文章编号: 1004-0609(2004)10-1705-06

LF2铝合金搅拌摩擦焊接接头的组织与性能

王希靖, 阿 荣, 郭瑞杰, 韩晓辉

(兰州理工大学 甘肃省有色金属新材料国家重点实验室, 兰州 730050)

摘 要: 对10mm厚LF2铝合金搅拌摩擦焊接进行了研究。 结果表明: 焊接厚板时, 为防止出现隧道型缺陷, 须在较低的焊速和转速下进行。 当焊速为9mm/min, 转速为950r/min, 焊接输入能量为6230W时, 接头强度值最高, 其值与母材强度值相等。 接头处由平均尺寸约为15μm的均匀细小的晶粒组成; 热影响区平均晶粒尺寸较大, 其最大值约为28μm; 热机械影响区内组织细长, 局部区域最大长度可达到85μm。 焊核区平均硬度与母材相当, 中心最高硬度可达HV95, 近缝区硬度低于母材硬度。

关键词: 搅拌摩擦焊; 铝合金; 接头; 微观组织; 焊接参数; 晶粒 中图分类号: TG44

文献标识码: A

Microstructures and properties of friction stir welding joints for LF2 aluminum alloy

WANG Xi-jing, A Rong, GUO Rui-jie, HAN Xiao-hui

(State Key Laboratory of Advanced Non-ferrous Metal Materials, Gansu Province, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The welding of 10mm thick LF2 aluminum alloy in friction stir welding was investigated. The results show that thicker plate should be jointed at lower welding velocity and rotation speed, otherwise there would get the joint with huge tunnel defect. The highest strength joints that are equal to parent metal can be obtained at 9mm/min of welding velocity, 950r/min of rotational speed and 6230W of input energy, which are regarded as the most ideal parameters under experimental welding conditions. There are the smallest size grains of 15μm in weld nugget; Heat affected zone are composed of coarse grains and the largest size of heat affected zone microstructure is 28μm; Thermomechanically affected zone consists of stripy structure which is 85μm in length in some area. Average microhardness in weld nugget is equal to parent metals, the most microhardness is HV95 and lower than parent metals in the area near weld nugget .

Key words: friction stir welding; aluminum alloy; joint; microstructure; welding parameters; grain

搅拌摩擦焊(FSW)作为一种高效、 优质、 环保、 低成本的新型焊接方法[1-3], 自问世以来已经引起了焊接界的广泛关注。 国内外焊接界的学者对各种不同铝合金薄板的FSW接头的显微组织和接头性能进行了研究[4-11], 但对铝合金厚板FSW焊接规律的认识尚有待深入。 本文作者针对LF2铝合金厚板进行FSW对接实验, 研究了FSW工艺参数对焊缝成型、 接头性能以及晶粒尺寸的影响规律, 分析LF2铝合金厚板焊接时可能出现的焊接缺陷, 得到厚板FSW接头成型原理及特点, 旨在为扩大FSW在航空、 船舶和高速列车等领域的工业应用提供理论和实践的依据。

1 实验

焊接用材料为10mm厚LF2铝合金, 属5XXX系列Al-Mg合金, 其化学成分和力学性能分别见表1、 2。 实验在自制的FSW焊机上进行。 实验用焊接参数见表3。 焊接参数由焊机控制系统的MCGS组态软件实时检测记录[12]。 焊后按照观测要求制成金相试样, 所选腐蚀剂为盐酸、 硝酸及氢氟酸的混合溶液, 其体积比为15∶5∶1。 腐蚀时间为50s。 采用S-520扫描电镜观察显微组织, 测量晶粒大小, 用HVS-1000型显微硬度计测量焊接接头的显微硬度, 在AG-10TA型万能材料实验机上进行力学性能实验。 得到工艺参数对力学性能以及能量对焊缝各区晶粒和组织的影响规律, 并确定了焊缝厚度中部各区的硬度分布。

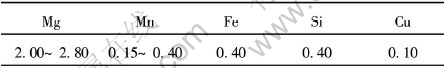

表1 LF2铝合金的化学成分

Table 1 Chemical composition of aluminum alloy LF2(mass fraction, %)

