H型钢万能轧制力计算方法

赵景云1,臧勇1,吴迪平1,逄晓男2,刘福宁2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 莱芜钢铁集团型钢厂,山东 莱芜,271126)

摘要:基于分离腹板和翼缘相互影响的思路建立2种特殊的H型钢万能轧制模型。通过研究不同延伸比和面积比条件下水平辊、立辊轧制力与平板轧制的关系,总结归纳出H型钢万能轧制力计算公式,并用其他规格道次的H型钢轧制力进行对比验证。研究结果表明:在相同的面积比条件下,随着腿腰延伸比λ的增大,水平辊轧制力减小,立辊轧制力增加;随着翼缘或者腹板面积的减小,不同延伸比情况下的水平辊中间位置轧制力和立辊轧制力分别收敛于1个稳定值;该H型钢轧制力计算公式能较好地反映不同工艺参数下轧制力的变化趋势;水平辊轧制力公式计算结果与有限元模型计算结果的最大相对误差为16.7%,与实测值的相对误差为3.4%;立辊轧制力公式计算结果与有限元模型计算结果的最大相对误差为8.7%,与实测值的相对误差为4.4%。

关键词:H型钢;万能轧制;轧制力公式;腿腰延伸比;面积比

中图分类号:TG331 文献标志码:A 文章编号:1672-7207(2013)05-1829-08

Calculation method for universal rolling force of H-beam

ZHAO Jingyun1, ZANG Yong1, WU Diping1, PANG Xiaonan2, LIU Funing2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Section Mill, Laiwu Iron & Steel Co. Ltd., Laiwu 271126, China)

Abstract: Two models of universal rolling were built with intention to get rid of influence of web and flange. The calculation formulas of H-beam’s rolling force were derived based on the research of differences and relationship between H-beam’s and flat’s rolling forces. Then, the calculation formulas were verified by rolling forces of other sizes and passes. The results show that force of horizontal roll decreases with the increase of ratio of elongation as well as the force of vertical roll increases in the same area ratio. Rolling force of the middle position of horizontal roller converges to a stable value with the reducing of flange’s area. Vertical rolling force converges to a stable value with the decrease of web’s area. The changing trend of rolling force in different process parameters was expressed well by calculation formulas. The maximum relative error between the rolling force formula of horizontal roll and finite element results is 16.7%. The average relative error between the formula and test values is 3.4%. The maximum error between the rolling force formula of vertical roll and finite element results is 8.7%. The average relative error between the formula and test value is 4.4%.

Key words: H-beam; universal rolling; rolling force model; ratio of elongation; area ratio

轧制力是金属轧制时的重要力能参数,准确预测轧制力对于合理制订工艺制度、控制轧件精度及充分发挥轧机潜能具有重要意义[1]。目前,人们对于利用平辊轧机轧制板带轧制过程的研究比较充分,用于计算板带轧制力的工程计算方法也有很多,且具有较高精度,但是,由于H型钢在轧制过程中的变形规律板材轧制要复杂得多,这就给其力能参数的理论解析带来困难。到目前为止,对H型钢力能参数的研究多集中在分开考虑翼缘和腹板的情况下,结合实验研究对板带轧制力公式进行修正,或者通过初等解析、能量法等对力能参数进行计算[2-12]。中岛浩卫[2]通过实验的方法,得到H型钢和纯粹板带轧制力之间的关系,但通过分离腹板和翼缘的实验研究并不充分,只考虑翼缘伸长率大于腹板伸长率的情况。须藤忠三利用三维塑性变形原理(初等解析法)对H型钢轧制过程中的轧制力进行理论推导,但并没给出通用的应力状态系数[3];潘亮等[4-5]在须藤忠三的基础上对应力状态系数进行修正,得到H型钢轧制力的回归公式,回归公式应用局限性很大;如梁明等[6]从内外功平衡的角度推导出H型钢轧制力模型,但此计算模型较为粗糙;王哲等[7-12]通过能量法对H型钢力能参数进行计算,比如,基于上限定理给出轧制力的计算模型,其重要的假设条件为腹板和翼缘之间无金属交换,该假设应用范围窄,在实际生产中H型钢的变形大多数工况并不符合该假设条件。在H型钢轧制过程中,腹板和翼缘互相影响导致轧制力计算复杂,不能进行传统的理论解析。若能详细分析H型钢万能轧制与板带轧制的区别及联系,则能为研究H型钢轧制力的工程算法提供一定的理论分析依据。

