热轧Cu-Cr和Cu-Cr-CNT纳米复合材料的比较研究

来源期刊:中国有色金属学报(英文版)2018年第10期

论文作者:S. SHAKIB HAMEDAN M. ABDI S. SHEIBANI

文章页码:2044 - 2052

关键词:Cu-Cr;碳纳米管;纳米复合材料;热轧

Key words:Cu-Cr; carbon nanotube; nanocomposite; hot rolling

摘 要:通过机械合金化制备Cu-1%Cr和Cu-1%Cr-5%CNT(碳纳米管)(质量分数)纳米复合粉体,用热压法将两种复合粉末压制成型,然后将样品在650 °C下热轧,其压下率为50%。分别通过X射线衍射分析(XRD)和扫描电镜(SEM)分析其相组成和显微组织,并检测材料的相对密度、显微硬度、热稳定性、电性能和耐磨性。与Cu-Cr样品相比,热轧后Cu-Cr-CNT 的相对密度从75%提高到几乎全致密的98%。虽然热轧后Cu-Cr和Cu-Cr-CNT样品的电导率和显微硬度均得到提高,但是含有碳纳米管的样品提高的效果更显著。热轧态Cu-Cr-CNT纳米复合材料的显微硬度和电导率分别达到HV 175和68%(IACS)。且与Cu-Cr复合材料相比,热轧对Cu-Cr-CNT纳米复合材料热稳定性的提高更加有效。然而,热轧后,与Cu-Cr-CNT纳米复合材料相比,Cu-Cr样品的摩擦因数和磨损量减少得更多(变化量分别为25%和 62%),这是两种材料的磨损机制不同造成的。

Abstract: Cu-1%Cr (mass fraction) and Cu-1%Cr-5% carbon nanotube (CNT) (mass fraction) nanocomposite powders were produced by mechanical alloying and consolidated by hot pressing. Then, nanocomposites were hot-rolled by the order of 50% reduction at 650 °C. The structure and microstructure were investigated by X-ray diffractometry (XRD) and scanning electron microscopy (SEM). Relative density, microhardness, thermal stability, electrical and wear properties were evaluated. Compared to the Cu-Cr sample, the relative density of Cu-Cr-CNT sample is greatly improved from 75% to near full density of 98% by hot rolling. Although electrical conductivity and microhardness increase in both Cu-Cr and Cu-Cr-CNT nanocomposites after hot rolling, the effect of hot rolling on the enhancement is more prominent in the presence of CNTs. The microhardness and electrical conductivity of hot-rolled Cu-Cr-CNT nanocomposite approach HV 175 and 68% (IACS), respectively. Also, hot rolling is more effective on thermal stability improvement of Cu-Cr-CNT nanocomposite compared to Cu-Cr composite. However, after hot rolling, both the friction coef?cient and wear loss of the Cu-Cr sample display higher reduction than those of Cu-Cr-CNT nanocomposite owing to different wear mechanisms. After hot rolling, friction coefficient and wear loss of Cu-Cr sample display variation of 25% and 62%, respectively.

Trans. Nonferrous Met. Soc. China 28(2018) 2044-2052

S. SHAKIB HAMEDAN, M. ABDI, S. SHEIBANI

School of Metallurgy and Materials Engineering, University of Tehran, P. O. Box 11155-4563, Tehran 13145-1318, Iran

Received 22 November 2017; accepted 19 June 2018

Abstract: Cu-1%Cr (mass fraction) and Cu-1%Cr-5% carbon nanotube (CNT) (mass fraction) nanocomposite powders were produced by mechanical alloying and consolidated by hot pressing. Then, nanocomposites were hot-rolled by the order of 50% reduction at 650 °C. The structure and microstructure were investigated by X-ray diffractometry (XRD) and scanning electron microscopy (SEM). Relative density, microhardness, thermal stability, electrical and wear properties were evaluated. Compared to the Cu-Cr sample, the relative density of Cu-Cr-CNT sample is greatly improved from 75% to near full density of 98% by hot rolling. Although electrical conductivity and microhardness increase in both Cu-Cr and Cu-Cr-CNT nanocomposites after hot rolling, the effect of hot rolling on the enhancement is more prominent in the presence of CNTs. The microhardness and electrical conductivity of hot-rolled Cu-Cr-CNT nanocomposite approach HV 175 and 68% (IACS), respectively. Also, hot rolling is more effective on thermal stability improvement of Cu-Cr-CNT nanocomposite compared to Cu-Cr composite. However, after hot rolling, both the friction coefficient and wear loss of the Cu-Cr sample display higher reduction than those of Cu-Cr-CNT nanocomposite owing to different wear mechanisms. After hot rolling, friction coefficient and wear loss of Cu-Cr sample display variation of 25% and 62%, respectively.

