基于QFD-Taguchi混合方法的型模铸造工艺优化

来源期刊:中国有色金属学报(英文版)2017年第11期

论文作者:K. Ch. APPARAO Anil Kumar BIRRU

文章页码:2345 - 2356

关键词:高压型模铸造;A380合金;QFD技术;Taguchi方法;铸造密度

Key words:high pressure die casting; A380 alloy; QFD technique; Taguchi method; casting density

摘 要:采用基于QFD-Taguchi的混合方法对高温型模铸造的多种重要工艺参数进行确认和优化,以便获得A380合金最适宜的铸造密度。为研究型模铸造工艺的性能特征,首先确认关键工艺参数,选择合适的正交序列,然后进行均差和方差分析。通过基于QFD-Taguchi的混合方法确认和优化了型模铸造的工艺参数,并将之应用于实验中。结果表明,在所选参数中,注射压力是最重要的参数。注射压力对平均铸造密度变化的贡献约为61.483%。95%一致性水平的置信区间约为0.000718,验证了A380合金优化铸造密度的预估区间。

Abstract: The present research work emphasized on identifying and optimizing various significant process parameters of high pressure die casting by using QFD-Taguchi based hybrid approach in order to yield the optimum casting density of the A380 alloy. Identification of critical process parameters, selection of appropriate orthogonal array, analysis of means and analysis of variance are employed to study the performance characteristic of the die casting process. The most critical process parameters identified and optimized by QFD-Taguchi based hybrid approach, such as the injection pressure, the molten metal temperature, the plunger velocity (first and second stage) and the die temperature were explored in the experimental work. The results show that injection pressure is the most significant factor among the selected parameters. The contribution of the injection pressure to the variation of mean casting density is around 61.483%. Confidence interval (CI) has also been estimated as 0.000718 for 95% consistency level to validate the predicted range of optimum casting density of aforesaid alloy.

Trans. Nonferrous Met. Soc. China 27(2017) 2345-2356

K. Ch. APPARAO, Anil Kumar BIRRU

Department of Mechanical Engineering, National Institute of Technology, Manipur 795004, India

Received 16 May 2016; accepted 24 September 2016

Abstract: The present research work emphasized on identifying and optimizing various significant process parameters of high pressure die casting by using QFD-Taguchi based hybrid approach in order to yield the optimum casting density of the A380 alloy. Identification of critical process parameters, selection of appropriate orthogonal array, analysis of means and analysis of variance are employed to study the performance characteristic of the die casting process. The most critical process parameters identified and optimized by QFD-Taguchi based hybrid approach, such as the injection pressure, the molten metal temperature, the plunger velocity (first and second stage) and the die temperature were explored in the experimental work. The results show that injection pressure is the most significant factor among the selected parameters. The contribution of the injection pressure to the variation of mean casting density is around 61.483%. Confidence interval (CI) has also been estimated as 0.000718 for 95% consistency level to validate the predicted range of optimum casting density of aforesaid alloy.

Key words: high pressure die casting; A380 alloy; QFD technique; Taguchi method; casting density

1 Introduction

In the present era, ample of industries are focused to seek light weight and high strength materials in the development of robust parts, particularly in automobile industry. Due to high specific strength, the global production of aluminium alloys has been increased and use of aluminium alloys has grown continuously for the past few decades. The future of aluminium industries is essentially related to the issue of global warming and emission of green house gases. Estimates provided by International Aluminium Institute represent that every kilogram of a heavier material that is replaced by aluminium in a vehicle, results in the reduction of 22 kg of carbon dioxide over the life span of the vehicle. Therefore, a key focus of the industry is the reduction in emissions by replacing useful nonferrous alloys, i.e., by increasing the usage of aluminium alloys in automobile, aircrafts and domestic application. Hence, aluminium alloys have played vital role due to light weight and a good combination of mechanical properties, machinability and castability [1,2]. As the applications of aluminium alloys are prominently increasing, it became necessary to develop corresponding manufacturing processes capable of presenting a high quality product. Among the present advanced manufacturing processes, casting is one of the oldest manufacturing processes and with the advancement of time; a lot of developments took place in the casting process. It is used for production of diverse complicated shapes that cannot be easily manufactured by any other process. Keeping in view the contribution of high temperature and safety aspects of the operators, different manual activities of the casting process are getting replaced by the high end automatic technologies. Based on the type of mold and way of filling the molten metal, various types of casting processes are now available in the market such as sand casting, die casting, continuous casting, investment casting, and squeeze casting.

But compared to other processes, die casting process is one of the most prominent and extensively used manufacturing processes for producing mass cost effective production that may be difficult to obtained through any other casting process [3]. Yet, a significant amount of research and development work have been done in order to optimize the die casting process and to enhance the quality of the castings. The optimization effort has been encouraged by net and/or near net shape technical characteristics of the pressure die casting process, in conjunction with its capability to produce complex engineering products. The quality of a die pressure casting is the result of a great number of parameters [4,5].

