文章编号:1004-0609(2011)06-1342-06

初始制备状态对Ni3Al表面纳米结构组织的影响

任江伟1,单爱党2

(1. 上海工程技术大学 材料工程学院,上海 201620;

2. 上海交通大学 材料科学与工程学院,上海 200240)

摘 要:采用表面机械研磨技术在定向凝固态和铸造态Ni3Al表面制备纳米结构表层,采用扫描电镜、XRD和TEM等对纳米结构表层的组织特征进行研究,探讨定向凝固和铸造两种制备状态对Ni3Al表面纳米结构组织特征的影响。结果表明:经过相同工艺表面机械研磨处理后,两种制备状态的Ni3Al发生了无序化转变和晶粒细化,但两者的表层组织特征间存在显著差异;铸造态Ni3Al试样中Ni(Al)固溶体的含量达65%,远高于定向凝固态Ni3Al试样中的7%;铸造态试样表层的晶粒尺寸约为56 nm,远大于定向凝固态试样的22 nm;两种Ni3Al试样制备态时,化学成分和显微硬度的差异可能是造成这种差异的原因。

关键词:金属间化合物;Ni3Al;表面机械研磨处理;塑性变形;微观组织

中图分类号:TG146.1 文献标志码:A

Influence of initial state on microstructure of

surface nanocrystallized Ni3Al

REN Jiang-wei1, SHAN Ai-dang2

(1. College of Materials Engineering, Shanghai University of Engineering Science, Shanghai 201620, China;

2. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The influence of two initial states, such as directional solidified and as-cast, on the microstructure of surface of nanocrystallized Ni3Al was investigated. The nanostructure layers were prepared on the surface of Ni3Al with different initial states by means of surface mechanical attrition treatment (SMAT). The characteristics of surface nanostructure layer were examined by scanning electronic microscopy (SEM), X-ray diffractometry (XRD) and transmission electronic microscopy (TEM). The results indicate that the transformations, such as disordering and grain refining, occur in all samples with different initial states after surface mechanical attrition treatment. However, obvious difference exists in the relative content of solid solution and the grain size of Ni3Al nanograins between the samples with two initial states. The Ni(Al) solid solution of as-cast Ni3Al surface reaches 65% and the grain size is about 56nm after surface mechanical attrition treatment. The directional solidified Ni3Al has less Ni(Al) solid solution (7%) and smaller grains (abut 22nm). This phenomenon may be attributed to the difference of the two initial states in chemical composition and microhardness.

Key words: intermetallic; Ni3Al; surface mechanical attrition treatment; plastic deformation; microstructure

纳米晶材料以其新颖结构特征和力学、物理、化学等性能特征而受到广大研究者的极大关注[1]。但是纳米晶材料的广泛应用受到了大尺寸块体材料制备困难等因素的制约。在结构件的实际使用中,材料除了要满足结构强度、刚度、抗疲劳等性能要求外,还需要考虑抗摩擦磨损和介质腐蚀等性能。表面改性可以提高零部件表面的耐磨、抗腐蚀、抗疲劳、抗氧化等性能,进而有效提高材料和结构的整体性能,因此具有良好的应用前景[2]。

表面机械研磨技术使材料中产生强烈塑性变形,形成自表面至基体的梯度组织结构。该技术可应用于机械零部件表面的局部,借助表层纳米结构的独特组织和性能,改善和提高材料表面及整体的性能[3-4]。采用表面机械研磨技术已经在Fe、Al、Cu、Ti和Zr等纯金属[5-9]和低碳钢、不锈钢和Ni3Al等合金[10-13]上制备表面纳米结构。但在大量的表面机械研磨技术研究中,研究的重点主要集中在工艺参数的影响、细化组织的演变及形成机制和表面纳米晶的力学和物理性能上,材料初始制备状态对材料表面强化组织特征的影响还鲜见报道。而材料初始状态对晶粒细化的启动和表面强化组织的形成具有非常重要的影响。本文作者针对Ni3Al金属间化合物研究定向凝固态和铸造态两种制备状态对其表面纳米结构组织特征的影响。

1 实验

实验中制备了两种状态的Ni3Al金属间化合物:一种状态为定向凝固态,其化学成分为71.92Ni-18.10Al-8.04Cr-1.12Zr-0.82B(摩尔分数,%);另外一种状态为铸造态,其化学成分为75.9Ni-24.0Al-0.1B(摩尔分数,%)。铸造态Ni3Al试样经过真空熔炼浇铸和1 200 ℃、8 h均匀化退火处理。两种状态的Ni3Al试样均直接制备成块状,并采用600#砂纸打磨表面以备后续的表面机械研磨处理。

