文章编号:1004-0609(2008)11-2082-05

粒度和调整剂对石英与菱镁矿浮选分离的影响

王金良,孙体昌

(北京科技大学 土木与环境工程学院,北京 100083)

摘 要:以石英和菱镁矿单矿物为试样,研究菱镁矿不同粒级对其可浮性的影响,考察调整剂KD-1(含钙的盐类化合物)和苛化玉米淀粉对单矿物上浮率的影响。结果表明:随菱镁矿粒度的逐渐减小,上浮率增加,证明细粒菱镁矿的上浮主要是由于泡沫的机械夹带作用;调整剂KD-1可以有效地降低泡沫的粘度从增加其流动性,因此有利于石英与菱镁矿的浮选分离;苛化玉米淀粉可很好地抑制细颗粒菱镁矿,而对石英的影响较复杂。

关键词:菱镁矿;石英;粒度;调整剂;反浮选

中图分类号:TD 923;TD 97 文献标识码:A

Effects of grain size and regulators on separation of

quartz from magnesite

WANG Jin-liang, SUN Ti-chang

(School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The loss of fine magnesite to the tailing in the process of separating quartz from magnesite by reverse flotation with the amine as collectors was investigated. The effects of some factors were investigated using pure quartz and magnesite as samples. The factors studied include particle size of magnesite, KD-1 and corn starch used as regulators. KD-1 is a trade name of a regulator mainly consisted of salts of calcium. The results show that, with the particle size declining, the floatation rate increases dramatically. This proves that the fine magnesite floated with the froth mainly due to the mechanical entrainment. The regulator KD-1 is favor of flotation separation quartz from magnesite, it can reduce effectively the viscosity of froth and increase its fluidity. Corn starch is the better depressant for fine magnesite. The effect of corn starch on the flotation of quartz is complex.

Key words: magnesite; quartz; particle size; regulator; reverse flotation

在我国已探明储量的矿产资源中,菱镁矿探明保有储量为31.2亿t,居世界首位,大约占世界菱镁矿总储量的25%~30%。

根据结晶状态的不同,菱镁矿可分为晶质和非晶质两种[1]。我国菱镁矿矿床绝大多数为层控晶质菱镁矿矿床,储量占全国的99.86%,其余为超基性岩风化壳淋滤型隐晶质菱镁矿矿床,储量很少且为级外品[2]。

由于高品位的菱镁矿石越来越少,因此,采用浮选的方法去除其中的杂质就显得越来越重要。张一 敏[3]、程建国等[4]和孙体昌等[5]对此都进行了研究,取得了一些进展。结果表明,虽然通过反浮选可以获得一部分高品位的菱镁矿精矿,但精矿产率比较低,分离效果不理想。如本文作者的研究结果是在产率为26.69%的尾矿中,SiO2含量仅为4.10%,而MgO的品位高达43.68%,即尾矿中绝大部分为损失的菱镁矿。张一敏和程建国的研究结果也存在同样的现象。由此可见,反浮选去除石英过程中大量菱镁矿损失在尾矿中是普遍存在的,因此选矿效率有待于进一步提高,研究造成选矿效率低的原因,降低菱镁矿在尾矿中的损失率,是解决此问题的关键所在。

在石英浮选的研究中,科研人员进行了大量的研究工作,如N-十二烷基-β-氨基丙酰胺(即DAPA)[6]、组合季铵盐[7]、醋酸十二烷基胺(DAA)[8]、N-烷基-1,3丙二胺和十二胺[9]等捕收剂得到了研究,在调整剂方面的研究中,石云良等[10]和王淀佐等[11]在金属离子影响方面进行了深入的研究。文献报道的对于石英浮选的研究主要集中在石英与磁铁矿、赤铁矿、镜铁矿、萤石、长石等的浮选分离方面,而对于石英与菱镁矿分离方面的研究较少,有待于进一步研究。

本研究以十二胺和醚胺为石英捕收剂,以单矿物为研究对象,目的是找到菱镁矿在尾矿中损失的原因,寻找有效的调整剂,抑制菱镁矿上浮,解决浮选分离过程中菱镁矿损失过多的问题。

