Development of magnesium composite alloy by

a new method combining B2O3 addition and melt stirring

BU Le-ping(卜乐平)1,2, S. TANAKA1, M. TSUSHIDA3, S. ANDO3, H. TONDA3

1. Graduate School of Science and Technology, Kumamoto University, 2-39-1 Kurokami,

Kumamoto 860-8555, Japan;

2. Machinery and Electronic Engineering Institute, Inner Mongolia University of Agriculture, Hohhot 010018, China;

3. Department of Materials Science and Engineering, Faculty of Engineering, Kumamoto University, 2-39-1

Kurokami, Kumamoto 860-8555, Japan

Received 28 July 2006; accepted 15 September 2006

Abstract: For developing high performance magnesium alloys, a new method in combination of B2O3 addition and melt stirring was applied. When 0, 3%, 6% and 12%( mass fraction) B2O3 was added into pure Mg, many twins were produced in each alloy. The average grain size of Mg was about 200 μm. In Mg-6Al alloy, the grain size is decreased from 50 to 35 μm by B2O3 addition. In Mg-6RE (rare earth) alloys, the grain size is decreased from 35 to 15 μm. The grain size of Mg-9Al- 6Ti-3B2O3 alloy is about 5 ?m. The hardness of pure Mg does not change by B2O3 addition. In Mg-6Al alloy, the hardness is increased by addition of 3% B2O3, however, the hardness of Mg-6RE alloy is decreased by B2O3 addition. Addition of B2O3 into Mg-Al, Mg-RE and Mg-Al-Ti alloys makes the fine grain structures, the hardness of Mg-RE alloy is decreased. This strange behavior may be interpreted with existence of many fine pores in the alloy. The mechanical properties of composite Mg-9Al-6Ti with 3%B2O3 are higher than those of AZ91C. The present results demonstrate the potential of this new method for developing high performance magnesium alloys.

Key words: magnesium alloy; composite; Mg-Al alloy; Mg-RE alloy; Mg-Al-Ti alloy; B2O3; melt stirring; grain size

1 Introduction

In recent years, to reduce energy consumption of automotive, research and development of magnesium alloys have been greatly promoted by the lightmass requirement in the automotive industries. Generally, Mg-Al system is the most widely used as commercial magnesium alloy. However, the applications of magnesium alloys are limited because of poor mechanical properties at higher temperatures. To improve high temperature properties of magnesium alloys, Mg-RE (rare earths) alloys were investigated[1]. On the other hand, the metal matrix composites with magnesium matrix were also investigated. For example, Mg2Si/Mg composites were developed by hot forging of magnesium and SiO2 powders compact[2-3] and by hot extrude of AZ31 and Si powders compact[4]. In these methods, reinforce particles, Mg2Si, were in-situ solid-state synthesized from the mixed Mg and Si powders. LU et al[5] reported that Mg-Al-Ti-B alloys using Ti3B4 and MgB2 as reinforcements were developed by mechanical alloying method. In these solid-state syntheses, reinforce particles can be produced from cheap materials, however the processing cost is high. The casting process is the useful technique for the preparation of alloy matrix composites because of easy treatment and high cost performance. SASAKI et al [6] tried to develop Al18B4O33 whisker/Mg composite by compo-casting.

In this study, the combination method of in-situ synthesis of reinforcement from cheap material and compo casting was developed to produce high performance magnesium composite with low cost. B2O3 powder was employed as reinforcement material. The microstructures and mechanical properties of Mg, Mg-Al, Mg-RE and Mg-Al-Ti composites were investigated.

2 Experimental

Pure Mg (99.9%), pure Al (99.9%), RE (mish- metal, 51.76%Ce, 26.05%La, 17.23%Nd, 4.89%Pr), Ti powders (particle size is from 30 to 50 ?m) and B2O3 powder (particle size is from 200 to 400 ?m) were used.

Fig.1 shows the photo of experimental device. Considering the reactivity of Mg melts, a mild steel crucible was used. A shaft and stirring blade were made by stainless steel. To avoid oxidation on surface of melt with air, argon gas was poured into the crucible. Pure Mg, Al and RE ingots were put into the crucible, and they were heated to 953-1 053 K by electric furnace. After melting the ingots, Ti and B2O3 powders were added into the crucible and the molten metal was stirred at 953-1 123 K for 20-60 min with stirring rate of 500-800 r/min. The molten metal was cast into a metal mold after the stirring process.

