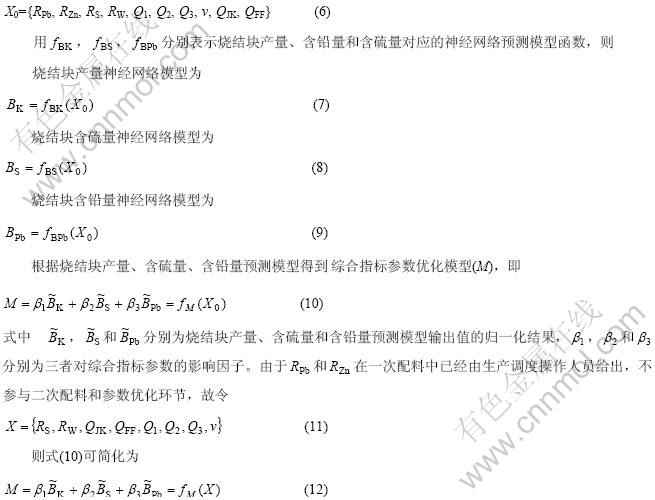

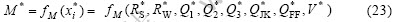

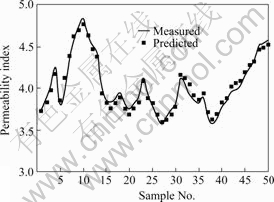

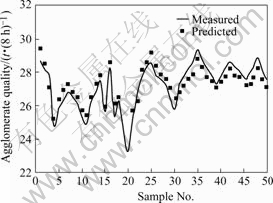

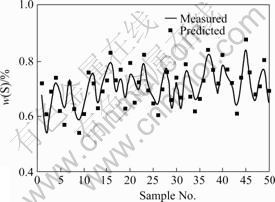

根据某冶炼厂的生产历史数据和实际情况,取2006年3月份的实际运行数据进行分析,分别建立综合透气性指数预测模型、烧结块产量预测模型、烧结块含铅量预测模型和烧结块含硫量预测模型,并将综合透气性指数预测模型、烧结块产量预测模型、烧结块含硫量预测模型和烧结块含铅量预测模型的输出作为评价指标。预测结果如图3~6所示。

图3 综合透气性预测结果

Fig.3 Predictive results of integrated permeability

图4 烧结块产量预测结果

Fig.4 Predictive results of agglomerate quality

图5 烧结块含铅量预测结果

Fig.5 Predictive results of Pb content of agglomerate

图6 烧结块含硫量的预测结果

Fig.6 Predictive results of S content of agglomerate

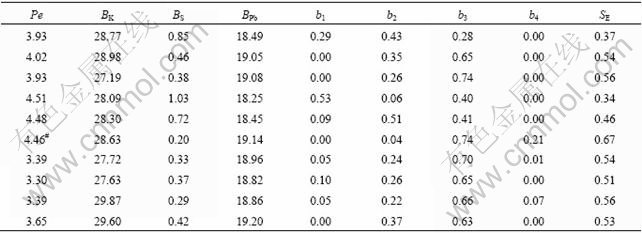

模糊权重向量A由统计方法确定,取100组数据构成矩阵I100×4,其中每一行代表一个样本,每一列代表一个指标。对每一个指标根据式(15)~(18)分别计算权重 ,另外取10组工况数据 I100×4,对每一组样本,按照3.3节中的步骤分别计算每一个指标的隶属度F、模糊评判向量B和综合评价函数S,从而得到如表2所示的烧结工况评判结果。

,另外取10组工况数据 I100×4,对每一组样本,按照3.3节中的步骤分别计算每一个指标的隶属度F、模糊评判向量B和综合评价函数S,从而得到如表2所示的烧结工况评判结果。

