Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel

R. PAVENTHAN1, P. R. LAKSHMINARAYANAN1, V. BALASUBRAMANIAN1, 2

1. Department of Manufacturing Engineering, Annamalai University,

Annamalainagar-608 002, Tamil Nadu, India;

2. Centre for Materials Joining & Research (CEMAJOR),

Annamalai University, Annamalainagar-608 002, Tamil Nadu, India

Received 4 August 2010; accepted 8 October 2010

Abstract: Friction welding (FW) is a process of solid state joining which is used extensively in recent years due to its advantages such as low heat input, production efficiency, ease of manufacture and environment friendliness. Friction welding can be used to join different types of ferrous metals and non-ferrous metals that cannot be welded by traditional fusion welding processes. The process parameters such as friction pressure, forging force, friction time and forging time play the major roles in determining the strength of the joints. In this investigation an attempt was made to develop an empirical relationship to predict the tensile strength of friction welded AA 6082 aluminium alloy and AISI 304 austenitic stainless steels joints, incorporating above said parameters. Response surface methodology (RSM) was applied to optimizing the friction welding process parameters to attain the maximum tensile strength of the joint.

Key words: friction welding; aluminium alloy; stainless steel; response surface methodology; optimization

1 Introduction

Joints of dissimilar metal combinations are employed in different applications requiring a certain special combination of properties as well as to save cost incurred towards costly and scarce materials [1]. Conventional fusion welding of many such dissimilar metal combinations is not feasible owing to the formation of brittle and low melting intermetallics due to metallurgical incompatibility, wide difference in melting point, thermal mismatch, etc. Friction welding is a solid-state welding process widely employed in such situations [2].

ANANTHAPADMANABAN [3] reported the experimental studies on the effect of friction welding parameters on properties of steel. DOBROVIDOV [4] investigated the selection of optimum conditions for the friction welding of high speed steel to carbon steel. MUMIM [5] investigated the hardness variations and microstructure at the interfaces of steel welded joints. While using austenitic stainless steel, negative metallurgical changes like delta ferrite formation and chromium carbide precipitation between grain boundaries take place during fusion welding. These changes are eliminated in friction welding. The effect of friction time on the fully plastically deformed region in the vicinity of the weld was investigated by SATHIYA et al [6]. The effect of friction pressure on the properties of hot rolled iron based super alloy was investigated by HAKAN et al [7].

From the literature review [3-8], it is understood that most of the published information on friction welding of dissimilar materials focused on the microstructural characteristics, microhardness variations, phase formation and tensile properties evaluation. All the above mentioned investigations were carried out on trial and other basis to attain optimum welding conditions. No systematic study has been so far reported to optimize the friction welding parameters to attain the maximum tensile strength in aluminium and stainless steel dissimilar joints. Hence in this investigation, an attempt was made to optimize friction welding process parameters to attain the maximum tensile strength in AA6082 aluminium alloy and AISI 304 austenitic stainless steel dissimilar joints using response surface methodology.

2 Experimental

The base materials, AA6082-T6 alloy and AISI 304 austenitic stainless steel, used in this investigation, were cylindrical rods with 12 mm in diameter and 75 mm in length. The chemical composition and mechanical properties of the base materials are presented in Table 1 and Table 2, respectively. A hydraulic controlled continuous drive friction welding machine (20 kN capacity) was used to weld the joints. From the literature the predominant factors having greater influence on the tensile strength of friction welded (FW) joints were identified as: 1) friction pressure; 2) forging force; 3) friction time and 4) forging time. Trial experiments were conducted to determine the working range of the above factors. Feasible limits of the parameters were chosen in such a way that the friction welded joints should be free from any visible external defects. The important factors influencing the tensile properties of FW joints and their working range for aluminium 6082-T6 and AISI 304 austenitic stainless steel are presented in Table 3.

