DOI:10.19476/j.ysxb.1004.0609.2017.09.09

GH4742合金疲劳裂纹扩展行为

张宝宁1,袁 超1,郭建亭1,秦鹤勇2,赵光普2

(1. 中国科学院 金属研究所,沈阳 110016;

2. 钢铁研究总院 高温材料研究所,北京 100081)

摘 要:研究GH4742合金在室温、700 ℃及750 ℃的疲劳裂纹扩展行为。分析温度和应力强度因子对疲劳裂纹扩展寿命与速率的影响,利用扫描电镜观察不同温度下的疲劳裂纹扩展断口。采用背散射电子衍射(EBSD)技术分析合金裂纹扩展的晶体学机制。结果表明,随着温度的升高,合金的裂纹扩展寿命降低,裂纹扩展速率增加,沿晶断裂特征更明显。应力强度因子越大,裂纹扩展速率越大。在原始大变形晶粒中裂纹以穿晶方式沿着小角度晶界扩展,裂纹扩展到再结晶晶界时以沿晶扩展为主,其扩展方式取决于相邻晶粒的面间角和取向差。

关键词:镍基高温合金;疲劳裂纹扩展;断口;微观机制

文章编号:1004-0609(2017)-09-1823-09 中图分类号:TG132.3 文献标志码:A

疲劳裂纹扩展速率是衡量裂纹构件抗疲劳性能的重要指标,也是涡轮盘等部件的损伤容限设计和寿命预测的重要指标之一,对于评估构件的安全可靠性和失效分析等有重要意义。影响合金疲劳裂纹扩展速率的因素很多,主要分为两个方面:外部因素和内部因素。外部因素指试件或构件的实验条件和服役条件,如环境温度、频率、应力比、保载时间等因素[1-6]。内部因素指材料本身的物理性质和组织状态,如合金的弹性模量、强度、晶粒尺寸、强化相种类、数量和形貌等显微组织[7-8]。目前,GH4742合金应用于某燃气轮机的一级高压涡轮盘,高压涡轮盘长期服役于高温、高离心力等复杂条件下,其疲劳裂纹扩展性能对其安全服役至关重要。而国内主要研究了GH4742合金的热变形行为[9]、热处理对合金组织、力学性能的影响等方面[10],探索均匀化处理制度和变形条件对GH4742合金组织与性能的影响,致力于寻找合金的最佳变形方法和条件,解决难变形合金GH4742合金的等温变形热加工问题,而GH4742合金的疲劳性能国内外报道甚少。因此,本文作者主要研究温度对GH4742合金的疲劳裂纹扩展性能的影响,为涡轮盘的安全可靠应用和寿命预测提供实验基础和理论支持。

1 实验

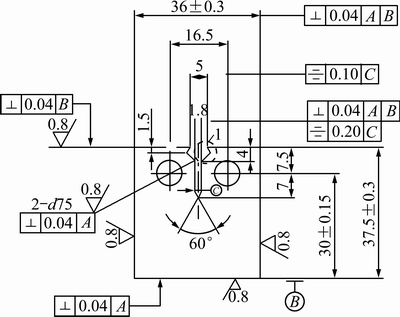

实验材料取自标准热处理态涡轮盘轮缘弦向,根据GB/T 6398-2000规定的金属材料疲劳裂纹扩展速率试验方法加工紧凑拉伸试样,宽度W=30 mm,厚度B=7.6 mm,试样示意图见图1。

图1 疲劳裂纹扩展试样示意图

Fig. 1 CT specimen showing dimensions for fatigue crack growth (FCG) test (Unit: mm)

实验分别在室温、700 ℃及750 ℃ 3个温度进行,为保证数据的可靠性,每个温度下测试3个样品。疲劳裂纹扩展实验在MTS810型疲劳机上完成,控制方法采用的是恒力幅测定材料的疲劳裂纹扩展速率da/dN,波形为正弦波,加载频率为10 Hz,应力比为0.1。本实验中采集的数据是裂纹扩展阶段中稳态扩展区的裂纹长度a和裂纹扩展速率da/dN,即da/dN在1×10-5~1×10-2 mm/cycle范围内,数据处理采用七点递增多项式法[11]。对于3个温度下合金的疲劳裂纹扩展断口进行扫描分析。根据GH4742合金使用温度,在700 ℃下进行了第四个未拉断试样的疲劳裂纹扩展实验,与之前的实验条件一致,对于未拉断的疲劳裂纹扩展试样采用EBSD技术分析其裂纹扩展晶体学机制。利用Hitachi S-3400N型扫描电镜附带的EBSD系统和Channel-5软件包对样品进行晶体学表征分析。

