DOI: 10.11817/j.ysxb.1004.0609.2020-36418

强流脉冲电子束作用下激光熔覆NiCoCrAlYSi涂层组织与性能

高承钻1, 2,蔡 杰1, 2,祖张坤1, 2,李 晨3,关庆丰3,李玉新4

(1. 江苏大学 先进制造与现代装备技术工程研究院,镇江 212013;

2. 江苏大学 机械工程学院,镇江 212013;

3. 江苏大学 材料科学与工程学院,镇江 212013;

4. 中北大学 材料科学与工程学院,太原030051)

摘 要:利用激光熔覆(Laser cladding, LC)技术在镍基高温合金表层制备NiCoCrAlYSi涂层,随后利用强流脉冲电子束(High current pulsed electron beam, HCPEB)技术对熔覆层表面进行辐照处理。利用X射线衍射仪(X-ray diffraction, XRD)、扫描电子显微镜(Scanning electron microscopy, SEM)等仪器观察HCPEB辐照前后激光熔覆层微观结构演变,并对比分析熔覆层表面显微硬度。结果表明:激光熔覆层主要由γ/γ′相构成,表面存在较多孔隙并具有典型的枝晶偏析现象;HCPEB辐照处理后熔覆缺陷消失,表面发生重熔并形成致密的重熔层,且重熔层厚度随辐照次数的增加而逐渐增加。此外,辐照表面诱发产生交滑移及纳米晶结构。表面显微硬度结果显示,HCPEB辐照处理后熔覆层表面硬度显著高于原始样品硬度。

关键词:强流脉冲电子束;激光熔覆;NiCoCrAlYSi涂层;微观结构;显微硬度

文章编号:1004-0609(2020)-07-1634-10 中图分类号:TG174.4 文献标志码:A

为了满足燃气轮机高效率与高推重比要求,涡轮进口温度已经达到甚至远高于高温叶片的最大工作温度,在这种极端的操作环境下仅凭高温叶片本身已经无法保证其力学性能与化学性能稳定。为此,在其表面制备高温防护涂层是一种最为简单且有效的方法[1-2]。MCrAlYX(M=Co、Ni或Ni+Co等,X=Si、Hf等)涂层因具有优异的抗高温氧化性能、耐热腐蚀性能、高热韧性以及成分调节范围广等优点,已成为动力及航空航天领域不可或缺的组成部分。目前,激光熔覆(Laser cladding,LC)技术所制备的涂层因其结合强度高、组织致密细小、成分调整范围广且易实现自动化生产等优点,在制备MCrAlYX涂层方面有着良好的应用前景[3-4]。与热喷涂技术相比,激光熔覆MCrAlYX涂层其硬度及耐磨性均有所提高[5-6]。但是,激光熔覆层也存在一定问题。首先,激光熔覆层容易产生气孔及微裂纹,且易产生组织偏析;其次,激光熔覆层表面十分粗糙,通常需要机加工,因此会产生较大的加工应力并残留加工缺陷。如果能够通过某种表面改性手段来克服这些问题,则可以发挥激光熔覆的长处,进而有效提高MCrAlYX熔覆层的高温防护性能及力学性能。

强流脉冲电子束(High current pulsed electron beam,HCPEB)是一种极具应用前景的高能束表面改性技术[7-8]。通过脉冲电子束辐照材料表面,使材料表面瞬间熔化甚至汽化,然后借助基体快速冷却与定向凝固,并伴随产生高幅值应力,最终实现材料表层净化、成分均匀化、晶粒超细化甚至纳米化以及产生丰富的晶体缺陷和变形结构。目前,国外学者将HCPEB技术多用于金属材料的表面改性中[9-11],以实现其表面净化、晶粒细化以及扩散合金化,进而提高材料的抗腐蚀及耐磨性能。国内有研究者将HCPEB技术运用到等离子喷涂MCrAlYX涂层的改性工作中,研究发现:脉冲电子束技术可以消除热喷涂涂层表面缺陷,得到均匀致密的表面组织并有效细化表层晶粒,进而有效提高涂层的高温防护性能[12-13]。但到目前为止,还缺少HCPEB对MCrAlYX激光熔覆层进行表面处理的相关报道。

鉴于此,本文采用激光熔覆技术制备MCrAlYX熔覆层,并利用HCPEB装置对其表面进行辐照处理。通过表征HCPEB处理前后微观结构的变化,揭示HCPEB与MCrAlYX熔覆层表面的相互作用机理,为利用HCPEB技术提高MCrAlYX熔覆层高温性能提供必要理论及实验储备。