本文作者采用表面机械研磨处理(Surface mechanical attrition treatment,SMAT)工艺在Ni3Al表面制备纳米结构表层。表面机械研磨处理的工作原理参见文献[4]。本研究采用的表面机械研磨处理工艺参数如下:钢球直径8 mm,振动幅度为25 mm,振动频率为50 Hz,处理时间为60 min,真空度为1.13×104 Pa。

对定向凝固态和铸造态Ni3Al的初始制备状态和表面处理态的微观组织特征进行表征。在HITACHI S-4200型扫描电子显微镜上观察制备态时Ni3Al试样的组织形貌,工作电压为10 kV。微观组织观察前试样经过常规机械研磨、抛光和腐蚀。采用Rigaku PRINT 2200/PC X射线衍射仪对初始制备态试样的相结构以及表面处理态试样表面纳米层的相结构和晶粒结构进行分析。XRD测试时采用Cu靶,管压40 kV,管流40 mA,步进角0.02°。根据X射线衍射谱线形的宽化,在Materials Data JADE 5.0上采用Scherre- Willson方程对晶粒尺寸和微观应变进行计算:

式中:B(S)为样品衍射峰的宽度;λ为X射线波长;K为晶格常数的形状因子;d为晶粒尺寸;ε为微观应变。采用JEOL JEM-200CX透射电镜(TEM)对表面处理态Ni3Al的表面纳米结构层进行观察,工作电压为160 kV。为了观察最表层纳米结构的组织特征,TEM薄膜试样制备过程中从基体侧进行机械减薄和离子减薄,以确保观察到最表层的晶粒特征。在AKASHI MVK-H21型显微硬度测试仪上测试定向凝固态和铸造态Ni3Al初始制备状态时的显微硬度,载荷为2 N,加载时间为15 s。显微硬度值为任意7点硬度的平均值。

2 结果与讨论

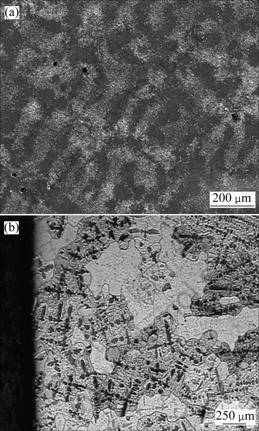

定向凝固态和铸造态Ni3Al初始制备态时的微观组织如图1所示。从图1可以看出,定向凝固态组织具有较强的方向性。组织由完整晶粒区和晶间碎晶区构成。晶粒在长度方向上约280 ?m,在宽度方向上约70 ?m。而铸造态时组织成分不均匀,在晶粒内部存在成分偏析。为此,对铸造态试样进行了1 200 ℃、8 h均匀化退火,消除了宏观的成分偏析,获得平均晶粒尺寸约200 ?m的均匀组织。

图1 定向凝固态和铸造态Ni3Al初始制备态时的微观组织

Fig.1 Microstructures of directional solidified (a) and as-cast (b) Ni3Al in initial state

定向凝固态和铸造态Ni3Al初始制备状态时的XRD谱如图2所示。从图2可以看出,定向凝固态和铸造态Ni3Al均为单相结构。相对于铸造态而言,试样的X射线衍射峰比较少,可能是因为存在织构。

图2 定向凝固态和铸造态Ni3Al初始制备态时的XRD谱

Fig.2 XRD patterns of directional solidified (a) and as-cast (b) Ni3Al in initial state

显微硬度测试结果显示,制备态时定向凝固态Ni3Al的硬度为335 MPa,高于铸造态Ni3Al的硬度(221 MPa)。

经过60 min表面机械研磨处理后,Ni3Al表层组织发生了显著的变化。表面纳米结构层的XRD谱如图3所示。

从图3可以看出,经过强烈塑性变形后,两种状态Ni3Al试样中都出现了Fe相和Ni相的衍射峰。试样中Fe相衍射峰的出现是由于在表面机械研磨处理时,钢球中的Fe原子通过变形和扩散进入Ni3Al试样中造成的。在Zr的表面机械研磨过程中,由于钢球中的Fe和Cr原子快速地从钢球中扩散到Zr表面,形成了FeCr金属间化合物[9]。纳米晶中包含的较大体积比晶界可以为扩散提供快速通道[14-15]。此外,存储在非平衡晶界中的能量可能会降低缺陷形成所需要的能量,从而促进其沿晶界的扩散,或者成为形成固溶体的驱动力[16]。Ni3Al的表面机械研磨过程中没有形成Fe基化合物,则可能是由于Fe/Ni、Fe/Al之间焓差比较高造成的。因为在固态反应中,是否形成化合物取决于两种元素间焓的差异[17]。