Fig.1 Photo of test device

The microstructures of the specimens were observed by optical microscopy and scanning electron microscopy(SEM). The mechanical properties of specimen were evaluated by micro Vickers hardness and tensile test.

3 Results and discussion

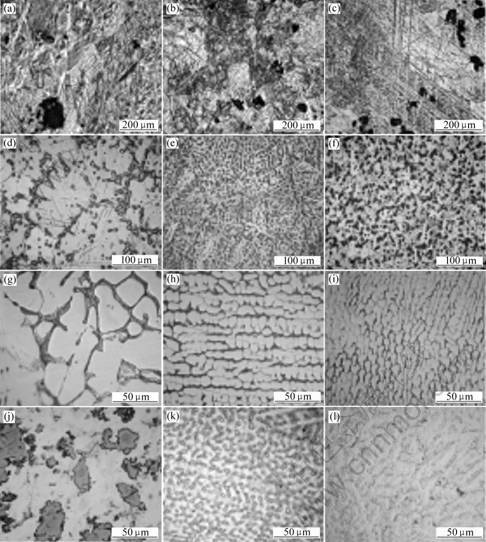

Fig.2 shows the microstructures Mg, Mg-6Al, Mg-6RE and Mg-9Al-6Ti alloys with B2O3 addition. When 3%, 6% and 12%(mass fraction) B2O3 is added into pure Mg, many twins appear. The average grain size of Mg matrix is about 200 ?m and it is scarcely changed by B2O3 addition. However, the observation results show that the grain sizes of other Mg alloys become smaller by B2O3 addition.

Fig.2 Microstructures of Mg, Mg-6Al,Mg-6RE and Mg-9Al-6Ti alloys system: (a) Mg-3B2O3; (b) Mg-6B2O3; (c) Mg-12B2O3; (d) Mg-6Al; (e) Mg-6Al-3B2O3; (f) Mg-6Al-6B2O3; (g) Mg-6RE; (h) Mg-6RE-3B2O3; (i) Mg-6Al-6B2O3; (j) Mg-9Al-6Ti; (k) Mg-9Al-6Ti-3B2O3; (l) Mg-9Al-6Ti-6B2O3

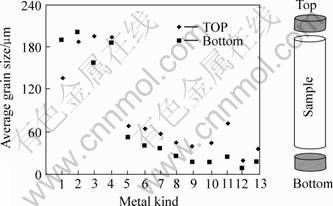

Fig.3 shows the changes of grain size of the alloys. It can be seen that the grain size becomes smaller by B2O3 addition in Mg-6Al, Mg-6RE and Mg-9Al-6Ti alloys. In the case of Mg-6Al and Mg-6RE alloys, the grain sizes are decreased from 50 to 35 ?m and from 35 to 15 ?m, respectively. In the case of Mg-9Al-6Ti alloys, the grain size is also decreased from 70 to 5 ?m. In Mg-9Al-6Ti alloy, as shown in Fig.2, Ti particles with the diameter from 30 to 50 ?m are observed, namely Ti powders are not dissolved. When 3% and 6 % B2O3 is added into Mg-9Al-6Ti alloy, Ti powders are dissolved. This result indicates that B2O3 has burning-assistant effect for Ti.

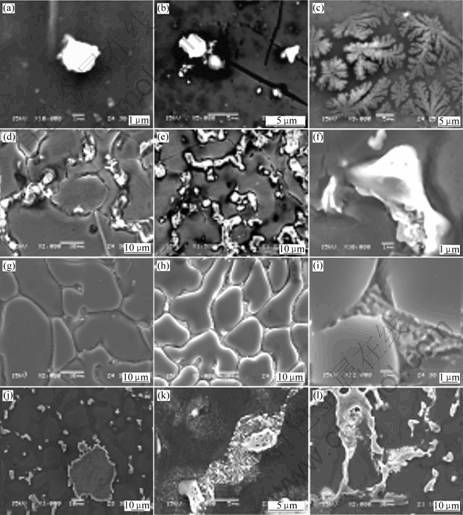

Fig.4 shows the changes of size, morphology and distribution of intermetallic compounds and the reinforce particles. These particles are increased and dispersed in the matrix metal with increasing B2O3 addition. These results show that the mechanical properties, such as hardness, strength and elongation, of these alloys will increase by the effects of intermetallic strengthen, grain interface strengthen and dispersing strengthen.