2 结果与分析

2.1 疲劳裂纹扩展性能

疲劳裂纹扩展速率da/dN是反映带裂纹的零构件抗疲劳断裂的一个重要指标,也是估算构件剩余疲劳寿命必不可少的参数。完整的疲劳裂纹扩展速率曲线,包括三部分:近门槛区、裂纹稳态扩展区和裂纹快速扩展区(瞬断区)。Paris公式只适用于稳态扩展区,通常采用帕里斯(Paris)公式[12-13]来表征稳态扩展阶段疲劳裂纹扩展速率。

Pairs用应力强度因子幅△K来定量描述疲劳裂纹扩展速率,提出的疲劳裂纹扩展速率表达式:

da/dN=C(ΔK)m (1)

式中:C、m是材料性能常数。

疲劳裂纹扩展的一般规律常用da/dN~△K在双对数坐标下的裂纹扩展速率曲线表示,对式(1)两边取对数,得到:

lg(da/dN)=lgC+mlg(ΔK) (2)

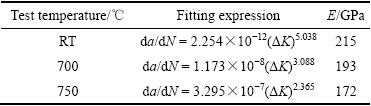

式(2)在双对数坐标中呈线性关系,用线性回归方法计算出GH4742合金疲劳裂纹扩展速率的表达式见表1。材料常数C和m值的变化随温度的升高呈相反的变化趋势,温度越高,C值越大,m值减小。

表1 GH4742合金疲劳裂纹扩展速率表达式

Table 1 FCGR formulas of GH4742 at RT, 700 ℃ and 750 ℃

根据Paris公式拟合得到材料常数C和m,和CT试样有效裂纹长度a处应力强度因子范围ΔK计算式[11]:

(3)

(3)

(4)

(4)

式中:α=a/W,a/W≥0.2的范围有效;a为有效裂纹长度;W为试样宽度;B为试样厚度。

将式(3)代入Pairs公式可得:

(5)

(5)

对式(5)积分有:

(6)

(6)

因此,得到合金构件的疲劳寿命积分表达式,进一步预测构件的剩余疲劳寿命。

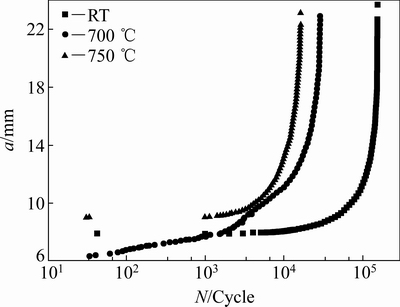

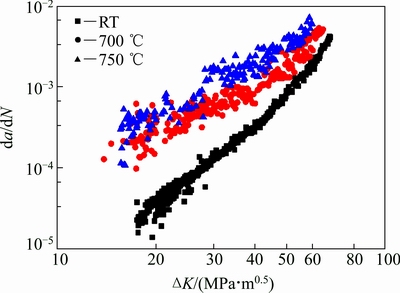

图2和图3所示分别是室温、700 ℃及750 ℃ 3个温度下的合金疲劳扩展寿命及疲劳裂纹扩展速率曲线。由图2可以看出裂纹扩展规律基本一致,合金的裂纹扩展寿命随着温度升高而降低。在整个稳态扩展区裂纹扩展速率随应力强度因子ΔK的增大而增大,如图3所示。应力强度因子ΔK的跨度越大,说明合金的抗疲劳裂纹扩展性能越优异。GH4742合金室温下应力强度因子ΔK在10.5~67.4 MPa,700 ℃下应力强度因子ΔK在12.2~65.9 MPa,750 ℃下应力强度因子ΔK在13.3~56.7 MPa。

由图2可以发现,温度越高,合金的疲劳寿命越低。在室温条件下,合金的疲劳裂纹扩展寿命是105数量级,700 ℃和750 ℃温度下,合金的疲劳裂纹扩展寿命是104数量级。由图3可以发现,在整个稳态区,3个温度下的裂纹扩展变化趋势相近,700℃的裂纹扩展速率与750 ℃的裂纹扩展速率更接近。随着温度升高,应力强度因子ΔK越大,裂纹扩展速率越大。在低应力强度因子ΔK(ΔK在15~50 MPa·m0.5)范围内,700与750 ℃的裂纹扩展速率比室温的裂纹扩展速率高很多,但在高应力强度因子ΔK(ΔK在50~65 MPa·m0.5)范围内,700与750 ℃的裂纹扩展速率比室温的裂纹扩展速率略高。即在低应力强度因子温度对裂纹扩展速率的影响比高应力强度因子对裂纹扩展速率的影响要大。