表2 烧结工况综合评判结果

Table 2 Compositive evaluation results of sintering status

以表2中带标记“#”的一组数据为例,其综合评价指数为SE=0.67,根据表1可以得到烧结工况综合评判等级为“良”。同时,从该组数据中看到综合透气性指数较高,烧结块含硫量较低,说明该条件下的烧结工况良好,与采用本文综合评判方法所的评判结果相符,说明本文作者提出的工况评判方法有效可行。

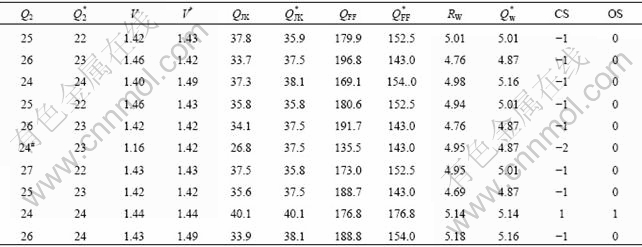

表3所列为可操作参数的实际采样值与优化值、实际工况与优化工况状态的对比说明。其中带有上标“*”的符号表示对应参数的优化值,如 表示通过参数优化算法求出的2号新鲜风机的优化值,依此类推。CS表示在实际参数采样值下工况的综合评价等级,OS表示在优化参数值下烧结工况的评价等级。其中,“-2”表示工况为“差”、“-1”表示工况为“中”、“0”表示工况为“良”、“1”表示工况为“优”。

表示通过参数优化算法求出的2号新鲜风机的优化值,依此类推。CS表示在实际参数采样值下工况的综合评价等级,OS表示在优化参数值下烧结工况的评价等级。其中,“-2”表示工况为“差”、“-1”表示工况为“中”、“0”表示工况为“良”、“1”表示工况为“优”。

表3 部分参数(工况)实际值与优化值对比表

Table 3 Contrast between actual value and optimal value

表3中,以带标记“#”的一组数据为例,在各个参数的实际检测数值下,采用上述工况评判模型得到的结果为“差”,调用本文所提出的优化算法,给出相应的参数优化值,并在此参数优化值下重新利用评判模型对烧结过程的综合工况进行评判,得到的工况等级为“良”。同时,该组数据表明:烧结机的台车速度偏低,投入的精矿量也偏少,需要适当提高台车速度,增加精矿流量,从而可有效地改善铅锌烧结生产工况。

5 结论

1) 采用本文所提基于综合评判模型的工况评判方法可以有效地对烧结生产过程状态进行判断,给出烧结工况等级,为烧结过程全局优化控制奠定了基础。

2) 所提基于聚类分析的参数匹配优化算法可以根据烧结工况的综合评判结果,获得具体的操作参数优化值,作为优化操作指导。通过调整参数值使当前非“优”的工况趋于较为优化和稳定的状态,减少由于操作盲目性造成的生产工况不稳定,进而提高了烧结块的产量和质量。

REFERENCES

[1] 胡军乔, 何 静, 曾令成. ISP烧结工艺的特点及发展趋势[J]. 有色冶炼, 2004, 25(1): 3-5.

HU Jun-qiao, HE Jing, ZENG Ling-cheng. Characters and developing trend of ISP sintering technology[J]. Nonferrous Smelting, 2004, 25(1): 3-5.

[2] WU Min, XU Chen-hua, DU Yu-xiao. Intelligent optimal control for lead-zinc sintering process state[J]. Trans Nonferrous Met Soc China, 2006, 16(4): 975-981.

[3] 杜玉晓, 吴 敏, 桂卫华. 面向生产目标的铅锌烧结过程智能集成建模与优化控制技术[J]. 中国有色金属学报, 2004, 14(1): 142-148.

DU Yu-xiao, WU Min, GUI Wei-hua. Intelligent integrated modeling and optimization control technology of product-orient for lead-zinc sintering process[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 142-148.

[4] WANG Ya-lin, MA Jie, GUI Wei-hua, YANG Cun-hua, ZHANG Chuan-fu. Multi-objective intelligent coordinating optimization blending system based on qualitative and quantitative synthetic model[J]. Journal of Central South University of Technology (English Edition), 2006, 13(5): 552-557.