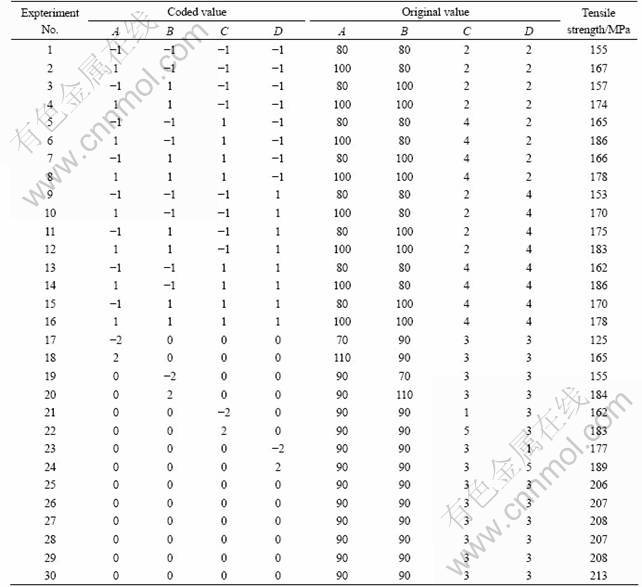

As the range of individual factor was wide, a central composite rotatable four-factor, five-level factorial design matrix was selected. The experimental design matrix (Table 4), consisting of 30 sets of coded conditions and comprising a full replication four-factor factorial design of 16 points, 8 star points, and 6 center points, was used. The upper and lower limits of the parameters were coded as +2 and -2, respectively. The coded values for intermediate levels can be calculated by

Xi=2[2X-(Xmax+Xmin)]/(Xmax-Xmin) (1)

where Xi is the required coded value of a variable X and X is any value of the variable from Xmin to Xmax. The friction welds were made under every condition dictated by the design matrix in random order so as to avoid the noise creeping output response. As prescribed by the design matrix, 30 joints were fabricated. The welded joints were machined to the standard dimensions. Three tensile specimens from each welding conditions were fabricated according to materials (ASTM E8M-04) standards to evaluate the tensile strength of the joints. Tensile test was carried out on a 100 kN electro- mechanical controlled universal testing machine. The specimen was loaded at the rate of 1.5 kN/min according to the ASTM specification.

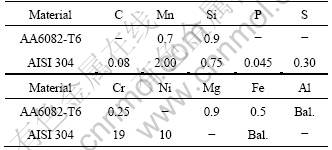

Table 1 Chemical composition of base metals (mass fraction, %)

Table 2 Mechanical properties of base metals

Table 3 Important factors and their levels

3 Developing empirical relationship

Relationship between tensile strength (σ) of the friction welded aluminium alloy and austenitic stainless steel joint is a function of the friction welding parameters such as a friction pressure (A), forging force (B), friction time (C) and forging time (D) which it can be expressed as:

σ=f{A, B, C, D} (2)

The second-order polynomial (regression) equation used to represent the response surface σ is given by:

σ=b0+ΣbiXi+ΣbiiXi2+ΣbijXiXj (3)

and for four factors, the selected polynomial could be expressed as:

σ=b0+b1A+b2B+b3C+b4D+b12AB+b13AC+ b14AD+b23BC+

b24BD+b34DT+b11A2+b22B2+b33C2+b44D2 (4)

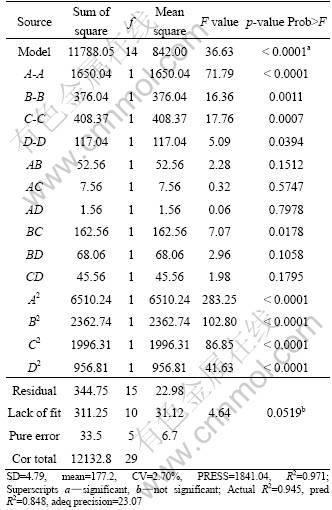

where b0 is the average of the responses, and b1, b2, b3, …, b44 are regression coefficients [8] that depend on the respective linear, interaction, and squared terms of factors. The value of the coefficient was calculated using Design Expert Software. The significance of each coefficient was determined by Student’s t test and p values, which are listed in Table 5. The values of “Prob>F” less than 0.05 indicate that the model terms are significant. In this case, A, B, C, D, AC, A2, B2, and D2 are significant model terms. The values greater than 0.10 indicate that the model terms are not significant. The results of multiple linear regression coefficients for the second- order response surface model are given in Table 6. The final empirical relationship was constructed using only these coefficients, and the developed final empirical relationship is given below:

σ=208.5+8.29A+3.95B+4.125C+2.20D-3.18BC-

15.406A2-9.28B2-8.53C2-5.90D2 (5)

Table 4 Designed matrix and experimental results

Analysis of variance (ANOVA) technique was used to check the adequacy of the developed empirical relationship. In this investigation, the desired level of confidence was considered to be 95%. The relationship may be considered to be adequate, which provides that 1) the calculated F value of the model developed should not exceed the standard tabulated F value and 2) the calculated R value of the developed relationship should exceed the standard tabulated R value for a desired level of confidence. It is found that the above model is adequate. Each predicted value matches well with its experimental value, as shown in Fig. 1.

