DOI: 10.11817/j.issn.1672-7207.2015.02.015

大型水压机操纵系统间隙在线补偿

杨俊,谭建平,舒招强

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:大型水压机操纵系统的凸轮顶杆与阀杆的间隙影响了水压机的控制精度和零部件更换的频率,为了保证水压机间隙增大情况下的控制精度和系统继续工作能力,提高水压机间隙故障的容错能力,通过检测操纵系统中油缸压力瞬变时的凸轮转角,与无间隙时的凸轮转角对比,对间隙量进行在线检测并补偿,并采用模糊PID补偿策略提高补偿精度。通过模拟间隙为5 mm和10 mm的工况,对在线补偿策略进行实验验证,对比无补偿策略和有补偿策略作用下的系统位移响应特性。研究结果表明:该在线补偿策略能有效地解决大型水压机操纵系统的间隙补偿问题,对提高水压机的控制精度、减少零部件的更换频率有一定作用。

关键词:大型水压机;操纵系统;间隙;在线补偿

中图分类号:TP271+.3 文献标志码:A 文章编号:1672-7207(2015)02-0479-06

Online compensation of gap in large hydraulic press operation system

YANG Jun, TAN Jianping, SHU Zhaoqiang

(State Key Laboratory of High Performance Complicated Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083 China)

Abstract: The gaps between the cam follower and the valve stem of large hydraulic press control system affect the control accuracy and parts replacement frequency in large hydraulic press. In order to improve the control accuracy and fault tolerance capacity when the gap increases, control and fuzzy PID compensation strategy were used by detecting the cam angle when cylinder transient pressure appears and by comparing with the normal cam angle. Experimental verification was carried out under simulated intervals of 5 mm and 10 mm and the displacement responses with compensation strategy and without compensation were contrasted. The results show that the online compensation strategy can effectively solve the problem of increased gap in large hydraulic press operating system. It is significant for reducing the frequency of replacement of the parts and improving the control accuracy.

Key words: large hydraulic press; operation system; gap; online compensation

大型水压机是航空航天、军事国防和现代工业的重要战略装备,是一个国家工业化程度和国防实力的重要标志之一[1-2]。谭建平等[1]对国内最大的300 MN模锻水压机进行了改造,利用电液操纵系统代替原有的大扳把机构,实现了水压机控制的自动化。该操纵系统由液压驱动系统和凸轮顶杆式提阀开启装置组成。由于阀芯开启力巨大和现场环境比较复杂,特别是开启装置中的凸轮顶杆与阀杆部分,由于载荷巨大和长期的使用经常出现磨损和变形的情况,导致凸轮顶杆和阀杆的间隙增大。间隙的存在对水阀的精确开启有重要的影响,当凸轮顶杆与阀杆间隙变化时,阀芯的开启高度发生变化,影响了水压机系统的动态特性。凭操作者人工观察并进行调整,误差较大,特别是在自动锻造过程中,程序无法对间隙变化进行实时修正。谭建平等[3]通过分析间隙情况下的水压机系统动态特性,给出了水压机正常工作情况下间隙的最大允许值,但并未给出解决间隙问题的有效方法。陈晖等[4]分析了水阀开启速度对系统动态特性的响应,结果表明间隙是水压机控制精度中的一个重要影响因素。工业现场针对间隙问题的通常解决办法是凭工作人员的经验定期更换装置的凸轮顶杆和阀杆,这种解决方法简单,但存在2个问题:1) 增加了零部件更换的频率,导致了不必要的浪费,增加了企业成本;2) 在较小磨损和小变形情况下,由于阀芯开启的规律发生了变化,导致控制精度不高,降低了产品质量。为了减少零部件的更换频率和实时监测系统的健康状况,提高水压机控制的精度,在操纵系统中进行间隙在线预测补偿,提高装置在磨损和较小变形下的继续工作能力。本文作者将凸轮顶杆与阀杆之间的间隙作为操纵系统的参考输入补偿量,反馈给操纵系统的目标转角,实现间隙补偿。具体来说,通过在线检测操纵系统中油缸压力瞬态时的凸轮转角,与无间隙时的凸轮转角对比,通过计算,得到1个间隙量,然后利用该间隙量对目标转角进行修正,实现凸轮顶杆与阀杆间隙的补偿。