图2 温度对GH4742合金的a-N曲线的影响

Fig. 2 Effects of temperature on a-N curves

图3 温度对GH4742合金裂纹扩展速率曲线的影响

Fig. 3 Effects of temperature on da/dN-ΔK curves

裂纹扩展的本质是外界加载条件提供的驱动力超过了材料的内在属性所具有的裂纹扩展抗力。加载的应力强度因子ΔK则是裂纹扩展的驱动力。当应力强度因子ΔK越大,裂纹前沿的加载应力越大,裂纹尖端张开量大,促使裂纹扩展更快。因此,应力强度因子ΔK越大,裂纹扩展速率越大。温度对疲劳裂纹扩展速率的影响比较复杂。温度越高,合金可能会发生高温氧化和蠕变,而且合金的强度和弹性模量都会变化,这些因素都会影响疲劳裂纹扩展速率。一般材料的弹性模量随着温度的升高而降低,GH4742合金室温的弹性模量高于700和750 ℃的弹性模量(见表1)。裂纹扩展速率随着弹性模量的的升高而下降,弹性模量对裂纹扩展速率的影响可以理解为:裂纹扩展必须是裂纹尖端张开,裂纹尖端张开引起裂纹尖端的钝化,为了达到一定的张开量,弹性模量越大的材料需要施加更大的外加载荷,因此高弹性模量的材料具有高的裂纹扩展抗力,即在相同的外加应力强度因子ΔK条件下材料具有较低的裂纹扩展速率。随着温度升高,材料的强度下降,在同样载荷下,裂纹尖端前沿的塑性变形增加,循环变形引起裂纹尖端的疲劳损伤加重,导致疲劳裂纹扩展速率增加。温度升高,晶界强度降低,也是裂纹扩展速率增大的原因之一。此外,温度越高,氧进入到裂纹扩展前沿与合金中的易氧化元素Ti、Al、Cr结合导致氧化越严重,合金的裂纹前沿脆化裂纹扩展速率增加。但另一种可能是,温度升高,裂纹前沿产生氧化物,氧化物使裂纹尖端张开量提前闭合而钝化,裂纹扩展速率下降。

应力强度因子ΔK和温度共同对裂纹扩展速率产生影响。在低应力强度因子范围内(ΔK在15~50 MPa·m0.5区间),裂纹尖端的载荷相对小,扩展速率慢,温度所影响的材料内在因素(弹性模量、材料强度)对裂纹扩展速率占主导作用。在高应力强度因子范围内(ΔK在55~65 MPa·m0.5区间),应力强度因子ΔK对裂纹扩展速率占主导作用,温度所影响的材料内在因素(弹性模量、材料强度)对裂纹扩展速率作用较小(见图3)。

2.2 疲劳裂纹扩展断口形貌

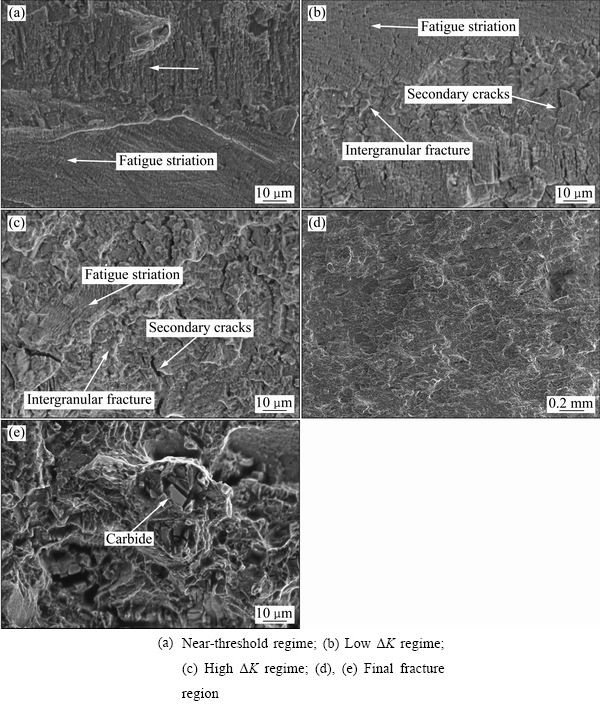

图4~6所示为GH4742合金在室温、700 ℃和750 ℃下的疲劳裂纹扩展断口形貌。疲劳裂纹断口可以分为疲劳裂纹近门槛区、稳态扩展区(低应力强度因子ΔK和高应力强度因子ΔK)和瞬断区。由图4可知,室温下合金疲劳裂纹扩展近门槛区和裂纹扩展区都有明显的疲劳条纹。在扩展近门槛区,疲劳条纹细,疲劳条纹间距小,说明裂纹扩展速率低(见图4(a))。低应力强度因子ΔK区域,疲劳条纹间距增大,二次裂纹增多,释放了裂纹尖端前沿的能量(见图4(b))。应力强度因子ΔK增大,疲劳条纹由韧性疲劳条纹开始转变为脆性疲劳条纹,疲劳条纹之间产生大量二次裂纹(见图4(c)),沿晶断裂特征不明显。裂纹扩展阶段属于纯疲劳扩展机制。研究发现[14],裂纹扩展有4种扩展机制:条带机制、微孔连接、微区解理和晶间分离。瞬断区断口粗糙,存在大量的韧窝,韧窝里有破碎的碳化物质点(见图4(d),(e))。

