文章编号:1004-0609(2010)08-1552-06

Ni-Al固/液扩散偶的组织结构演变及其形成机理

蒋淑英,李世春

(中国石油大学(华东) 机电工程学院,东营 257061)

摘 要:采用镶嵌式扩散偶技术制备Ni-Al扩散偶,在Al熔点和Ni熔点之间的不同温度保温不同时间进行扩散处理。研究Ni-Al固/液扩散偶的组织结构演变及形成机理。结果表明:在Ni基被完全消耗之前,扩散偶的组织结构为Ni/Ni2Al3/NiAl3/Al+NiAl3,Ni基耗完之后继续保温一段时间,Ni2Al3消失,整个扩散偶均由Al+NiAl3的混合组织组成;Ni2Al3层是保温过程中第一个出现的也是唯一出现的连续单相层,NiAl3层则是在冷却过程中形成的;Al基中存在粗大块状和弥散细小状的NiAl3析出相,在NiAl3析出相之间存在无析出区,从界面附近到远离界面,NiAl3析出相和无析出区的尺寸逐渐变小。

关键词:Ni-Al系; 金属间化合物; 固/液扩散偶; 组织结构演变; 形成机理

中图分类号:TG146 文献标志码:A

Microstructure evolution and forming mechanism of

Ni-Al solid/liquid diffusion couple

JIANG Shu-ying, LI Shi-chun

(School of Electromechanical Engineering, China University of Petroleum (Huadong), Dongying 257061, China)

Abstract: The diffusion couples of Ni/Al were prepared using embedded diffusion couple technology, then, treated at different temperatures between the melting point of Al and Ni for different holding times. The microstructure evolution and forming mechanism of Ni-Al solid/liquid diffusion couple at different temperatures for different holding times were investigated through embedded diffusion couple technology. The results show that the structures of the diffusion couples are Ni/Ni2Al3/NiAl3/Al+NiAl3 before the Ni substrate is fully consumed. If Ni substrate is consumed completely and heat is hold for some time, Ni2Al3 layer disappears and the structure changes into Al+NiAl3. Ni2Al3 layer forms first and is only single-phase layer during holding time and NiAl3 layer forms during cooling. The large bulk and small particle NiAl3 precipitate in the Al substrate. At the same time, the non-precipitation zones also emergence because of Ni-poor. From the vicinity of the interface to the distance, the NiAl3 precipitates and the size of non-precipitation zones gradually become small.

Key word: Ni-Al system; intermetallic compounds; solid/liquid diffusion couple; microstructure evolution; forming mechanism

Ni-Al系金属间化合物熔点高、密度低, 具有较好的热传导性和良好的抗氧化性, 是航空航天领域很有希望的高温结构材料及高温复合材料基体[1]。与其工程应用息息相关的Ni-Al界面扩散反应引起众多研究者的关注,但目前的研究大多集中在铝熔点以下的 固-固扩散[2-5]及粉末涂层[6-12],而对Al熔点以上Ni熔点以下的固-液扩散偶的研究相对较少。因此,本文作者采用镶嵌式扩散偶技术制备了Ni-Al扩散偶,在铝熔点以上Ni熔点以下的温度保温不同时间,研究Ni-Al固/液扩散偶的组织结构演变及形成机理,对Ni-Al系金属间化合物及其涂层的制备、Ni-Al复合材料的制备以及Ni-Al异种金属的连接提供实验及理论基础。

1 实验

1.1 扩散偶的制备与热处理条件

在工业纯铝的铸锭上锯取10 mm×10 mm×10 mm的铝块作为外围基体材料,在钻床上钻出d 4.8 mm通孔,用锉刀和砂纸将铝块表面及内孔的氧化膜除掉。将直径为5 mm的工业镍丝按照铝块内孔直径大小锉成等锥度销子,并用砂纸打磨光滑,然后将镍丝销子采用过盈配合的方式压入铝块内孔铆合。将铆合好的试样放入小型陶瓷坩埚内加热到铝熔点温度以上,铝块熔化后,铝液包围镍丝,形成固-液扩散偶。为避免铝液粘锅,在扩散偶放入坩埚之前,在坩埚底部铺洒一层Al2O3陶瓷粉末。