Some of these parameters affecting the quality are controllable while others are noise factors. Recently, a few researchers also made an attempt on effect of various properties by using die casting process [6-12]. But the influences of all these parameters are greatly complicated in the die casting process. Therefore, the selection of appropriate process parameters for fabricating a high quality die casting aluminium alloy products is becoming one of the primary challenges in the technology of the die casting process [13,14]. The most common and easily applicable method in the foundries environment is the trial and error method. However, this method demands extensive experimental work which might lead to decrease of the productivity of the firm. The QFD-Taguchi based hybrid approach appears to be an ideal tool for continuous rapid quality improvement. Casting efficiency and quality product design become easier and more productive for today’s highly competitive international market.

The focus of this research is on the robustness of the high pressure die casting process by identifying the most significant critical process parameters and optimization of the die casting process through QFD-Taguchi based hybrid approach. Detailed description about the QFD and Taguchi methodologies has mentioned below.

1.1 Quality function deployment

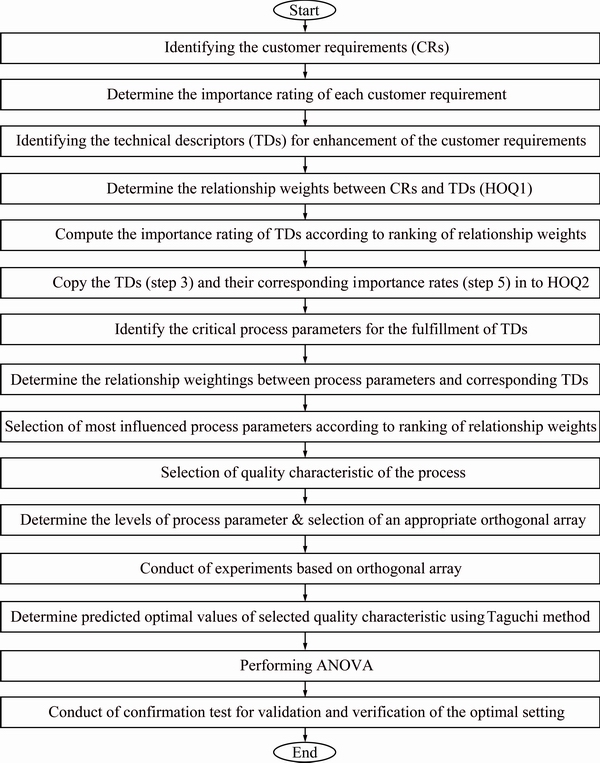

Quality function deployment (QFD) is a methodology that extracts customer requirements (CRs) and inducting them in the final product. Once CRs are extracted from customer, the QFD approach uses absolute importance to identify the degree of importance for each CR. By this method, CRs are translated into technical descriptors (TDs). These TDs are then translated into product or parts characteristics, which are then in-turn translated into process plans. These plans are then translated into specific operations, conditions [15]. The conventional four-phased, manufacturing based QFD methodology needs some adaptations to be applied in the die casting optimization process through QFD-Taguchi based hybrid approach in order to yield the optimum casting density. The adapted methodology is two-phased QFD cascade as shown in Fig. 1.

In this QFD process, a matrix called the house of quality (HOQ) [16] is used to display the relationship between the CRs and TDs [17]. In conventional QFD applications, a cell (i, j) in the relationship matrix of HOQ is assigned 1, 3, 9 (■=1, ▲= 3, O = 9) to represent a weak, medium and strong relationships respectively between CRj and TDj.

If m technical descriptors are considered for the purpose of satisfying ‘n’ customer requirements, the absolute and relative weights of each TD are computed as:

Absolute weight: Absolute weight (AW) is a popular and easy method for determining the weight is to assign numerical values to symbols in the relationship matrix. The absolute weight of jth technical descriptor by using the formula is [18].

(1)

(1)

where WAj is the row vector of absolute weight of technical descriptors; Rij is the weight assigned to relationship matrix (i=1, 2, …, n, and j=1, 2, …, m); Ci is the column vector of importance to customer for the Customer requirement (i=1, 2,…, n)

Fig. 1 Cascade of two phased QFD charts to determine critical process parameters in die casting process

Relative weight: The relative weight (RW) for the jth technical descriptor is then given by replacing the degree of importance for the customer requirement with the absolute weight for customer requirements. It is calculated by using the formula [18].

(2)

(2)

where WRj is the row vector of relative weight for the technical descriptors (j=1, 2,…, m).

Higher absolute and relative ratings indicates where engineering efforts need to be concentrated.