1 实验

选用GH4169镍基高温合金作为基体,对其表面进行打磨并用无水乙醇进行清洗。采用YSL-4000型激光器以四路同轴送粉的方式在基体上制备NiCoCrAlYSi熔覆层,成分见表1。在总结课题组前期实验的基础上进行实验,选择优化的激光熔覆工艺为:功率1.8 kW,速度550 mm/min,光斑直径5 mm,送粉量1.2 r/min,载气量5 L/min,搭接率50%,氦气保护。

表1 NiCoCrAlYSi熔覆层成分组成

Table 1 Chemical composition of NiCoCrAlYSi cladding coating (mass fraction, %)

采用HOPE-I型HCPEB装置对NiCoCrAlYSi熔覆层进行表面辐照处理。在HCPEB处理之前,将熔覆后的样品先进行打磨抛光,以降低表面粗糙度及去除氧化皮的破坏作用,随后对抛光态的熔覆层表面进行HCPEB辐照处理,具体辐照工艺参数为:真空度5.5×10-3,电子束能量27 keV,能量密度4 J/cm2,脉宽1.5 μs,辐照次数15、30及45次。

采用X射线衍射仪(X-ray diffraction,XRD)确定熔覆层的物相结构,采用扫描电子显微镜(Scanning electron microscopy,SEM)与能谱仪(Energy dispersive spectrometer,EDS)观察熔覆层的微观形貌与成分分布。此外,采用显微硬度仪(Hardness tester,HT)观察熔覆层的硬度变化,硬度测试参数为:载荷0.25 N,加载10 s。为减小测量误差,在熔覆层表面选取10个点取其平均值为最终硬度。

2 结果与分析

2.1 激光熔覆层微观形貌分析

图1(a)所示为NiCoCrAlYSi激光熔覆层截面SEM像,熔覆层厚度约1.1 mm。图1(b)所示为图1(a)中局部区域的放大图,可以看出,熔覆层呈现典型的树枝晶形态。激光熔覆过程是急速冷却过程,熔覆层组织的生长受最大温度梯度即最大热流流失方向控制,具有典型的定向凝固特征。在凝固过程中,固液界面形成成分过冷区,溶质原子在界面前沿形核,并沿着优先生长方向在熔体内延伸,进而快速生长成树枝晶结构。

