文章编号:1004-0609(2016)-06-1204-10

DP工艺GH4169合金热加工高通量测试方法

司家勇1, 2,宋思远1,廖晓航1,黄再旺2

(1.中南林业科技大学 机电工程学院,长沙 410004;

2.中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以经DP工艺处理的GH4169合金为对象,研究热加工高通量双圆锥台试样测试方法,利用数值模拟方法进行双圆锥台试样关键尺寸设计,探讨热加工工艺参数对双圆锥台试样等效应变场分布的影响规律,进行实际试验验证,分析晶界取向差和晶界分布特征。结果表明:摩擦因数对等效应变影响显著,随着摩擦因数的提高,试样中心位置应变量增加,应变梯度加大;随着变形温度的升高和变形速率的减小,试样中心附近的等效应变降低,能促进δ相的溶解和断裂,加快动态再结晶的发生,增大动态再结晶晶粒尺寸;经(1000 ℃,0.01 s-1)热变形后高通量双圆锥台试样中心由于动态再结晶导致小角晶界数量很少,统计频率仅为5.6%,外缘变形量低,晶界数量中大角晶界占比高达92.3%,晶内分布有原始孪晶;随着变形温度提高,小角晶界不断减少,孪晶数量有所增加。

关键词:GH4169合金;热加工;高通量测试;数值模拟

中图分类号:TG146.1 文献标志码:A

高温合金显微组织特征对于热加工过程中的应变速率、温度和应变量极为敏感,即便在相对简单的热模锻造过程中,锻件各部位的热加工参数也会存在差异,这就会给实际变形组织及晶粒尺寸的研究带来困难[1]。目前,高温合金热变形行为和变形机制的研究均使用传统的圆柱形试样,热压缩实验时不同试样之间的测试条件,如加热时间、温度、应变速率等,难以保证不存在误差。本文作者提出应用一种新型的、可在同一个试样中获得多个应变量分布的高通量双圆锥台形试样测试方法来避免以上问题的影响,可更为快速、可靠的获取高温合金高温变形时组织转变特征及异常晶粒长大等信息[1-5]。

GH4169合金是属于铌强化的沉淀硬化型铁镍基高温合金,具有优良的高温力学性能,在航空工业中被广泛用于制造一些关键零部件,如压气机盘、涡轮盘、轴和叶片等[6-8]。GH4169合金以体心四方结构的γ″相(Ni3Nb)为主要强化相,同时辅以面心立方结构的弱强化相γ′(Ni3AlTi),正交结构的δ相(Ni3Nb)是γ″相的平衡相。GH4169合金的组织性能对热加工工艺很敏感,工艺控制不当会产生粗晶、混晶等现象,进而影响锻件的持久缺口敏感性和冲击韧度等[9]。在过去的几十年里,GH4169合金的热变形行为己采用扭转或热压缩的方法进行了比较广泛的研究[10-15]。因GH4169合金中δ相通过钉扎晶界阻碍晶粒长大,目前发展出了一种δ相时效处理(DP)工艺,即在变形前的合金中有意预析出δ相,通过控制热加工过程中的变形工艺来获取晶粒均匀细小且性能优良的锻件。RUIZ等[16]通过这种DP工艺获得了平均晶粒尺寸为ASTM 8级的直径为150和200 mm的GH4169合金锻坯,以及晶粒尺寸等级为11级的直径为76和38 mm的棒坯。DIX等[17]利用DP工艺获得了晶粒尺寸等级为9级的GH4169合金锻坯,并通过闭模锻造获得了晶粒尺寸为ASTM 13级的涡轮盘锻件。BHOWAL等[18]将Delta工艺和Gatorizing工艺相结合获得了晶粒尺寸等级高于ASTM 11级的GH4169合金涡轮盘锻件。吕宏军等[19]结合Delta工艺和轧制技术,可以得到ASTM 12~14级的超细晶粒组织 GH4169合金板材。张海燕等[20-21]研究了GH4169合金等温压缩变形过程中δ相的演变机制,在变形断裂和溶解断裂的综合作用,片层/长针状δ相发生球化,转变为颗粒/短棒状δ相。YUAN等[22]对比了不同δ相含量对GH4169合金热变形行为的影响,结果显示δ相的存在不仅会降低合金的峰值应变和峰值应力,而且可以促进峰值应力后的流变软化过程。WANG等[23-24]研究了δ相溶解行为及对变形机制的影响,高温变形时δ相主要以弯曲、扭折和切断等方式来协调塑性变形,并在界面能降低的驱动力下由针状逐渐转变为短针状乃至球状,其动态再结晶机制主要是δ相诱发动态再结晶形核和非连续动态再结晶形核。CONE等[25]观察了不同形态δ相合金轧制过程中的δ相转变过程。