1 大H型钢万能轧制有限元模型

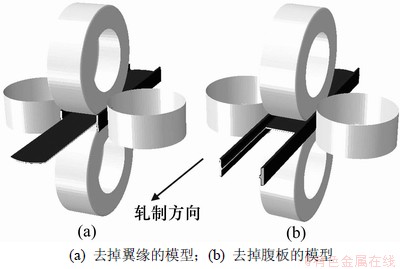

选择H496×199规格连轧第4道次中的UF轧制道次进行研究。基于分离腹板和翼缘相互影响的思路建立2种特殊的轧制模型分别用于研究水平辊轧制力和立辊轧制力与平板轧制力的区别和联系规律。UF轧制模型如图1所示,其中上、下2个水平辊为主动辊,左、右2个立辊为从动辊。

在第1种轧制模型中,轧件前半部分去掉翼缘及R角部分,仅留下腹板部分变为平板轧制,后半部分为完整H形轧件。为提取不同部位的轧制力水平,将水平辊分割为3部分(图2)。通过调整翼缘压下量改变腿腰延伸比,以研究H型钢轧制时水平辊的轧制力与纯粹板带轧制的差异以及水平辊各个位置轧制力的分配情况。

在第2种轧制模型中,轧件前半部分去掉腹板部分,翼缘部分变为异径搓轧;后半部分为完整H形轧件,通过调整腹板压下量改变腿腰延伸比以研究立辊轧制力的变化规律;另外,对翼缘部分还建立独立的同径平板轧制模型,与搓轧模型进行对比以找出联系规律。

图1 UF轧制模型

Fig.1 Rolling model of UF

图2 水平辊分解示意图

Fig.2 Schematic diagram of horizontal roll separation

1.1 有限元模型的建立

1.1.1 材料模型

对现场取得Q345轧制前的坯料进行不同温度、不同变形速率下的变形抗力实验,得到Q345的变形抗力曲线。将该材料的应力和应变引入有限元模型。

1.1.2 接触与摩擦

在轧制过程中,采用面对面接触方式定义轧辊与轧件之间的接触定义,采用库仑摩擦方式定义摩擦。一般热轧生产中的摩擦因数为0.2~0.4[13-14]。本文的模型中轧辊和轧件之间的摩擦因数设定为0.3。

1.1.3 温度边界条件

为得到H型钢轧制过程中的温度条件,采用非接触式红外热像仪G90对轧制过程进行连续温度采集,得到H型钢表面温度场。

在H型钢轧制模型中,对腹板和翼缘位置设置不同的换热系数,通过前面道次的轧制过程仿真得到该轧制道次的H型钢整体模型的温度场,计算得到的H型钢的表面温度和测试数据相符,说明模型中的温度场基本合理。

1.1.4 H型钢轧制模型

由于万能轧制的孔型和载荷上下左右对称,所以建立第4道次UF轧制道次的1/4有限元模型进行仿真模拟,并设轧辊为刚性,不计机架间张力。表1所示为第4道次UF轧制的主要工艺条件。