为了研究扩散偶在不同热处理条件下的组织结构演变及生长行为,将扩散偶置于SK2-6-12型管式空气炉内,在Al熔点以上Ni熔点以下的温度分别保温不同时间。从实际的工业应用考虑,热处理温度不宜过高,一是节约能源,更重要的是扩散反应对温度极其敏感,温度太高不容易控制扩散反应层的生长,但热处理温度要保证铝溶液对固态镍有良好的润湿性。因此,本实验的热处理温度选择为700、750、800、850、900、1 000 ℃,分别保温10、20、30、60 min,随炉冷却。

1.2 扩散反应层的观察与测试

扩散偶经不同热处理条件烧结后,经打磨、抛光,在金相显微镜下观察界面结合情况及扩散反应层的组织结构。利用电子探针能谱定点分析技术及线分析技术测定扩散反应层各定点成分及元素分布情况,结合相图判定扩散反应层物相组成。

2 结果与分析

2.1 扩散反应层形貌特征

当热处理温度为700 ℃时,由于铝液对固体镍的润湿性差,在4种保温时间里均没有反应层出现,而在(800 ℃,60 min)、(850 ℃,30 min)、(900 ℃,20 min)、(1 000 ℃,10 min)的条件下,镍基已经消耗完。在镍基未耗完的所有条件下,得到的实验现象相似,只是反应层厚度及析出物尺寸和数量有所增加,在镍基消耗完的所有条件下,得到的均是析出相和Al的混合组织,因此,鉴于篇幅限制,本实验只列出800 ℃保温10、20、30、60 min,750、800、850、900 ℃保温10 min的热处理条件下的金相实验结果进行分析。

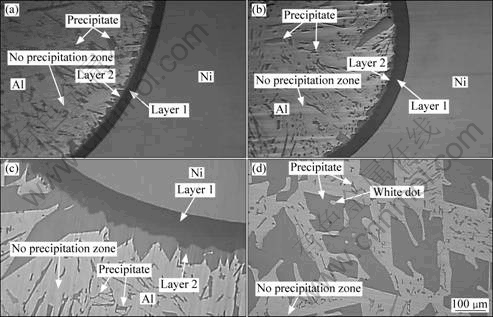

Ni-Al扩散偶在800 ℃下保温10、20、30、60 min,得到的扩散反应层金相照片分别如图1所示。由图1可看出,在800 ℃下保温10、20、30 min,扩散反应层均由两层组成,比邻Ni基侧的层1为深灰色,比邻Al基侧的层2为浅灰色。深灰色的层1厚度较大,随着保温时间的延长增长明显,与Ni基的接触界面规则且平滑,与层2的接触界面则呈不规则的波浪形;浅灰色的层2厚度较薄,随着保温时间的延长增长不明显,以柱状形态向铝基中生长;Ni基中无任何析出相,Al基中则出现了许多浅灰色的大块状的和细小弥散的析出相,在析出相之间存在无析出区。随着保温时间的延长,Ni基消耗迅速,在800 ℃下保温60 min,Ni基已经全部消耗,整个扩散偶形成了如图1(d)所示的组织形貌,Al基上分布着大块状和细条状的析出相,析出相之间也存在无析出带,在一些块状析出相上存在白色小圆点。

图1 在800 ℃保温不同时间后扩散反应层的形貌

Fig.1 Morphologies of diffusion-reaction layer after being treated at 800 ℃ for different holding times: (a) 10 min; (b) 20 min; (c) 30 min; (d) 60 min

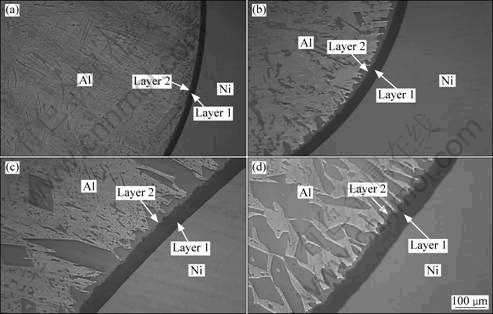

Ni-Al扩散偶在750、800、850、900 ℃下分别保温10 min,得到的扩散反应层金相照片分别如图2所示。由图2可看出,扩散反应层形貌与800 ℃下保温10、20、30 min的基本相同。在相同的保温时间下,深灰色的层1随烧结温度的升高不断长大;Ni基消耗量也增长迅速,在900 ℃保温20 min即已消耗完毕;浅灰色的层2增长缓慢,但在900 ℃保温10 min的条件下,层2的柱状晶生长形态已经非常明显。