本文作者以经DP工艺处理的GH4169合金为研究对象,利用数值模拟方法设计了高通量双圆锥台试样关键尺寸,分析了其与普通圆柱试样在高温压缩变形时的差异,探讨了摩擦因数、变形温度及应变速率对双圆锥台试样等效应变场分布的影响规律,进而进行高通量双圆锥台试样测试技术的实验验证工作,分析了显微组织分布特征,获得了晶界取向差和晶界特征分布,可为高温合金热加工工艺研究和晶粒尺寸控制提供技术参考。

1 实验

试验用材料为辽宁抚顺特钢公司生产的d 200 mm的GH4169合金锻棒,其化学成份为(质量分数,%):C 0.036,Ni 52.12,Cr 18.75,Nb 5.36,Mo 2.99,Ti 1.00,Al 0.49,B 0.004,Si 0.10,Mn 0.02,Co 0.04,余量为 Fe。对锻态材料进行δ相时效处理:1040 ℃保温40 min水冷,随后在900 ℃时效24 h水冷至室温。经DP工艺处理的GH4169合金机加工成图1(a)所示d 10 mm×15 mm圆柱形热压缩试样和图1(b)所示高通量双圆锥台试样,高温热压缩试验在计算机控制的MTS力学试验机上进行。将获取的圆柱试样等温压缩真应力-真应变数值输入Deform-3D软件数据库,建立高通量双圆锥台试样三维有限元模型,进行试样压缩过程的有限元分析。采用电火花线切割将压缩后试样沿轴向切开,机械抛光后进行化学腐蚀,腐蚀液配比为50 mL H2O+40 mL HCl+10 mL HF,加入几滴双氧水可以促进化学反应进行,使用LEICA DM4000光学显微镜进行显微组织观察。利用电子背散射衍射(Electron backscattered diffraction, EBSD)方法对高温压缩变形后的试样进行晶界取向差和晶界特征等的定量分析。将上述经显微组织观察后的试样重新机械研磨并震动抛光后,在带有牛津仪器Aztec HKL EBSD附件的FEI Quanta 650型扫描电镜下进行EBSD分析,样品台相对于入射电子倾斜70°,操作电压为20 kV。

图1 热变形试样宏观形貌

2 结果与分析

2.1 高通量测试试样几何设计

已有文献[1-4]中3种典型高通量双圆锥台试样尺寸如图2(a)~(c)所示。为设计适合本研究用GH4169合金的双圆锥台试样几何尺寸,将通过圆柱热压缩实验获取的真应力-真应变数据嵌入Deform 3D软件,利用Deform软件对3种尺寸双圆锥台试样进行有限元模拟,分析等效应变场分布及最大载荷数值,对其进行优化设计,以确定本实验中所研究试样的几何尺寸。

有限元模拟条件设定为变形温度1000 ℃,压下速率1.0 mm/s,压后剩余高度为试样侧面直壁段高度数值,比较载荷、等效应变及等效应变速率分布可见,依据图2(a)尺寸的双圆锥台试样经数值模拟后获得的等效应变分布范围为0.465~2.26,最大载荷1.18×105 N;依据图2(b)尺寸的双圆锥台试样经数值模拟后获得的等效应变分布范围为0.244~1.42,最大载荷1.87×104 N;依据图2(c)尺寸的双圆锥台试样经数值模拟后获得的等效应变分布范围为0.383~1.92,最大载荷1.85×105 N,考虑模拟条件和等温热压缩设备吨位,初步选定图2(b)尺寸的双圆锥台试样,进行后续尺寸优化设计,有限元数值模拟结果见图2(d)~(e)。