在仿真分析中采用正交右手坐标系:Z向为轧件长度方向(纵向),正向为前,负向为后;Y为翼缘高度方向(垂直方向),正向向上,负向向下;另一水平方向为X向。

表1 UF轧机主要的轧制条件

Table 1 Main rolling conditions of UF mill

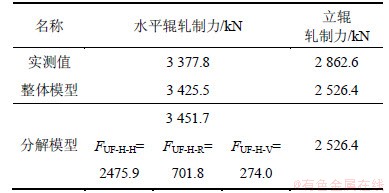

1.2 有限元模型的验证

为验证模型精度,对实际轧制第4道次的轧制力进行测试并与有限元计算数据进行对比分析,如图3所示为实测轧制力。由于本文模型是没有张力的,所以,选取测试数据中尚未形成张力阶段的轧制力与本文有限元模型计算的轧制力进行对比。本文建立的第一种有限元模型(模型1)中,水平辊被分为3部分,简称分解模型。为验证该模型的正确,另外,建立1个完整水平辊的模型(整体模型,模型2)与之对比。测试具体数据如图3所示,FUF-H,FUF-V和FUE分别为UF轧机水平辊轧制力(Y向)、UF轧机立辊轧制力(X向)和UE轧机水平辊轧制力(Y向)。整体模型和分解模型中稳定轧制段的平均轧制力如表2所示,其中FUF-H-H,FUF-H-R和FUF-H-V分别为水平辊中间位置、圆角位置和侧面的轧制力(Y向)。分解模型的水平辊轧制力和整体模型相当,且与实测轧制力的相对误差约为2.2%,立辊的计算轧制力与实测轧制力的相对误差约为11.7%,证明本文所建立的有限元轧制模型基本正确,可用于后面的研究。

图3 实测轧制力

Fig.3 Measured rolling force

表2 万能轧制模型的轧制力

Table 2 Rolling force of universal rolling model

2 分析工况

模型1中保持腹板位置的压下量不变,通过调整立辊压下量改变腿腰延伸比λ,研究水平辊各个位置以及整体轧制力的变化规律。模型2中保持翼缘位置的压下量不变,通过调整腹板压下量改变腿腰延伸比λ,研究立辊轧轧制力的变化规律。具体计算工况如表3所示,其中:h0为腹板轧前厚度;h1为腹板轧后厚度;t0为翼缘轧前厚度;t1为翼缘轧后厚度;εw为腹板位置的相对变形量εw=ln(h0/h1); εf为翼缘位置的相对变形量εf=ln(t0/ t1);λ为腿腰延伸比,当忽略宽展时,λ= ln(t0/t1)/ln(h0/h1)。

H型钢万能轧制区别于平板轧制的主要特征包括:(1) 轧辊中只有2个水平辊是主动的,2个立辊是完全被动的,所以,立辊所消耗的轧件变形功及各处的摩擦功等均由水平辊通过腹板至翼缘再到立辊传递;(2) 由腹板和翼缘构成的H型断面作为整体延伸,二者纵向延伸的任何不一致将导致腹板和翼缘之间产生附加的拉压应力,因此,腹板对翼缘的纵向(轧制方向)作用力可以分解为2部分(如图4):第1部分是纵向剪切力FH-V,其驱动翼缘变形和立辊转动;第2部分是由于腿腰延伸不匹配形成的局部拉压应力,当λ<1时,翼缘制约腹板的延伸,腹板受翼缘作用的纵向挤压力(图4(a)),当λ>1时,腹板制约翼缘的延伸,腹板受翼缘作用的纵向拉伸力(图4(b))。

表3 计算工况

Table 3 Calculation conditions mm

不论是附加的拉应力还是附加压应力,它们在变形区两侧应是平衡的。腹板对翼缘总的作用力应体现在第一部分用于翼缘变形的纵向剪切力FH-V。根据腹板变形区的纵向受力平衡,该力对水平辊垂直方向的轧制力影响为

(1)

(1)

其中: 为摩擦力和水平方向的夹角。

为摩擦力和水平方向的夹角。

图4 腹板受力分析(纵向)

Fig.4 Stress analysis of web (z direction)

在前述各个工况条件下,水平辊总轧制力在2.5~ 7.0 MN范围内,FH-V为280 kN左右,而tan <0.06,因此,FH-V对水平辊垂直轧制力的影响不超过0.6%,本文近似认为FH-V对轧制力无影响。

<0.06,因此,FH-V对水平辊垂直轧制力的影响不超过0.6%,本文近似认为FH-V对轧制力无影响。

3 水平辊轧制力构成及影响规律

3.1 水平辊轧制力的构成

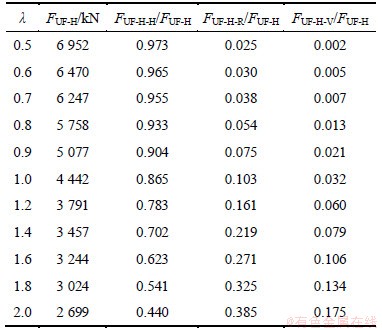

根据模型1,可得到不同λ情况下水平辊总轧制力FUF-H及其在各位置的分布(表4)。从表4可知:随着λ增大,FUF-H-H与FUF-H之比降低;FUF-H-R与FUF-H之比增大,所以,当λ比较大时,计算H型钢轧制力时不能忽略圆角位置的影响。同样,随着λ增大,FUF-H-V与FUF-H之比增大。