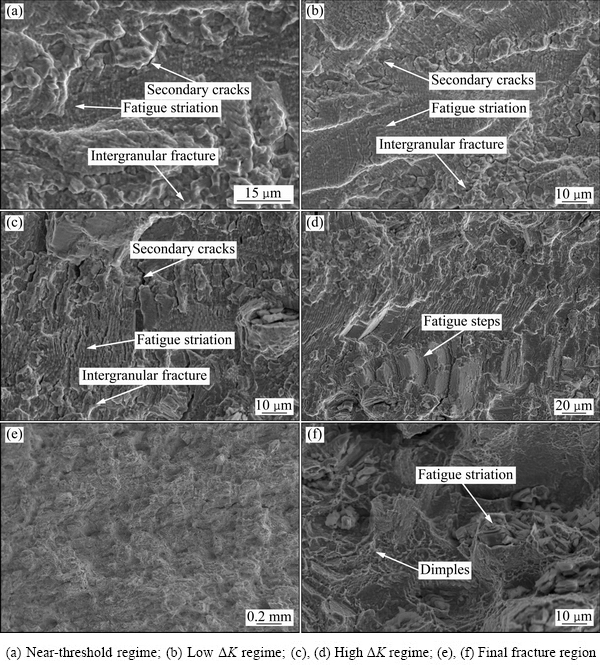

700 ℃的疲劳裂纹扩展断口由穿晶断裂向穿晶沿晶混合断裂方式转变。在近门槛区和低应力强度因子ΔK区裂纹有明显的沿晶扩展特征,疲劳条纹区变少,沿晶界处有二次裂纹(见图5(a)和5(b))。应力强度因子ΔK越大,疲劳条纹间距增大,二次裂纹增多,还存在疲劳台阶(见图5(c)和5(d))。瞬断区断口较室温断口更加不平整,存在韧窝,韧窝中有破碎的碳化物(见图5(e)和5(f))。

图4 GH4742合金室温疲劳裂纹扩展断口形貌

Fig. 4 Morphologies of fatigue crack propagation fracture of GH4742 at RT

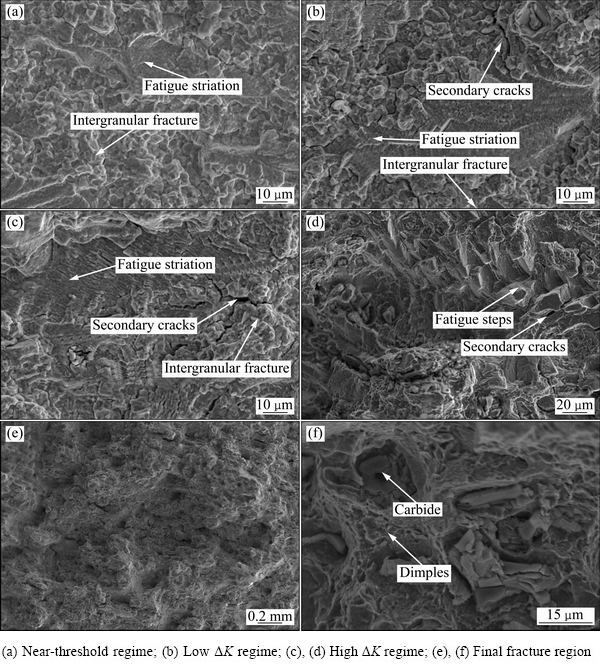

750 ℃的疲劳裂纹扩展断口与700 ℃类似,在裂纹扩展区存在明显的沿晶断裂特征(见图6(a)和6(b)),沿晶断裂区域更大。应力强度因子ΔK越大疲劳条纹间距越大,裂纹扩展速率da/dN越大。沿晶二次裂纹更多(见图6(c)),存在疲劳台阶。瞬断区断口表面粗糙,有韧窝,韧窝里有破碎的碳化物(见图6(d)和6(e))。