进而,对图2(b)所示尺寸的双圆锥台试样进行优化设计。因该尺寸双圆锥台试样最大等效应变仅1.42,

图2 3种典型双圆锥台试样尺寸及等效应变分布

表1 双圆锥台试样外缘直壁段高度H值数值模拟结果(900 ℃,8.0 mm/s)

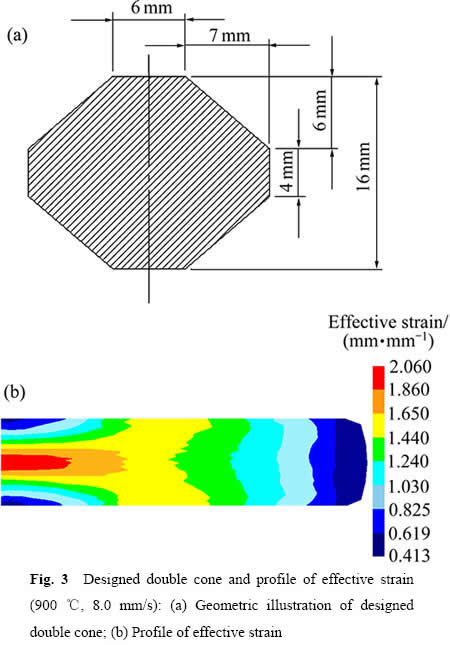

较其他两种尺寸双圆锥台试样变形后获得的最大应变量要低,为增加试样内部等效应变场阶梯差异,考虑通过侧边直壁段高度(H)的改变来提高最大等效应变值,模拟结果如表1所列,对比最大载荷和等效应变分布范围,综合考虑,优先选择H为4 mm,如设备最大载荷限制,可适当将H数值提高,最终确定具体尺寸的双圆锥台试样纵截面中心至外缘有7个阶梯等效应变数值,试样尺寸如图3(a)所示,(900 ℃,8.0 mm/s)变形后的等效应变分布如图3(b)所示。

图3 双圆锥台试样尺寸及其等效应变(900 ℃,8.0 mm/s)

2.2 高通量测试试样变形特征

为研究双圆锥台试样变形特征,利用Deform软件模拟了(980 ℃,0.01 s-1)条件时,不同压下量对双圆锥台试样等效应变场分布的影响,分析其变形特征,模拟结果如图4所示。在双圆锥台试样刚开始压缩变形时,外圆锥面开始参与变形,变形区域出现于上下两端面外缘与外圆锥面的交界处,此处应变量最大,并呈弧形向试样内中心部位扩展,值得注意的是由于摩擦的存在导致两端面接近中心区域出现难变形区域,如图4(a)所示;随着变形量的增加,外圆锥面继续发生变形,试样内部纵截面上形成“X”形的变形区域,上下端面仍然存在未变形区域,从试样中心至外缘开始出现阶梯应变分布,如图4(b)所示;变形量进一步加大,阶梯应变区域不断增多,且中心至外缘应变分布范围不断扩大,直至变形完成,如图4(c)和(d)所示。

高通量双圆锥台测试方法避免了传统圆柱试样压缩变形时多个试样之间的加热时间、温度、应变速率等的差异,单一试样中可获取同一变形温度、应变速率,不同变形量下的组织分布,与传统圆柱试样相比更为可靠、快捷、经济。为分析双圆锥台试样与传统圆柱试样变形特征差异,对其变形原理进行了进一步分析。如图5所示,双圆锥台试样的外圆锥面可看作由无数微小台阶组成,在变形过程中,随着压下量的增加,变形扩展至外圆锥面时,每一时刻参与变形的均为外圆锥面微小台阶水平面至试样中心构成的上下端面和瞬时高度所组成的圆柱试样,也即是说双圆锥台试样压下量不断增加的变形过程中,瞬时参与变形部分总是一圆柱体形状,且这一圆柱体形部分的高度在变形过程中不断降低,圆周直径在不断加大,而最终变形完成后试样内部各参量值可视作由变形过程中无数个圆柱体试样变形后的参量数值叠加而成,因此变形后试样中部至外缘应变量呈阶梯递减分布。