[5] GUI Wei-hua, WANG Ya-lin, YANG Chun-hua. Composition-prediction-model-based intelligent optimization for lead-zinc sintering blending process[J]. Measurement and Control, 2007, 40(6): 176-181.

[6] CHEN Xiao-fang, GUI Wei-hua, WANG Ya-lin. Integrated modeling method for prediction of sulfur content in agglomerate[J]. Journal of Central South University of Technology (English Edition), 2003, 10(2): 145-150.

[7] 陈明智, 娄寿春, 张多林, 刘志勤. 一个用于反导作战建模与仿真的智能集成模型[J]. 系统仿真学报, 2003, 15(2): 167-170.

CHEN Min-zhi, LOU Shou-chun, ZHANG Duo-lin, LIU Zhi-qin. The intelligent integration model of modeling & simulation for missile defense battle[J]. Journal of System Simulation, 2003, 15(2): 167-170.

[8] Parlos A G. An accelerated learning algorithm for multiplayer perception networks[J]. IEEE Transactions on Neural Networks, 1994, 5(3): 86-88.

[9] WANG Li-po, SHI Hai-xiang. A gradual noisy chaotic neural network for solving the broadcast scheduling problem in packet radio networks[J]. IEEE Transactions on Neural Networks, 2006, 17(4): 989-1000.

[10] 王玉涛, 严其艳, 杨 钢, 徐万仁. 基于主成分分析的动态神经网络预报方法及其应用[J]. 控制与决策, 2006, 21(11): 1312-1320.

WANG Yu-tao, YAN Qi-yan, YANG Gang, XU Wan-ren. Predictive dynamic in neural network method based on principal component analysis and its application[J]. Control and Decision, 2006, 21(11): 1312-1320.

[11] 刘丹红, 张世英. 基于小波神经网络的非线性误差校正模型及其预测[J]. 控制与决策, 2006, 21(10): 1114-1118.

LIU Dan-hong, ZHANG Shi-ying. Nonlinear error correction model and forecasting based on wavelet neural networks[J]. Control and Decision, 2006, 21(10): 1114-1118.

[12] LUO Lin, ZOU Cai-rong, YANG Feng-fan. Modified algorithm of principal component analysis for face recognition[J]. Journal of Southeast University (English Edition), 2006, 22(1): 26-30.

[13] 翟军勇, 费树岷. 基于主元分析的RBF神经网络多模型切换控制[J]. 系统工程与电子技术, 2006, 28(7): 1051-1054.

ZHAI Jun-yong, FEI Shu-min. RBF neural network multiple model switching control based on principal component analysis[J]. Systems Engineering and Electronics, 2006, 28(7): 1051-1054.

[14] WU Xiao-hong, ZHOU Jian-jiang. Alternative possibilitic fuzzy c-means clustering algorithm[J]. Journal of Computational Information Systems, 2006, 2(3): 925-932.

[15] 范九伦, 吴成茂. FCM算法中隶属度的新解释及其应用[J]. 电子学报, 2004, 32(2): 350-352.

FAN Jiu-lun, WU Cheng-mao. The new explanation of membership degree in FCM and its applications[J]. Acta Electronica Sinica, 2004, 32(2): 350-352.

[16] 高新波, 李 洁, 姬红兵. 基于加权模糊C均值聚类与统计检验指导的多阈值图像自动分割算法[J]. 电子学报, 2004, 32(4): 661-664.

GAO Xin-bo, LI Jie, JI Hong-bing. A multi-threshold image segmentation algorithm based on weighting fuzzy C-means clustering and statistical test[J]. Acta Electronica Sinica, 2004, 32(4): 661-664.

基金项目:国家杰出青年科学基金资助项目(60425310)

收稿日期:2007-04-17;修订日期:2007-09-21

通讯作者:吴 敏,教授,博士;电话:0731-8836091; E-mail:min@mail.csu.edu.cn

(编辑 龙怀中)