1 实验

1.1 样品与试剂

实验用菱镁矿取自辽宁海城某菱镁矿矿区,经手选除杂,瓷球磨机磨矿,湿式筛分和水析分别得到57~76、43~57、30~43、20~30、10~20 μm和粒径小于10 μm几个粒级。用去离子水反复冲洗后,自然晾干,置于磨口瓶中备用。纯矿物含量大于99%。石英为高纯度石英,手碎后采用瓷球磨机磨矿,湿式筛分得到43~76 μm和粒径小于43 μm两个粒级,经盐酸处理后用去离子水反复漂洗,直至洗液呈中性为止,低温烘干后放置磨口瓶中备用,纯矿物含量大于99%,实验用水为去离子水。

十二胺为化学纯,醚胺、2号油、玉米淀粉为工业品,调整剂盐酸、碳酸钠、KD-1均为分析纯。十二胺和醚胺分别与盐酸按物质量的比1?1.1配成盐酸盐溶液。玉米淀粉与氢氧化钠按质量比2?1加入去离子水混合搅拌,水浴加热并同时搅拌约1 h,逐渐加去离子水稀释保持流动性,待溶液变为啤酒色为止,待降至室温后移至容量瓶中定容。

1.2 实验方法

1.2.1 浮选实验

采用RK/FGC5-35挂槽式浮选机,浮选槽容积为30 mL,主轴转速为1 500 r/min。浮选实验过程为:取2 g矿样于30 mL浮选槽中,加30 mL去离子水,搅拌2 min,再依次加入调整剂各搅拌2 min,加捕收剂搅拌2 min,浮选时间为4 min。实验所用石英,非特别指明时的粒级为43~76 μm。用矿物上浮率评价不同条件下的浮选效果。

1.2.2 机理研究

采用美国尼力高公司NEXUS-670型红外光谱仪研究十二胺与菱镁矿的作用情况,分辨率为4 cm-1。采用英国VG公司MICROLAB MKII型X射线光电子能谱仪,研究KD-1与石英的作用情况。选择Mg Kα靶,分辨率为0.85 eV。

2 结果与讨论

2.1 十二胺和醚胺对菱镁矿上浮率的影响

为了寻找菱镁矿大量损失于尾矿的原因,以菱镁矿不同粒级为研究对象,考察其在捕收剂十二胺、醚胺及起泡剂存在的条件下随气泡上浮的情况。

石英单矿物浮选实验表明,当pH=8.70时,十二胺和醚胺对石英的捕收能力强,且基本相同,上浮率分别为98.31%和97.71%。为保证石英的上浮率和便于对比,选择十二胺、醚胺浓度均为4.0×10-5 mol/L进行不同粒级菱镁矿的浮选实验。

2.1.1 十二胺和醚胺对菱镁矿不同粒级上浮率的影响

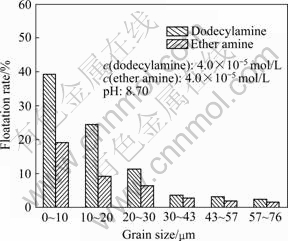

图1所示为在碳酸钠为pH调整剂,十二胺、醚胺对不同粒级菱镁矿的浮选试验结果。由图1可知,当pH=8.70时,分别采用两种捕收剂浮选时,都有菱镁矿上浮,且随着粒度的减小,菱镁矿的上浮率逐渐增加,用十二胺为捕收剂时尤为明显;当菱镁矿粒度小于10 μm时,菱镁矿的上浮率已达到39.16%,而醚胺为捕收剂时菱镁矿的上浮率要少的多,这与十二胺的起泡性强于醚胺相符。说明在硅、镁分离过程中,醚胺的分离效果优于十二胺的。

图1 粒级对菱镁矿上浮率的影响

Fig.1 Effects of grain size on floatation rate of magnesite

2.1.2 十二胺、醚胺和2号油用量对细粒菱镁矿上浮率的影响

考察了十二胺、醚胺和2号油在碳酸钠为pH调整剂时对粒径小于30 μm菱镁矿上浮率的影响,结果如图2所示。由图2可知,随着3种药剂用量的增加,粒径小于30 μm菱镁矿的上浮率增加,十二胺浮选时菱镁矿的上浮率高于醚胺的;只加起泡剂2号油时,粒径小于30 μm菱镁矿也可达到很高的上浮率,此时上浮是泡沫的机械夹带作用所致。

图2 十二胺、醚胺和2号油用量对粒径小于30 μm菱镁矿上浮率的影响

Fig.2 Effects of dosage of dodecylamine, ether amine and pine camphor oil on floatation rate of magnesite with grain size less than 30 μm