图3 定向凝固态和铸造态Ni3Al表面处理后的XRD谱

Fig.3 XRD patterns of directional solidified (a) and as-cast (b) Ni3Al after surface mechanical attrition treatment

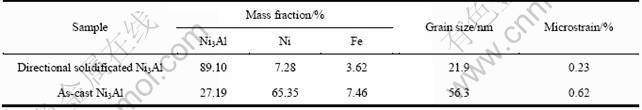

Ni相衍射峰的出现表明,在强烈塑性变形过程中Ni3Al相发生了无序化转变,即由L12有序结构的Ni3Al转变为FCC结构的无序Ni(Al)固溶体。根据XRD衍射谱计算得到的各相的构成见表1。由表1可看出,铸造态Ni3Al试样中Ni(Al)固溶体的含量达65%,远高于定向凝固态Ni3Al试样中的含量(约7%)。

此外,两种制备状态试样中Ni3Al相的衍射峰都发生明显的宽化现象。X射线衍射中衍射峰宽化的原因可能是由晶粒细化和微观应变所致。这表明经过强烈塑性变形后,Ni3Al相的晶粒形态也发生了显著变化。根据Ni3Al相(111)、(200)和(220)晶面衍射峰计算得到的Ni3Al相的晶粒尺寸和微观应变如表1所列。经过强烈塑性变形后,两种状态Ni3Al表层中的Ni3Al相都细化成纳米晶,其中定向凝固态试样中Ni3Al相的晶粒尺寸约为22 nm,小于铸造态试样中Ni3Al相的晶粒尺寸(56 nm)。

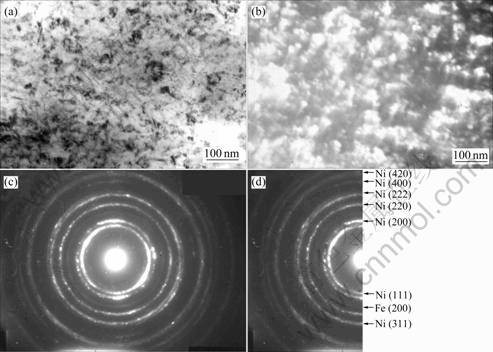

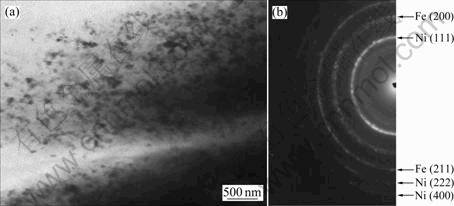

根据XRD谱计算得到的晶粒尺寸是一定厚度层中Ni3Al相的平均结果,为了显示最表层组织中的晶粒形态,对表面处理态Ni3Al试样的表层进行TEM观察,表层组织的典型形貌及其选取电子衍射如图4和5所示。

从图4和5中的晶粒形态可以看出,两种制备状态Ni3Al的原始粗晶在强烈塑性变形后完全消失,形成纳米晶,纳米晶的晶界不很清晰,晶粒尺寸约为10 nm。其选区电子衍射为均匀、完整的衍射环。这是由于大量各种不同位相的纳米晶参与电子衍射而形成的,是纳米晶的典型特征之一[18]。由此可以认为,形成的纳米晶具有大角度晶界。将选区电子衍射得到的衍射环进行标定后发现,最表层材料的相结构发生了转变,由Ni3Al相完全转变为Ni(Al)固溶体相。这个结果同X射线衍射的结果一致。在球磨过程中,Ni3Al发生了类似的无序化和逐步的晶粒细化,并形成了纳米晶[18-19]。

通过上面的观察分析可以发现,经过60 min表面机械研磨处理后,定向凝固态和铸造态Ni3Al的最表层均为晶粒尺寸约10 nm的Ni(Al)固溶体相。但在XRD可检测的深度范围内,定向凝固态试样中Ni3Al相的晶粒尺寸(约22 nm)小于铸造态试样中Ni3Al相的(约56 nm),而铸造态试样中Ni(Al)固溶体的含量(65%)则远高于定向凝固态试样的(约为7%)。

表1 SMAT后Ni3Al试样表面纳米结构层的相构成和Ni3Al相的结构特征

Table 1 Phase constitute of surface nanostructure layer in SMATed Ni3Al and structrual characteristics of Ni3Al phase

图4 表面机械研磨处理后定向凝固态Ni3Al最表层处的纳米晶形态及选区电子衍射谱

Fig.4 Bright field image (a), dark field image (b), selected area electron diffraction pattern (c) and labeled diffracion ring (d) of nanocrystallines at top surface of directional solidified Ni3Al after SMAT