经分析可知:当翼缘伸长率小于腹板伸长率时,腹板受翼缘纵向压应力,根据塑性屈服条件,垂直方向的轧制力增大;当翼缘伸长率大于腹板伸长率时,腹板受翼缘纵向拉应力,垂直方向的轧制力减小。总的来说,随着翼缘压下量的增加,FUF-H-H减小。同时,翼缘压下量增加会使金属有向圆角处流动的趋势增加,导致圆角位置的压力增大,从而使FUF-H-R增大;而FUF-H-V增大的主要原因是翼缘压力增大造成水平辊侧面竖直方向的摩擦力增大。

表4 各位置轧制力占总轧制力的比例

Table 4 Proportion of each rolling force in total force

3.2 水平辊中间位置轧制力FUF-H-H的计算

图5所示为不同λ时水平辊中间位置轧制力。从图5可见:当λ=1.0时,FUF-H-H略高于平板轧制力;当λ=0.5时,FUF-H-H远高于平板轧制力,说明此时腹板在变形区受到很大的纵向压应力,导致轧制力增大;当λ=2.0时,FUF-H-H低于平板轧制力,说明此时腹板在变形区受到很大的纵向拉应力,导致轧制力减小。

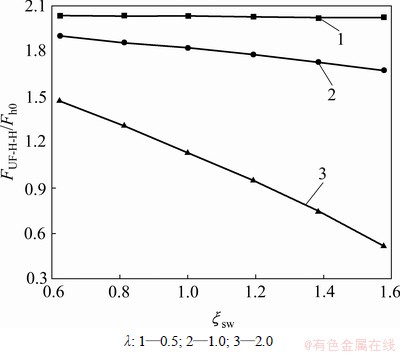

图5 水平辊中间位置轧制力

Fig.5 Rolling force in middle position of horizontal roll

同样,在相同的腿腰延伸比下,翼缘的面积也会影响变形区内纵向拉压应力。所以,在一般情况下,H型钢水平辊的轧制力应是腰腿相对伸长率和相对面积综合影响的结果。为研究方便,引入翼缘与腹板的面积比ξsw(ξsw=2Sf/Sw,其中Sw为整个腹板位置的面积,Sf为单边翼缘的面积)。

图6所示为不同面积比时FUF-H-H/Fh0随 的变化规律。如前所述,λ对轧制力的影响是轧件2部分伸长率不一致所致。从力学上讲,腰腿间的变形不协调最终表现为相互间的纵向拉压关系。为符合物理上的对称关系,横坐标采用

的变化规律。如前所述,λ对轧制力的影响是轧件2部分伸长率不一致所致。从力学上讲,腰腿间的变形不协调最终表现为相互间的纵向拉压关系。为符合物理上的对称关系,横坐标采用 。当

。当 =0时,FUF-H-H略高于平板轧制力。从图6可见:以

=0时,FUF-H-H略高于平板轧制力。从图6可见:以 =0为界,相同面积比下的曲线大致呈反对称关系;随着面积比减小,系数曲线的斜率减小。这是因为变形不协调所引起的腹板纵向应力变化趋缓,轧制力的变化减小。当

=0为界,相同面积比下的曲线大致呈反对称关系;随着面积比减小,系数曲线的斜率减小。这是因为变形不协调所引起的腹板纵向应力变化趋缓,轧制力的变化减小。当 =0时,腿腰变形协调,FUF-H-H随ξsw变化不大,为了计算方便,可把

=0时,腿腰变形协调,FUF-H-H随ξsw变化不大,为了计算方便,可把 =0时的FUF-H-H当作一个恒定值来考虑,此恒定值FUF-H-H≈1.15Fh0。

=0时的FUF-H-H当作一个恒定值来考虑,此恒定值FUF-H-H≈1.15Fh0。

图7所示为水平辊中间位置轧制力随ξsw的变化规律。从图7可以看出:在腿腰延伸比相同时,FUF-H-H随面积比ξsw的变化呈线性关系,并随着ξsw的减小向1个稳定值收敛,这符合实际的物理关系;当λ=1.0时(腿腰延伸协调),FUF-H-H基本恒定。这说明此时水平辊的轧制力只取决于腹板自身的情况。当然,在实际工程中,翼缘是存在宽展的[15],且相对宽展量随着翼缘高度(面积)的减小而增大,相应的纵向伸长率下降。所以λ=1.0时,翼缘高度(面积)减小使水平辊轧制力有所上升。