1.2 Taguchi method

Genichi Taguchi has developed a methodology for the application of designed experiments. Commonly, it has been used in analyzing the engineering problems to optimize quality characteristics (QCs) by means of settings of design parameters. PHARDE [19] states that the effect of uncontrollable factors (humidity, noise, vibrations etc.) can be nullified by the proper selection of the level combination of controllable factors or process parameters. The aim of the Taguchi method is to establish the parameter settings which render the product quality robust to unavoidable variations in external noise, a few researchers made an attempt on various manufacturing processes by using Taguchi method [20-22]. This method uses a very special set of arrays called orthogonal arrays (OAs), which could provide full information about all the factors that affect the quality characteristics. While there are standard OAs available, each of the array is intended for a specific number of independent design variables and levels. The selection of OA is based on total DOF (degree of freedom) of all the factors and the number of rows of the selected OA should be greater than or equal to the total DOF of any process. Taguchi recommended the use of Signal-to-Noise (S/N) ratio to quantify the effect of variations. Depending on the particular type of quality characteristics (QCs) involved, different S/N ratios are applicable, including “Lower is better”(LB), “Nominal is best” (NB) and “Higher is better” (HB). For the present investigations, density is a “Higher is better” type of quality characteristic and is taken into consideration, so S/N ratio of HB is given as

(3)

(3)

where η is the S/N ratio; yi is the response value for a test condition repeated in n times.

Taguchi also recommended the use of another tool called analysis of variance (ANOVA) to study the significance of process parameters. If a parameter is found to be significant, it implies that this parameter plays a vital role in determining the optimal solution of the present design problem.

1.3 Proposed optimal procedure

The integrated approach combines the QFD with Taguchi method in order to determine the die casting process parameters with optimal response characteristics, as depicted in Fig. 2.

Fig. 2 Flow chart of proposed hybrid approach for present investigation

2 Parameter design

The most significant process parameters and their respective levels and appropriate orthogonal array (OA) for design of experiment here selected to determine optimum casting density of the A380 alloy.

2.1 Selection of process parameters

To identify the casting process parameters which may affect the die casting density, an Ishikawa diagram (Cause and effect of die casting process for present investigation diagram as shown in Fig. 3) was constructed based on the exploratory significant parameters that affect processes, which were indistinguishable to the present investigation [23-26].

The process parameters can be listed in four categories as follows:

1) Parameters related to die casting machine: Plunger velocity during 1st and 2nd stage, fast shot set point, cavity filling time, multiple pressures during 3rd stage;

2) Parameters related to shot sleeve: Dimensions and filling time of shot sleeve;

3) Type of die lubricant;

4) Parameters related to die: Temperature of the die, size and shape of the gate, venting system of die design, cooling system of die design;

5) Parameters related to cast metal: Temperature of the casting metal, condition and composition of the cast metal.

All these aforesaid parameters have diverse influences on die casting process. But, optimization of all these parameters at same time might lead to complication in the system. So, among the aforesaid parameters, which are systematically explained by cause and effect diagram as shown in Fig. 3, identification of the most significant process parameters that may affect the die casting density to enhance the customer satisfaction is considered as prominent in the present investigation.

Here, QFD has been used as quality tool to identify the most significant critical process parameters for optimization of the die casting process in order to yield the optimum casting density. The following steps express the applications of proposed methods.

Step 1: Identifying the customer requirements (CRs)

To evaluate and select the best optimized casting process in order to yield the customized products, the customer requirements were identified first. Here, six customer requirements have been taken in HOQ-1.

Step 2: Determining the importance rating of each customer requirement.

The importance rating of each customer requirement needs to be determined, because a customer requirement with a higher importance rating means that it has higher impact on the selection process. Numbers through 1 to 10 are listed in the importance to customer column to indicate a rating of 1 for the least important and 10 for the most important. These impact ratings are determined on the basis of customer feed-back on casted products.

Step 3: Identifying the technical descriptors (TDs)

The technical descriptors capture the Hows. Hows are ways of achieving Whats (CRs) and consist of processes, facilities and methods. Emphasis shifts from identifying the problem to solving the problem. Technical descriptors were identified by QFD team through brainstorming session. The brainstorming session resulted in five technical descriptors. They are taken in HOQ-1.

Fig. 3 Cause and effect diagram of die casting process for present investigation

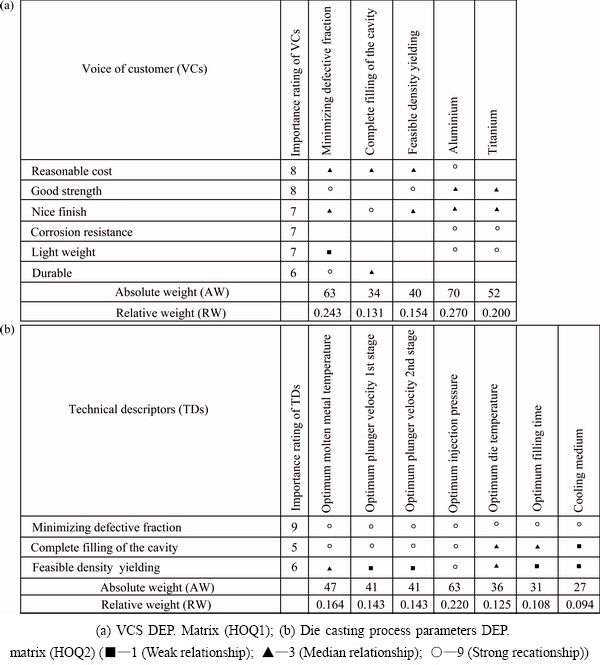

Fig. 4 Critical process parameters deployment matrices

Step 4: Determining the relationship weights between CRs and TDs

Relationship can be defined by answering a particular question for each cell in a matrix. For example, the relationships between customer requirements and technical descriptors might be defined by asking “To what degree does this measure predict the customer’s satisfaction with this requirement?” by asking this same question consistently for each measure and required combination, a set of relationship will be established in the matrix which will help to determine which measures are the most important to control in order to achieve a desired level of customer satisfaction.