Fig.3 Change of grain size of basal matrix: 1 Mg; 2 Mg-3B2O3; 3 Mg-6B2O3; 4 Mg-12B2O3; 5 Mg-6Al; 6 Mg-6Al-3B2O3; 7 Mg-6Al-6B2O3; 8 Mg-6RE; 9 Mg-6RE-3B2O3; 10 Mg-6RE- 6B2O3; 11 Mg-9Al-6Ti; 12 Mg-9Al-6Ti-3B2O3; 13 Mg-9Al- 6Ti-6B2O3

Fig.4 SEM images of Mg, Mg-6Al,Mg-6RE and Mg-9Al-6Ti alloys system with addition of B2O3: (a) Mg-3B2O3; (b) Mg-6B2O3;

(c) Mg-12B2O3; (d) Mg-6Al; (e) Mg-6Al-3B2O3; (f) Mg-6Al-6B2O3; (g) Mg-6RE; (h) Mg-6RE-3B2O3; (i) Mg-6RE-6B2O3;

(j) Mg-9Al-6Ti; (k) Mg-9Al-6Ti-3B2O3; (l) Mg-9Al-6Ti-6B2O3

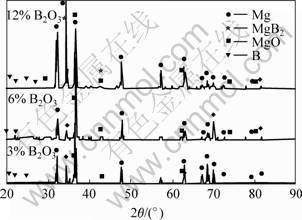

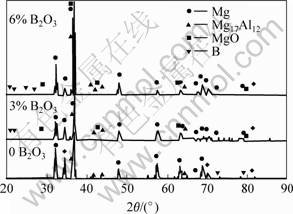

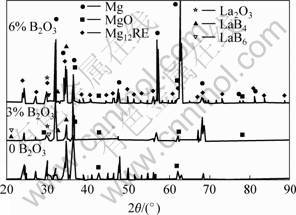

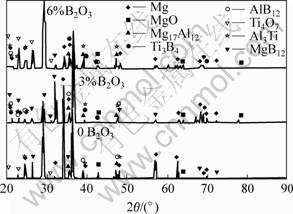

The phases of specimens were analyzed by X-ray diffraction analysis(XRD), and the results are shown in Figs.5-8. When B2O3 is added into pure Mg, the peaks of MgB2 are observed(Fig.5). In the case of Mg-6Al alloys, the peaks of Mg17Al12 and metallic B are observed (Fig.6). In the case of Mg-6RE alloys, the peaks of α-Mg, MgO, Mg12RE, La2O3, LaB4 and LaB6 are observed(Fig.7). In the case of Mg-9Al-6Ti alloys, the peaks of α-Mg, MgO, Mg17Al12, Al3Ti, Ti3B4, Ti4O7, AlB12 and MgB12 are observed (Fig.8).

Fig.5 XRD patterns of Mg-xB2O3

Fig.6 XRD patterns of Mg-6Al-xB2O3

Fig.7 XRD patterns of Mg-6RE-xB2O3

Fig.8 XRD patterns of Mg-9Al-6Ti-xB2O3

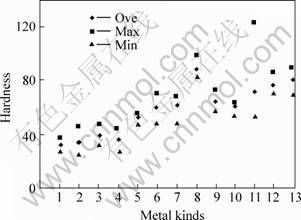

Fig.9 shows the results of micro Vickers hardness test. Addition from 2.5% to 12% B2O3 into pure Mg does not make remarkable change of the hardness. In the case of Mg-6Al and Mg-9Al-6Ti, the hardness is increased by 3% B2O3 addition, but the more addition of B2O3 does not provide more increasing for hardness. In Mg-6RE, on the other hand, the hardness is decreased by addition of B2O3. It is well known that the mechanical properties of metals are improved by grain size refinement.

Fig.9 Hardness(HV0.03) of alloys: 1 Mg; 2 Mg-3B2O3; 3 Mg-6B2O3; 4 Mg12B2O3; 5 Mg-6Al; 6 Mg-6Al-3B2O3; 7 Mg-6Al-6B2O3; 8 Mg-6RE; 9 Mg-6Re-3B2O3; 10 Mg-6RE- 6B2O3; 11 Mg-9Al-6Ti; 12 Mg-9Al-6Ti3-B2O3; 13 Mg-9Al- 6Ti-6B2O3

Though the grain size of Mg-Al, Mg-RE and Mg-Al-Ti is decreased by B2O3 addition, only the hardness of Mg-RE is decreased. As shown in Figs.2 and 4, there are fine pores in intermetallic compounds at grain interfaces. This strange behavior of change in hardness of Mg-RE may be related to the existence of many fine pores in the alloys.