1 操纵系统描述

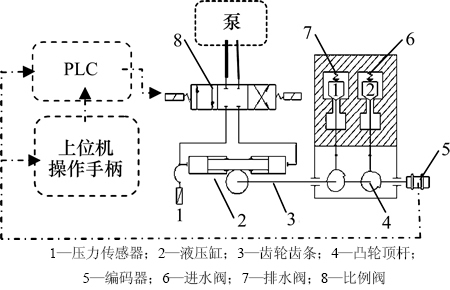

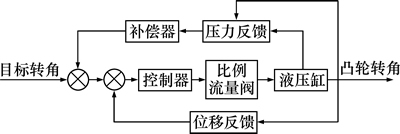

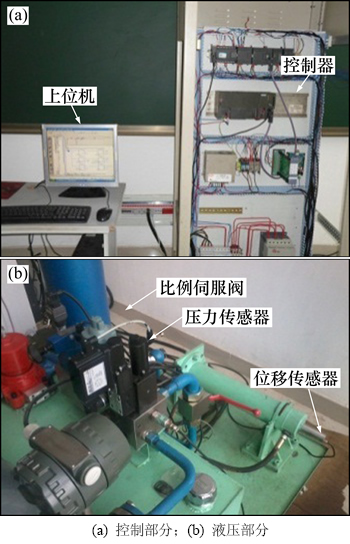

大型水压机的操纵系统示意图如图1所示,包括液压传动部分、控制部分、上位机部分及一套阀芯开启装置。液压传动部分包括泵站及其附属设施,为操纵系统的工作提供动力;控制部分由PLC及附属设备组成,包括接受上位机控制指令,为比例阀流量阀给定控制信息;上位机部分包括上位机及操作手柄等,主要提供控制的参考指令和系统状态监控;阀芯开启装置由齿轮齿条、凸轮顶杆机构组成,将液压缸的位移转变成阀芯的位移,实现水压机的启闭过程。

在凸轮顶杆系统中,凸轮的转动带动顶杆的上下移动,顶杆驱动阀杆,实现水阀阀芯的开启与关闭。由于阀芯的结构是提阀结构,阀芯的开启高度与凸轮的升程直接相关,当有间隙出现时,在同样的输入转角下,阀芯开启的高度小于期望的开启高度。

图1 操纵系统原理图

Fig. 1 Schematic diagram of operation system

2 补偿原理

陈晖等[4]对水阀开启力进行了研究,得到其开启力具有瞬变重载的特点,所以,操纵系统系统中的油缸压力也存在着瞬变。图2所示为在线预测补偿过程示意图,图3所示为补偿的过程框图。随着间隙的增大,整个开启力变化过程是向后移动的,根据文献[4],当顶杆接触阀杆一段很短时间后,油缸中的压力将出现1个瞬变值。通过角位移传感器采集压力出现瞬变时的凸轮转角位置,并与无间隙情况下瞬变压力出现时的凸轮转角对比,在控制器中进行运算处理后,将补偿值输入控制指令,修正目标转角值。将修正后的目标指令输入液压系统中的比例控制阀,实现间隙的检测与补偿。

设凸轮转角的控制目标为θ,凸轮转角的补偿值为Δθ,则补偿值满足以下函数关系:

其中:Δh为间隙量;f(θ)表示顶杆的升程与凸轮转角的函数关系。当凸轮的轮廓曲线确定后,凸轮升程与转角的函数关系是已知的,若能检测到间隙量Δh,则由式(1)可解出控制目标凸轮转角的补偿值Δθ。