图4 双圆锥台试样变形过程等效应变场分布(980 ℃,0.01 s-1)

2.3 热加工参数对高通量测试的影响

2.3.1 摩擦因数的影响

与传统圆柱试样压缩类似,试样端面的摩擦因数也是影响高通量双圆锥台试样热加工实验结果的主要因素之一。模拟分析(980 ℃,0.01 s-1)条件,摩擦因数分别为0、0.3、0.6和0.9时双圆锥台试样变形完成后试样内部等效应变场和应变速率场的分布情况。结果表明:摩擦因数显著影响着双圆锥台试样变形后纵截面等效应变分布,随着摩擦因数的提高,试样纵截面中心位置的应变不均匀性增加,应变梯度加大,越靠近试样外缘,等效应变差异减小。不同摩擦因数变形试样纵截面中心线上各点对应等效应变数值比较如图6(a)所示。

2.3.2 热加工温度的影响

采用数值模拟方法,分析了应变速率为0.01 s-1,变形温度为1000、1020、1040 ℃时双圆锥台试样变形后纵截面等效应变数值分布,发现温度改变对等效应变数值分布有一定影响,随着变形温度的提高,试样靠近中心部位约6mm范围内的等效应变数值有所下降,其他位置受温度的影响很小,几乎可以忽略不计。相应纵截面等效应变数值分布如图6(b)所示。

图5 双圆锥台试样变形过程分析

图6 热加工参数对高通量双圆锥台试样纵截面等效应变分布影响

2.3.3 热变形速率的影响

采用数值模拟方法,分析了变形温度1000 ℃,应变速率为0.001、0.01和0.1 s-1时,双圆锥台试样内部等效应变场和应变速率场分布情况,可知,与热加工温度相比,热变形速率的改变对等效应变的数值分布的影响进一步缩小。相应纵截面等效应变数值分布如图6(c)所示。

2.4 高通量测试及显微组织分析

2.4.1 光学显微组织分析

对经DP工艺处理的GH4169合金进行了变形温度为1000、1020和1040 ℃,应变速率为0.1、0.01、0.001 s-1时的双圆锥台热压缩变形实验,对距试样中心分别为0、3、6、9和12 mm的5个位置处进行了显微组织观察,各组织观察点分布如图7所示。

经(1000 ℃,0.01 s-1)变形时,由于双圆锥台试样变形后纵截面从中心至外边缘应变呈梯度降低的,因此试样中心高应变量区域显微组织动态再结晶显著,平均晶粒尺寸约为9 μm,δ相含量显著降低,而外边缘应变量较低导致显微组织中仍有大量弯折、扭曲的长针状δ相存在,平均晶粒尺寸约为133 μm,其余为过渡区域;随着变形温度从1000 ℃增加至1040 ℃时,动态再结晶晶粒尺寸增大,δ相由于高温溶解和变形断裂的共同作用,使得各位置点长针状δ相含量均减少,再结晶程度增加,再结晶晶粒尺寸持续长大,且平均晶粒尺寸分布较为均匀,中心和外缘的平均晶粒尺寸约为40和61 μm,各位置点显微组织中难以发现长针状δ相的存在;随着热变形速率从0.01 s-1提高至0.1 s-1时,各位置点的再结晶程度下降,发生弯折或扭曲的δ相数量增多,中心和外缘的平均晶粒尺寸约为10 μm和130 μm,显微组织如图8所示。