在断口的近门槛区,疲劳条纹细,疲劳条纹间距小,说明裂纹扩展速率低。应力强度因子ΔK增大,裂纹尖端扩展的驱动力越大,疲劳条纹间距增大,裂纹扩展速率增大。二次裂纹的产生可以释放裂纹扩展前沿的能量。随着温度升高,裂纹快速扩展区(瞬断区)的粗糙度增大,出现微孔。断口粗糙度增大是由于在高温下裂纹沿晶界偏转造成的[15],微孔是由于在高的应力强度因子ΔK下碳化物、一次γ′相破碎或被拉出产生大量分散的孔洞[15]。温度越高,氧化越严重(见图5(a),6(a)),疲劳条纹不明显,沿晶断裂特征更明显。温度升高,晶界呈薄弱环节,易发生晶界氧化致脆,裂纹易沿晶界扩展。在3个温度下都为混合断裂方式。

2.3 疲劳裂纹扩展EBSD分析

为了研究合金的疲劳裂纹扩展的晶体学机制,定性和定量地研究了合金的形变组织,包括晶粒取向差、晶界分布、应变分布等,首先必须清晰的分辨合金的晶界。由于GH4742合金的组织复杂性,有非常细小的再结晶晶粒,其再结晶晶粒的晶界、孪晶界和小角度晶界用常规的金相侵蚀法难以分辨。EBSD技术可以获得样品中不同晶粒的取向,根据取向信息重构出对应的微观形貌。取向差分布与位置的关系可以得到不同位置处界面特征信息。通过每个取向计算相邻晶粒间的取向差,可确定该取向位置是在晶内还是晶界,是小角度晶界还是大角度晶界[16]。因此,采用EBSD技术分析疲劳裂纹的扩展路径及晶体学机制。

图5 GH4742合金700 ℃疲劳裂纹扩展断口形貌

Fig. 5 Morphologies of fatigue crack propagation fracture of GH4742 at 700 ℃

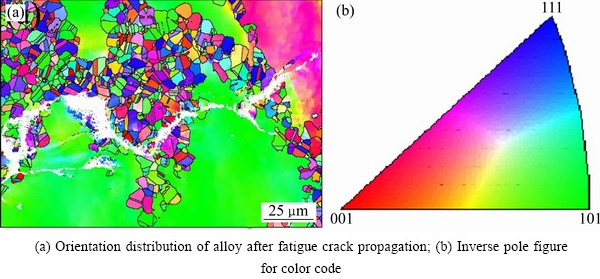

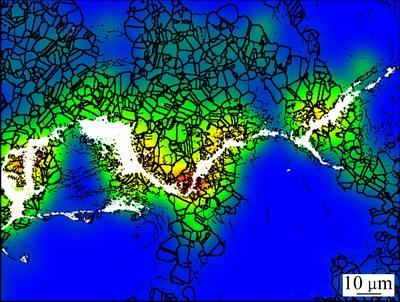

图7所示是合金的疲劳裂纹的扩展形貌及其IPF取向分布图。由图7(a)所示明显可见不同取向的晶粒,图7(b)所示是晶粒取向颜色码。不同的颜色代表不同取向的晶粒,清晰可见细小的等轴晶晶界和孪晶界。由于局部裂纹宽度较宽,部分晶粒尺寸与裂纹宽度差不多,难以分清裂纹扩展的路径。在大的变形晶粒中以穿晶扩展为主,在细小晶粒中可见沿晶穿晶混合扩展,以沿晶扩展为主。