2.2 扩散反应层的组织结构

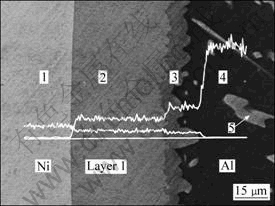

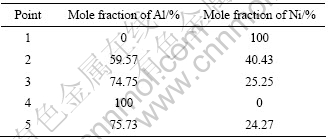

为了进一步了解Ni-Al固/液扩散偶扩散反应层的组织结构,本文作者对800 ℃保温10 min和850 ℃保温10 min的扩散偶做电子探针能谱线成分及点成分分析,两者实验结果一致。本研究列出800 ℃保温10 min的背散射电子相和电子探针线扫描谱,如图3所示。由图3可看出,扫描线从Ni基开始,穿过层1、层2到铝基侧的无析出区。

从图3还可以看出,Al和Ni元素的线扫描能谱曲线在经过镍基和层1的交界处、层1和和层2的交界处、层2和铝基的交界处时,均在强度上出现明显的台阶,说明在交界处发生了成分的突变,生成了金属间化合物;在层1和层2区,Al和Ni元素的能谱线表现为两个平台,说明层1和层2均为单相组织,层1和层2由不同的金属间化合物组成。

为了确定扩散反应层物相组成,对扩散偶进行定点能谱分析,点1到5的能谱分析数据如表1所列。从定点能谱数据可以看出,点1、点2、点3、点4、点5的Al元素摩尔分数分别为0、59.57%、74.75%、100%和75.73%。根据Ni-Al二元相图[13],Ni2Al3相中Al元素的摩尔分数范围为59.5%~63.2%, NiAl3相中Al元素的摩尔分数为75%。由此可以判断,点1、点2、点3、点4、点5的物相分别为Ni、Ni2Al3、NiAl3、Al和NiAl3,即层1和层2分别由Ni2Al3和NiAl3组成,Al基中的析出相为NiAl3。

因此,在Ni基没有完全消耗完之前的热处理条件下,扩散偶烧结后的结构组成为Ni/Ni2Al3/NiAl3/Al+ NiAl3;在镍基消耗完之后的热处理条件下,扩散偶的组织结构为Al+ NiAl3的混合组织。

图2 不同温度下保温10 min后扩散反应层的形貌

Fig.2 Morphologies of diffusion-reaction layer after being treated at different temperatures for 10 min: (a) 750 ℃ ; (b) 800 ℃ ; (c) 850 ℃ ; (d) 900 ℃

图3 在800 ℃和10 min的烧结条件下扩散偶能谱线成分及点成分分析

Fig.3 Line and point composition analyses of diffusion couple after being treated at 800 ℃ for 10 min by EDX

表1 在800 ℃和10 min的烧结条件下扩散偶定点能谱分析结果

Table 1 EDX results of points composition of diffusion couple after being treated at 800 ℃ for 10 min

3 讨论

3.1 扩散反应层的组织结构演变及形成机理

对于二元金属界面,根据相律,在扩散反应过程中不能出现两相共存的区域。因此,在高温扩散反应时,金属间化合物只能以逐层的方式生长。这是本实验中层1和层2均为单相组织的根本原因。