图6  对FUF-H-H的影响规律

对FUF-H-H的影响规律

Fig.6 Variation rules of FUF-H-H with

图7 翼缘和腹板的面积比ξsw对FUF-H-H的影响规律

Fig.7 Variation rules of FUF-H-H with ξsw

根据分析可知:若忽略翼缘的宽展,则当 =0时,FUF-H-H保持恒定,此时FUF-H-H≈1.15Fh0;面积比不变的情况下,FUF-H-H关于

=0时,FUF-H-H保持恒定,此时FUF-H-H≈1.15Fh0;面积比不变的情况下,FUF-H-H关于 =0呈反对称关系;当λ不变时,FUF-H-H随ξsw呈线性变化,并随着ξsw的减小收敛于1.15Fh0附近。由此,可以假设FUF-H-H的计算公式模式为

=0呈反对称关系;当λ不变时,FUF-H-H随ξsw呈线性变化,并随着ξsw的减小收敛于1.15Fh0附近。由此,可以假设FUF-H-H的计算公式模式为

(2)

(2)

其中:Fh0为平板轧制力;kw为图7中拟合直线的斜率,kw为 的函数,

的函数,

(3)

(3)

故

(4)

(4)

根据本文的大量数据点对公式进行回归得到未知系数:a=0.396 7,b=-0.886 7。在一般情况下,式(3)中的3次项较小,可以忽略不计。

3.3 水平辊总轧制力计算

FUF-H-H与水平辊总轧制力之比随延伸比增加而减小的变化规律,图8所示为3种不同面积比情况下该比例的变化规律。将该比例设为A,可以看出A与ξsw呈线性关系,但线性系数随λ不同而改变;当面积比ξsw=0时,A≈1。总结归纳A的计算公式为

(5)

(5)

其中:K为与λ有关的系数。

图8 FUF-H-H占总轧制力的比例的变化规律

Fig.8 Variation rules of proportion of FUF-H-H in total force

对式(4)引入1个比例系数A,得到H型钢水平辊总轧制力FUF-H=FUF-H-H/A。

4 立辊轧制力及其影响

λ不同时的立辊轧制力FUF-V如图9所示。前半部分模型由主动的水平辊和被动的立辊对翼缘位置进行搓轧。由于改变腹板压下量时,对圆角位置也有下移,所以,FV1随λ的变化略有不同,在此可以忽略。从图9可见:当λ=1时,立辊轧制力稍小于FV1;当λ=0.5时,立辊轧制力远低于搓轧的轧制力FV1;当λ=2时,立辊轧制力高于平板搓轧的轧制力FV1。

图9 立辊轧制力

Fig.9 Rolling force of vertical roll

同样,为研究λ和腹板面积对立辊轧制力的影响规律,引入腹板和翼缘的面积比ξsf(ξsf=Sw/2Sf)。图10所示为不同面积比时FUF-V/FV0随 的变化规律。从图10可见:当

的变化规律。从图10可见:当 =0时,立辊轧制力FUF-V小于翼缘单独搓轧的轧制力FV1,但与翼缘部分同径(立辊直径)平板轧制力FV0相当;FUF-V随着

=0时,立辊轧制力FUF-V小于翼缘单独搓轧的轧制力FV1,但与翼缘部分同径(立辊直径)平板轧制力FV0相当;FUF-V随着 的增加而增大,随着ξsf减小曲线趋于平缓,轧制力的变化范围缩小;当

的增加而增大,随着ξsf减小曲线趋于平缓,轧制力的变化范围缩小;当 =0时,不同面积比下的FUF-V基本不变;但是,每条曲线关于

=0时,不同面积比下的FUF-V基本不变;但是,每条曲线关于 =0并不呈完全的反对称关系。

=0并不呈完全的反对称关系。

图10  对FUF-V的影响规律

对FUF-V的影响规律

Fig.10 Variation rules of FUF-V with

图11所示为FUF-V随ξsf的变化规律。从图11可见:在相同延伸比条件下,FUF-V随面积比ξsf的变化大致呈线性关系,并随着ξsf的减小向一个稳定值收敛;当λ=1时(腿腰延伸协调),立辊的轧制力基本恒定,且与平板轧制力FV0大致相等。