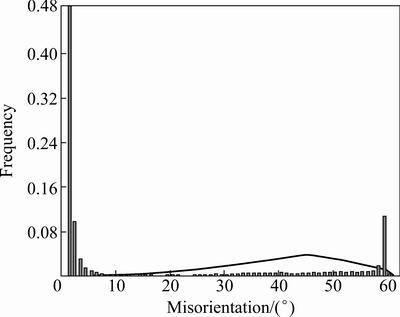

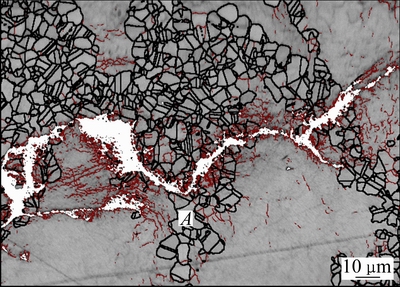

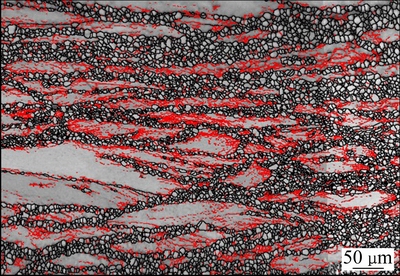

金属材料晶体学中,根据相邻晶粒之间的位向差θ角的大小不同可将晶界分为两类:相邻晶粒之间的位向差小于10°的晶界称为小角度晶界;相邻晶粒之间的位向差大于10°的晶界称为大角度晶界。一般来说,多晶体中的晶界多属于大角度晶界。图8所示是合金的晶粒取向差分布图。由图8可知,裂纹尖端附近的晶粒取向差在0°~10°的小角度晶界超过64%,大角度晶界在10°~58°几乎分布均匀,而在取向差60°的孪晶界大约占13%。由图9的晶界分布图可见小角度晶界主要分布在裂纹附近。裂纹附近的小角度晶界密度高于其他地方的,是因为裂纹扩展过程中,在裂纹两侧附近造成局部塑性变形,位错密度增加,位错堆垛产生小角度晶界[17]。这与黄亚敏等[18]的观点一致,小角度晶界代表位错,其分布显示了局部取向差梯度。GH4742合金的晶粒包括原始变形晶粒、亚晶粒和再结晶晶粒。合金晶粒本身内部包含大量的小角度晶界,图10可见标准态合金组织中小角度晶界主要分布在大的变形晶粒和亚晶粒中,所以研究此合金的裂纹扩展路径与一般的等轴晶组织合金的裂纹扩展不同。

图6 GH4742合金750 ℃疲劳裂纹扩展断口形貌

Fig. 6 Morphologies of fatigue crack propagation fracture of GH4742 at 750 ℃

图7 GH4742合金疲劳裂纹的扩展形貌及其取向分布图

Fig. 7 SEM images of GH4742 alloy

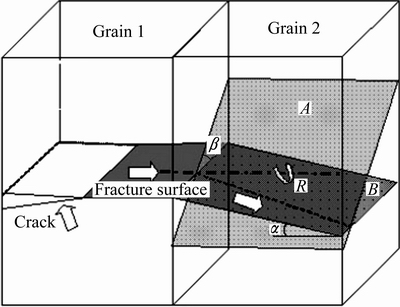

ZHAI等[19-21]都研究了裂纹扩展过程中遇到晶界,提出了裂纹扩展偏转模型,如图11所示。裂纹扩展越过晶界时,裂纹的进一步扩展主要受偏转角α和扭折角β两个参数控制。由于两个相邻晶粒1和2之间存在取向差,从晶粒1扩展进入下一个晶粒2时,裂纹可以从晶粒1的断裂面偏转α角后沿B面继续向前扩展,或者沿轴线R扭转一定的扭折角β沿A面向前扩展。裂纹扩展是通过偏转还是扭转主要取决于裂纹扩展时的两相邻晶粒的晶界平面发生偏转和扭转时的能量大小。但对于多晶材料晶界平面的确定比较困难,雷家峰等[22]在研究β钛合金的疲劳短裂纹扩展时利用晶界两侧裂纹的面间角概念提出了疲劳短裂纹扩展的晶体学模型,他认为晶界两侧的裂纹面间角(相邻两个晶粒内裂纹面即活动滑移面间的夹角)越小,裂纹扩展越过晶界的阻力就越小,更有利于裂纹穿晶扩展。在GH4742合金中,裂纹扩展遇到再结晶晶界时明显可见裂纹扩展发生了偏转,如图9中区域A所示。再结晶晶界属于大角度晶界,由图9也可见以沿晶扩展为主。不考虑氧化,仅从晶体学角度研究,其扩展方式取决于相邻晶粒的面间角和取向差大小。原始大变形晶粒中存在大量的小角度晶界,裂纹扩展到大变形晶粒以穿晶方式扩展,主要沿着小角度晶界的位置扩展(由图9和图10可知)。因此,裂纹扩展遇到大角度晶界时,裂纹扩展路径会发生偏转沿着能量低的路径扩展,遇到小角度晶界时主要沿着小角度晶界扩展。

位错界面主要是小角度晶界,小角度晶界的密度及其分布能够反映微区应变程度及其分布[23]。EBSD分析软件Channel-5可以利用颜色分布清晰的表示裂纹附近的局部取向梯度,也称应变分布图,如图12所示。局部取向梯度反映了裂纹附近处的晶格畸变程度,越靠近裂纹处取向差分布越大,应变程度越大。

图8 GH4742合金晶粒取向差分布图

Fig. 8 Misorientation angles diastribution of GH4742 alloy

图9 GH4742合金晶界分布图

Fig. 9 Grain boundary map of GH4742 alloy

图10 标准热处理态GH4742合金的晶界分布图

Fig. 10 Misorientation angles diastribution of GH4742 alloy (SHT)

图11 裂纹遇到晶界扩展进入下一个晶粒时发生偏转和扭转的模型图[20]

Fig. 11 Shematic illustration of deflection and twist of crack propagating into adjacent grain[20]