以大型水压机现场应用的等速凸轮顶杆为例,对补偿原理进行进一步说明。该凸轮轮廓线是线性的,凸轮升程与凸轮转角呈比例关系,即凸轮的升程与转角的关系为

其中:k为比例系数。由式(1)和(2)可知

图2 补偿过程示意图

Fig. 2 Diagram of operation system

图3 补偿原理图

Fig. 3 Schematic diagram of compensation

其中:θ0为无间隙情况下,液压缸压力出现瞬变时的凸轮转角;θ1为凸轮顶杆机构运行一段时间后,在有间隙情况下,实时检测到压力出现瞬变时的凸轮转角。根据检测到的间隙量,反馈修正凸轮的目标转角。

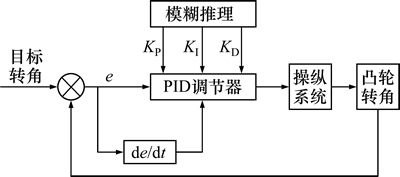

3 补偿策略

间隙补偿实质是一种在线修正目标值的电液伺服控制过程,为了提高控制精度,需要采用一些先进的控制策略。PID控制策略的是一种基于误差去消除误差的控制策略,不需要系统的精确数学模型,在工程控制应用领域得到广泛应用[5-6]。其缺点在于控制量是3个参数的加权和形式,快速性与超调之间的矛盾很难得到完美解决。随着控制器向数字化方向发展,限制加权和形式已经没有必要[7-10]。作为PID的改进策略,自抗扰控制PID、模糊PID及其他智能PID等先进的PID控制策略得到了广泛应用[11-14]。其中,模糊PID由于设计简单、便于理解且具有较高的控制精度,在复杂的工业现场环境下得到广泛应用[6],特别是对于PLC作控制器的控制系统,模糊控制策略容易实现。为了提高预测补偿的精度,将模糊PID控制策略应用于间隙的预测补偿中。

模糊逻辑控制器基于语言变量,首先对输入信号进行模糊化处理,然后基于经验和专家知识进行模糊逻辑推理,最后解模糊化后得到控制信号。模糊PID控制策略以传统的PID控制策略为基础。

传统的PID控制策略为

为了在PLC中实现方便,引入状态变量 ,故

,故

其中:KP,KI和KD分别为比例系数、积分系数和微分系数。在传统的PID控制策略中,这3个参数都是常数,输出是这3个参数的加权和形式。模糊控制策略基于传统PID,区别在于这3个参数是变化的。

模糊PID策略解决了传统PID控制量是参数的加权和形式,以不同时刻的偏差e和偏差的导数de作为输入,以KP,KI和KD为输出,得到一个非线性的控制形式,建立模糊逻辑推理系统,其模糊控制器结构如图4所示。

图4 模糊控制结构图

Fig. 4 Schematic diagram of fuzzy control

4 实验

4.1 实验设备

由于大型水压机设备的重要性,不方便在其上进行现场实验。根据前面的系统描述可知,操纵系统中凸轮的转角和活塞杆的位移具有函数关系,即凸轮的升程与驱动油缸的活塞位移具有一一对应关系,所以,将在线预测补偿策略在液压实验台上进行验证,通过分析活塞杆的位移响应特性验证补偿策略的有效性。

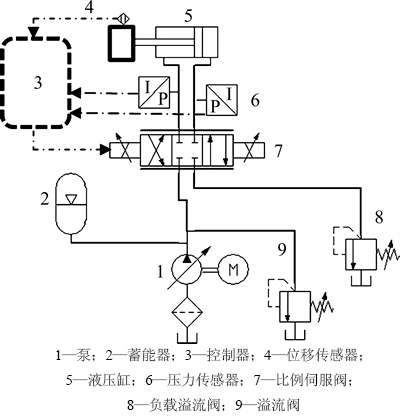

实验台的原理图和实验系统分别如图5和图6所示。蓄能器2和电机驱动的液压泵1为系统提供稳定的压力油,以减少输入压力波动对系统的影响。溢流阀9控制系统的最高压力,起到溢流保护作用。比例溢流阀8作为系统的负载使用,可以方便调节系统的外负载力。比例阀7接受控制器3的指令,控制液压缸的运动。控制系统的硬件部分由PC机、工控机PLC和数据采集卡共3个传感器组成。软件部分采用西门子公司自带的PLC编程软件,控制界面采用winCC6.0编制,方便控制信号与相关参数的设定和数据存储。