After prioritization of the voice of customers (VCs), these VCs are translated into technical descriptors (TDs). Once the VCs and TDs were placed in HOQ1, the strength of their relationships is identified as prioritization and trade-offs might take place further. In QFD application, each TD can correlate VCs at one of four levels of relationship: strong, moderate, weak or non-existent, for non-existent relation the cell remains as blank. With the relationship matrix furnished, the column weights of each TD were computed by using Eqs. (1) and (2).

The raw scores obtained were then used to rank the various TDs on relative scales as shown in Fig. 4. The relative weights of the technical assessments indicate how important it is to control these requirements in order to meet customer satisfactions. So according to relative weights, much attention has to be given first for the attribute of optimum injection pressure (relative weight at 22%), secondly, for optimum molten metal temperature (relative weight at 16%) and then to optimum plunger velocity 1st and 2nd stage (relative weight at 14%) and optimum die temperature (relative weight at 12%) in order to meet the customer expectations.

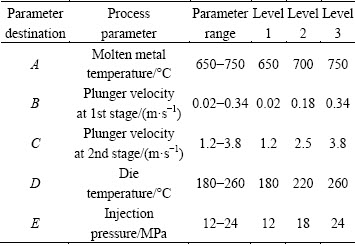

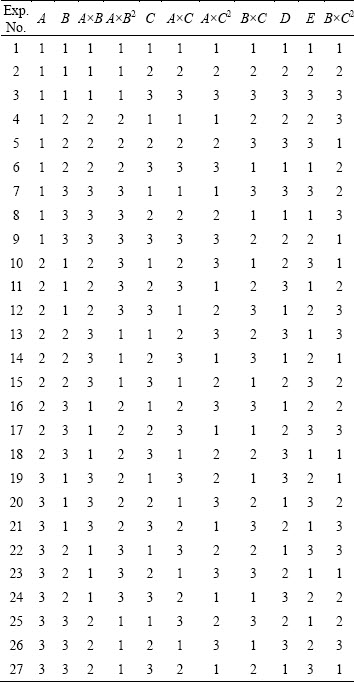

From QFD quality technique, injection pressure, molten metal temperature, plunger velocity (1st and 2nd stage) and die temperature are identified as most significant process parameters which are affecting the casting density in order to yield customized products. Based on the previous researchers [27-29], the range of the injection pressure was selected as 12-24 MPa, molten metal temperature was chosen as 650-750 °C, the piston velocity in the first stage was selected as 0.02-0.34 m/s and in the second stage piston velocity was 1.2-3.8 m/s and the die temperature is varied between 180-260 °C. The selected casting parameters, along with their ranges, are given in Table 1.

Table 1 Process parameters with their ranges and values at three levels

2.2 Selection of orthogonal array

From the previous researchers, it was revealed that non-linear behavior of the process parameters of a die casting can be determined only if more than two levels per each parameter are used [30,31]. Therefore, each parameter was analyzed in three levels. The process parameters along with their values at selected levels are also given in Table 1. Literature reveals that the molten metal temperature imposed in conjunction with the piston velocity in first and second stages, affects the density of the die casting process. Thus, it was also decided to study the interaction effects of these parameters on the density of the die casting process. These interactions were the molten metal temperature imposed in conjunction with piston velocity (first stage) (A×B), molten metal temperature with piston velocity (second stage) (A×C) and the piston velocity first and second stage (B×C) [31].

As per Taguchi’s method, the total DOF (degree of freedom) of selected OA must be greater than or equal to the total DOF required for the experiment. The total DOF for five factors, each factor at three levels and three interactions, is 22 [32]. Therefore, a three-level OA with 27 experimental runs (DOF=27-1=26) has been selected for the present research. Since each interaction has 4 DOF, a total of six columns (two columns for each inter- action) was needed for assigning the interactions [33]. Using a triangular table for three-level OA, the interacting columns in L27 OA were identified and the parameters were assigned to columns accordingly. The assignment of the casting process parameters (A to E) and parameter interactions (A×B, A×B2, A×C, A×C2, B×C and B×C2) in columns also shown in Table 2.