3 结论

1) 随着温度的升高,GH4742合金的裂纹扩展寿命降低,裂纹扩展速率增加。在低应力强度因子(ΔK在15~50 MPa·m0.5范围内)温度对裂纹扩展速率的影响比高应力强度因子(ΔK在50~65 MPa·m0.5范围内)的影响大。

2) 温度越高,疲劳裂纹断口的沿晶扩展特征越明显,扩展阶段典型的疲劳条纹脆性增大和二次裂纹增多,瞬断区越粗糙,主要是韧窝断裂特征。同一温度下,应力强度因子ΔK越大,疲劳条纹间距增大,二次裂纹越多。

3) 采用EBSD技术分析,GH4742合金中小角度晶界为主。大变形晶粒中存在大量的小角度晶界,裂纹扩展到大变形晶粒以穿晶方式沿着小角度晶界扩展。裂纹扩展到再结晶晶界时明显可见裂纹扩展发生了偏转,其扩展方式取决于相邻晶粒的面间角和取向差大小。

图12 裂纹附近应变分布图

Fig. 12 Strain contouring map near crack

REFERENCES

[1] 高文柱, 吴 欢, 赵永庆. 金属材料疲劳裂纹扩展研究综述[J]. 钛工业进展, 2007, 24(6): 33-37.

GAO Wen-zhu, WU Huan, ZHAO Yong-qing. Summary of fatigue crack growth study on metallic material[J]. Tanium Industry Progress, 2007, 24(6): 33-37.

[2] CLAVEL M, PINEAU A. Frequency and wave-form effects on the fatigue crack growth behavior of alloy 718 at 298 K and 823 K[J]. Metallurgical Transactions A, 1978, 9: 471-480.

[3] OSINKOLU G A, ONOFRIO G, MARCHIONNI M. Fatigue crack growth in polycrystalline IN718 superalloy[J]. Materials Science and Engineering A, 2003, 356(1/2): 425-433.

[4] ZHONG Z H, GU Y F, OSADA T, YUAN Y, CUI C T, YOKOKAWA T, TETSUI T, HARADA H. Fatigue crack growth characteristics of a new Ni-Co-base superalloy TMW-4M3: Effects of temperature and load ratio[J]. Journal of Materials Science, 2011, 46(23): 7573-7581.

[5] TUCKER A M, HENDERSON M B, WILKINSON A J, HIDE N J, REED P A S. High temperature fatigue crack growth in powder processed nickel based superalloy U720Li[J]. Materials Science and Technology, 2013, 18(3): 349-353.

[6] ANDRIEU E, MOLINS R. Intergranular crack tip oxidation mechanism in a nickel-based superalloy[J]. Materials Science and Engineering A, 1992, 154: 21-28.

[7] 王 泓. 材料疲劳裂纹扩展和断裂定量规律的研究[D]. 西安: 西北工业大学, 2002.

WANG Hong. Quantitative assessment of fatigue and fracture properties of materials[D]. Xi’an: Northwestern Polytechnical University, 2002.

[8] 王 璞, 董建新, 杨 亮, 郑 磊, 魏守恒. 高温合金裂纹扩展速率的影响因素[J]. 材料导报, 2008, 22(6): 61-69.

WANG Pu, DONG Jian-xin, YANG Liang, ZHENG Lei, WEI Shou-heng. Influencing factors of crack propagation rate of superalloy[J]. Materials Review, 2008, 22(6): 61-69.

[9] 赵海洋. GH4742热变形行为的研究[D]. 沈阳: 东北大学, 2010.

ZHAO Hai-yang. Hot deformation behavior of GH4742 superalloy[D]. Shenyang: Northeastern University, 2010.

[10] 龙正东, 邓 群, 林 平, 马培立, 庄景云, 仲增塘. 热处理对GH742合金组织和力学性能的影响究[J]. 材料工程, 1999(3): 41-44.

LONG Zheng-dong, DENG Qun, LIN Ping, MA Pei-li, ZHUANG Jing-yun, ZHONG Zeng-yong. Effects of heat treatment on microstructure and mechanical properties of GH742 superalloy[J]. Journal of Materials Engineering, 1999(3): 41-44.

[11] HB 7680-2000. 金属材料高温疲劳裂纹扩展速率试验方法[S].

HB 7680-2000. Fatigue crack growth rate test method of metallic material at high temperature[S].

[12] PARIS P, ERDOGAN F. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, 1963, 85(4): 528-533.

[13] PARIS P C, GOMEZ M P, ANDERSON W E. A rational analytic theory of fatigue[J]. The Trend in Engineering, 1961, 13: 9-14.

[14] RICHARDS C E, LINDLEY T C. The influence of stress intensity and microstructure on fatigue crack propagation in ferritic materials[J]. Engineering Fracture Mechanics, 1972, 4(4): 951-978.