2.4.2 电子背散射衍射分析

电子背散射衍射(EBSD)作为一种新的分析多晶体晶粒取向的手段,可以用于表征形变的不均匀性及织构演化等,有助于更为深入地分析材料的变形行 为,因而在金属塑性变形研究中的应用也越来越广泛[26-27]。高通量双圆锥台试样经(1000 ℃,0.01 s-1)条件热压缩变形后纵截面各处和(1040 ℃,0.01 s-1)条件变形试样中心晶界与亚晶界形貌及取向分布如图9所示。图9中粗实线代表大角度晶界(>15°),细实线代表小角度晶界(<15°,亦称为亚晶界)。为了便于分析比较,将图9中不同变形条件下各角度取向差分布数据统一为一定角度范围的取向差数量分布及取向差出现的频率,去除小于2.5°的晶界后数据如表2所列。可见,试样中心(0 mm)处动态再结晶明显,大角晶界占到93.2%,如图9(a)所示;距离试样中心3 mm处由于应变量水平较低,动态再结晶不完全,小角晶界出现频率增加,为22.3%,可观察到少量弯折或扭曲的长针状δ相,如图9(b)所示;随着距离进一步加大,应变量梯度降低,试样纵截面δ相继续增多,在δ相附近出现大量小角晶界,这是由于δ相是硬相,基体是软相,因此基体先于δ相发生塑性变形,变形后产生的位错会聚集在δ相附近,形成小角度的亚晶界,统计频率分别约为13.3%和11.5%,如图9(c)和(d)所示;特别要指出的是在试样外缘由于变形量最低,基本没有产生变形,晶界数量中大角晶界占比高达92.3%,晶粒内分布有原始孪晶,但与前述光学显微组织相比,片层状/长针状δ相基本没有被EBSD检测到,可能与EBSD测试时的放大倍数较小和片层状/长针状δ相的宽度较窄有关,其余点状黑色相为颗粒/短棒状δ相或碳(氮)化物,如图9(e)所示;经(1040 ℃,0.01 s-1)条件变形后高通量双圆锥台试样中心晶界特征如图9(f)所示,随着变形温度的提高,由于热激活作用,小角晶界不断减少,统计频率仅为4.3%,δ相完全消失,晶粒尺寸不断增大,且孪晶数量也有所增加。此外,依据表2的高通量双圆锥台试样变形取向差范围晶界数量与频率统计结果,在GH4169合金高温塑性变形过程中,持续有较大比例取向差在5°以下的小角度晶界存在,随变形温度或应变速率的改变,5°以下的小角度晶界与16°以上的大角度晶界之间不断进行转换,而6°~15°范围内的小角晶界数量和频率变化不大,这表明变形过程中5°以下的小角度晶界与大角晶界之间的转变是直接进行的,且小角度晶界数量和频率与大角度晶界数量和频率趋于动态平衡。

图7 高通量双圆锥台试样变形后纵截面显微组织观察位置

图8 变形条件对高通量双圆锥台试样显微组织的影响

图9 高通量双圆锥台试样变形组织晶界取向分析(0.05 s-1)

表2 高通量双圆锥台试样变形取向差范围晶界数量与频率统计

3 结论

1) 随着高通量测试用双圆锥台试样外缘直壁段高度降低,变形所需最大载荷不断增大,阶梯等效应变场数值范围扩大,且等效应变升高。

2) 摩擦因数对等效应变影响显著,随着摩擦因数的提高,试样中心位置应变量增加,应变梯度加大,而随着变形温度的提高和变形速率的减小,试样中心附近的等效应变数值只略有降低。

3) 经DP工艺处理的GH4169合金进行高通量测试时,从试样中心至外缘各处动态再结晶程度呈阶梯分布,变形温度的增加和应变速率的降低均能促进δ相的溶解和断裂,加快动态再结晶的发生,增大动态再结晶晶粒尺寸。

4) 高通量双圆锥台试样经(1000 ℃,0.01 s-1)热变形后,中心部位由于动态再结晶导致小角晶界数量很少,统计频率仅为5.6%,外缘变形量低,大角晶界占比高达92.3%,晶内分布有原始孪晶,随着变形温度提高,小角晶界不断减少,孪晶数量有所增加,且高温变形过程中小角度晶界与大角晶界之间的转变是直接进行的。

REFERENCES

[1] Antolovich B F, Evans M D. Predicting grain size evolution of udimet alloy 718 during the “cogging” process through use of numerical analysis[C]// LORIA E A. Superalloys 2000. Warrendale, PA: TMS, 2000: 39-47.

[2] Semiatin S L, Weaver D S, Kramb R.C, Fagin P N,Glavicic MG, Goetz RL,Frey ND, Antony MM. Deformation and recrystallization behavior during hot working of a coarse-grain, nickel-base superalloy ingot material[J]. Metallurgical and Materials Transactions A, 2004, 35(2): 679-693.

