J. Cent. South Univ. (2012) 19: 1583-1589

DOI: 10.1007/s11771-012-1180-5

Performance evaluation of a diesel engine by using producer gas from some under-utilized biomass on dual-fuel mode of diesel cum producer gas

D. K. Das1, S. P. Dash2, M. K. Ghosal1

1. Department of Farm Machinery and Power, College of Agricultural Engineering and Technology,

Orissa University of Agriculture and Technology, Bhubnaneswar-751003, Orissa, India;

2. Department of Water Resources, Orissa Lift irrigation Corporation, Government of Orissa, India

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract: Producer gas through gasification of biomass can be used as an alternate fuel in rural areas due to high potential of biomass resources in India. Experiments were conducted to study the performance of a diesel engine (four stroke, single cylinder, 5.25 kW) with respect to its thermal efficiency, specific fuel consumption and diesel substitution by use of diesel alone and producer gas-cum-diesel (dual fuel mode). Three types of biomass, i.e. wood chips, pigeon pea stalks and corn cobs were used for generation of producer gas. A producer gas system consisting of a downdraft gasifier, a cooling cum cleaning unit, a filtering unit and a gas air mixing device was designed, fabricated and used to power a 5.25 kW diesel engine on dual fuel mode. Performance of the engine was reported by keeping biomass moisture contents as 8%, 12%, 16%, and 21%, engine speed as 1 600 r/min and with variable engine loads. The average value of thermal efficiency on dual fuel mode was found slightly lower than that of diesel mode. The specific diesel consumption was found to be 60%-64% less in dual fuel mode than that in diesel mode for the same amount of energy output. The average diesel substitution of 74% was observed with wood chips followed by corn cobs (78%) and pigeon pea stalks (82%). Based on the performance studied, the producer gas may be used as a substitute or as supplementary fuel for diesel conservation, particularly for stationary engines in agricultural operations in the farm.

Key words: biomass gasification; producer gas; downdraft gasifier; diesel engine

1 Introduction

The escalating oil prices and scarcity of fuel oils coupled with exploding population have resulted in serious energy crisis. There is thus a pressing need to develop technology for utilizing the renewable energy sources that can make significant contribution to the economy and the well being of the rural people.

Of all the alternative sources of energy for rural areas, producer gas from biomass appears to have the greatest potential. As an agricultural country, India has large supply of biomass resources. It is estimated that about 40%-60% of agricultural residues are either lost or put to inefficient use. This calls for better utilization of these resources by thermo-chemically converting into producer gas in the current context of limitedness of petroleum based fuels for use in internal combustion engines. Producer gas is generated from solid carbonaceous fuels such as wood, charcoal, coal, agricultural and forest residues and also animal wastes by gasification process [1-6]. Gasification is an irreversible thermo-chemical process by which feed stock is thermally decomposed and the end products are principally in gaseous form, with the main combustible components being carbon monoxide and hydrogen. The main advantages of gases as a fuel over liquid or solid fuels are that 1) gases burn with higher efficiency than the solid or liquid fuels; 2) they have a higher rate of heat release; 3) the rate of energy output is easily controlled and adjustable; 4) gaseous fuels with good energy utilization can be used for power sources. A good quality producer gas has an energy content of about 5 200 kJ/(N·m3). A gas producer requires 2.5-3 kg of wood to generate about the same energy as 1 L of diesel [7].

Diesel engines are widely used in Indian agricultural farms for a variety of stationary and mobile operations. The usual approach of producer gas utilization in diesel engines consists of operating existing compression ignition engines on producer gas cum diesel dual-fuel mode. The thermal efficiency of gasifiers in which producer gas is produced has been found to be 70%-80% and that of the gasifier-engine system to be 16%-20% [7]. The problem is more acute and serious in nature when producer gas is used to run motor vehicles particularly for agricultural operations [8-12]. Previous studies [13-16] indicate that a very little effort has been made in this direction. There is also a lack of information on the use of different types and conditions of biomass to generate producer gas as a supplement fuel for diesel engines. Therefore, an effort was made to develop a gas producer system utilizing the locally available raw materials to power a 5.25 kW (7 hp), single cylinder diesel engine that can be used on small horse power tractors, known as power tillers. The major objectives in this work are as follows:

1) To design and fabricate the different components of a gas producer system to operate a 5.25 kW (7 hp) diesel engine.