图1 NiCoCrAlYSi熔覆层截面SEM像

Fig. 1 Cross-sectional SEM images of NiCoCrAlYSi cladding coating

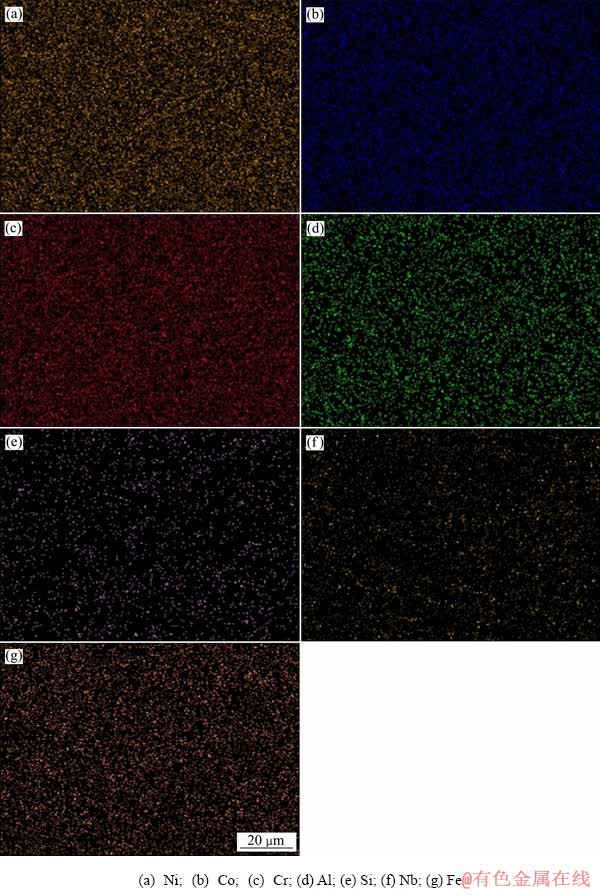

图2所示为打磨抛光后NiCoCrAlYSi熔覆层腐蚀前后的表面形貌。其中,图2(a)所示为熔覆层腐蚀前的原始形貌,可以看出其表面分布着大量的尺寸大小不等的孔隙,这是由于在激光熔覆过程中,熔覆层借助基体与环境快速冷却,粉末中夹杂的气体未能及时排出熔覆层就已经凝固,进而产生的气孔。图2(b)所示为熔覆层经王水腐蚀后的表面形貌,可以看出熔覆层组织主要由基体和白亮的枝晶组织构成。对其进行面扫描分析(见图3)可知,熔覆层成分约为Ni-31%、Co-15%、Cr-29%、Al-7%、Si-3%、Nb-5%、Fe-10%(质量分数)。其中,Nb元素主要富集在白色枝晶处。由于原始熔覆层粉末成分并不含有Nb和Fe,其主要来源于高温合金,说明激光熔覆期间熔覆层成分发生稀释。在前期激光熔覆正交实验中,通过计算发现熔覆层稀释率普遍较高。冯君等[14]在高温合金GH4169镍基高温合金表面对比分析了同轴送粉和压片预置激光熔覆NiCoCrAlY涂层工艺参数对稀释率的影响,发现在保证熔覆层界面能形成良好冶金结合的优选工艺参数条件下,同轴送粉激光熔覆稀释率超过40%。这主要是由于在同轴送粉熔覆过程中,基体与熔覆层粉末吸收能量相差不大。基体吸收能量占比越大,则熔池越深,稀释率也相应越大。因此,在激光熔覆过程中,由于熔覆层与基体间形成对流,基体中Nb、Fe等成分扩散至熔覆层内。激光熔覆在制备Ni基熔覆层时,由于Nb熔点较高,快速凝固过程中先结晶,因此在枝晶处易产生成分偏析。随后,基体中开始析出富γ-Ni相,从EDS结果可知基体成分中Ni、Fe及Cr元素含量较多,这三种元素均属于具有立方晶系的Fe族元素,且Fe与Cr原子半径接近,易形成Ni、Cr及Fe元素富集的γ固溶体。Nb元素是镍基合金最重要的合金元素,不仅可以在Ni-Fe-Cr基奥氏体基体中起到较强的固溶强化作用,提高合金弹性模量,还可以在合金中形成主要的强化相[15-16]。但是,在激光熔覆的过程中,由于Nb元素的偏聚(即构成粗大的柱状树枝晶)会脆化奥氏体晶界,成为该类镍基合金的性能薄弱区,这也限制了激光熔覆技术在镍基合金及其镍基涂层中的进一步应用。

图2 腐蚀前后NiCoCrAlYSi熔覆层表面形貌

Fig. 2 Surface morphologies of NiCoCrAlYSi cladding coating before(a) and after(b) corrosion

图3 图2(b)中NiCoCrAlYSi熔覆层表面EDS面扫描结果

Fig. 3 Surface EDS mapping results of NiCoCrAlYSi cladding coating detected from Fig. 2(b)

2.2 HCPEB处理后熔覆层XRD分析

HCPEB处理前后NiCoCrAlYSi熔覆层的XRD谱如图4所示。NiCoCrAlYSi粉末主要由γ-Ni/γ′-Ni3Al及少量的β-CoAl/NiAl相构成;NiCoCrAlYSi激光熔覆层则主要由γ/γ′相组成。但值得注意的是NiCoCrAlYSi粉末的最强衍射峰是(111)晶面衍射,而激光熔覆后基体相的最强峰为(200),此时,(111)晶面衍射峰则十分微弱,说明激光熔覆导致晶体取向发生变化,凝固时沿低指数晶面(晶向),即[100]方向择优生长成柱状晶(枝晶)。HCPEB处理后,激光熔覆层成分依旧是由γ/γ′相构成,但衍射峰强度再次发生明显变化,即(200)和(220)晶面的衍射峰强度随辐照次数的增加而有所降低,(111)晶面衍射峰强度逐渐增加,说明脉冲电子束处理后熔覆层表面晶体取向再次发生转变,这可能是由于HCPEB处理诱导熔覆层表面产生剧烈塑性变形所致(见图6)。此外,HCPEB辐照处理后熔覆层的衍射峰向高角度发生偏移,根据布拉格公式:

(2dsinθ=nλ), n=1, 2, 3… (1)

式中:d为晶面间距;θ为入射束与反射面的夹角(2θ为衍射角);n为衍射技术(计算时n取1,即一级衍射);λ为X射线波长。可以得出,衍射峰向高角度发生偏移(θ增加),说明γ-Ni基体晶格间距d减小,说明脉冲电子束处理后有新相从基体中脱溶析出,进而导致衍射峰右移,这在后文图8 中的TEM分析中将得到验证;此外,在脉冲电子束冷却过程中,材料表层会形成极高的温度梯度,诱发高幅值残余应力,当晶体受到压缩应力作用时,亦会使基体晶格间距减小,衍射峰右移[17]。

图4 HCPEB处理前后NiCoCrAlYSi熔覆层XRD谱

Fig. 4 XRD patterns of NiCoCrAlYSi cladding coatings before and after HCPEB irradiation