[3] Weaver D S, Semiatin S L. Recrystallization and grain-growth behavior of a nickel-base superalloy during multi-hit deformation[J]. Scripta Materialia, 2007, 57(11): 1044-1047.

[4] Huron E, Srivatsa S, Raymond E d. Control of Grain Size Via Forging Strain Rate Limits for R'88DT[C]// LORIA E A. Superalloys 2000. Warrendale, PA: TMS, 2000: 49-58.

[5] 司家勇. Delta工艺GH4169合金高温变形行为及数值模拟研究[D]. 长沙: 中南大学, 2014.

Si Jia-yong. Deformation characteristics and simulation of delta-processed GH4169 Superalloy[D]. Changsha: Central South University, 2014.

[6] KENNEDY R L. Allvac? 718TM, superalloy for the next forty years[C]// LORIA E A. Sixth International Symposium on Superalloys 718, 625, 706 and Derivatives. Warrendale, PA: TMS, 2005: 1-14.

[7] 郭建亭. 高温合金材料学[M]. 北京: 科学出版社, 2010.

GUO Jian-tin. Materials science and engineering for superalloys[M]. Beijing: Science Press, 2010.

[8] 罗恒军, 谢 静, 程 槿. GH4169合金涡轮盘锻件晶粒度分析和控制[J]. 大型铸锻件, 2010, 6: 17-19.

LUO Heng-jun, XIE Jing, CHENG Jin. Analysis and control of g rain size of GH4169 alloy turbine disc forging[J]. Heavy Casting and Forging, 2010, 6: 17-19.

[9] 庄景云. 变形高温合金GH4169锻造工艺[M]. 北京: 冶金工业出版社, 2008.

ZHUANG Jin-yun. Forging process of wrought super alloy GH4169[M]. Beijing: Metallurgical Industry Press, 2008.

[10] Weis M J, Mataya M C, Thompson S W. The hot deformation behavior of an as-cast alloy 718 ingot[C]// LORIA E A. Superalloys 718. Warrendale, PA: TMS, 1989: 135-154.

[11] Zhou L X, Baker T N. Effects of strain rate and temperature on deformation behaviour of IN718 during high temperature deformation[J]. Mater Sci Eng A, 1994, 177: 1-9.

[12] Zhang J M, Gao Z Y, Zhuang J Y, Zhong Z Y. Mathematical modeling of the hot-deformation behavior of superalloy IN718[J]. Metallurgical and Materials Transactions A, 1999, 30: 2701-2713.

[13] Guest R P, Tin S. The dynamic and metadynamic recrystallization of IN718[C]// LORIA E A. Superalloys 718, 625, 706 and various derivatives. Warrendale, PA: TMS, 2005: 373-383.

[14] Thomas A, El-Wahabi M, Cabrera J M, Prado J M. High temperature deformation of Inconel 718[J]. J Mater Process Technol, 2006, 177: 469-472.

[15] 杨 平, 赵玉涛, 王安东, 缪 栋, 陈 刚, 何 毅. Delta工艺Inconel 718合金热变形条件下的流变行为[J]. 中国有色金属学报, 2012, 22(1): 72-79.

YANG Pin, ZHAO Yu-tao, WANG An-dong, MIAO Dong, CHEN Gang, HE Yi. Flow stress behavior of delta-processed Inconel 718 superalloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 72-79.

[16] RUIZ C, Obabueki A, Gillespie K. Evaluation of the microstructure and mechanical properties of delta processed alloy 718[C]// ANTOLOVICH S D. Seventh International Symposium on Superalloys. Pennsylvania: TMS, 1992: 33-42.

[17] Dix A W, Hyzak J M, Singh R P. Application of ultra fine grain alloy 718 forging billet[C]// ANTOLOVICH S D. Superalloys. Warrendale, PA: TMS, 1992: 23-32.

[18] Bhowal P R, Schirra J J. Full scale Gatorizing TM of fine grain Inconel 718[C]// LORIA E A. Superalloys 718, 625, 706 and Various Derivatives. Warrendale, PA: TMS, 2001: 193-201.