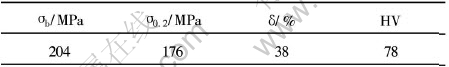

表2 LF2铝合金的力学性能

Table 2 Mechanical properties of aluminum alloy LF2

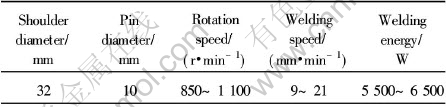

表3 焊接参数

Table 3 Welding parameters

2 结果与分析

2.1 摩擦头转速对接头强度的影响

由于焊接时选择焊速较低, 所以摩擦头转速对于接头成型及其强度有很大的影响。 转速过低, 接头处得不到足够摩擦热量使金属塑化, 因此易出现空洞或底部未焊透等现象, 从而不能完成两板的完全连接[5]。 如果转速太高, 接头处金属温度太高而使焊缝宽度相应变大, 且接头处由于晶粒长大而易出现粗大的组织, 也会影响接头的强度。 如果焊速、 转速都很高, 那么接头处除了出现上述缺陷之外还在接头内部出现贯穿前后的巨大隧道型缺陷, 大大降低接头强度[6, 13]。 实验结果表明, 除转速1100r/min时接头处出现小孔外, 其他参数下得到的接头内部均无空洞。 这是由于在此转速下焊接输入能量较大, 焊缝金属处于完全热塑性状态且热影响区较宽、 晶粒较大, 造成了接头的薄弱区。

对每个接头进行力学性能测试发现, 几乎所有试样被拉伸时均断裂在前进边一侧的热影响区。 图1所示为接头力学性能测试实验后的相关曲线。 可见焊速一定(9mm/min)时, 抗拉强度、 屈服强度和延伸率最大值均出现于转速950r/min时, 此时输入能量为6230W, 抗拉强度和屈服强度分别为204、 175MPa, 均与母材相同; 延伸率最大值为30%, 为母材延伸率的79%。

图1 转速与接头强度的关系

Fig.1 Relation between rotation speed and strength

2.2 输入能量对接头强度的影响

图2所示为焊接时输入能量与接头强度的关系。 由图2可见, 随输入能量的增加, 接头抗拉强度、 屈服强度及延伸率均逐渐增加, 输入能量为6230W时强度最高。 随着输入能量继续增加, 以上[CM(22]力学性能却有下降的趋势, 但均不低于最低输入能and welding energy量时的值。 输入能量为5330W时, 焊缝质量最差。 输入能量分别为6230W和5330W时, 对应焊接规范分别为945r/min, 9mm/min和1100r/min, 9mm/min。