Key words: Cu-Cr; carbon nanotube; nanocomposite; hot rolling

1 Introduction

Copper matrix composites have received much attention for application in electric and electronic industries owing to excellent thermal and electrical conductivities [1]. The mechanical strength of copper is usually enhanced by the addition of alloying elements or a second phase. However, it is important to enhance the strength without compromising the conductivities [2]. Among copper matrix composites, Cu-Cr is an in situ composite [3-5]. Extension of Cr solubility in Cu during mechanical alloying and the effect of Al2O3 nano- particles on the Cr solubility have already been investigated [6,7]. Considering noticeable properties of carbon nanotube (CNT), it is considered as an excellent candidate reinforcing for the copper matrix [8-12]. On the other hand, a further improvement of different properties can be achieved in copper matrix by both Cr and CNT reinforcements [12,13]. CHU et al [12] prepared Cu-Cr-CNT composites by using Cr as an alloying element to improve the interface strength of Cu and CNT by the formation of thin intermediate Cr3C2 transition layer at the interface.

Among different approaches for the preparation of copper matrix composites, powder metallurgy through mechanical milling is a simple and low cost method. Also, it is an efficient way for dispersing CNTs reinforcement in copper matrix [11,13,14]. Based on our previous research work [13], Cu-1%Cr-5%CNT (mass fraction) nanocomposite powders were produced by wet milling process as an efficient way to reach perfect embedded CNTs. Bulk Cu-CNT composite prepared by powder metallurgy process consists of the milling step followed by a consolidation process. Therefore, the consolidation behavior of Cu matrix nanocomposite powders has been investigated by various methods such as cold pressing [15], spark plasma sintering [16] and hot pressing [17,18]. In recent years, a number of studies have been reported on the effect of secondary processing of rolling on the microstructure and mechanical properties of Cu-Cr [19] and Cu-CNT [17,20,21] composites prepared by powder metallurgy. Although, few studies [12,22] have been directed towards consolidation of Cu-Cr-CNT nanocomposite powder, there has not been detailed study on the effect of hot rolling on the properties of Cu-Cr-CNT nanocomposite prepared by powder metallurgy process until now. Therefore, in the present study, the effect of hot rolling as a post-sintering deformation process on the properties improvement of hot-pressed Cu-1%Cr and Cu-1%Cr-5%CNT nanocomposites prepared by mechanical milling was evaluated. Indeed, the effects of hot rolling on the structural properties, relative density, microstructure, hardness, electrical conductivity, wear properties and high temperature softening of Cu-Cr composite with and without CNTs were compared.

2 Experimental

2.1 Sample preparation

Cu powder (99.5%, <75 μm), Cr powder (99.5%, <75 μm) and multi-walled CNTs (~10 μm in length, and 10-30 nm in diameter) were used as starting materials for preparing composites. It should be mentioned that, the CNTs were sonicated in ethanol for 90 min to break up the CNTs agglomerates. Powder mixtures were ball milled in a planetary high energy ball mill (PM2400) with hardened steel vial under argon atmosphere. In the first step, Cu-1%Cr solid solution was prepared as the matrix phase. The ball-to-powder mass ratio (BPR) and milling speed were 30:1 and 300 r/min, respectively. Toluene (1%, mass fraction) was used as a process control agent. Based on our previous works [7,13], it was established that 20 h milling was sufficient to reach a steady state in Cu-Cr solid solution formation. In the second step, Cu-Cr solid solution alloy together with 5% (mass fraction) of CNTs was wet-milled in 10 mL of ethanol for 5 h with milling speed of 300 r/min and BPR of 30:1 (hereafter called CCCNT sample). Also, Cu-Cr solid solution alloy without CNT was wet-milled under the same condition for comparison (hereafter called CC sample). The milled samples were dried on hotplate at 80 °C for about 1 h to evaporate the ethanol. Complete experimental details of powder production and reasons for selection of ball milling parameters were reported elsewhere [7,13].