图11 腹板与翼缘的面积比ξsf对 FUF-V的影响规律

Fig.11 Variation rules of FUF-V with ξsf

根据分析可知:当 =0时,FUF-V保持恒定,此时FUF-V≈Fh0;当λ不变时,FUF-H-H随ξsf呈线性变化,并随着ξsf的减小收敛于FV0附近。由此,可以假设FUF-V的计算公式模式为

=0时,FUF-V保持恒定,此时FUF-V≈Fh0;当λ不变时,FUF-H-H随ξsf呈线性变化,并随着ξsf的减小收敛于FV0附近。由此,可以假设FUF-V的计算公式模式为

(6)

(6)

其中:FV0为平板轧制力;kf为图11中拟合直线的斜率。

(7)

(7)

由式(6)~(7)可得FUF-V的计算模式为

(8)

(8)

根据本文的大量数据点对公式进行回归得到未知系数:a=-1.087 3,b=0.469 8,c=1.661 8。

5 计算公式应用

以700 mm×300 mm(截面宽×高)规格(Q235)的H型钢万能轧制第4道次的UF轧制为基本工况,改变翼缘的相对压下量εf得到不同的轧制工况。

应用本文计算归纳的轧制力计算公式计算以上各个工况的轧制力,将其与有限元仿真模型的计算结果和实测值对比,结果见图12和图13。从图12和图13可以看出:本文的计算公式和有限元仿真模型计算结果的变化趋势大致相同;水平辊轧制力与有限元结果的最大相对误差为16.7%,与相同工况下的测试值相对误差为3.4%;立辊轧制力与有限元结果的最大相对误差为8.7%,与相同工况下的测试值相对误差为4.4%。对比结果说明本文的计算公式具有一定的适 用性。可见:立辊的轧制力计算误差相对水平轧制力计算相对误差较小。是由于水平辊轧制力由中间位置、圆角位置和侧面位置的轧制力构成,影响因素较多。这里仅考虑不同腿腰延伸比和面积比下中间位置轧制力与总轧制力之比,而该比例系数还受到圆角以及占腹板长度的比值等因素的影响,所以,水平辊轧制力的计算相对误差稍大。在后续研究中,可以根据产生误差的原因进行深入研究,从而对本文公式进行修正。

图12 水平辊轧制力对比

Fig.12 Comparison of rolling forces of horizontal roll

图13 立辊轧制力对比

Fig.13 Comparison of rolling forces of vertical roll

6 结论

(1) 水平辊各个位置的轧制力与总轧制力之比随着腿腰延伸比的调整而变化,圆角位置的轧制力与总轧制力之比随腿腰延伸比增大而增加;当腿腰延伸比比较大时,H型钢的水平辊轧制力不能忽略圆角的影响。

(2) H型钢万能轧制力与平板轧制的区别主要在于受到腹板和翼缘间纵向拉压应力的影响,而该影响主要体现在腿腰延伸比以及面积比2个方面。

(3) 在相同的面积比时,腿腰延伸比增大,水平辊轧制力减小;翼缘与腹板的面积比ξsw减小时,不同延伸比时的水平辊中间位置轧制力FUF-H-H收敛于1个稳定值。根据其变化规律得出水平辊轧制力的计算公式。

(4) 在面积比相同时,腿腰延伸比增大,立辊轧制力增大;当腹板与翼缘的面积比ξsf减小时,不同延伸比时的立辊轧制力FUF-V收敛于1个稳定值。根据其变化规律得出立辊轧制力的计算公式。

(5) 采用700 mm×300 mm(截面宽×高)的H型钢万能轧制第4道次的UF轧制工况进行验证,发现本文公式使用方便,其结果能够较好地反映轧制力的变化趋势,与有限元的最大相对误差为16.7%,与实测值的相对误差保持在5%之内。

参考文献:

[1] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2004: 339-400.