随着烧结温度的升高和保温时间的延长,Ni2Al3层不断生长直到镍基消耗完毕,NiAl3层厚度变化不明显,镍基消耗迅速,在800 ℃ 保温60 min后,不但镍基全部消耗,Ni2Al3层也全部溶解,整个扩散偶均由Al+NiAl3的混合组织形成。综合以上实验现象,推断出扩散反应层的组织结构演变过程及形成机理为Ni原子向Al溶液中溶解并在浓度梯度的作用下由界面向铝液内部扩散,在此过程中,镍基消耗迅速;随后,在铝溶液与镍基界面处,Ni原子率先达到热处理温度下的极限溶解度。由于本实验中,热处理温度均高于Al和NiAl3的共晶温度,因此,界面处液相成分高于共晶成分,此时,液相和NiAl3相的化学位相等。根据相律,Ni基和液相铝在界面不可能生成NiAl3相,否则在保温过程中扩散反应无法继续进行。因此,当Ni原子在界面处的铝液中达到饱和之后,Ni基与液相铝即在此通过化学反应生成了Ni2Al3相。Ni2Al3层在靠近铝基侧的界面极不规则,表现为与液相界面作用的特征[14-15]也证实了这一点。而YANG等[16]认为NiAl3层最先形成,Ni2Al3层是随后通过Al和Ni原子的固态扩散而形成的,但此结论没法解释本实验中Ni2Al3层在镍基耗完后继续保温的情况下溶解消失的现象。因为如果NiAl3层最先形成,Ni2Al3层不会与液态Al接触,也就不会出现镍基耗完后Ni2Al3层和NiAl3层的消失,得到图1(d)所示的混合组织的情况,且NiAl3层最先出现违背相律。 Ni2Al3相形核后,先沿界面横向生长,连成整体,形成单相Ni2Al3层;一旦连续的单相Ni2Al3层形成,Ni基和液相铝的接触即被阻断。此后,Ni2Al3层的生长则主要依赖于Al原子在固相Ni2Al3层中的扩散,反应在Ni2Al3层与Ni基的固-固界面进行,因此,Ni2Al3层与Ni基的接触界面规则平滑,表现为固-固界面作用特征。Ni2Al3层在通过扩散反应生长的同时,在富铝液相的浸蚀下,也不断地向液相铝溶解。在Ni基消耗完之前,扩散反应的速度比溶解的速度要快,因此,Ni2Al3层总体上表现为随温度的升高和时间的延长不断长大。而一旦Ni基耗完,扩散反应停止,如果继续保温,则只剩下Ni2Al3层的溶解过程。因此,在800 ℃ 下保温10、20、30 min,Ni2Al3层还在持续生长,而到800 ℃ 下保温60 min,Ni2Al3层消失,整个扩散偶均为Al+NiAl3的混合组织。

从图1和2可以看出,扩散反应层除了Ni2Al3层之外,还有一层很薄的NiAl3层,可能这一层很薄的NiAl3是在冷却过程中形成的,从图1可以看到NiAl3层的厚度与保温时间基本无关证实了这一点。且如果NiAl3层是在保温过程中形成的,也无法解释Ni基耗完后Ni2Al3层和NiAl3层的消失的现象。随着Ni2Al3层的溶解,在Ni2Al3层与液相的边缘处形成Ni的富积层,在冷却过程中,首先在界面处析出过共晶NiAl3相,由于液相成分远高于共晶成分,因此有足够的过共晶NiAl3相析出并连成整体,形成连续的NiAl3单相层。由于在制作扩散偶时,Al是外围基体材料,Ni是心部材料,在冷却过程中,存在由心部到外围的温度梯度,造成NiAl3相向Al基沿温度梯度方向成柱状生长。随着温度的进一步降低,铝液内部开始析出过共晶NiAl3。到达共晶点后,形成Al和NiAl3的共晶组织。在远离界面的铝液中,则可能由于Ni浓度较低形成亚共晶组织。

3.2 Al层组织特征分析

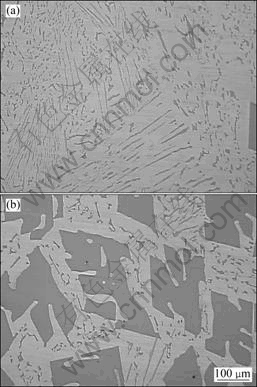

图4所示为850 ℃下保温10 min得到的远离界面和界面附近的Al层组织形貌。由图4可看出,界面附近的Al层中,大块状的NiAl3析出相之间弥散分布着细小的NiAl3析出相;远离界面的Al层中则只有细小而弥散的NiAl3析出相,从界面附近到远离界面,NiAl3析出相的尺寸逐渐变小。

图4 在850 ℃和10 min的烧结条件下铝层组织形貌

Fig.4 Morphologies of Al substrate after being treated at 850 ℃ for 10 min: (a) Away from interface; (b) Near interface

在Al层中靠近界面的附近区域,Ni的浓度较高,在冷却时率先达到饱和,析出NiAl3晶核,此时,由于温度较高,Ni原子能够扩散的距离也远,所以NiAl3析出相通过Ni的长程扩散可以生长得比较粗大。随着温度的降低,Ni原子的长程扩散变得越来越困难,一旦Ni原子难以进行长程扩散时,初始析出的NiAl3便逐渐停止生长。此时,铝液已不能通过Ni原子的长程扩散和高温均匀形核以及NiAl3析出相的长大来降低Ni的浓度,因此只能以不断的非均匀形核的方式析出NiAl3。由于Ni原子只能短程扩散,所以析出相都难以长得很大,从而形成在粗大析出相之间弥散分布的细小的析出相。此外,在一些粗大的块状析出相内部存在白色小圆点,这些白色小圆点是纯Al相。NiAl3相析出并通过周围Ni原子的扩散而长大,如果生长的NiAl3相与邻近的NiAl3相碰巧连成一周,被包围的铝液由于Ni原子的扩散路径被阻断而逐渐形成贫质区,在其中的Ni原子全部参与NiAl3的生长后,便以纯Al相的形式留了下来。