2) To evaluate the performance of the above engine with respect to thermal efficiency, specific diesel consumption and diesel substitution by using different types of biomass.

2 Design and fabrication of gas producer system

A gas producer system consisting of a gasifier, a cooler cum cleaner unit, a filtration unit and a mixing device was designed and fabricated to operate a 5.25 kW diesel engine on dual fuel mode (Fig. 1). A downdraft type gasifier operating under suction induced flow was designed for a maximum engine gas requirement of 10.70 N·m3/h taking a maximum hearth load of 0.9 N·m3/(cm2·h). The upper part of the gasifier was the fuel container and the lower part was the hearth with ash pit. The hearth section of the gasifier was V-shaped.

The primary air intake was through a pipe extended from top to the hearth with a provision to adjust the air inlet height. The ignition tube was passed through the hearth which was closed during gasification and opened only while starting to introduce fire. Ash pit was covered with a metal filter known as grate through which ash and soot particles were collected. A hand blower was attached to the gasifier for initial charging. The cooler-cum-cleaner unit consisted of a radiator to radiate heat from hot water, a venturi to provide sufficient space for cooling the gas and a water tank. The other attachment to the cooling system was a fan driven by a 0.375 kW motor to lift water from the tank to the radiator. A two stage filtering unit was developed to filter the dust and soot particles. The first stage consisted of gravel, charcoal, coconut coir and cotton layers of 15 cm in thickness whereas the second stage consisted of only two layers of cotton of 15 cm in thickness. Both the filtering units were packed in different boxes.

3 Methodology

3.1 Gas producer system

A single-cylinder 4-stroke 5.25 kW diesel engine of a commercial power tiller was used for the experiment. The intake manifold of the engine was modified using a T-section to introduce the mixture of air and gas into the engine during suction stroke. The quantities of gas and air flowing to the engine were measured separately with the help of two venturi sections provided in the T-section. The U-tube manometers were connected to the venturi section with polythene tube to measure the pressure drop across them. The original fuel supply of the engine from its fuel tank was cut off for the operation on dual fuel mode and the diesel fuel was supplied from an auxiliary tank provided with a fuel measuring set-up. In order to measure the load applied to the engine, a prony brake dynamometer was used. A strain gauge transducer was used to measure the temperatures of oxidation and reduction zones in the gasifier and the exit gas from the gasifier and the filtration unit.

Fig. 1 Gas producer system: 1-Gasifier; 2-Venturi tube; 3-Radiator; 4-Primary filter; 5-Secondary filter; 6-Mixing device; 7-Diesel engine; 8-Auxiliary fuel tank; 9-Manometers

3.2 Performance evaluation of engine

The diesel engine (specifications given in Table 1) was tested on diesel as well as on dual fuel mode at the engine speed 1 600 r/min and six loads (7.5, 12.5, 20, 30, 40 and 50 N). For dual fuel operation, the types of biomass used were pigeon pea stalks, wood chips and corn cobs. Three materials were used at four different moisture contents (8%, 12%, 16% and 21% on wet basis). Each test was conducted for a period of 5 min with two replications. During each test on diesel, the engine load, engine speed and fuel consumption were measured. The observed data were utilized to calculate the engine thermal efficiency, specific diesel consumption and percent diesel substitution. The performance of a diesel engine operated on dual-fuel mode was generally evaluated in terms of specific diesel consumption, engine thermal efficiency and percent diesel substitution. These parameters were determined as follows.

Table 1 Specifications of gas producer engine system under test

3.2.1 Specific diesel consumption (SCD)

SDC is given by

(1)

(1)

where CSD is the specific diesel consumption, g/(kW·h); Vd is the volume of diesel consumed, cm3; ρd is the density of diesel, kg/L; t is the time required to consume Vd, s; p is the engine power, kW.