2.1.3 十二胺与菱镁矿作用的红外光谱分析

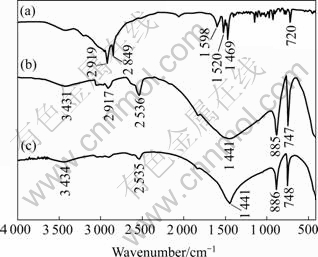

为考察十二胺是否与菱镁矿发生作用,进行了红外光谱分析。图3所示为十二胺盐酸盐、菱镁矿、十二胺与菱镁矿作用后的红外光谱图。图3(a)所示为十二胺经过盐酸处理后的红外光谱,在2 919 cm-1和 2 849 cm-1的两个吸收峰是—CH2—中C—H键的不对称伸缩振动和对称伸缩振动吸收峰,1 598 cm-1为 —NH3+的不对称弯曲振动吸收峰,1 469 cm-1为—CH3和—CH2—的弯曲振动吸收峰,1 520 cm-1为—NH3+的对称弯曲振动吸收峰,720 cm-1为—CH2—面内摇摆振动吸收峰[12-14]。

图3 菱镁矿与十二胺作用前后的红外光谱

Fig.3 IR spectra of magnesite interact with dodecylamine: (a) Dodecylamine and hydrochloric acid; (b) Magnesite; (c) Magnesite and dodecylamine

图3(b)所示为菱镁矿的红外光谱,1 441 cm-1、 885 cm-1和747 cm-1分别为菱镁矿CO32-的C—O不对称伸缩振动吸收峰、O—C—O面外弯曲振动吸收峰和O—C—O面内弯曲振动吸收峰[15],3 431 cm-1有羟基吸收峰存在,说明样品有水分。

图3(c)所示为菱镁矿与十二胺盐酸盐作用后的红外光谱,与图3(b)比较,图3(c)中与十二胺盐酸盐的吸收峰对应波数附近未见有明显的波峰出现,表明菱镁矿表面对十二胺未产生吸附或吸附甚微。

在图2结果中,2号油对菱镁矿的上浮是泡沫对菱镁矿的机械夹带作用所致,细颗粒的菱镁矿粘附于气泡而上浮。由图3可知,细粒级菱镁矿在十二胺、醚胺浮选时上浮的主要原因也是如此。因此,寻找合适的调整剂,抑制细粒菱镁矿粘附于气泡上浮是解决菱镁矿损失问题的重要途径之一。

2.2 醚胺为捕收剂时调整剂对石英和菱镁矿上浮率的影响

2.2.1 KD-1的影响

在对某菱镁矿实际矿石浮选实验过程中发现,反浮选分离石英与菱镁矿时,添加调整剂KD-1能够明显改善分离效果和泡沫流动性,且泡沫变得大小均匀。如在碱性条件,捕收剂醚胺用量为350 g/t,起泡剂2号油用量为80 g/t时,添加1 500 g/t KD-1,可使菱镁矿精矿产率从不添加KD-1时的84.78%下降到73.12%,SiO2含量从1.45%下降到0.48%。由此可见,添加KD-1对反浮选石英的过程有利,因此,采用纯矿物研究了KD-1改善分离效果的原因。

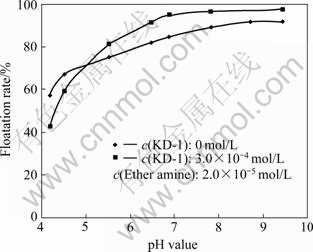

图4所示为醚胺为捕收剂、盐酸或碳酸钠为pH调整剂,添加与不添加KD-1时pH值对石英上浮率的影响。由图4可知, 当pH值较低时,KD-1对石英的上浮不利;当pH>5时,有利于石英的上浮,石英的上浮率平均提高约5%,最大提高了10%左右,这与实际矿石分选时的规律一致。

图4 不同KD-1用量时pH值对石英上浮率的影响

Fig.4 Effects of pH value on floatation rate of quartz with or without KD-1

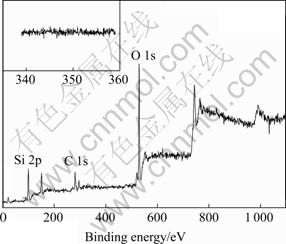

2.2.2 KD-1与石英作用后石英的XPS能谱分析

图5所示为KD-1与石英作用的X射线光电子能谱。图中左上角为Ca 2p窄扫描电子能谱,在348 eV附近并未出现Ca 2p谱峰[16-18],说明Ca2+在石英表面的吸附量很小。由此可以证明,KD-1对石英与菱镁矿浮选分离的作用主要表现在使浮选泡沫流动性增强,泡沫变得细腻均匀,增加了泡沫的表面积,增强了气泡与石英作用效果,同时减少了对细粒菱镁矿的夹带。