在远离界面处,开始冷却时,Ni原子浓度低于饱和浓度而不析出。随着温度的不断降低,Ni原子溶解度不断减小,当温度低于其脱溶温度时方才开始析出。在此温度下,Ni原子已经难以长程扩散,所以析出相难以长大,从而得到细小而弥散的NiAl3相。由于Al层中存在Ni的浓度梯度,Ni的浓度越低,脱溶温度也越低,Ni原子的扩散越困难,从而造成NiAl3析出相的尺寸从界面附近到远离界面逐渐变小。

3.3 Al层无析出区形成机理分析

从图1可以看出,Al层中出现无析出区,无析出区是由溶质原子贫乏而造成的。在Ni浓度高的区域,脱溶温度也较高,析出相可以通过Ni的长程扩散而长大。析出相的生长导致其周围形成Ni的贫乏区,随着温度的降低,Ni的扩散能力越来越小,使Ni的贫乏区难以消除,从而在粗大的析出相周围形成无析出区。在Ni浓度较低的区域,脱溶温度较低,析出相形核后只能通过短程扩散生长,难以长大;但此时因为Ni原子能扩散的距离很短,造成溶质贫乏区很窄,即无析出区变窄。所以,从界面附近到远离界面,Al层中的无析出区越来越窄。当Ni的浓度低于某一临界浓度时,脱溶温度低得连Ni原子短程扩散也困难,过饱和Ni只能就地析出,从而使无析出区消失。

4 结论

1) Ni-Al固/液扩散偶在Ni基没被全部消耗的所有热处理条件下,其结构组成均为Ni/Ni2Al3/NiAl3/Al+ NiAl3,在800 ℃下保温60 min,镍基全部消耗,Ni2Al3层也全部溶解,整个扩散偶均由Al+NiAl3的混合组织组成。

2) 在保温过程中,Ni2Al3层是第一个出现的也是唯一出现的连续单相层,NiAl3层则是在冷却过程中形成的。

3) Ni基完全消耗之前,在保温过程中,Ni2Al3层一方面通过Al原子的扩散而生长,另一方面又不断地向Al液溶解,但生长过程占主导地位,因此随烧结温度的升高和保温时间的延长,Ni2Al3层厚度不断增加。

4) Al层中从界面附近到远离界面,NiAl3析出相的尺寸逐渐变小,无析出区也逐渐变窄。

REFERENCES

[1] 郭建亭, 任维丽, 周 健. Ni-Al合金化研究进展[J]. 金属学报, 2002, 38(6): 667-672.

GUO Jian-ting, REN Wei-li, ZHOU Jian. Progresss in research on alloying effects in Ni-Al intermetallic alloys[J]. Acta Metall Sin, 2002, 38(6): 667-672.

[2] ZHANG Jiao, SUN Bao-de, XIA Zhen-hai. Layered structure of Ni-Al multi-layered metal-intermetallic composites fabricated by in-situ reactions[J]. Trans Nonferrous Met Soc China, 2004, 14(6): 1117-1123.

[3] 王华彬, 韩杰才, 张幸红, 杜善义. Ni-Al粉连续加热过程中的反映机理[J]. 金属学报, 1998, 34(9): 992-999.

WANG Hua-bin, HAN Jie-cai, ZHANG Xing-hong, DU Shan-yi. Reaction mechanism of continually heating Ni and Al particles[J]. Acta Metall Sin, 1998, 34(9): 992-999.

[4] 徐卓辉, 唐国翌. 铝/镍层状复合金属的工艺制备技术研究[J]. 稀有金属材料与工程, 2007, 36(2): 296-301.

XU Zhuo-hui, TANG Guo-yu. Research of manufacturing technique of Al/Ni clad composite metal[J]. Rare Metal Materials and Engineering, 2007, 36(2): 296-301.