图2 强度与焊接能量的关系

Fig.2 Relation between strength

2.3 焊接接头组织分析

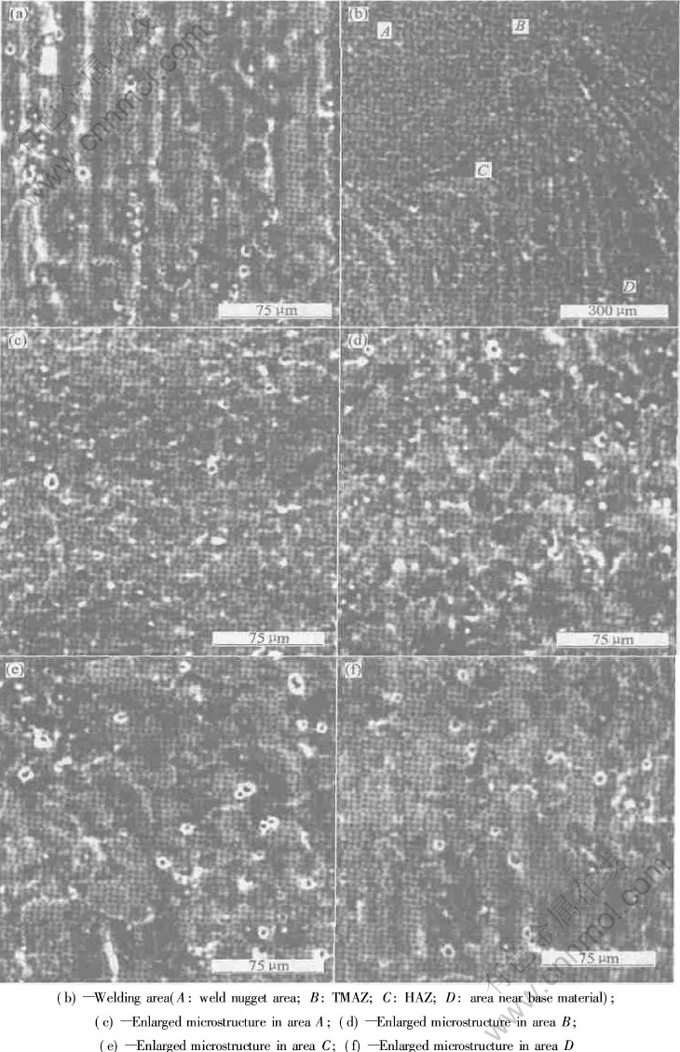

接头强度高是由接头内部组织引起的。 焊接接头可分为3个区: 焊核区(weld nugget)、 热机械影响区(TMAZ)、 热影响区(HAZ)[4, 7]。 焊前母材晶粒细长, 平均长度45μm, 宽度22μm。 焊后焊核区由均匀的等轴晶组成[14]。 图3所示为输入能量6230W时, 接头区各区内晶粒对比图。 在焊核区(图3(c))晶粒均匀细小, 平均尺寸约15μm[13]。 在搅拌摩擦焊过程中, 搅拌针与工件及搅拌摩擦头肩部与工件之间产生大量的热量, 使周围金属塑化并充分流动, 焊缝温度上升到再结晶要求的温度[15]。 此时位错在搅拌力作用下密度不断增加, 当储存能增加到一定程度, 足够发生再结晶时, 金属内便开始不断形成晶核[16]。 这些晶粒对于提高接头强度有很大的作用。 焊后, 再结晶晶粒的尺寸和数量取决于接头的热量和搅拌力, 即搅拌头的转速和焊接速度。 TMAZ区紧靠焊核区, 且宽度很窄, 几乎成一条线。 当输入能量适当时, TMAZ内金属塑性较好, 易于流动、 成形, 所以搅拌摩擦头在高速旋转时此区易出现被拉长或扭曲的组织[7](见图4)。 由图4可见组织细长, 有明显被拉长迹象, 平均长度约85μm, 宽度约7μm。 图3(b)中, B点处于焊缝上下部分的分界点, 其放大组织如图3(d)所示, 虽属TMAZ区, 但在焊接时由于受热影响程度与焊缝相当, 故此处金属可视为处于完全塑性状态, 再加上有强烈的力的作用, 也发生了动态再结晶, 得到与焊缝晶粒尺寸相当的组织。 图3(b)中C、 D点均处于HAZ区, 其放大组织如图3(e)、 3(f)所示, 晶粒为典型受热长大的组织。 此处主要是受热影响, 受力很小或完全不受力, 所以畸变能很低。 由于铝及其合金的层错能高, 变形时扩展位错的宽度窄, 位错交滑移和攀移容易进行, 而使异号位错相互抵消, 位错密度下降, 畸变能易降低。 所以此处不会发生动态再结晶, 在焊缝缓慢冷却的过程中组织仍会沿变形方向长大, 而其亚晶粒仍保持等轴状[4, 8, 17], 形成大小不均匀的, 甚至变形的组织。

对焊核区及其附近区域做能谱分析后, 并未发现上述区域内有合金元素偏析。 母材中少量的Mg与基体形成的β相(主要为Mg3Al3)在焊接过程中受到了强烈均匀的搅拌, 均匀、 弥散地分布于晶粒内部。 晶粒内合金基体中有细小的弥散β相时, 可有效地阻碍位错移动, 提高合金的塑性变形抗力, 从而大大提高强度[18]。

2.4 输入能量与焊核区晶粒尺寸的关系

焊接时不同输入能量下得到不同尺寸的接头组织。 图5所示为焊核区晶粒尺寸与焊接输入能量之间的关系。 随着输入能量的增加, 焊核区晶粒尺寸逐渐变小, 输入能量为6040和6230W时, 晶粒尺寸最小, 约为15 μm。 这是因为输入能量增加使焊核区塑性增加, 再结晶过程充分进行, 致使晶粒细小。 输入能量继续增加, 晶粒尺寸也变大, 这是因为当焊接输入能量增大时, 焊核区内温度过高, 导致晶核过热长大引起的。 由于焊接材料为厚板, 故在冷却过程中散热缓慢, 使原有的已长大的动态再结晶晶粒在此时间内进一步长大, 最终得到较粗大组织。