[15] ZHONG Z H, GU Y F, YUAN Y, CUI C T, YOKOKAWA T, HARADA H. Fatigue crack growth behavior of a newly developed Ni-Co-base superalloy TMW-2 at elevated temperatures[J]. Materials Science and Engineering A, 2012, 552: 464-471.

[16] 杨 平. 电子背散射衍射技术及其应用[M]. 北京: 冶金工业出版社, 2007.

YANG Ping. Electron back scattering diffraction technique and its application[M]. Beijing: Metallurgical Industry Press, 2007.

[17] 王 欢. GH4698合金疲劳性能研究[D]. 沈阳: 中国科学院金属研究所, 2014.

WANG Huan. Investigation on the fatigue properties of GH4698 alloy[D]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2014.

[18] 黄亚敏, 潘春旭. 基于电子背散射衍射(EBSD)技术的材料微区应力应变状态研究综述[J]. 电子显微学报, 2010, 29(1): 662-672.

HUANG Ya-min, PAN Chun-xu. Micro-stress-strain analysis in materials based upon EBSD technique: A review[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(1): 662-672.

[19] ZHAI T, WILKINSON A J, MARTIN J W. A crystallographic mechanism for fatigue crack propagation through grain boundaries[J]. Acta Mater, 2000, 48: 4917-4927.

[20] 蹇海根, 姜 锋, 郑秀媛, 韦莉莉, 文 康. 采用EBSD研究高强铝合金的疲劳裂纹扩展行为[J]. 材料热处理学报, 2011, 32(2): 75-80.

QIA Hai-gen, JIANG Feng, ZHENG Xiu-yuan, WEN Kang. EBSD analysis of propagation behaviour of fatigue cracks in high strength aluminum alloy[J]. Transaction of Materials and Heat Treatment, 2011, 2011, 32(2): 75-80.

[21] ZHAI T, JIANG X P, LI J X, GARRATT M D, BRAY G H. The grain boundary geometry for optimum resistance to growth of short fatigue cracks in high strength Al-alloys[J]. International Journal of Fatigue, 2005, 27: 1202-1209.

[22] 雷家峰, 刘羽寅, 杨 锐, 李 东. 一种亚稳β钛合金中疲劳短裂纹穿晶扩展晶体学特征的EBSD研究[J]. 金属学报, 2002, 38(增刊): 272-276.

LEI Jia-feng, LIU Yu-yin.YANG Rui, LI Dong. EBSD study on the crystallographic characteristics of fatigue crack propagation through a grain boundary in a metastable beta titanium alloy[J]. Acta Metallurgica Sinica, 2002, 38(Supplement): 272-276.

[23] 刘廷光, 夏 爽, 茹祥坤, 杨辉辉, 李 慧, 白 琴. 利用EBSD技术分析低应变量形变显微组织[J]. 电子显微学报, 2011, 30(4/5): 408-413.

LIU Ting-guang, XIA Shuang, RU Xiang-kun, YANG Hui-hui, LI Hui, BAI Qin. Application of EBSD to analyzing low strain level microstructure[J]. Journal of Chinese Electron Microscopy Society, 2011, 30(4/5): 408-413.

Fatigue crack growth behavior of GH4742 alloy

ZHANG Bao-ning1, YUAN Chao1, GUO Jian-ting1, QIN He-yong2, ZHAO Guang-pu2

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. High Temperature Materials Research Institute, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: The crack propagation behavior of GH4742 alloy was studied respectively at room temperature, 700 ℃ and 750 ℃. Fatigue fracture was observed by scanning electron microscopy (SEM). Effects of temperature and stress intensity factor (ΔK) on crack growth life and rate were studied. The electron back scattering diffraction (EBSD) technique was applied to investigate the crystallographic mechanism of crack propagation. The results show that with the increase of temperature, crack propagation life of the alloy decreases and crack propagation rate increases as well as the intergranular fracture characteristics is more obvious. Crack growth in the original large deformation grain is in a transgranular manner along a low angle boundary. While crack meets the recrystallized grain boundaries, the mode of fracture is mainly the intergranular expansion and the way of crack growth depends on the magnitude of the interfacial angle and the misorientation of adjacent grain plane.

Key words: nickel-based superalloy; fatigue crack growth; fracture; micromechanism

Received date: 2016-06-17; Accepted date: 2016-11-25

Corresponding author: YUAN Chao; Tel: +86-24-23971930; E-mail: ychao@imr.ac.cn

(编辑 王 超)

收稿日期:2016-06-17;修订日期:2016-11-25

通信作者:袁 超,研究员,博士;电话:024-23971930;E-mail:ychao@imr.ac.cn