3.2.2 Thermal efficiency

The thermal efficiency is expressed as the ratio of output power to the power supplied by the fuel.

1) Thermal efficiency of engine on diesel alone

Thermal efficiency of engine on diesel alone is given by

(2)

(2)

The power input from fuel in Eq. (2) is given by

(3)

(3)

where pB is the brake power of the engine; pf is the power input from fuel, kW; cd is the calorific value of diesel, 39 MJ/kg; ρd is the density of diesel, 640 kg/m3; fc is the fuel consumed, cm3/h.

Substituting the values of cd and ρd, Eq. (3) yields

(4)

(4)

Using Eq. (4), Eq. (2) gives

(5)

(5)

2) Thermal efficiency of engine on dual fuel mode.

The formula used for calculating the thermal efficiency of engine on dual fuel mode is given by

(6)

(6)

Power input from producer gas is given by

(7)

(7)

where pg is the power from producer gas, kW; cg is the calorific value of producer gas, kJ/(N·m3); gc is the gas consumption, N·m3/h.

Substituting Eqs. (5) and (7) in Eq. (6), there is

(8)

(8)

3.2.3 Diesel substitution

The percent diesel substitution is given by

(9)

(9)

where ds is the diesel substitution, %; Dd is the diesel consumption by the engine on diesel alone, cm3/h; Ddg is the diesel consumption by the engine on dual fuel mode, cm3/h.

4 Results and discussion

The relationship between engine load and thermal efficiency at the four levels of moisture content (8%, 12%, 16% and 21%) for the different types of biomass (pigeon pea stalks, wood chips, corn cobs) is shown in Figs. 2 , 3 and 4 at engine speed of 1 600 r/min. The trend shows that the thermal efficiency increases with a decreasing rate with the increase in engine load for all the biomass fuels at all the biomass moisture levels tested. This may be due to better combustion of relatively rich gas-air mixture at higher loads. It is also observed that with the increase in biomass moisture from 8% to 21%, the thermal efficiency also increases marginally from 28% to 31% with pigeon pea stalks, 30% to 32% with wood chips and 29% to 32% with corn cobs. The slight increase in thermal efficiency from 8% to 21% moisture range might have been caused due to better combustion of premixed mixture of gas and air on dual-fuel mode resulting in reduced requirement of total energy input at different loads.