图5 表面机械研磨处理后铸造态Ni3Al最表层处的纳米晶形态及选区电子衍射谱

Fig.5 Bright field image (a) and selected area electron diffraction pattern (b) of nanocrystallines at top surface of as-cast Ni3Al after SMAT

造成定向凝固态和铸造态Ni3Al强烈塑性变形后相构成和晶粒细化程度产生差异的原因可能是初始制备态时Ni3Al在组织性能方面的差异。从化学成分的角度来看,铸造态Ni3Al中B和Al的含量低于定向凝固态Ni3Al的,而且缺少Cr、Zr元素。Ni3Al中B主要聚集在晶界和反相筹界(APB)上,使富Ni的Ni3Al晶界贫Al,抑制晶界上的Al与空气中的H2O发生反应,阻止生成H2时造成的沿晶脆断。B含量增大会使晶界强化,从而强化合金。Zr的原子半径大于Al的,当Zr原子替代Al原子时会产生晶格畸变。同时,Zr在晶界上偏聚,使晶界贫Al,强化晶界。Cr在Ni3Al中既可以占据Ni原子的位置,又可以占据Al原子的位置,因此具有一定的固溶强化作用[20]。由于B、Cr和Zr等晶界强化元素的含量较高,因此,定向凝固态Ni3Al的硬度高于铸造态Ni3Al的。

强烈塑性变形时晶粒的细化是在应力应变作用下孪晶和位错运动的结果[4]。对于硬度比较低的材料,在同样的应力和应变条件下,其位错开始运动所需要的应力和应变相对比较低,因此,晶粒细化过程开始得比较早。对于Ni3Al的有序结构,在强烈塑性变形过程中除了晶粒细化的作用外,还产生无序化转变,即由L12有序结构的Ni3Al相转变成了FCC结构的无序Ni(Al)固溶体相。在经受同样程度强烈塑性变形的情况下,硬度较低的有序合金发生无序化转变的程度会比较大。由于铸造态Ni3Al制备态时的硬度比较低,因此,在同样的应力和应变条件下,其发生无序化转变形成Ni(Al)固溶体相的含量就比定向凝固态Ni3Al的高。这与定向凝固态和铸造态Ni3Al相组成中Ni(Al)固溶体相含量的结果一致。

在相对较小的应力和应变的作用下,原始的粗晶Ni3Al发生晶粒细化。而当应力和应变增大到一定程度时,Ni3Al发生无序化转变。在相同的应力和应变条件下,硬度较低的铸造态Ni3Al中的Ni3Al发生了无序化转变,而硬度较高的定向凝固态Ni3Al中的Ni3Al相仍然保持有序状态。因此,根据两种状态试样表面处理后X射线衍射谱线计算Ni3Al相的晶粒尺寸和微观应变时,铸造态Ni3Al表层形成的Ni3Al纳米晶的晶粒尺寸和微观应变较定向凝固态Ni3Al的大。

此外,铸造态Ni3Al中的织构和定向凝固态Ni3Al中的晶粒位向也可能影响定向凝固态和铸造态Ni3Al表面强化层组织中的相组成和晶粒特征差异,相关内容还需进行深入的研究。

3 结论

1) 经过60 min表面机械研磨处理后,定向凝固态和铸造态Ni3Al都发生了晶粒细化和无序化转变。

2) 表面机械研磨处理后,铸造态Ni3Al试样中Ni(Al)固溶体的含量达65%,远高于定向凝固态Ni3Al试样的。同时,铸造态Ni3Al试样表层的晶粒尺寸约为56 nm,远大于定向凝固态Ni3Al试样的(22 nm)。

3) 制备状态时定向凝固态和铸造态Ni3Al在化学成分和显微硬度方面的差异可能是造成上述差异的主要原因。

REFERENCES

[1] SURYANARAYANA C. The structure and properties of nanocrystalline materials: Issues and concerns[J]. JOM, 2002, 54(9): 24-27

[2] 徐滨士, 刘世参. 表面工程新技术[M]. 北京: 国防工业出版社, 2002.

XU Bin-shi, LIU Shi-can. New technologies of surface engineering[M]. Beijing: National Defense Industry Press, 2002.

[3] LU Ke, LU Jian. Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach[J]. Journal of Materials Science and Technology, 1999, 15(3): 193-197.

[4] LU Ke, LU Jian. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment[J]. Materials Science and Engineering A, 2004, 375/377: 38-45.