Table 2 L27 orthogonal array

3 Experiment and discussion

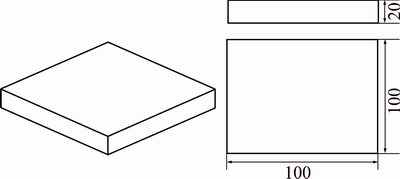

The experiments have been conducted on high pressure die casting machine of technocrats model TDC-120 available at Private Industry, Hyderabad, Telangana State, India. The main parts of the machine are moving plate, fixed plate, control box panel, accumulator, injection cylinder, ejector mechanism, pressure regulating valve, die regulating valve. Control panel is provided on the machine for die opening and die closing and for ejection of the casting parts. The machine can be operated on manual as well as automatic. Figure 5 shows the pattern used in the die casting process.

Fig. 5 Schematic representation of die casting pattern used in experimental procedure (unit: mm)

The test sample was a square plate of A380 alloy (Al, 8% Si, 3% Cu, 1.3% Fe) with dimensions 100 mm × 100 mm × 20 mm. Thick test casting has been selected to facilitate the experimental procedure. As per Taguchi design, 27 experiments were conducted at each test condition. For each test condition, three test castings were made using a randomization technique. Figure 6 is the pictorial view of the casting part. The casting density was measured using the immersion technique. Castings were weighed first in air and then immersed completely in degassed distilled water. All weighings were conducted on Mettler Balance with an accuracy at 0.0001 g. Application of this technique leads to the following expression for the density of the casting [34].

(4)

(4)

where m is the mass of the casting part in air, m1 is the mass of the same casting part in degassed distilled water and ρw is the density of the degassed distilled water. The density of degassed distilled water at 20 °C is 998 kg/m3. Using aforesaid method, the densities of the experimental casted parts were measured and furnished in Table 3.

Fig. 6 Image of A380 die casted part

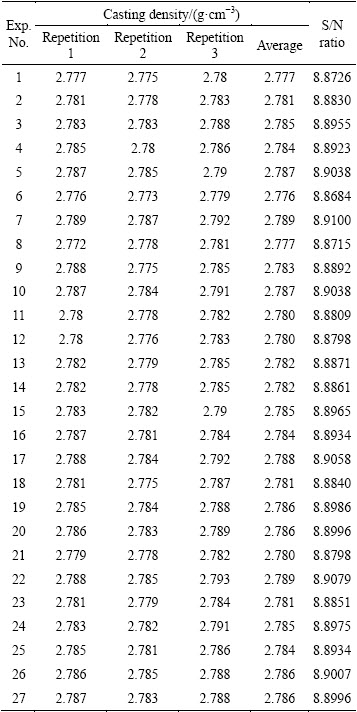

Table 3 Casting density values and S/N ratios against trial numbers

Experimental data are traditionally used to analyze the mean response. The Taguchi method stresses the importance of studying the variation of the response using the Signal-to-Noise (S/N) ratio [35]. The reason for this is to minimize the variation in the quality characteristics due to uncontrollable parameters. Hence, the density is a “Higher the better” type of quality characteristic. So the S/N ratio was used for that type of response, and is given by Eq. (3).

For next step, the S/N ratios were computed for each of the 27 test conditions. The values, the average for each parameter at different levels and the S/N ratios of each test are shown in Table 3.

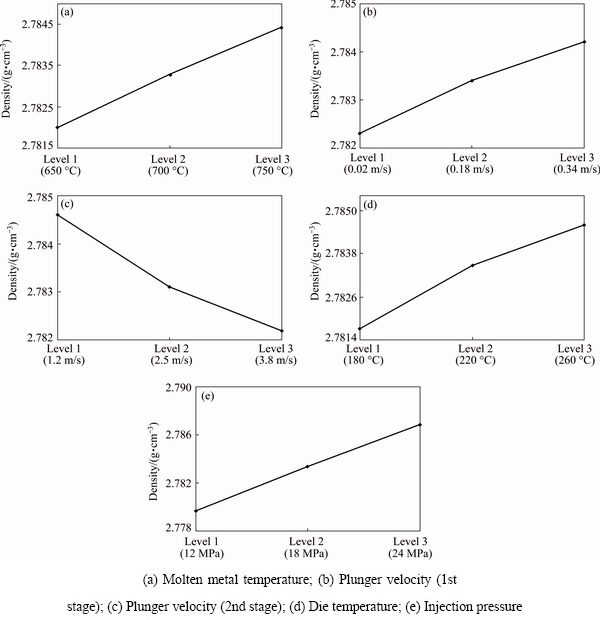

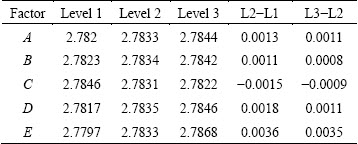

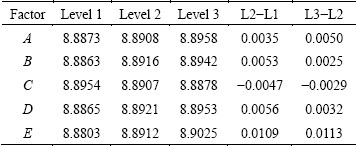

The average values of casting density for each parameter at levels 1 to 3 are given in Table 4 and are plotted in Figs. 7(a)-(e). The main effects of various parameters when changed from the lower to higher level are also shown in the Table 4.