[5] L?PEZ G A, SOMMADOSSI S, ZIEBA P, GUST W, MITTEMEIJER E J. Kinetic behaviour of diffusion-soldered Ni/Al/Ni interconnections[J]. Materials Chemistry and Physics, 2003, 78(2): 459-463.

[6] 高伟丽, 严红革, 盛绍顶, 陈振华. 气相沉积制备Ni-Al合金纳米粉末的相生成规律[J]. 中国有色金属学报, 2006, 16(2): 339-345.

GAO Wei-li, YAN Hong-ge, SHENG Shao-ding, CHEN Zhen-hua. Phase formation regularities of Ni-Al alloy nano powders prepared by vapor deposition[J]. The Chinese Journal of Nonferrous Metal, 2006, 16(2): 339-345.

[7] 樊湘芳, 邱长军, 刘瑞林. Ni/Al喷涂层反应烧结的组织演变及结合机制[J]. 材料科学与工艺, 2002, 10(2): 183-185.

FAN Xiang-fang, QIU Chang-jun, LIU Rui-lin. Microstructure evolution and bonding mechanism of thermal sprayed Ni-Al coating during reactive sintering[J]. Materials Science & Technology, 2002, 10(2): 183-185.

[8] 杜艳玲, 邱长军, 周 伟, 樊湘芳, 何 彬. Ni-Al涂层反应烧结界面组织与特性[J]. 材料科学与工艺, 2007, 15(4): 586-589.

DU Yan-ling, QIU Chang-jun, ZHOU Wei, FAN Xiang-fang, HE Bin. Microstructure and properties of interface of thermal sprayed Ni/Al coatings after sintering[J]. Materials Science & Technology, 2007, 15(4): 586-589.

[9] 邱长军, 樊湘芳, 刘瑞林. Ni-Al喷涂层反应烧结时界面结构的择优演变[J]. 材料导报, 2001, 15(4): 65-66.

QIU Chang-jun, FAN Xiang-fang, LIU Rui-lin. Selecting for best evolution of interface microstructure in thermal sprayed Ni-Al coating during reaction sintering[J]. Materials Journal, 2001, 15(4): 65-66.

[10] 章 跃, 周广宏. 退火工艺对Ni-Al复合涂层的组织和力学性能的影响[J]. 材料热处理, 2001, 26(8): 7-9.

ZHANG Yue, ZHOU Guang-hong. Influence of annealing process on microstructure and mechanical properties of Ni/Al composite coating[J]. Metal Heat Treatment, 2001, 26(8): 7-9.

[11] 王红星, 盛晓波, 储成林. 包渗时间对Cu表面Ni-Al涂层组织和性能的影响[J]. 材料工程, 2008(8): 52-57.

WANG Hong-xing, SHENG Xiao-bo, CHU Cheng-lin. Influences of slurry pack cementation time on microstructure and properties of Ni-Al coating on Cu substrate[J]. Materials Engineering, 2008(8): 52-57.

[12] 索进平, 冯 涤, 骆合力. 耐磨耐蚀Ni-Al 金属间化合物基复合保护层的研制[J]. 材料保护, 2002, 35(2): 34-36.

SUO Jin-ping, FENG Di, LUO He-li. Developing of anticorrosion and anti-wear composite coating by nickel2-aluminum intermetallic compound[J]. Materials Protection, 2002, 35(2): 34-36.

[13] BRANDES E A, BROOK G B. Smithells metals reference book[M]. American: Butterworth-Heinemann Ltd, 1992: 172.

[14] 袁 媛. Sn-Ni固扩散偶的界面反应[J]. 粉末冶金材料科学与工程, 2006, 11(5): 268-272.

YUAN Yuan. Interfacial reactions between Sn liquid and Ni substrate using Sn/Ni liquid/solid diffusion couple[J]. Materials Science and Engineering of Powder Metallurgy, 2006, 11(5): 268-272.

[15] BOUCH? K, BARBIER F, COULET A. Intermetallic compound layer growth between solid iron and molten aluminium[J]. Materials Science and Engineering A, 1998, 249: 167-175.

[16] YANG T Y, WU S K, SHIUE R K. Interfacial reaction of infrared brazed NiAl/Al/NiAl and Ni3Al/Al/Ni3Al joints[J]. Intermetallics, 2001, 9(4): 341-347.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50371059)

收稿日期:2009-09-11;修订日期:2010-01-13

通信作者:蒋淑英,讲师;电话:0546-8393907;E-mail:jsy0430@gmail.com