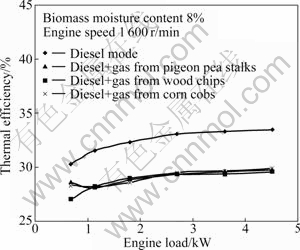

The effect of different types of fuel on engine thermal efficiency at 1 600 r/min is shown in Fig. 5. The trend shows that there is a slight drop in thermal efficiency of engine on dual-fuel mode, compared to that on diesel alone. Based on mean values, it may be reported that the thermal efficiency of diesel engine when tested, drops from 32.3% on diesel fuel mode to 30.5% on dual-fuel mode using pigeon pea stalks. However, the efficiency of engine on dual-fuel mode using wood chips and corn cobs is found almost at par with that on diesel mode. This shows that the combustion of air-gas mixture while using wood chips and corn cobs is better compared to pigeon pea stalks, even though the energy content of pigeon pea stalks is relatively high. The variations of specific diesel consumption and diesel substitution with engine load on dual-fuel mode of a diesel engine at different biomass moisture levels are shown in Figs. 6-11. The trend of the curves shows that the specific diesel consumption, in general, decreases with the increase in engine load at different moisture levels for all the three types of biomass used. However, a definite trend of variation of diesel substitution with engine load has not been established. It has shown increasing trend with load in most of the cases, whereas in a few cases a decreasing pattern has also been observed. This kind of trend is not common in the existing literatures. It is usually reported that if the energy content of the gas remains relatively stable, a higher load means a higher consumption of diesel fuel and thus a lower percentage of diesel fuel replacement. But if the quality of the gas in terms of its energy content is not stable, an increase in load can also increase the percentage of diesel fuel substitution. The decrease in specific diesel consumption with load is primarily due to the increase in diesel fuel consumption at a decreasing rate. From the mean values of specific diesel consumption and diesel substitution in the test engine at different operational parameters (taking all loads into consideration), it is observed that the specific diesel consumption of engine on dual-fuel mode using pigeon pea stalks decreases from 87.9 g/(kW·h) at 8% moisture level to 75.9 g/(kW·h) at 12% moisture level beyond which it again increases and rises to 161.8 g/(kW·h) at a biomass moisture level of 21%. The diesel substitution on the other hand, varies from 50.5% to 68.8% in the same moisture range showing the maximum value of 72.3% at a moisture level of 12%. Similar trends of variation of specific diesel consumption and diesel substitution are also noticed in the case of the other two biomass fuels. For the sake of comparison, the minimum values of specific diesel consumption using wood chips and corn cobs are observed to be 82 and 87 g/(kW·h), respectively, whereas the maximum values of diesel substitution for these fuels are found to be about 71.3% at a moisture level of 12%. This shows that the minimum values of specific diesel consumption are derived at a particular biomass moisture level (12%) where diesel substitution is maximum. This is perhaps due to better quality of gas obtained at this moisture level as reflected by its higher CO content resulting in better combustion of air gas mixture. The variation of specific diesel consumption with engine load for the test engine on diesel mode as well as on dual-fuel mode using different types of biomass is shown in Fig. 12 for a particular set of operating parameters. The data indicate a slight decrease in specific diesel consumption with engine load both on diesel as well as on dual fuel operations. As expected, the specific diesel consumption on diesel mode is much higher than that on dual-fuel mode for all the engine loads tested.

Fig. 2 Variation of thermal efficiency with engine load on dual fuel mode at different moisture contents of wood chips

Fig. 3 Variation of thermal efficiency with engine load on dual fuel mode at different moisture contents of pigeon pea stalks

Fig. 4 Variation of thermal efficiency with engine load on dual fuel mode at different moisture contents of corn cobs

Fig. 5 Effect of engine load on thermal efficiency with different types of fuel

Fig. 6 Variation of specific diesel consumption with engine load on dual fuel mode at different moisture contents of wood chips

Fig. 7 Variation of diesel substitution with engine load on dual fuel mode at different moisture contents of wood chips

Fig. 8 Variation of specific diesel consumption with engine load on dual fuel mode at different moisture contents of pigeon pea stalks

Fig. 9 Variation of diesel substitution with engine load on dual fuel mode at different moisture contents of pigeon pea stalks

Fig. 10 Variation of specific diesel consumption with engine load on dual fuel mode at different moisture contents of corn cobs

Fig. 11 Variation of diesel substitution with engine load on dual fuel mode at different moisture contents of corn cobs

Fig. 12 Effect of engine load on specific diesel consumption with different types of fuel

Comparing the performance of engine on the basis of the mean values of specific diesel consumption, it is observed that the engine consumes 60%-64% less diesel on dual-fuel mode than that on diesel mode for the same amount of energy output. The effect of engine load on percent diesel substitution for different types of biomass is shown in Fig. 13. The trend shows increasing pattern of diesel substitution with engine load as explained earlier. Based on the mean values of diesel substitution, it can be pointed out that the average diesel substitution of 64% is found with wood chips followed by corn cobs (63%) and pigeon pea stalks (62%) throughout the range of biomass moisture. From the results discussed above, it can be stated that the gasifier system developed for 5.25 kW diesel engine has indicated satisfactory performance by showing on an average 60%-65% saving in diesel consumption while utilizing three types of locally available biomass fuels.

Fig. 13 Effect of engine load on diesel substitution with different types of fuel

5 Conclusions

1) The gas producer system designed and developed for a 5.25 kW diesel engine is found to perform satisfactorily by using different types of biomass such as pigeon pea stalks, wood chips and corn cobs.