由于焊核区产生了不同尺寸的组织, 所以接头强度值也有所不同。 晶粒尺寸较小时, 相应强度也较高; 晶粒尺寸较大时, 相应强度值均较小。 此结论完全与前述结论相符合, 即接头晶粒尺寸越小, 接头强度越大。

2.5 接头硬度分布

由于不同规范下得到接头组织不同, 所以在接头硬度上也有很大差异。 图6所示为焊接输入能量为6230W时接头组织的显微硬度分布。 以接头厚度中部的硬度值作为接头组织的显微硬度。 由图6可见, 焊核区除某些点硬度比母材高外, 其余点上硬度均与母材硬度相当; 在TMAZ和HAZ内, 硬度分布不均匀, 且比母材硬度低。 从前述分析中得知焊核区内出现均匀细小的等轴晶可提高接头的强度和韧性, 故焊核区内硬度相应较高。 近缝区受力和热的影响, 易于出现大尺寸或不规则晶粒。 晶粒尺寸大, 晶粒内部与晶界附近应变相差较大, 变形不均匀, 且变形阻力大, 相对来说, 应力集中引起的开裂机会也较大, 这就有可能在断裂前不能承受较大的变形量而导致强度下降, 相应硬度变小[18]。

图3 母材与近缝区的显微组织

Fig.3 Microstructures in welding areas

图4 TMAZ组织

Fig.4 Microstructure in TMAZ

图5 接头组织晶粒尺寸与焊接能量的关系

Fig.5 Relation between grain size and welding energy

图6 接头显微硬度的分布

Fig.6 Micro-hardness distribution of FSW joint

3 结论

1) 对10mm厚LF2铝合金进行搅拌摩擦焊接, 得到外观整洁、 无变形、 内部无缺陷的FSW焊接接头。

2) 10mm厚LF2铝合金对接最佳焊接规范为: 转速945r/min, 焊速9mm/min, 输入能量6230W。 此规范下接头强度与母材相同, 延伸率为母材延伸率的79%。 输入能量在6040~6500W范围内全部接头强度均较高。

3) 焊核区组织由细小均匀的等轴晶组成, 最小焊核区晶粒尺寸可达到15μm, 有少量第二相Mg3Al3弥散分布于晶内, 起到了接头强化作用。 HAZ内晶粒尺寸较大, 最大值可达28μm; TMAZ区很窄, 由于受到力的作用, 部分晶粒被扭曲变形, 得到最大长度约85μm的组织。

4) 焊核区显微硬度平均值稍高或等于母材硬度, 焊核区最高硬度值约为HV95; 近缝区显微硬度略低于母材。

REFERENCES

[1] Prada R A, Murr L E, Shindo D J, et al. Friction-stir welding[A]. Jata K V, Mahoey M W. Symposium Sponsored by the Shaping and Forming Committee of the Materials Processing & Manufacturing Division of TMS[C]. Indianapolis: TMS, 2001. 77-81.

[2] 王希靖. 搅拌摩擦焊技术在铝合金加工中地应用[A]. 宋天虎. 2001年中国机械工程学会年会论文集[C]. 北京: 机械工业出版社, 2001. 85-88.

WANG Xi-jing. Application of friction stir welding in aluminum alloy processing[A]. SONG Tian-hu. Dissertations in 2001 Annual Meeting Sponsored by Chinese Mechanical Engineering Academy[C]. Beijing: China Mechanical Industry Press, 2001. 85-88.

[3] Rollin Mr, Collins E. The use of friction welding technology in maritine application[A]. Jata K V, Mahoey M W. Aluminum 2001-Processing of the TMS 2001 Aluminum Automotive and Joining Sessions[C]. Indianapolis, America: TMS, 2001. 189-195.

[4] 邢 丽, 柯黎明, 刘鸽平, 等. 铝合金LD10的搅拌摩擦焊组织及性能分析[J]. 焊接学报, 2002, 23(6): 55-58.

XING Li, KE Li-ming, LIU Ge-ping, et al. Microstructure and mechanical properties of a friction stir welded LD10 aluminum[J]. Transactions of the China Welding Institution, 2002, 23(6): 55-58.

[5] 刘小文, 鄢君辉, 杜随更. LY12搅拌摩擦焊接技术[J]. 焊接学报, 2001, 22(4): 55-57.