[19] 吕宏军, 姚草根, 张凯峰, 贾新朝. GH4169合金细晶成形工艺与机理及其性能研究[J]. 机械工程材料, 2003, 27(1): 15-18.

L? Hong-jun, YAO Cao-gen, ZHANG Kai-feng, JIA Xin-chao. Fine-grain forming process, mechanism and properties of GH4169 alloy[J]. MaterialsforMechanicalEngineering, 2003, 27(1): 15-18.

[20] 张海燕, 张世宏, 程 明. Delta工艺中Inconel 718合金中δ相的演变机制[J]. 金属学报, 2009, 45(12): 1451-1455.

ZHANG Hai-yan, ZHANG Shi-hong, CHENG Ming. Evolution of δ phase in Inconel 718 alloy during delta process[J]. Acta Metallurgica Sinica, 2009, 45(12): 1451-1455.

[21] Zhang H Y, Zhang S H, Cheng M, et al. Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy[J]. Materials Characterization, 2010, 61: 49-53.

[22] Yuan H, Liu W C. Effect of the delta phase on the hot deformation behavior of Inconel 718[J]. Mater Sci Eng A, 2005, 408: 281-289.

[23] Wang Y, Zhen L, Shao W Z, YANG L, ZHANG X M. Hot working characteristics and dynamic recrystallizationof delta-processed superalloy 718[J]. J Alloy Compd, 2009, 44: 341-346.

[24] 王 岩, 邵文柱, 甄 良. GH4169合金δ相的溶解行为及对变形机制的影响[J].中国有色金属学报, 2011, 21(2): 341-349.

WANG Yan, SHAO Wen-zhu, ZHEN Liang. Dissolution behavior of δ phase and its effects on deformation mechanism of GH4169 alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 341-349.

[25] Cone F P. Observations on the development of delta phase in Inconel 718 alloy[C]// LORIA E A. Superalloys 718, 625, 706 and Various Derivatives. Warrendale, PA: TMS, 2001: 323-332.

[26] 杨 平. 电子背散射衍射技术及其应用[M]. 北京: 冶金工业出版社, 2007.

YANG Ping. Electron back scatter diffraction technique and its application [M]. Beijing: Metallurgical Industry Press, 2007.

[27] WATANABE T. Approach to grain boundary design for strong and ductile polycrystals[J]. Res Mech, 1984, 11: 47-48.

High-throughput testing on hot working of delta-processed GH4169 alloy

SI Jia-yong1, 2, SONG Si-yuan1, LIAO Xiao-hang1, HUANG Zai-wang1

(1. College of Mechanical and Electrical Engineering, Central South University of Forestry and Technology,

Changsha 410004, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: High throughput testing technology for the hot working of superalloy was put forward for GH4169 alloy with delta process. The key dimension of the double cone sample was designed by finite element modeling method. The effects of hot working parameters on the effective strain were discussed. Then experiments were carried out, grain boundary orientation and grain boundary distribution character were researched. The results show that effect of friction coefficient on the effective strain is significantly. With increasing the friction coefficient, the strain of specimen center and the strain gradient increase. With increasing deformation temperature and decreasing strain rate, the effective strain of specimen center reduces. It can promote the dissolution and breakage of δ phase. Then the dynamic recrystallization volume fraction and dynamic recrystallization grain size are raised. When the hot working parameter is (1000 ℃, 0.01 s-1), the number of low angle grain boundaries is 5.6% at the center of double cone sample. The ratio of high angle grain boundaries is 92.3%, and twin crystals mainly distribute at the outer rim due to the lowest strain. With increasing deformation temperature, the number of low angle grain boundaries decrease, the grain size and twin increase.

Key words: GH4169 alloy; hot working; high-throughput testing technology; numerical simulation

Foundation item: Project(2012AA03A514) supported by the National High Research Development Program of China; Project supported by Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province, China

Received date: 2015-11-13; Accepted date: 2016-03-27

Corresponding author: SI Jia-yong; Tel: +86-731-85623381; E-mail: sjy98106@163.com

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2012AA03A514);湖南省高校科技创新团队支持计划资助

收稿日期:2015-11-13;修订日期:2016-03-27

通信作者:司家勇,副教授,博士;电话:0731-85623381;E-mail: sjy98106@163.com