2) The average value of thermal efficiency of engine is found to drop slightly from 32.3% on diesel mode to 28.7% on dual fuel mode using pigeon pea stalks as biomass fuel. However, the efficiency found on dual fuel mode with wood chips and corn cobs is comparable to that on diesel mode.

3) The mean values of specific diesel consumption of engine on dual-fuel mode for all the three biomass fuels are less compared to diesel mode and their diesel substitution is more.

4) The average diesel substitution in a 5.25 kW diesel engine is found in the range of 62%-64% using three types of biomass fuels.

References

[1] HINDSGAUL C, SCHRAMM J, GRATZ L, HENRIKSAN U, BENTZEN J D. Physical and chemical characterization of particles in producer gas from wood chips [J]. Bio Resource Technology, 2000, 73: 147-155.

[2] DOGRU M, HOWARTH C R, AKAY G, KESKINLER B, MALIK A A. Gasification of hazelnut shells in a downdraft gasifier [J]. Energy, 2000, 27: 415-427.

[3] BHATTACHARYA S C, SHWE S S, PHAM H L. A study on a multi-stage hybrid gasifier-engine system [J]. Biomass and Bioenergy, 2001, 21: 445-460.

[4] SRIDHAR G, PAUL P J, MUKUNDA H S. Biomass derived producer gas as a reciprocating engine fuel-An experimental analysis [J]. Biomass and Bioenergy, 2001, 21: 61-72.

[5] DAS D K, PANDEY K P. Some studies on biomass based gas producer system for a diesel engine [D]. Kharagpur: Engineering Department, IIT, 1993.

[6] PATHAK B S, JAIN A K. Engine quality producer gas from leucaena leucocephala and selected agricultural residues [J]. Journal of Agril Engineering, 2004, 21(3): 43-50.

[7] TIWARI G N, GHOSAL M K. Fundamentals of renewable energy sources: Basic principles and applications [M]. New Delhi: Narosa Publishing House, 2007: 216.

[8] CHOPRA S, JAIN A. A review of fixed bed gasification systems for biomass [J]. Agricultural Engineering International, 2007, 9: 187- 192.

[9] TIWARI G, SARKAR B, GHOSH L. Design parameters for a rice husk throatless gasifier reactor [J]. Agricultural Engineering International: The CIGR Journal of Scientific Research and Development, 2006, 8: 88-93.

[10] SINGH R N, JENA U, PATEL J B, SHARMA A M. Feasibility study of cashew nut shells as an open core gasifier feedstock [J]. Renewable Energy, 2006, 31(4): 481-487.

[11] RIVA G. Utilization of biofuels on the farm [J]. Agricultural Engineering International, 2006, 8: 107-113.

[12] JAIN A. Design parameters for a rice husk throatless gasifier [J]. Agricultural Engineering International, 2006, 8: 57-60.

[13] PATHAK B S. Biomass to power rural development [C]// Proc of National Seminar on Biomass Based Decentralized Power Generation. Vallabh Vidhyanagar: Sardar Patel Renewable Energy Research Institute, 2005: 107-111.

[14] CARLOS L. High temperature air/steam gasification of biomass in an updraft fixed batch type gasifier [D]. Royal Institute of Technology, Energy Furnace and Technology. Stockholm, Sweden, 2005.

[15] GHOSH S, DAS T K, JASH T. Sustainability of decentralized wood fuel-based power plant: An experience in India [J]. Energy, 2004, 29: 155-166.

[16] WANDER P R, ALTAFINI C R, BARRETO R M. Assessment of a small sawdust gasification unit [J]. Biomass and Bioenergy, 2004, 27: 467-476.

(Edited by HE Yun-bin)

Received date: 2011-07-26; Accepted date: 2011-11-14

Corresponding author: M. K. Ghosal; Associate Professor, PhD; Tel: +91-9556271208; E-mail: mkghosal1@rediffmail.com