2.3 HCPEB处理后熔覆层微观形貌分析

图5(a)~(c)所示为HCPEB辐照15、30、45次后NiCoCrAlYSi熔覆层表面的金相形貌。可以看出,15次辐照处理后,熔覆层表面出现较多尺寸约为80 μm的火山坑状形貌,即熔坑。由于HCPEB辐照后,样品次表层的物质率先熔化,体积发生膨胀从材料内部喷发而出,进而使材料表面产生了这种类似火山喷发状的熔坑[18]。由于材料表层的夹杂物和第二相颗粒熔点相对更低,将会首先喷发,进而对材料表面起到选择性净化的作用[19]。辐照15次的样品熔坑数量较多且不均匀,辐照30次的样品表面熔坑数量明显下降,辐照45次后样品表面的熔坑几乎消失。图5(d)所示为不同辐照次数下的熔坑密度,可以看出,辐照次数与熔覆层表面的熔坑密度成负相关,即熔坑密度随着辐照次数的增加而逐渐降低,熔覆层表面也因此变得更加平整,这主要是由于最初形成的熔坑在随后的辐照过程 中得到了熔合,并且在辐照的过程中先前杂质区得到了喷发与净化,从而降低了熔覆层表面熔坑的形成几率。

图5 HCPEB不同辐照次数下NiCoCrAlYSi熔覆层的表面光镜与熔坑密度

Fig. 5 Surface optical microscope images of HCPEB irradiated NiCoCrAlYSi cladding coatings with different pulses and crater density

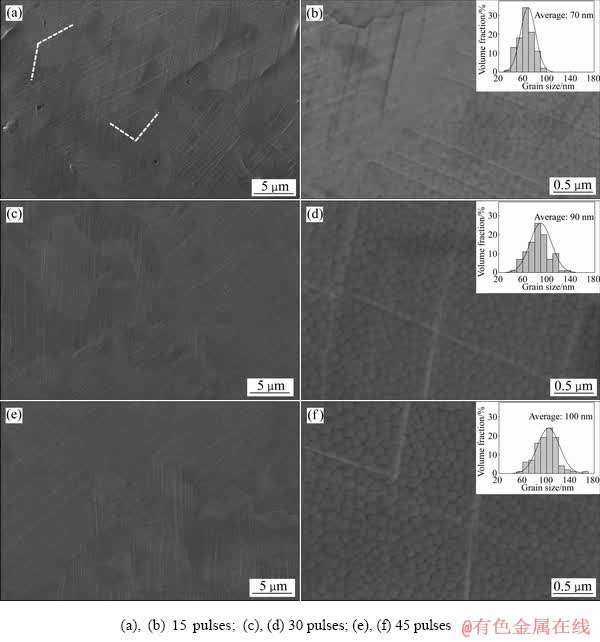

图6所示为HCPEB不同辐照次数下NiCoCrAlYSi熔覆层表面的SEM像。可以看出,随辐照次数增加,熔覆层表面逐渐变得平整、致密,之前残留的微小孔洞完全消失。此外,HCPEB辐照处理后还在熔覆层表面诱发大量的滑移带等变形结构,如图6(a)~(c)所示,滑移带方向不尽相同,相互之间存在一定夹角,角度主要为90o或60o/120o两种。XRD中所产生的晶体取向变化则与位错滑移有关。根据XRD分析可知,熔覆层γ基体为典型的面心立方结构(FCC),且脉冲处理后出现{111}晶面的择优取向。FCC结构的滑移系为{111}/ ,即位错在密排面{111}上沿原子最密集方向

,即位错在密排面{111}上沿原子最密集方向 晶向进行滑移。若多个滑移系同时开动,则会从不同的

晶向进行滑移。若多个滑移系同时开动,则会从不同的 方向观察到不同的滑移线角度,即90o或60o/120o。由此判断,HCPEB辐照处理后会在材料表层诱发高幅值残余应力而造成表面多滑移系同时开动,产生交滑移。图6(d)~(f)所示为图6(a)~(c)局部区域的放大形貌,可见经不同次数HCPEB辐照处理后,原始激光熔覆层表面枝晶偏析现象完全消失,熔覆层表面形成大量的纳米晶结构,经过定量分析测得15次辐照处理后,晶粒尺寸约70 nm;经过30次辐照处理后,晶粒尺寸约90 nm;经过45次辐照处理后,晶粒尺寸约100 nm。在HCPEB辐照过程中,高能电子束使熔覆层表面瞬间熔化并借助自身导热迅速凝固。在凝固初期,且液态熔体中固溶的其他元素可以提供熔覆层异质形核核心,从而导致熔覆层在凝固过程中形成大量的晶核,而这些晶核来不及长大进而形成如图所示的纳米晶。随着辐照次数的增加,熔覆层表层累积的能量逐渐增加,其表层受热时间相对延长,熔覆层也具有更大的熔池深度,因此,晶粒长大时间较低次数辐照有所延长,晶粒尺寸也相对较大。此外,在极为快速的凝固过程中,极高的冷凝速度使得合金元素来不及析出,进而可以有效地消除枝晶偏析,使合金熔覆层微观成分更加均匀。