LIU Xiao-wen, YAN Jun-hui, DU Sui-geng. Friction stir welding of LY12 alloys[J]. Transactions of the China Welding Institution, 2001, 22(4): 55-58.

[6] 邢 丽, 柯黎明, 周细应, 等. 防锈铝LF6的固态塑性连接工艺[J]. 中国有色金属学报, 2002, 12(6): 1162-1165.

XING Li, KE Li-ming, ZHOU Xi-ying, et al. Solid-state plasticized joining for aluminum alloy LF6[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1162-1166.

[7] Su J Q, Nelson T W, Misgra R. Microstructural investigation of friction stir welded 7050-T651 aluminum[J]. Acta Materialia, 2003, 51(1): 713-729.

[8] Lee W B, Yeon Y M, Jung S B. The improvement of mechanical properties of friction-stir-welded A356 Al alloy[J]. Materials Science and Engineering A, 2003, 355(5): 154-159.

[9]Sutton M A,Yang B,Reynolds A P, et al. Micro- structural studies of friction stir welds in 2024-T3 aluminum[J]. Materials Science and Engineering A, 2002, 323(3): 160-166.

[10] Peel M,Steuwer A,Preuss M, et al. Microstructure mechanical properties and residual stresses as a function of welding speed in aluminum AA5083 friction stir welds[J]. Acta Materialia, 2003, 51(8): 4791-4801.

[11] 王大勇, 冯吉才, 刘会杰, 等. Al-Cu-Li合金搅拌摩擦焊接头的微观组织和力学性能[J]. 中国有色金属学报, 2004, 14(1): 69-73.

WANG Da-yong, FENG Ji-cai, LIU Hui-jie, et al. Microstructures and mechanical properties of friction-sir welding joint of Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 69-73.

[12] 王希靖, 陈书锦, 李常锋, 等. 搅拌摩擦焊机控制器的研制[J]. 兰州理工大学学报, 2004, 30(1): 15-18.

WANG Xi-jing, CHEN Shu-jin, LI Chang-feng, et al. Development of friction stir welding controller[J]. Journal of Lanzhou University of Technology, 2004, 30(1): 15-18.

[13] 王希靖. 铝合金搅拌摩擦焊技术应用研究[J]. 中国有色金属学报, 2001, 11(9): 78-82.

WANG Xi-jing. The application of friction stir welding technology for aluminum alloy[J]. Journal of Nonferrous Metal, 2001, 11(9): 78-82.

[14] 王大勇, 冯吉才, 狄 欧, 等. 铝合金搅拌摩擦焊接头焊核区等轴晶组织的形成机制[J]. 焊接学报, 2003, 24(4): 33-35.

WANG Da-yong, FENG Ji-cai, DI Ou, et al. Forming process analysis of equiaxed grain in weld nugget zone during friction-stir welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2003, 24(4): 33-35.

[15] Guerra M, McClure J C, Murr L E, et al. Metal flow during friction stir welding[A]. Jata K V, Mahoey M W. Friction Stir Welding and Processing[C]. Indianapolis: TMS, 2001. 25-31.

[16] 王祖唐, 关廷栋, 肖景容, 等. 金属塑性成形理论[M]. 北京: 机械工业出版社, 1989. 34-36.

WANG Zhu-tang, GUAN Ting-dong, XIAO Jing-rong, et al. The Theory of Metal Plasticized Figuration[M]. Beijing: China Mechanical Industry Press, 1989. 34-36.

[17] 余汉清, 陈金德. 金属塑性成型原理[M]. 北京: 机械工业出版社, 2002. 22-23.

YU Han-qing, CHEN Jin-de. The Principle of Metal Plasticized Figuration[M]. Beijing: China Mechanical Industry Press, 2002. 22-23.

[18] 胡德林. 金属学及热处理[M]. 西安: 西北工业大学出版社, 1995. 200-206.

HU De-lin. Metal Theory and Heat Treating[M]. Xian: Northwest University of Technology Press, 1995. 200-206.

基金项目: 甘肃省科技攻关资助项目(GS012-A52-069)

收稿日期: 2004-04-06; 修订日期: 2004-06-28

作者简介: 王希靖(1956-), 男, 教授, 博士生导师.

通讯作者: 王希靖, 教授; 电话: 0931-2973941; 传真: 0931-2806962; E-mail: wangxj@lut.cn

(编辑 陈爱华)