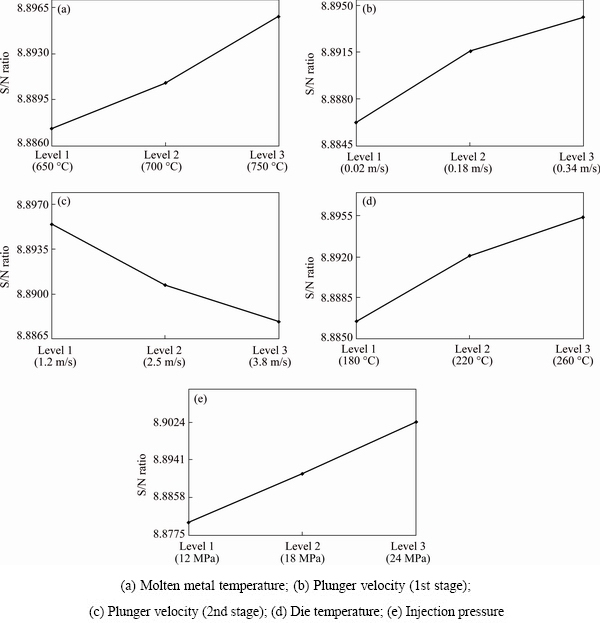

Average values of S/N ratio of varies considered parameters at three levels are given in Table 5 and plotted in Figs. 8(a)-(e). The main effects in terms of S/N data are also given in Table 5.

From Figs. 7 and 8, it shows that the parameter E is more prominent than remaining four parameters (molten metal temperature, plunger velocity at 1st and 2nd stages and die temperature). From Fig. 7, it is revealed that the casting density is maximum at the 3rd level of the parameters A, B, D and E and also at the 1st level of the parameter C. Moreover, the S/N ratio analysis exposed in Figs. 8((a)-(e)) also recommended that the parameter levels A3, B3, C1, D3 and E3 are the optimizing levels for reducing the variability of the die casting process of A380 alloy. It must be noted that the above combination of factorial levels (3, 3, 1, 3 and 3) was not one of the 27 combinations tested in our set of experiments. This was expected because of the small number of experiments conducted in the employed experimental design (27 from 35=243 possible combinations).

In order to study the significance of process parameters, ANOVA was performed in Table 6. From Table 6, it shows that the injection pressures of the machine (parameter E) significantly affect the mean average of casting density of 61.483%. The die temperature (parameter D) and molten metal temperature (parameter A) also affect the casting density of 11.023% and 9.301%, respectively. Table 7 presents the ANOVA of S/N ratio. It also shows that the same parameters (E, D and A) significantly affect the variability of casting density of 65.66%, 10.521% and 9.599%, respectively.

Fig. 7 Average values of casting density of each parameter at levels 1-3

Table 4 Average values of casting density (g/cm3) at varies levels with main effects

4 Estimation of density mean

From the analysis of S/N ratio and the mean response characteristic, optimum levels of the control factors are determined as: A3, B3, C1, D3 and E3. Hence, utilizing the estimation model of Taguchi based on the average values of optimum levels of factors and equivalent “β-factors” the estimated mean of the quality characteristic (experimental casting density) is achieved by the following equation [35]:

μ=Mβ(M)+(A3-M)β(A)+(B3-M)β(B)+(C1-M)β(C)+(D3-M)β(D)+(E3-M)β(E) (5)

where M is the overall average of trials. β(A), β(B), β(C), β(D), β(E) are the β-factors of factors A-E, respectively, and defined by Eq. (6) [36]:

(6)

(6)

where FP is the F-ratio of factor P.

A3, B3, C1, D3 and E3 are the near optimal levels of the control parameters. The β(M) is the overall β-factor which is defined by Eq. (7) [36]:

(7)

(7)

where T is the sum of squares of all trials and Ve is the variance due to error.

From Tables 3 to 6 it can be computed that M=2.7834, T=209.169 and Ve=3.21026×10-7. So the long-range means performance estimation of casting density is calculated as μ=2.79057 g/cm3.

Fig. 8 Average values of S/N ratios of each parameter at levels 1-3

Table 5 Average values of S/N ratios at varies levels (1-3) with main effects

Table 6 ANOVA of die casting density

Table 7 S/N ANOVA of die casting density

5 Confidence interval (CI) around estimated mean of density

Confidence interval (CI) has been calculated for 95% consistency level and some conformational experiments have been conducted at optimum level of the process parameters for validation of the adequacy of the Taguchi method. The mean percentage defect (μ) calculated by Eq. (5) for the selected trial condition is 2.79057 g/cm3. To verify predictions, the confidence levels, i.e., the maximum and minimum values have been calculated, between which the values of conformational experiments should fall. The interval was obtained by the set of Eqs. (8) and (9) [31]:

(8)

(8)

where F(1, α, ne) is the F value from the F table for α=risk, confidence = 1- risk (DOF of mean = 1), ne is the DOF of error, Ve is the pooled error variance and Ne is the effective sample size:

(9)

(9)

where N is the total number of trials, up the DOF of factor P and β(P) the β-factor of factor P.