图5 KD-1与石英作用后石英的XPS能谱

Fig.5 XPS spectrum of quartz treated by KD-1

2.2.3 淀粉的影响

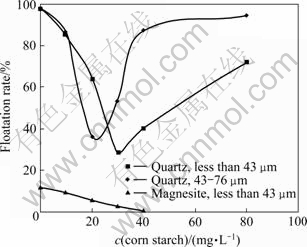

SANTANA等[19]在研究用反浮选从菱镁矿中去除石英时发现,以玉米淀粉为菱镁矿的抑制剂,虽然菱镁矿精矿中MgO品位稍有下降,SiO2含量有所提高,但MgO回收率从85.13%提高至95.20%,其对细粒级菱镁矿的影响并未报导。因此,本研究考察了苛化玉米淀粉对两种纯矿物上浮率的影响,尤其对细粒级菱镁矿的抑制能力,结果如图6所示。由图6可知,两个粒级石英的上浮率均随苛化玉米淀粉用量的增加,上浮率先下降而后又上升。在此过程中,上浮率变化幅度都很大,43~76 μm石英上浮率变化最大差值为61.79%,粒径小于43 μm石英上浮率变化最大差值为69.10%。当苛化玉米淀粉用量超过40 mg/L后,粒径小于30 μm菱镁矿基本无上浮。当用量达到80 mg/L时,与不加玉米淀粉相比,43~76 μm石英上浮率只减少3.92%,粒径小于43 μm石英上浮率减少了26.0%,重复实验证实了这一现象,出现这种变化的原因正在进一步研究。由此可见,添加苛化玉米淀粉可抑制菱镁矿的上浮,总体上来说对石英和菱镁矿的浮选分离是有利的。

图6 玉米淀粉对石英和菱镁矿上浮率的影响

Fig.6 Effects of corn starch on floatation rate of quartz and magnesite

通过两种调整剂的实验结果可知,调整剂KD-1有利于石英浮选和提高石英的上浮率,同时,通过对浮选泡沫的改善,减少了对细粒菱镁矿的夹带。苛化玉米淀粉对细粒菱镁矿有很强的抑制作用,对石英的影响较为复杂,总的来说对石英与菱镁矿的分离有利。

3 结论

1) 在反浮选分离石英与菱镁矿的过程中,菱镁矿损失于尾矿的主要原因是由于泡沫对细粒级菱镁矿的机械夹带作用,细颗粒粘附于气泡上浮。

2) 调整剂KD-1对石英与菱镁矿浮选分离作用主要表现在使浮选泡沫流动性增强,泡沫变得细腻均匀,增加了泡沫的表面积,增强了气泡与石英作用效果,同时减少了对细粒菱镁矿的夹带。

3) 苛化玉米淀粉可有效抑制微细粒菱镁矿的上浮,对石英的上浮影响较复杂。

REFERENCES

[1] 郑水林. 非金属矿加工与应用[M]. 北京: 化学工业出版社, 2003: 38.

ZHENG Shui-lin. Processing and application of non-metallic mine[M]. Beijing: Chemical Industry Press, 2003: 38.

[2] 《中国矿床》编委会. 中国矿床[M]. 北京: 地质出版社, 1994: 514.

Editorial Committee of Chinese Deposits. Chinese deposits[M]. Beijing: Geological Press, 1994: 514.

[3] 张一敏. 低品级菱镁矿提纯研究[J]. 金属矿山, 1990(10): 39-42.

ZHANG Yi-min. Study on purification of low-grade magnesite[J]. Metal Mine, 1990(10): 39-42.

[4] 程建国, 余永富. 海城三级菱镁矿浮选提纯的研究[J]. 矿冶工程, 1993, 13 (4): 19-23.

CHENG Jian-guo, YU Yong-fu. Purification of grade 3 magnesite of Haicheng mine by flotation separation[J]. Mining and Metallurgical Engineering, 1993, 13(4): 19-23.