图5 液压系统原理图

Fig. 5 Schematic diagram of hydraulic system

图6 实验系统

Fig. 6 Layout of hydraulic test bench

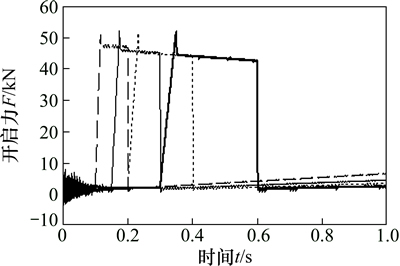

4.2 间隙的模拟

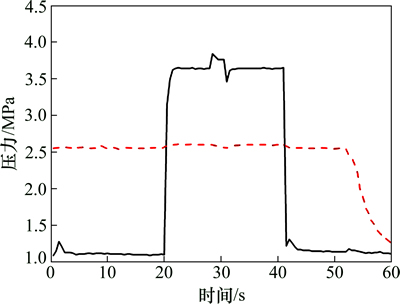

在实验室直接建立具有凸轮顶杆与阀杆间隙的平台比较复杂,文献[4]说明了当间隙量增大时,瞬变压力出现的转角位置会后移,通过在不同的位置启闭溢流阀模拟不同间隙。负载溢流阀作用时,液压缸的出油压力会出现1个瞬变值。图7所示为进出油口的压力曲线。由图7可知:系统的进油压力是比较稳定的,当溢流阀开始作用时,系统出现了明显的压力瞬变过程,波动的幅值取决于溢流阀设定的溢流压力。

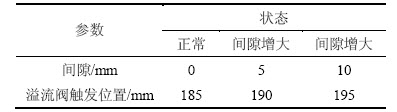

模拟不同间隙下的溢流阀作用情况,在无间隙情况下,设定活塞杆位移到185 mm,溢流阀出现溢流压力的瞬变,作为标准参考值,如表1所示。当间隙为5 mm和10 mm时,按照前面的分析,溢流阀出现压力瞬变的位置将会后移5 mm和10mm,即为190 mm和195 mm。

图7 瞬态压力冲击曲线

Fig. 7 Curve of transient hydraulic pressure

表1 不同间隙量模拟

Table 1 Simulation of different intervals

4.3 结果与讨论

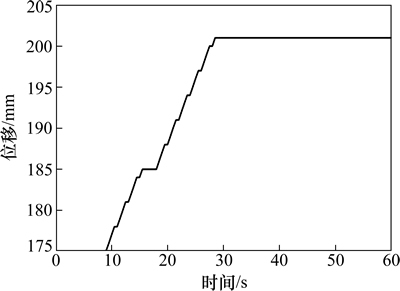

在无间隙情况下,给定活塞杆的目标位移为200 mm,溢流阀触发位置在185 mm处。图8所示为无间隙情况下的液压系统位移响应曲线,在185 mm处位移出现了1个台阶,说明在负载压力突然增加的瞬间,活塞杆处于暂时停止状态。最终活塞位移到201 mm时停止,与目标值比较,其误差为1 mm。

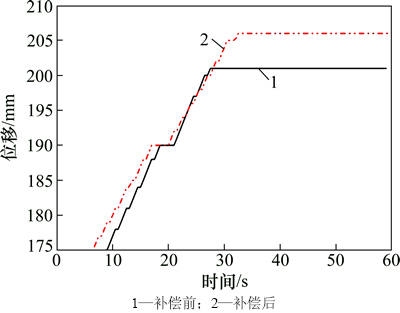

当间隙为5 mm时,补偿前后的系统位移响应曲线如图9所示。理论上,当间隙增加5 mm后,按照表1,此时溢流阀开启作用的位置在190 mm处,活塞杆的目标位移应该增加5 mm,即为205 mm。