An interval confidence level of 95% for the casting density, the F(1, 5%, 70)=3.98, Ve=3.21026×10-7 and the effective size of sample is Ne=2.4725. Thus, the confidence level of interval is computed as CI=0.000718. So, the 95% CI of the predicted optimum is 2.78985 g/cm3<μ<2.79128 g/cm3.

6 Conclusions

1) The significant target of present investigation is to establish the guidelines for the implementation of QFD approach in the die casting process for identifying significant critical process parameters in order to yield the customized products. Hence, molten metal temperature, Plunger velocity (1st and 2nd stages), die temperature and injection pressure were identified as influential parameters affecting the casting density of A380 alloy castings. Present contributions of each parameter to the variation of the mean casting density of A380 alloy castings are as follows: molten metal temperature, 9.301%; plunger velocity (1st stage), 4.61%; plunger velocity (2nd stage), 7.636%; die temperature, 11.023%; injection pressure, 61.483%.

2) The optimal levels of varies die casting parameters for optimum casting density are: molten metal temperature, 750 °C (the third level); plunger velocity (the 1st stage), 0.34 m·s-1 (the third level); plunger velocity (the 2nd stage), 1.2 m·s-1 (the first level); die temperature, 260 °C (the third level); injection pressure, 24 MPa, (the third level).

3) The predicted range of optimum casting density is 2.78985 g/cm3<μ<2.79128 g/cm3.

Acknowledgement

Authors would like to acknowledge the National Institute of Technology, Manipur, Imphal for Financial Support to carry out the experimental work of Mr. K. Ch. Apparao, Research Scholar (Enrolment No.: 15PME001) under the guidance of Dr. Anil Kumar Birru, Assistant professor in Mechanical Engineering Department- India-795004.

References

[1] HUA Gao, ZHAO Bin, ZHAO Zhen-bo, LIU Cheng. A cluster of inclusions on Al-Si-Cu die casting cylinder block [J]. Engineering Failure Analysis, 2015, 55: 370-375.

[2] MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A J, DE SMET P, HASZLER A, VIEREGGE A. Recent development in aluminium alloys for the automotive industry [J]. Materials Science and Engineering A, 2000, 280: 37-49.

[3] OTARAWANNA S, GOURLAY C M, LAUKLI H I, DAHLE A K. Microstructure formation in high pressure die casting [J]. Transactions of the Indian Institute of Metals, 2009, 62: 499-503.

[4] BALASUBRAMANIAN S, KANNAN S, SHIVAPURI R. Improving the quality in die casting production using statistical analysis procedures [J]. In NADCA Transactions of the 20th International Die Casting Congress and Exposition, 1999: 227-234.

[5] KARBAN R. The effects of intensification pressure, gate velocity and intermediate shot velocity on the internal quality of aluminium die castings [C]//In NADCA Transactions of the 21st International Die Casting Congress and Exposition, 2001: T01-074.

[6] ZHENG Cheng-kun, ZHANG Wei-wen, ZHANG Da-tong, LI Yuan-yuan. Low cycle fatigue behavior of T4-treated Al-Zn-Mg-Cu alloys prepared by squeezecastingand gravitydiecasting [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3505-3514.

[7] LI Sheng-yong, LI De-jiang, ZENG Xiao-qin, DING Wen-jiang. Microstructure and mechanical properties of Mg-6Gd-3Y-0.5Zr alloy processed by high-vacuum die -casting [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3769-3776.

[8] WANG Qing-liang, XIONG Shou-mei. Vacuum assisted high-pressure die casting of AZ91D magnesium alloy at different slow shot speeds [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3051-3059.

[9] YANG Ling, HOU Hua, ZHAO Yu-hong, YANG Xiao-min. Effect of applied pressure on microstructure and mechanical properties of Mg-Zn-Y quasicrystal-reinforced AZ91D magnesium matrix composites prepared by squeeze casting [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3936-3943.

[10] SAEED FARAHANY, ALI OURDJINI, HAMID REZA BAKHSHESHI-RAD. Microstructure, mechanical properties and corrosion behaviour of Al-Si-Cu-Zn-X (X=Bi, Sb, Sr) die cast alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 28-38.

[11] WANG Zhi-qin, ZHANG Bin, LI De-jiang, FRITZSCH Robert, ZENG Xiao-qin, ROVEN Hans J, DING Wen-jiang. Effect of heat treatment on microstructures and mechanical properties of high vacuum die casting Mg-8Gd-3Y-0.4Zr magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3762-3768.

[12] LIANG Song-mao, ZHANG Hua-wei, XIA Ming-xu, CHEN Rong-shi, HAN En-hou, FAN Zhong-yun. Microstructure and mechanical properties of melt-conditioned high-pressure die-cast Mg-Al-Ca alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1205-1211.

[13] WU D H, CHANG M S. Use of Taguchi method to develop a robust design for the magnesium alloy die-casting process [J]. Mater Sci Eng A, 2004, 379: 366-371.