Ball-milled powders were uniaxially hot-pressed using a cylindrical steel die at 500 °C for holding time of 30 s under a pressure of 120 MPa. More details about the hot pressing process can be found elsewhere [18]. This procedure resulted in discs with the diameter of 20 mm and thickness of 10 mm. The hot-pressed samples were isothermally sintered at 800 °C for 1 h in argon atmosphere. The sintered samples were multi-pass hot- rolled at 650 °C. A total reduction of 50% in thickness was induced by three similar passes. Before each pass, the discs were heated to 650 °C. The hot-rolled samples were annealed at 650 °C for 1 h after rolling operation to remove the contribution of strain hardening.

2.2 Sample characterization

The structural evaluation of the products was performed by Philips PW-1730 XRD diffractometer using Cu Kα radiation (λ=1.78892  ). Also, the mean crystallite size of consolidated samples was determined using Scherrer formula [23]. The microstructure of samples was investigated using OLYMPUS-BH2UMA metallographic microscope and Tescan high-resolution SEM. Vickers microhardness measurements were performed by ESE Way-DVRBM test machine using a load of 100 g for 15 s. The mean hardness value of five random points was calculated and reported for each sample. Also, the relative density of the consolidated samples was determined by Archimedes principle (ASTM D792-08). The theoretical density of samples was calculated according to the mixture rule. Friction tests were carried out to evaluate the effects of hot rolling on wear properties of nanocomposites using a pin-on-disk type test machine under atmospheric and dry conditions. The pin material was St. 52100 steel with the diameter of 2 mm. The wear speed was 0.1 m/s with rotation diameter of 6.5 mm under the load of 10 N. Subsequently, friction coefficient and mass loss were calculated. Electrical conductivity was measured by a standard 4-probe method with a constant current of 100 mA and each sample was measured at least five times. The samples consolidated under optimal conditions were additionally subjected to the high temperature exposure in argon at 400 and 600 °C for 50 h to examine their thermal stability.

). Also, the mean crystallite size of consolidated samples was determined using Scherrer formula [23]. The microstructure of samples was investigated using OLYMPUS-BH2UMA metallographic microscope and Tescan high-resolution SEM. Vickers microhardness measurements were performed by ESE Way-DVRBM test machine using a load of 100 g for 15 s. The mean hardness value of five random points was calculated and reported for each sample. Also, the relative density of the consolidated samples was determined by Archimedes principle (ASTM D792-08). The theoretical density of samples was calculated according to the mixture rule. Friction tests were carried out to evaluate the effects of hot rolling on wear properties of nanocomposites using a pin-on-disk type test machine under atmospheric and dry conditions. The pin material was St. 52100 steel with the diameter of 2 mm. The wear speed was 0.1 m/s with rotation diameter of 6.5 mm under the load of 10 N. Subsequently, friction coefficient and mass loss were calculated. Electrical conductivity was measured by a standard 4-probe method with a constant current of 100 mA and each sample was measured at least five times. The samples consolidated under optimal conditions were additionally subjected to the high temperature exposure in argon at 400 and 600 °C for 50 h to examine their thermal stability.