方向观察到不同的滑移线角度,即90o或60o/120o。由此判断,HCPEB辐照处理后会在材料表层诱发高幅值残余应力而造成表面多滑移系同时开动,产生交滑移。图6(d)~(f)所示为图6(a)~(c)局部区域的放大形貌,可见经不同次数HCPEB辐照处理后,原始激光熔覆层表面枝晶偏析现象完全消失,熔覆层表面形成大量的纳米晶结构,经过定量分析测得15次辐照处理后,晶粒尺寸约70 nm;经过30次辐照处理后,晶粒尺寸约90 nm;经过45次辐照处理后,晶粒尺寸约100 nm。在HCPEB辐照过程中,高能电子束使熔覆层表面瞬间熔化并借助自身导热迅速凝固。在凝固初期,且液态熔体中固溶的其他元素可以提供熔覆层异质形核核心,从而导致熔覆层在凝固过程中形成大量的晶核,而这些晶核来不及长大进而形成如图所示的纳米晶。随着辐照次数的增加,熔覆层表层累积的能量逐渐增加,其表层受热时间相对延长,熔覆层也具有更大的熔池深度,因此,晶粒长大时间较低次数辐照有所延长,晶粒尺寸也相对较大。此外,在极为快速的凝固过程中,极高的冷凝速度使得合金元素来不及析出,进而可以有效地消除枝晶偏析,使合金熔覆层微观成分更加均匀。

图7所示为不同辐照次数下NiCoCrAlYSi熔覆层经王水腐蚀后的截面形貌。经15次HCPEB辐照后,熔覆层表面形成了一层十分均匀的且厚度相对较薄的致密重熔层,且随着辐照次数的增加,重熔层厚度逐渐增加,经15次辐照后,重熔层的2.9 μm增加至45次辐照后的5.7 μm。

2.4 TEM分析

图6 HCPEB不同辐照次数下NiCoCrAlYSi熔覆层的表面形貌

Fig. 6 Surface morphologies of HCPEB irradiated NiCoCrAlYSi cladding coatings with different pulses

图7 HCPEB不同辐照次数下NiCoCrAlYSi熔覆层截面的SEM像

Fig. 7 Cross-sectional SEM images of HCPEB irradiated NiCoCrAlYSi cladding coatings with different pulses

图8所示为NiCoCrAlYSi熔覆层表面TEM像及相应的选取电子衍射图。图8(a)~(b)所示为原始熔覆层TEM形貌,可以看出,原始涂层晶粒尺寸较大,存在低密度位错缠结,局部区域发现尺寸较大的第二相析出,经过选区电子衍射分析可知,其主要为Fe2Nb和CoNb相,由此也说明在激光熔覆过程中熔覆层成分发生稀释。经15次HCPEB处理后,重熔层内部呈现两种截然不同的组织结构,即图8(c)所示的多晶(纳米晶)组织,其衍射斑点呈典型的多晶衍射环,标定结果显示其主要为γ-Ni基体以及Co-Fe相,由此说明,HCPEB辐照过程中,材料表层会有Co-Fe相析出;另一典型形貌为图8(d)所示的规则排列的胞状组织,其大小在100 nm以内,呈多晶态组织特征,但该区域衍射图谱显示其为典型的点阵斑点,说明此区域胞状晶粒之间并无取向差,对其进行标定得知,该区域主要为γ-Ni基体。如前所述,HCPEB辐照诱发的快速加热和冷却是实现表层晶粒细化及成分均匀化的主要因素。HCPEB辐照过后,材料表层快速加热并急速冷却,冷却速度高达107~109 K/s,并形成极高的温度梯度及超高应变速率,这势必会在材料表层形成极端的非平衡相变过程,使其呈现特殊的凝固特征[11, 20]。从图8中可以看出,不同区域材料表层呈现不同的凝固特征。图8(c)所示的多晶组织位于熔化层的最表层,为典型的晶体平面生长方式,即晶体快速形核并沿不同取向分布。图8(d)所示的胞晶组织应该位于熔化层次表层,该区域凝固速度稍晚于多晶区域的,且凝固释放的结晶潜热使熔池温度有所回升,进而导致该区域温度梯度及晶粒生长速度均有所降低,从而形成胞状晶组织。从图8(c)~(d)中可以看出,原始涂层中由于元素偏析所产生的较大的第二相颗粒及其枝晶偏析重新固溶到γ基体中,最终实现表层成分均匀化。

图8 HCPEB辐照前后NiCoCrAlYSi熔覆层表面TEM像

Fig. 8 Surface TEM images of NiCoCrAlYSi cladding coatings before and after HCPEB irradiation