PENG Dashu. The principle of metal plastic forming processing[M]. Changsha: Central South University Press, 2004: 339-400.

[2] 中岛浩卫. H型钢的万能轧制特性[J]. 申光宪, 译. 国外重型机械-型钢轧制专辑, 1983, 1(3): 1-18.

ZHONGDAO Haowei. The universal rolling characteristic of H-beam[J]. SHEN Guangxian, trans. Heavy machinery of foreign, 1983, 1(3): 1-18.

[3] 王有铭. 型钢生产理论与工艺[M]. 北京: 冶金工业出版社, 1996: 71-90.

WANG Youming. The theory and process of section steel production[J]. Beijing: Metallurgy Industry Press, 1996: 71-90.

[4] 潘亮, 程知松, 范爱琴. X-H轧制法轧制H型钢轧制力模型的研究[J]. 钢铁, 2007, 42(6): 54 -57.

PAN Liang, CHENG Zhisong, FAN Aiqin. Study of rolling force model of X-H rolling H-Beam[J]. Iron and steel, 2007, 42(6): 54-57.

[5] 张海龙, 张勤河, 贺庆强. H型钢连轧过程轧制力模型的研究[J]. 钢铁, 2009, 44(4): 46-49.

ZHANG Hailong, ZHANG Qinhe, HE Qingqiang. Study on continuous rolling force model for H-Beam[J]. Iron and steel, 2009, 44(4): 46-49.

[6] 梁明, 赵志业. 四辊孔型中轧制H形件的轧制力[J]. 钢铁, 1986, 21(7): 10-16.

LIANG Ming, ZHAO Zhiye. Rolling load in the passes for H-beam in 4-high universal mill[J]. Iron and steel, 1986, 21(7): 10-16.

[7] 王哲, 曹鸿德. 用能量法求解H型钢万能轧制的力能参数[J]. 重型机械, 1993, 1(6): 29-34.

WANG Zhe, CAO Hongde. On the use of the energy method for force and torque in H-beam rolling[J]. Heavy Machinery, 1993, 1(6): 29-34.

[8] Zhang W, Zhu C, Widera G E O. On the Use of the Upper-bound Method for load Determiation in H-beam Rolling[J]. Journal of Materials Processing Technology, 1996, 56(1/2/3/4): 820-833.

[9] Jin X G,, Liu Y L, Lian J C, et al. A three- dimensional analysis of the universal beam tandem rolling process. Part Ⅰ: Deformation analysis[J]. Journal of Materials Processing Technology, 2000, 102(1): 59-64.

[10] Jin X G, Liu Y L, Lian J C, et al. A three- dimensional analysis of the universal beam tandem rolling process. Part Ⅱ: Stress analysis[J]. Journal of Materials Processing Technology, 2000, 102(1): 65-69.

[11] DONG Yonggang, ZHANG Wenzhi. Theoretical and experimental research on rolling force for rail hot rolling by universal mill[J]. Journal of Iron and Steel Research, International, 2010, 17(1): 27-32.

[12] Karen A, Alireza F. Three-dimensional analysis of shape rolling using a generalized upper bound approach[J]. Journal of Materials Processing Technology, 2009, 209(7): 3264-3277.

[13] 曹鸿德. 塑性变形力学基础与轧制原理[M]. 北京: 机械工业出版社, 1981: 47-54.

CAO Hongde. The base of plasticity and rolling theory[M]. Beijing: Mechanical Industry Press, 1981: 47-54.

[14] 王延博, 齐克敏. 金属塑性加工学: 轧制理论与工艺[M]. 北京: 冶金工业出版社, 2005: 50-85.

WANG Yanbo, QI Kemin. Metal plastic processing: Rolling theory and technology[M]. Beijing: Metallurgy Industry Press, 2005: 50-85.

[15] XU Xudong. Research on flange spread of H-Beam on universal mill[J]. Journal of Iron and Steel Research, 2006, 13(1): 27-30.

(编辑 邓履翔)

收稿日期:2012-07-03;修回日期:2012-08-30

基金项目:国家高技术研究发展计划(“863”计划)资助项目(2009AA03Z515)

通信作者:臧勇(1963-),男,江苏铜山人,教授,从事塑性加工工艺研究;电话:010-62334441;E-mail: yzang@ustb.edu.cn