3 Results and discussion

3.1 Structural properties

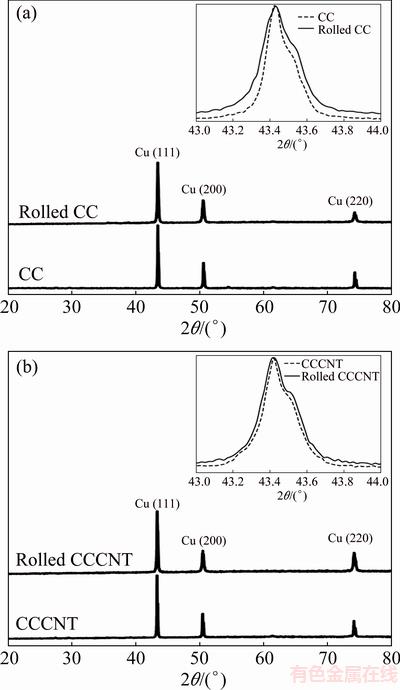

figure 1 shows XRD patterns of CC and CCCNT samples. All the XRD patterns showed similar characteristic peaks of Cu. All the diffraction peaks were indexed as (111), (200) and (220) reflections of Cu. No peaks corresponding to Cr were detected in all XRD patterns due to the small amount of Cr. It was found that the small peaks at the diffraction angles of 26°-30°, 54°, and 61° were indexed as copper oxides (Cu2O and CuO). The presence of copper oxides peaks can be related to the slight oxidation during hot pressing and/or hot rolling processes. Also, no peak appeared for CNTs at 2θ=26° in XRD patterns of CCCNT sample (fig. 1(b)). This is possibly related to the less amount of CNTs in the nanocomposite and the low diffraction efficiency of carbon [24]. The comparison of the peak broadening in the 2θ range of 43° to 44° is shown in the insets of figs. 1(a) and (b). It is observed that with hot rolling, the peak width has increased for both CC and CCCNT samples. This is attributed to the Cu grain refinement after rolling.

fig. 1 XRD patterns of CC (a) and CCCNT (b) samples before and after hot rolling

According to Scherrer formula [23], the mean crystallite size of CC sample decreased from 83 to 56 nm (decreased by 33%) after hot rolling process. However, as shown in the inset of fig. 1(b), the presence of CNT in CCCNT sample gives slightly different results in the effect of hot rolling on the peak broadening. The mean crystallite size of CCCNT sample decreased from 61 to 53 nm (decreased by 13%) after hot rolling process. The slight difference in the crystallite size of the CCCNT sample is related to smaller initial crystallite size and retarded grain growth during hot rolling by CNTs. Similar behavior of Cu crystallite size refinement in the presence of CNTs has been reported by AKBARPOUR et al [25].