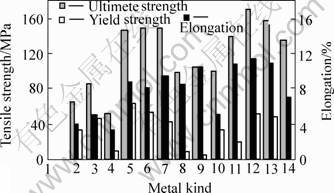

Fig.10 shows the tensile property of the alloys. The strength and elongation of commercial AZ91C alloy are also listed as reference alloy. The strengths of Mg-6Al made by new method employed in this study are higher than that of AZ91C alloy in spite of low aluminum content. The elongations of Mg-6Al, Mg-RE and Mg-9Al-6Ti alloys with B2O2 are higher than AZ91C alloy. In this research, the best alloy with comprehensive mechanical properties is Mg-9Al-6Ti-3B2O3. The ultimate strength, yield strength and elongation of the alloy are 170 MPa, 113 MPa and 5%, respectively.

Fig.10 Tensile properties of alloys at ambient temperature: 1 Mg; 2 Mg-3B2O3; 3 Mg-6B2O3; 4 Mg12B2O3; 5 Mg-6Al; 6 Mg-6Al-3B2O3; 7 Mg-6Al-6B2O3; 8 Mg-6RE; 9 Mg-6Re- 3B2O3; 10 Mg-6RE-6B2O3; 11 Mg-9Al-6Ti; 12 Mg-9Al- 6Ti3-B2O3; 13 Mg-9Al-6Ti-6B2O3; 14 AZ91C alloy

In the research, the mechanical properties of the novel particle disperse reinforce composite material Mg-9Al- 6Ti- 3B2O3 increase. The microstructure is very interesting.

4 Conclusions

1) The grain sizes of Mg-Al, Mg-RE and Mg-Al-Ti alloys are decreased by B2O3 addition. Micro Vickers hardness of Mg-Al and Mg-Al-Ti alloys is increased by B2O3 addition. In Mg-RE, the hardness is decreased because of the formation of many fine pores in intermetallic compounds at grain boundary.

2) The tensile strength and elongation of M-9Al-6Ti with 3%B2O3 are higher than those of commercial AZ91C alloy.

3) The combination of melt stirring method and B2O3 addition is applicable for developing high performance magnesium alloys.

References

[1] L? Yi-zhen, WANG Qu-dong, ZENG Xiao-qin, DING Wen-jiang, ZHAI Chun-quan, ZHU Yan-ping. Effects of rare earths on the microstructure, properties and fracture behavior of Mg-Al alloys[J]. Mater Sci Eng A, 2000, A278: 66-76.

[2] DU Wen-bo, KONDOH K, YUASA E, TSUZUKI R, AIZAWA T. In-situ solid-state synthesis of Mg2Si/MgO/Mg composites[J]. Materials Science Forum, 2003, 419-422: 783-788.

[3] MURAMATSU H, KONDOH K, AIZAWA T, YUASA E. Tribological property of Mg composites via powder metallurgy process[J]. Materials Science Forum, 2003, 419-422: 801-804.

[4] TSUZUKI R, KONDOH K, DU Wen-bo, AIZAWA T, YUASA E. Effect of extrusion conditions on properties of hot extruded Mg composite with Mg2Si dispersions via solid-state synthesis[J]. Materials Science Forum, 2003, 419-422: 789-794.

[5] LU U, LAI M O, TOH Y H, FROVEN L. Structure and properties of Mg-Al-Ti-B alloys synthesized via mechanical alloying[J]. Mater Sci Eng A, 2002, A334: 163-172.

[6] SASAKI G, YOSHIDA M, YANAGISAWA O, FUYAMA N, FUJII T. Mechanical properties and microstructure of Al18B4O33/ magnesium alloy composites prepared by compo-casting[J]. Materials Science Forum, 2003, 419-422: 777-782.

(Edited by CHEN Wei-ping)

Corresponding author: BU Le-ping; E-mail: 041d9012@gsst.stud.kumamoto-u.ac.jp; buleping123@yahoo.com