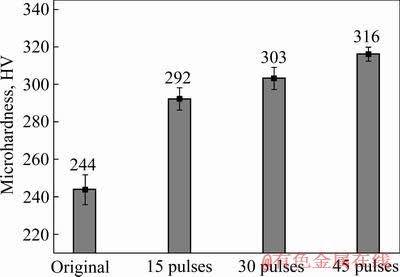

2.5 表面显微硬度

图9所示为HCPEB不同辐照次数下NiCoCrAlYSi熔覆层表面的显微硬度。原始熔覆层表面显微硬度平均值为244HV,15次HCPEB辐照后,硬度增加至292HV;30次辐照后,硬度增加至303HV;45次辐照后,硬度达到最高值316HV,相对于原始熔覆层其表面显微硬度提高了约30%。HCPEB处理后熔覆层表面硬度的增加主要有以下3点原因:首先,HCPEB辐照在熔覆层表面诱发了平均尺寸小于100 nm的纳米晶结构,这些纳米晶可以显著提高材表面的屈服强度,并使熔覆层表面硬度提高,即细晶强化效应;其次,经过HCPEB辐照处理后,重熔层中部分Nb、Cr等元素固溶到基体(Ni)中,元素固溶引起的点阵畸变提高了熔覆层的表面硬度,即固溶强化效应;再者,HCPEB辐照处理在熔覆层表面诱发高幅值残余应力而使表面产生强烈的塑性变形,高密度位错缠结结构阻碍了位错的运动,进而有效提高了熔覆层表面的硬度,即位错强化效应。因此,在细晶强化、固溶强化及位错强化的协同作用下,HCPEB处理后熔覆层表面硬度显著提高。

从高温防护性能角度分析,熔覆层表面形成的高密度位错缠结及纳米晶结构可以有效促进保护性氧化膜形成元素Al或Cr的选择性扩散速率[21-22],且熔覆层表面成分均匀化可以防止氧化膜成分不均,获得更加均匀致密的保护性氧化膜[23]。此外,也有研究者认为,熔覆层表面晶粒细化可以增加氧化膜的蠕变速率从而释放氧化膜内应力[24-25]。由此可见,HCPEB辐照处理后熔覆层表面微观结构演变对提高熔覆层力学性能、抗高温氧化寿命及耐热腐蚀性能均具有积极作用。

图9 HCPEB不同辐照次数下NiCoCrAlYSi熔覆层表面的显微硬度

Fig. 9 Surface microhardness of HCPEB irradiated NiCoCrAlYSi cladding coatings with different HCPEB pulses

3 结论

1) NiCoCrAlYSi熔覆层主要由γ-Ni相构成,具有典型的枝晶偏析现象,且熔覆层表面存在有较多孔隙。HCPEB辐照处理后,熔覆层相结构不变,但产生{111}晶面择优取向;熔覆层表面发生重熔,表面孔隙及枝晶偏析现象消失,不同辐照次数下表面形成了平均尺寸小于100 nm的纳米晶,且辐照诱发的高幅值应力使表层产生交滑移;随辐照次数的增加,重熔层厚度由15次辐照后的2.9 μm增加至45次辐照后的5.7 μm。TEM结果显示,原始涂层内部存在尺寸较大的第二相颗粒,HCPEB处理后,重熔层内部呈现两种典型的凝固组织,即胞状组织及纳米晶组织,涂层成分趋于均匀化。

2) NiCoCrAlYSi熔覆层表面显微硬度为244HV,15次HCPEB辐照处理后,显微硬度值增加至292HV;30次辐照处理后,增加至303HV;45次辐照后,显微硬度值最大,达到316HV。HCPEB辐照处理诱发的细晶强化、固溶强化及位错强化效应是熔覆层表面硬度提升的主要原因。

REFERENCES

[1] 张天佑, 吴 超, 熊 征, 周圣丰. 热障涂层材料及其制备技术的研究进展[J]. 激光与光电子学进展, 2014, 51(3): 31-36.

ZHANG Tian-you, WU Chao, XIONG Zhen, ZHOU Sheng-feng. Research progress in materials and preparation techniques of thermal barrier coatings[J]. Laser & Optoelectronics Progress, 2014, 51(3): 31-36.

[2] 刘纯波, 林 锋, 蒋显亮. 热障涂层的研究现状与发展趋势[J]. 中国有色金属学报, 2007, 17(1): 1-13.

LIU Chun-bo, LIN Feng, JIANG Xian-liang. Current state and future development of thermal barrier coating[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 1-13.

[3] 王东生, 田宗军, 沈理达, 黄因慧. 激光熔覆MCrAlY涂层的研究现状[J]. 机械工程材料, 2013, 37(12): 1-5.