图8 无间隙时的系统响应

Fig. 8 System response without interval

补偿前,瞬变压力出现在190 mm处,活塞停止在201 mm处,与目标值205 mm比较,误差为4 mm;而补偿后,瞬变压力出现在190 mm处,活塞的停止位置在206 mm处,误差为1 mm。

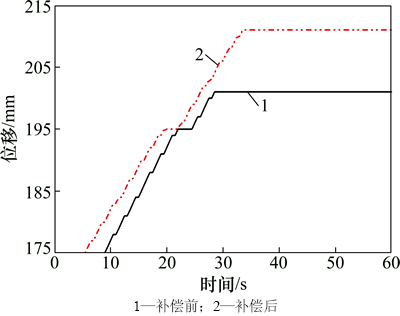

当间隙为10 mm时,补偿前后的系统位移响应曲线如图10所示。理论上,当间隙增加10 mm后,按照表1,此时溢流阀开启作用的位置在195 mm处,活塞杆的目标位移应该增加10 mm,即为210 mm。

补偿前,瞬变压力出现在195 mm处,活塞停止在201 mm处,与目标值201 mm比较,误差为9 mm;而补偿后,瞬变压力出现在195 mm处,活塞的停止位置为211 mm,误差为1 mm。

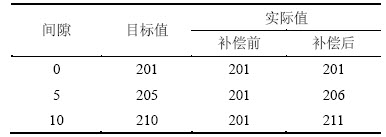

对比图9和图10分析不同间隙情况下的补偿效果,对比结果如表2所示。

图9 间隙为5 mm时的补偿前后系统响应

Fig. 9 System response under 5 mm intervals with compensation and without compensation

图10 间隙为10 mm时的补偿前后系统响应

Fig. 10 System response under 10 mm intervals with compensation and without compensation

表2 不同间隙时的补偿效果对比

Table 2 Comparison of compensation effect in different intervals mm

由表2可知:补偿前,随着间隙增加,实验值与目标值误差越来越大;当间隙由0 mm增加到10 mm后,其误差相应增加;采用补偿策略后,误差与间隙没有关系,始终为1 mm。这说明采用在线补偿后,间隙的影响得到消除,表明了补偿策略的有效性,同时也说明采用补偿策略后,在一定的磨损和变形情况下,凸轮顶杆装置具有继续工作的能力。但由于所用的位移传感器的精度和外界干扰的原因,该在线补偿策略的误差至少有1 mm。选用高精度的位移传感器和提高补偿策略鲁棒性还需要更进一步研究。

5 结论

1) 针对大型水压机凸轮顶杆与阀杆的间隙问题,提出利用检测液压缸压力瞬变出现时凸轮转角位置对间隙量进行检测,并提出了在线补偿策略对间隙进行补偿。

2) 以直线轮廓凸轮为例,对补偿策略进行了验证,证明了补偿策略在的可行性。并提出利用模糊PID控制策略提高补偿的精度。

3) 通过对间隙进行在线补偿,提高了操纵系统间隙故障情况下的容错能力,并为故障情况下的高精度水阀开启提供了参考。

参考文献:

[1] 谭建平, 黄长征, 刘彬, 等. 瞬变载荷下巨型水压机液压操作控制策略[J]. 机械工程学报, 2008, 44(11): 272-277.

TAN Jianping, HUANG Changzheng, LIU Bing, et al. Control strategy of hydraulic operation system under the transient load in giant hydrulic press[J]. Chinese Journal of Mechanical Engineering, 2008, 44(11): 272-277.

[2] 高峰, 郭为忠, 宋清玉, 等. 重型制造装备国内外研究与发展[J]. 机械工程学报, 2010, 46(19): 93-108.

GAO Feng, GUO Weizhong, SONG Qingyu, et al. Current development of heavy duty manufacturing equipment[J]. Chinese Journal of Mechanical Engineering, 2010, 46(19): 93-108.