Fig. 1 Correlation graph

Table 5 Analyses of variance

4 Optimizing welding parameters

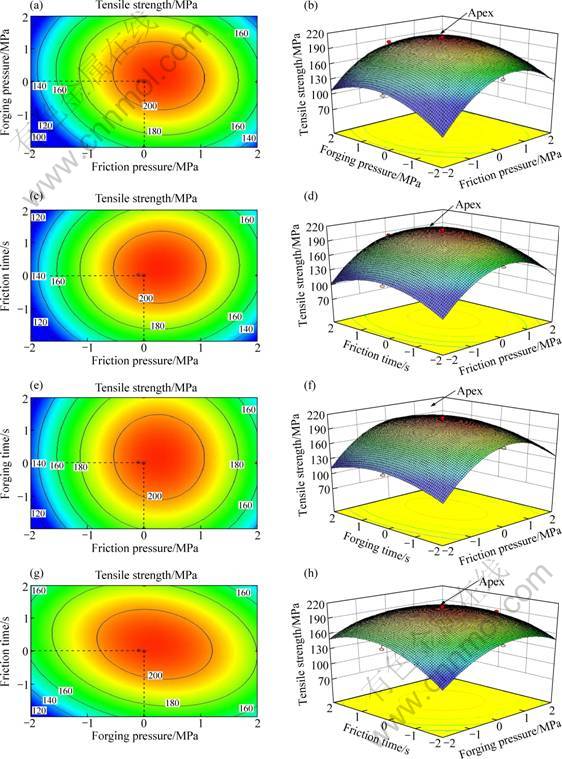

The response surface methodology (RSM) was used to optimize the parameters in this study. RSM is a collection of mathematical and statistical techniques that are useful for designing a set of experiments, developing a mathematical model, analyzing the optimum combination of input parameters, and expressing the values graphically [9-10]. To obtain the influencing nature and optimized condition of the process on tensile strength, the surface plots and contour plots which are the indications of possible independence of factors were developed for the proposed empirical relation by considering two parameters in the middle level and two parameters in the X- and Y-axis, as shown in Fig. 2. These response contours can help to predict the response (TS) for any zone of the experimental domain [11]. The apex of the response plot shows the maximum achievable tensile stength. A contour plot is produced to display the region of the optimal factor settings visually. For the second-order responses, such a plot can be more complex compared to the series simple of parallel lines that can occur with the first-order models. Once the stationary point is found, it is usually necessary to characterize the response surface in the immediate vicinity of the point. Characterization involves identifying whether the stationary point is a minimum response or maximum response or a saddle point. To classify this, it is most straightforward to examine it through a contour plot. Contour plot plays a very important role in the study of a response surface. It is clear from Fig. 2 that the tensile stength increases with the increase of friction pressure, forging force and friction time, forging time to a certain value and then decreases.

By analyzing the response surfaces and contour plots (Fig. 2), the maximum achievable tensile stength value is found to be 213 MPa. The corresponding parameters that yielded this maximum value are friction pressure of 90 MPa, forging pressure of 90 MPa, friction time of 3 s, and forging time of 3 s. Contributions made by the process parameters on ultimate tensile stress can be ranked [12-13] from their respective F value in Table 5, showing that the degrees of freedom are the same for all the input parameters. The higher F value implies that the respective term is more significant and vice versa.

From the F values, it can be concluded that friction pressure contributes more to tensile strength, followed by friction time, forging time, and forging force in the considered range in this investigation.

Table 6 Estimated regression coefficients

Fig. 2 Response graphs and contour plots

5 Conclusions

1) An empirical relationship was developed to predict the tensile strength of friction welded AA6082 aluminium alloy and AISI 304 austenitic stainless steel dissimilar joints, incorporating process parameters. The developed relationship can be effectively used to predict the tensile strength of friction welded joints at a confidence level of 95%.