[5] TAO N R, WANG Z B, TONG W P, SUI M L, LU J, LU K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment[J]. Acta Materialia, 2002, 50(18): 4603-4616.

[6] WU X, TAO N, HONG Y, XU B, LU J, LU K. Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of Al-alloy subject to USSP[J]. Acta Materialia, 2002, 50(8): 2075-2084.

[7] WANG Y M, WANG K, PAN D, LU K, HEMKER K J, MA E. Microsample tensile testing of nanocrystalline copper[J]. Scripta Materialia, 2003, 48(12): 1581-1586.

[8] ZHU K Y, VASSEL A, BRISSET F, LU K, LU J. Nanostructure formation mechanism of alpha-titanium using SMAT[J]. Acta Materialia, 2004, 52(14): 4101-4110.

[9] SUN Cai-yun, XIE Ji-jia, WU Xiao-lei, HONG You-shi, LIU Gang, LU Jian, LU Ke. In situ synthesis of nanocrystalline intermetallic compound layer during surface mechanical attrition treatment of zirconium[J]. Transactions of Materials and Heat Treatment, 2004, 25(5): 1242-1246.

[10] LIU G, WANG S C, LOU X F, LU J, LU K. Low carbon steel with nanostructured surface layer induced by high-energy shot peening[J]. Scripta Materialia, 2001, 44(8/9): 1791-1795.

[11] 张洪旺, 刘 刚, 黑祖昆, 吕 坚, 卢 柯. 表面机械研磨诱导AISI304不锈钢表层纳米化(Ⅰ): 组织与性能[J]. 金属学报, 2003, 39(4): 342-346.

ZHANG Hong-wang, LIU Gang, HEI Zu-kun, LU Jian, LU Ke. Surface nanocrystallization of AISI 304 stainless steel induced by surface mechanical attrition treatment (Ⅰ): Structure and property[J]. Acta Metallurgica Sinica, 2003, 39(4): 342-346.

[12] TAO N R, WU X L, SUI M L, LU J, LU K. Grain refinement at the nanoscale via mechanical twinning and dislocation interaction in a nickel-base alloy[J]. Journal of Materials Research, 2004, 19(6): 1623-1629.

[13] REN Jiang-wei, SHAN Ai-dang, ZHANG Jun-bao, SONG Hong-wei, LIU Jun-liang. Surface nanocrystallization of Ni3Al by surface mechanical attrition treatment[J]. Materials Letters, 2006, 60(17/18): 2076-2079.

[14] WANG Z B, TAO N R, TANG W P, LU J, LU K. Diffusion of chromium in nanocrystalline iron produced by means of surface mechanical attrition treatment[J]. Acta Materialia, 2003, 51(14): 4319-4329.

[15] BARO M D, KOLOBOV Y R, OVIDKO I A, SCHAEFER H E, STRAUMAL B B, VALIEV R Z, ALEXANDROV I V, IVANOV M, REIMANN K, REIZIS A B, SURINACH S, ZHILYAEV A P. Diffusion and related phenomena in bulk nanostructured materials[J]. Reviews on Advanced Materials Science, 2001, 2(1): 1-43.

[16] YERMAKOV Y A, GAPONTZEV V L, KONDRATYEV V V, GORNOSTYREV Y N, UIMIN M A, KOROBEINIKOV A Y. Phase instability of nanocrystalline driven alloys[J]. Materials Science Forum, 2000, 343 (II): 577-584.

[17] SURYANARAYANA C. Mechanical alloying and milling[J]. Progress in Materials, 2001, 46(1/2): 1-184.

[18] JANG J S C, KOCH C C. Amorphization and disordering of the Ni3Al ordered intermetallic by mechanical milling[J]. Journal of Materials Research, 1990, 5(3): 498-510.

[19] MALAGELADA J, SURINACH S, BARO M D, GIALANCLLA S, CAHN R W. Kinetics of ordering in Ni3Al based alloys disordered by ball milling[J]. Materials Science Forum, 1992, 88/90: 497-499.

[20] 张永刚, 韩雅芳, 陈国良, 郭建亭, 万晓景, 冯 涤. 金属间化合物结构材料[M]. 北京: 国防工业出版社, 2001.

ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang, GUO Jian-ting, WAN Xiao-jing, FENG Di. Structural intermetallics[M]. Beijing: National Defense Industry Press, 2001.

(编辑 龙怀中)

基金项目: 上海市优青专项基金资助项目(gjd08011);上海工程技术大学校启基金资助项目(校启08-9)

收稿日期:2010-06-22;修订日期:2010-07-23

通信作者:任江伟,讲师,博士;电话:021-67791474;传真:021-67791377;E-mail: jwren@163.com