[14] CERRI E, LEO P, de MARCO P P. Hot compression behavior of the AZ91 magnesium alloy produced by high pressure die casting [J]. Mater Process Technol, 2007, 189: 97-106.

[15] AKAO Y. Quality function deployment: integrating customer requirements in to product design [M]. Cambridge, MA: Productivity Press, 1990.

[16] HAUSER J, R CLAUSING. The house of quality [J]. Harv Bus Rev, 1988(5): 63-73.

[17] CHAN Wu. QFD: A literature review [J]. European Journal of Operations Research, 2002, 143: 463-497.

[18] RONALD G D. Quality function deployment [M]. New Delhi: Tata Mc Graw Hill, 1995: 129-134.

[19] PHARDE M S. Quality engineering using robust design [M]. Englewood Cliffs. Prenice-Hall, 1989.

[20] AZIMI A, SHOKUHFAR A, NEJADSEYFI O, FALLAHDOOST H, SALEHI S. Optimizing consolidation behavior of Al 7068–TiC nanocomposites using Taguchi statistical analysis [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2499-2508.

[21] LIN Mao-yong, TSAO Chung-chen, HSU Chun-yao, CHIOU Ai-huei, HUANG Peng-cheng, LIN Yu-cheng. Optimization of micro milling electrical discharge machining of Inconel 718 by Grey-Taguchi method [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 661-666.

[22] LAKSHMINARAYANAN A K, BALASUBRAMANIAN V. Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 548-554.

[23] WANG Bai-shu, XIONG Shou-mei. Effects of shot speed and biscuit thickness on externally solidified crystals of high-pressure diet cast AM60B magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 767-772.

[24] LIAO Hui-min, LONG Si-yuan, GUO Cun-bao, ZHU Zhi-bing. Effect of Ce-rich misch metal addition on squeeze cast microstructure and mechanical properties of AZ81 alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: s44-s49.

[25] ZHANG Jing, LI Zhong-sheng, GUO Zheng-xiao, PAN Fu-sheng. Solidification microstructural constituent and its crystallographic morphology of permanent-mould-cast Mg-Zn-Al alloys [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 452-458.

[26] ANIL KUMAR BIRRU, BENNY KARUNAKAR D. The effect of grain refinement and residual elements on hot tearing of A713 aluminium cast alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1783-1790.

[27] ASM. Metals Handbook vol. 10 [M]. 10 ed. Metals Park, OH, ASM International, 1990.

[28] JOHNSTON R E. Statistical methods in Foundry experiments [J]. AFS Trans, 1964, 72: 17-18.

[29] JOHNSTON R E. Design of experiments: Taguchi in the foundry [J]. AFS Trans, 1989, 82: 415-418.

[30] MAKHLOUF M, WANG L, APELIAN D, YANG L. Thermal conductivity of Al die casting alloys [J]. AFS Trans, 1999, 12: 501-505.

[31] SYRCOS G P. Die casting process optimization using Taguchi methods [J]. J Mater Process Technol, 2003, 135: 68-74.

[32] BYRNE D M, TAGUCHI S. The Taguchi approach to parameter design [J]. Quality Progress, 1987, 20: 19-26.

[33] BARUA P B, KUMAR P, GAINDHAR J L. Surface roughness optimization of V-process casting through Taguchi’s method [J]. AFS Trans, 1997, 45: 763-768.

[34] PRASAD Dora Siva, SHOBA Chintada, RAMANAIAH Nallu. Investigations on mechanical properties of aluminum hybrid composites [J]. Mater Ses Technol, 2014, 3(1): 79-85.

[35] ROY R K. Design of experiments using the taguchi approach: 16 steps to product and process improvement [M]. New York: John Wiley, 2001.

[36] ROY R K. A primer on taguchi method [M]. New York: Van Nostrand Reinhold, 1990.

K. Ch. APPARAO, Anil Kumar BIRRU

Department of Mechanical Engineering, National Institute of Technology, Manipur 795004 India

摘 要:采用基于QFD-Taguchi的混合方法对高温型模铸造的多种重要工艺参数进行确认和优化,以便获得A380合金最适宜的铸造密度。为研究型模铸造工艺的性能特征,首先确认关键工艺参数,选择合适的正交序列,然后进行均差和方差分析。通过基于QFD-Taguchi的混合方法确认和优化了型模铸造的工艺参数,并将之应用于实验中。结果表明,在所选参数中,注射压力是最重要的参数。注射压力对平均铸造密度变化的贡献约为61.483%。95%一致性水平的置信区间约为0.000718,验证了A380合金优化铸造密度的预估区间。

关键词:高压型模铸造;A380合金;QFD技术;Taguchi方法;铸造密度

(Edited by Yun-bin HE)

Corresponding author: Anil Kumar BIRRU; Tel: +91-8331866984; E-mail: anilbirru@gmail.com

DOI: 10.1016/S1003-6326(17)60260-7