[5] 孙体昌, 王金良, 邹安华, 常 亮. 辽宁某菱镁矿可选性研究[J]. 金属矿山, 2007(10): 68-71.

SUN Ti-chang, WANG Jin-liang, ZOU An-hua, CHANG Liang. Study on beneficiability of a magnesite ore from Liaoning[J]. Metal Mine, 2007(10): 68-71.

[6] 伍喜庆, 刘长淼, 黄志华. 石英浮选的新型捕收剂—N-十二烷基-β-氨基丙酰胺[J]. 中南大学学报: 自然科学版, 2005, 36(3): 412-416.

WU Xi-qing, LIU Chang-miao, HUANG Zhi-hua. A new collector for quartz flotation: N-dodecyl-β-amino-propylamide[J]. Journal of Central South University: Science and Technology, 2005, 36(3): 412-416.

[7] WANG Y, REN J. The flotation of quartz from iron minerals with a combined quaternary ammonium salt[J]. International Journal of Mineral Processing, 2005, 77(2): 116-122.

[8] TAKEDA S, USUI S. Adsorption of dodecylammonium ion on quartz in relation to its flotation[J]. Colloids and Surfaces, 1987, 23(1/2): 15-28.

[9] SCOTT J L, SMITH R W. Diamine flotation of quartz[J]. Minerals Engineering, 1991, 4(2): 141-150.

[10] 石云良, 邱冠周, 胡岳华, 陈 淳. 石英浮选中的表面化学反应[J]. 矿冶工程, 2001, 21(3): 43-48.

SHI Yun-liang, QIU Guan-zhou, HU Yue-hua, CHEN Chun. Surface chemical reactions in oleate flotation of quartz[J]. Mining and Metallurgical Engineering, 2001, 21(3): 43-48.

[11] 王淀佐, 胡岳华. 氢氧化物表面沉淀在石英浮选中的作用[J]. 中南大学学报: 自然科学版, 1990, 21(6): 248-253.

WANG Dian-zuo, HU Yue-hua. The investigation of role of surface precipitation of meta hydroxide in flotation of quartz[J]. Journal of Central South University: Science and Technology, 1990, 21(6): 248-253.

[12] 王宗明, 何欣翔, 孙殿卿. 实用红外光谱学[M]. 北京: 石油工业出版社, 1982: 155-230.

WANG Zong-ming, HE Xin-xiang, SUN Dian-qing. Practical infrared spectroscopy[M]. Beijing: Petroleum Industry Press, 1982: 155-230.

[13] BELLAMY L J. 复杂分子的红外光谱[M]. 北京: 科学出版社, 1975: 5-8.

BELLAMY L J. The infra-red spectra of complex molecules[M]. Beijing: Science Press, 1975: 5-8.

[14] 田丹碧. 仪器分析[M]. 北京: 化学工业出版社, 2004: 188-205.

TIAN Dan-bi. Instrumental analysis[M]. Beijing: Chemical Industry Press, 2004: 188-205.

[15] FARMER V C. 矿物的红外光谱[M]. 北京: 科学出版社, 1982: 184.

FARMER V C. The infrared spectra of minerals[M]. Beijing: Science Press, 1982: 184.

[16] 刘世宏, 王当憨, 潘承璜. X射线光电子能谱分析[M]. 北京: 科学出版社, 1988: 312.

LIU Shi-hong, WANG Dang-han, PAN Cheng-huang. X-ray photoelectron spectroscopy analysis[M]. Beijing: Science Press, 1988: 312.

[17] HU Xiao-ming, JOSHI P, MUKHOPADHYAY S M, HIGGINS S R. X-ray photoelectron spectroscopic studies of dolomite surfaces exposed to undersaturated and supersaturated aqueous solutions[J]. Geochimica, 2006, 70(13): 3342-3350.

[18] 丁 锐. 水玻璃与粘土矿物之间表面反应的实验研究[J]. 岩土工程学报,1999, 21(3): 334-337.

DING Rui. Experimental study of the surface reactions between clay minerals and water-glass[J]. Chinese Journal of Geotechnical Engineering, 1999, 21(3): 334-337.

[19] SANTANA A N, PERES A E C. Reverse magnesite flotation[J]. Minerals Engineering, 2001, 14(1): 107-111.

收稿日期:2008-01-14;修订日期:2008-09-16

通讯作者:孙体昌,教授,博士;电话:010-62333603;E-mail: suntc@ces.ustb.edu.cn

(编辑 李艳红)