2) A maximum tensile strength of 213 MPa could be attained under the welding conditions: 90 MPa of friction pressure, 90 MPa of forging force, 3 s of friction time, and 3 s of forging time.

3) Friction pressure was found to have greater influence on tensile strength of the joints, followed by friction time, forging time, and forging pressure.

Acknowledgements

The authors are grateful to the Department of Manufacturing Engineering, Annamalai University, for extending the facilities of Material Testing Laboratory to carry out this investigation. The authors also wish to record their sincere thanks to the University Grant Commission (UGC), New Delhi, for the Research Fellowship in Science for Meritorious Students scheme.

References

[1] OZDEMIR N. Investigation of mechanical properties of friction welded joints between AISI 304 L and AISI 4340 steel as a function of rotational speed [J]. Materials Letters, 2005, 59: 2504-2509.

[2] YOON H K, KONG Y U, KIM S J, KOHYAMA A. Mechanical properties of friction welds of RAFs (JLF-1) to SUS 304 steels as measured by the acoustic emission technique [J]. Fusion Engineering and Design, 2006, 81: 945-950.

[3] ANANTHAPADMANABAN D. A study of mechanical properties of friction welded mild steel to stainless steel joints [J]. Materials and Design, 2009, 30: 2642-2646.

[4] DOBROVIDOV A N. Selection of optimum conditions for the friction welding of high speed steel 45 [J]. Weld Prod, 1975, 22(3): 22-26.

[5] MUMIM S. Evaluation of the joint interface properties of austenitic stainless steel joined by friction welding [J]. Materials and Design, 2007, 28: 2244-2250.

[6] SATHIYA P, ARAVINDAN S, NOORUL HAG A. Mechanical and metallurgical properties of friction welded AISI 304 austenitic stainless steel [J]. Int J Adv Manufact Technol, 2005, 26: 505-511.

[7] HAKAN A, MEHMET T, ADEM K. Effect of friction pressure on the properties of friction welded MA956 iron based super alloy [J]. Materials and Design, 2007, 28: 948-953.

[8] MURTI K G, SUNDERESAN S. Structure and properties of friction welds between high-speed steel and medium carbon steel for bimetal tools [J]. Mater Sci Technol, 1986, 2: 865-870.

[9] KHURI A I, CORNELL J. Response surfaces design and analysis [M]. New York: Marcel Dekker, 1996.

[10] GUNNARAJ V, MURUGAN N. Application of response surface methodology for predicting weld bead quality in submerged arc welding of pipes [J]. J Mater Process Technol, 1999, 88: 266-275.

[11] TIEN C L, LIN S W. Optimization of process parameters of titanium dioxide films by response surfaces methodology [J]. Opt Commun, 2006, 266: 574-581.

[12] PHILLIP J R. Taguchi techniques for quality engineering [M]. New York: McGraw-Hill, 1988.

[13] LAKSHIMINARAYANAN A K, BALASUBRAMANIAN V. Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminum alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 9-18.

铝合金和不锈钢摩擦焊接参数的预测和优化

R. PAVENTHAN1, P. R. LAKSHMINARAYANAN1, V. BALASUBRAMANIAN1, 2

1. Department of Manufacturing Engineering, Annamalai University,

Annamalainagar-608 002, Tamil Nadu, India;

2. Centre for Materials Joining & Research (CEMAJOR),

Annamalai University, Annamalainagar-608 002, Tamil Nadu, India

摘 要:搅拌摩擦焊是一种固态连接工艺,具有低的热量输入、高的生产效率、容易操作和环境友好等优点而被广泛使用。搅拌摩擦焊能够焊接不同类型的黑色金属和有色金属,而传统的熔焊则不能。焊接工艺参数如摩擦压力、顶锻压力、摩擦时间和施压时间对接头的强度起主要作用。本研究旨在建立一个经验方程去预测搅拌摩擦焊AA 6082和AISI 304不锈钢接头的拉伸强度。采用响应面法去优化搅拌摩擦焊工艺参数,从而得到接头的最大拉伸强度。

关键词:搅拌摩擦焊接;铝合金;不锈钢;响应面法;优化

(Edited by YANG Hua)

Corresponding author: R. PAVENTHAN; Tel: +91-09944013323; Fax: +91-4144-2308080/238275; E-mail: mr_paventhan@yahoo.com

DOI: 10.1016/S1003-6326(11)60884-4