[3] 谭建平, 刘石梅, 陈晖. 300 MN模锻液压机液压变压系统故障仿真研究[J]. 锻压技术, 2011, 36(2): 59-63.

TAN Jianping, LIU Shimei, CHEN Hui. Simulation on Research on hydraulic transformer system fault of 300mn die forging hydraulic press[J]. Forging and Stamping Technology, 2011, 36(2): 59-63.

[4] 陈晖, 谭建平. 大型模锻水压机高压大流量水阀开启力特性[J]. 中南大学学报(自然科学版), 2012, 43(8): 2993-2999.

CHEN Hui, TAN Jianping. Opening force characteristic of water valve with high pressure and large flow capacity in large die forging hydraulic press[J]. Journal of Central South University (Science and Technology), 2012, 43(8): 2993-2999.

[5] Zhao S D, Zheng J M, Wei S G. Application of self-tuning fuzzy PID controller for a SRM direct drive volume control hydraulic press[J]. Control Eng Pract, 2009, 17(12): 1398-1404.

[6] Romero J A, Sanchis R, Balaguer P. PI and PID auto-tuning procedure based on simplified single parameter optimization[J]. Journal of Process Control, 2011, 21(6): 840-851.

[7] 韩京清. 自抗扰控制技术[J]. 前沿科学, 2007(1): 24-31.

HAN Jingqing. Auto disturbances rejection control technique[J]. Frontier Science, 2007(1): 24-31.

[8] 黄一, 张文革. 自抗扰控制器的发展[J]. 控制理论与应用, 2002, 19(4): 485-492.

HUANG Yi, ZHANG Wengei. Development of active disturbance rejection controller[J]. Control Theory and Applications, 2002, 19(4): 485-492.

[9] Kahkeshi M S, Sheikholeslam F, Zekri M. Design of adaptive fuzzy wavelet neural sliding mode controller for uncertain nonlinear systems[J]. ISA Trans, 2013, 52(3): 342-350.

[10] Ahn K K, Truong D Q. Online tuning fuzzy PID controller using robust extended Kalman filter[J]. Journal of Process Control, 2009, 19(6): 1011-1023.

[11] Truong D Q, Ahn K K. Force control for press machines using an online smart tuning fuzzy PID based on a robust extended Kalman filter[J]. Expert Syst Appl, 2011, 38: 5879-5894.

[12] Zhao Y M, Xie W F, Tu X W. Performance-based parameter tuning method of model-driven PID control systems[J]. ISA Trans, 2012, 51(3): 393-399.

[13] Deticek E, Zuperl U. An intelligent electro-hydraulic servo drive positioning[J]. Journal of Mechanical Engineering, 2011, 57(5): 394-404.

[14] 杨俊, 谭建平. 阀控非对称缸与气鲁棒的线化控制[J]. 华中科技大学学报, 2014, 42(2): 106-110.

YANG Jun, TAN Jianping. Robust feed back linearization control of valve controlled asymmetric cylinder system[J]. J Huazhong Univ of Sci and Tech.

(编辑 陈灿华)

收稿日期:2014-03-05;修回日期:2014-05-22

基金项目(Foundation item):高性能复杂制造国家重点实验室自主研究项目(zzyjkt2013-04);流体动力与机电系统国家重点实验室开发基金资助项目(GZKF-201023);中央高校研究生自主探索项目(2013zzts030)(Project (zzyjkt2013-04) supported by the High Performance Complex Manufacturing of Independent Research Project of State Key Laboratory; Project (GZKF-201023) supported by the Fluid Dynamic and Development Fund Project of State Key Laboratory of Electromechanical System; Project (2013zzts030) supported by the Independently Exploration Research of Centre on College Students)

通信作者:谭建平,教授,博士生导师,从事现代机电液控制理论与技术、机电系统状态监测故障诊断、微型流体机械设计与驱动控制研究;E-mail:jptan@163.com