WANG Dong-sheng, TIAN Zong-jun, SHEN Li-da, HUANG Yin-hui. Research status of MCrAIY coatings prepared by laser cladding[J]. Materials for Mechanical Engineering, 2013, 37(12): 1-5.

[4] TOBAR M J, AMADO J M, YAnEZ A, PEREIRA J, AMIGo V. Laser cladding of MCrAlY coatings on stainless steel[J]. Physics Procedia, 2014, 56: 276-283.

[5] WANG Hong-yu, ZUO Dun-wen, WANG Ming-di, SUN Gui-fang, MIU Hong, SUN Yu-li. High temperature frictional wear behaviors of nano-particle reinforced NiCoCrAlY cladded coatings[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1322-1328.

[6] 郭 纯, 陈建敏, 姚润钢, 周健松. 激光熔覆NiCoCrAlY/ZrB2复合涂层结构及高温耐磨性能[J]. 稀有金属材料与工程, 2013, 42(8): 1547-1551.

GUO Chun, CHEN Jian-min, YAO Run-gang, ZHOU Jian-song. Microstructure and high temperature wear resistance of laser cladding NiCoCrAlY/ZrB2 coating[J]. Rare Metal Materials and Engineering, 2013, 42(8): 1547-1551.

[7] GUAN Q F, ZOU H, ZOU G T, WU A M, HAO S Z, ZOU J X, QIN Y, DONG C, ZHANG Q Y. Surface nanostructure and amorphous state of a low carbon steel induced by high-current pulsed electron beam[J]. Surface & Coatings Technology, 2005, 196(1/3): 145-149.

[8] QIN Y, ZOU J X, DONG C, WANG X G, WU A, LIU Y, HAO S Z, GUAN Q F. Temperature–stress fields and related phenomena induced by a high current pulsed electron beam[J]. Nuclear Instruments & Methods in Physics Research, 2004, 225(4): 544-554.

[9] Lü P, SUN X, CAI J, ZHANG C L, LIU X L, GUAN Q F. Microstructure and high temperature oxidation resistance of nickel based alloy GH4169 irradiated by high current pulsed electron beam[J]. Surface and Coatings Technology, 2017, 309: 401-409.

[10] ZHANG T C, ZHANG K M, ZOU J X, YAN P, YANG H Y, SONG L X, ZHANG X. Surface microstructure and property modifications in a Mg-8Gd-3Y-0.5Zr magnesium alloy treated by high current pulsed electron beam[J]. Journal of Alloys and Compounds, 2019, 788: 231-237.

[11] SAMIH Y, MARCOS G, STEIN N, ALLAIN N, FLEURY E, DONG C, GROSDIDIER T. Microstructure modifications and associated hardness and corrosion improvements in the AISI 420 martensitic stainless steel treated by high current pulsed electron beam(HCPEB)[J]. Surface and Coatings Technology, 2014, 259: 737-745.

[12] 韩志勇, 韩 剑. 强流脉冲电子束作用下CoCrAlY熔敷铝膜的表面微观形貌和元素分布[J]. 河北师范大学学报(自然科学版), 2017, 41(2): 134-138.

HAN Zhi-yong, HAN Jian. The distribution of element and morphology of aluminized CoCrAlY coating irradiated by HCPEB[J]. Journal of Hebei Normal University(Natural Science Edition), 2017, 41(2): 134-138.

[13] 蔡 杰. 强流脉冲电子束作用下热障涂层热生长氧化物生长行为与应力状态[D]. 镇江: 江苏大学, 2015.

CAI Jie. Growth behavior and stress characteristics of thermally grown oxide in thermal barrier coatings irradiated by high current pulsed electron beam[D]. Zhenjiang: Jiangsu University, 2015.

[14] 冯 君, 田宗军, 王东生, 杨友文. 同轴送粉和压片预置激光熔覆NiCoCrAlY涂层工艺比较[J]. 应用激光, 2015, 35(1): 29-34.

FENG Jun, TIAN Zong-jun, WANG Dong-sheng, YANG You-wen. Process comparison between coaxial powder feeding and squash presenting laser cladding NiCoCrAlY coatings[J]. Applied Laser, 2015, 35(1): 29-34.

[15] 曹国鑫, 张麦仓, 董建新, 姚志浩, 郑 磊. Nb含量对GH4169合金钢锭凝固及均匀化过程相演化规律的影响[J]. 稀有金属材料与程, 2014, 43(1): 103-108.

CAO Guo-xin, ZHANG Mai-cang, DONG Jian-xin, YAO Zhi-hao, ZHENG Lei. Effects of Nb content variations on precipitates evolution of GH4169 ingots during their solidification and homogenization processes[J]. Rare Metal Materials and Engineering, 2014, 43(1): 103-108.

[16] LIN Y C, HE M, CHEN M S, WEN D X, CHEN J. Effects of initial δ phase (Ni3Nb) on hot tensile deformation behaviors and material constants of Ni-based superalloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 107-117.

[17] GONG M F, CHEN J, DENG X, WU S H. Sliding wear behavior of TiAlN and AlCrN coatings on a unique cemented carbide substrate[J]. International Journal of Refractory Metals and Hard Materials, 2017, 69: 209-214.

[18] ZHANG L Y, PENG C T, YAO X W, GUAN Q F, LU R F. Surface alloying of Cr on Ti6Al4V alloy induced by high-current pulse electron beam[J]. Surface and Coatings Technology, 2019, 370: 288-297.

[19] ZOU J, ZHANG K, DONG C, QIN Y, HAO S Z, GROSDIDIER T. Selective surface purification via crater eruption under pulsed electron beam irradiation[J]. Applied Physics Letters, 2006, 89(4): 041913.

[20] GAO Y K. Surface modification of TC4 titanium alloy by high current pulsed electron beam(HCPEB) with different pulsed energy densities[J]. Journal of Alloys and Compounds, 2013, 572: 180-185.

[21] LIU Z Y, GAO W, DAHM K, WANG F H. The effect of coating grain size on the elective oxidation behavior of Ni-Cr-Al alloy[J]. Scripta Materialia, 1997, 37(10): 1551-1558.

[22] CHEN Y, ZHAO X F, XIAO P. Effect of microstructure on early oxidation of MCrAlY coatings[J]. Acta Materialia, 2018, 159: 150-162.

[23] CAI J, YANG S Z, JI L, GUAN Q F, WANG Z P, HAN Z Y. Surface microstructure and high temperature oxidation resistance of thermal sprayed CoCrAlY coating irradiated by high current pulsed electron beam[J]. Surface and Coatings Technology, 2014, 251: 217-225.

[24] TOLPYGO V K, CLARKE D R. Competition between stress generation and relaxation during oxidation of an Fe-Cr-Al-Y alloy[J]. Oxidation of Metals, 1998, 49(1/2): 187-212.

[25] CAI J, Lü P, GUAN Q F, XU X J, LU J Z, WANG Z P, HAN Z Y. Thermal cycling behavior of thermal barrier coatings with MCrAlY bond coat irradiated by high-current pulsed electron beam[J]. ACS Applied Materials & Interfaces, 2016, 8(47): 32541-32556.

Microstructure and properties of laser cladding NiCoCrAlYSi coating irradiated by high current pulsed electron beam

GAO Cheng-zuan1, 2, CAI Jie1, 2, ZU Zhang-kun1, 2, LI Chen3, GUAN Qing-feng3, LI Yu-xin4

(1. Engineering Institute of Advanced Manufacturing and Modern Equipment Technology, Jiangsu University, Zhenjiang 212013, China;

2. School of Mechanical Engineering, Jiangsu University, Zhenjiang 212013, China;

3. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

4. School of Materials Science and Engineering, North University of China, Taiyuan 030051, China)

Abstract: The NiCoCrAlYSi coating was prepared on the surface of nickel-based superalloy by laser cladding(LC) technique, and then was irradiated by high current pulsed electron beam(HCPEB). X-ray diffraction(XRD) and scanning electron microscopy(SEM) were used to compare the microstructure evolution of the laser cladding coating before and after HCPEB irradiation. The surface microhardness of the cladding coating was also analyzed. The microstructural results show that the cladding coating is mainly composed of γ/γ′ phase. Many pores and typical dendritic segregation are found on the surface. After HCPEB treatment, the cladding defects disappear. The surface is remelted, and the thickness of the remelted layer gradually increase with the increase of HCPEB pulses. Besides, the cross-slip and nanocrystalline structures are induced on the irradiated surface. The surface microhardness results show that the surface hardness of the cladding coating after HCPEB treatment is significantly higher than that of the original sample.

Key words: high current pulsed electron beam; laser cladding; NiCoCrAlYSi coating; microstructure; microhardness

Foundation item: Projects(51601072, U1810112)supported by the National Natural Science Foundation of China; Project(BK20160530) supported by the Jiangsu Natural Science Foundation-Youth Foundation, China; Project supported by the Young Talents Training Program of Jiangsu University, China

Received date: 2019-06-18; Accepted date: 2019-10-30

Corresponding author: CAI Jie; Tel: +86-511-88797906; E-mail: caijie@ujs.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51601072,U1810112);江苏省自然科学基金-青年基金资助项目(BK20160530);江苏大学青年英才培育计划资助项目

收稿日期:2019-06-18;修订日期:2019-10-30

通信作者:蔡 杰,副研究员,博士;电话:0511-88797906;E-mail:caijie@ujs.edu.cn