3.2 Relative density and microstructure

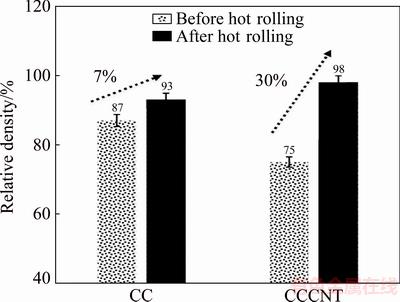

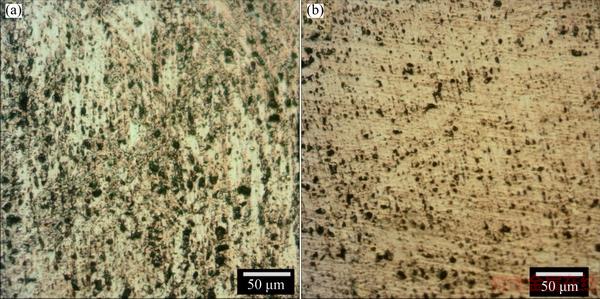

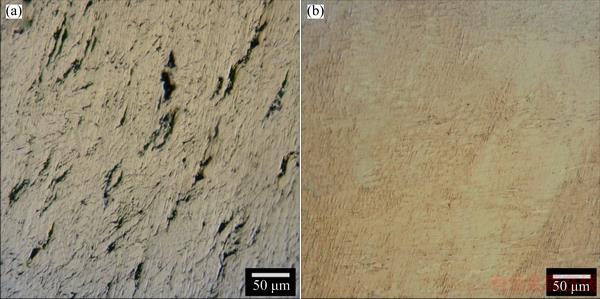

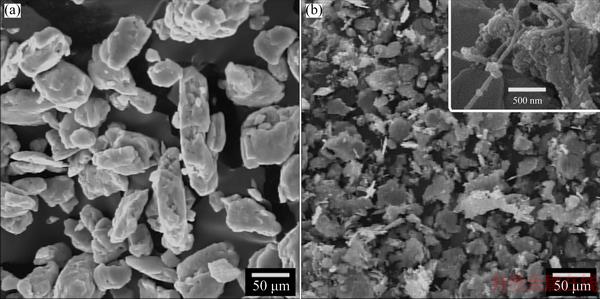

figure 2 shows the effect of hot rolling operation on relative density of CC and CCCNT samples. The relative density results in fig. 2 reveal that, the hot-rolled Cu-Cr and Cu-Cr-CNT nanocomposites have high densities between 93% and 98% of the theoretical density. Although a slight densification of 7% in CC sample is achieved by hot rolling, it could result in a significant densification of 30% in CCCNT sample. For a better understanding of the present results, optical microscope has been used to observe the internal microstructure change of each sample. figures 3 and 4 show the optical micrographs of CC and CCCNT samples, respectively. firstly, different natures of porosity of CC and CCCNT samples before hot rolling can be seen by the comparison of figs. 3(a) and 4(a). This is possibly related to different powder morphologies of CC and CCCNT samples after mechanical alloying step. figure 5 shows the SEM images of CC and CCCNT powder samples after mechanical alloying. As shown in fig. 5(a), Cu particles were welded on each other and larger particles with an equiaxed shape were formed in CC sample. However, as indicated in the previous work [13], the Cu particles were deformed and flake-like particles were produced during mechanical milling owing to the lubricant effect of CNTs in CCCNT sample (see fig. 5(b)). Also, it can be seen at higher magnification in the inset of SEM image of mechanically milled CCCNT sample in fig. 5(b) that, the CNTs were tightly embedded in the microstructure. Therefore, different powder morphologies of CC and CCCNT samples led to different natures of porosity. In fact, the larger linear pores in CCCNT sample before hot rolling were related to the flake-like mechanically milled particles. Secondly, as seen in figs. 3(a) and (b) for Cu-Cr composite (CC sample), pore fragmentation and collapsing took place by hot rolling process. This leads to the decrease of pore size and porosity, but some small pores still exist. On the other hand, microstructural comparison in figs. 4(a) and (b) shows that the densification of Cu-Cr-CNT nanocomposite (CCCNT sample) from the relative density of 78% to 98%, is associated with the powder particles rearrangement and the increase in interparticle contact area and finally pore compaction. It is possible that the lubricant effect of CNT could be the reason of this mechanism. It can be seen in fig. 5(b) that the CNTs are embedded in the particle during the mechanical milling step. Hence, the ends of CNTs which are not embedded can act as a lubricant and promote the particles rearrangement during plastic deformation by hot rolling. Indeed, the interconnected porosity changes to the isolated one, until most of the porosities have been eliminated. DUBE and BAGDI [26] also confirmed the change of amount and nature of porosity in porous nickel strips during hot rolling. Therefore, the presence of CNTs in CCCNT samples has obvious effect on the relative density of final product.

fig. 2 Effect of hot rolling on relative density of CC and CCCNT samples

fig. 3 Optical micrographs of CC sample before (a) and after (b) hot rolling

fig. 4 Optical micrographs of CCCNT sample before (a) and after (b) hot rolling

fig. 5 SEM images of CC (a) and CCCNT (b) powder samples after mechanical alloying

3.3 Hardness and electrical conductivity

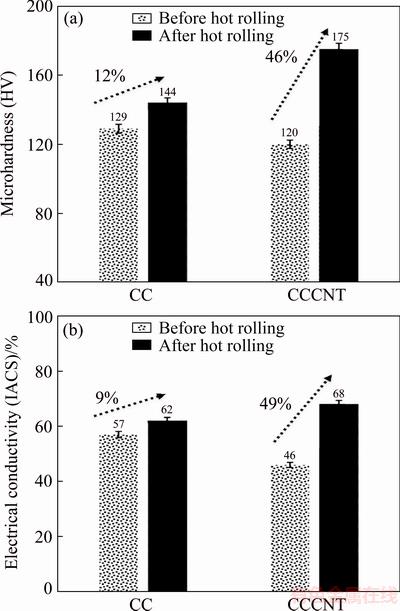

figure 6 shows the effect of hot rolling on hardness and electrical conductivity of CC and CCCNT samples. It is evident from fig. 6(a) that, after hot rolling, the microhardness value of CCCNT sample (HV 175) is higher than that of CC sample (HV 144). This might have contributed to the higher relative density and the CNTs presence as the reinforcement. There are four possible strengthening mechanisms for the CNT- reinforced metal matrix composites: Orowan strengthening, load transfer effects due to the presence of CNTs, the increase of the dislocation density due to strain generated by thermal expansion mismatch between the matrix and the CNTs or by plastic working, and grain size refinement [20]. On the other hand, it is observed in fig. 6(a) that by hot rolling process, the microhardness values of CC and CCCNT samples are increased by 12% and 46%, respectively. These increases are due to the improvement of densification, grain refinement, dispersion of CNTs, and also dislocation density enhancement, and interface modification during hot rolling [25]. Considering the relative density results in fig. 2, it seems that the improvement of densification by hot rolling has the greatest contribution among the above factors. figure 6(b) reveals that the change of electrical conductivity of CC and CCCNT samples shows similar trends after hot rolling. In both CC and CCCNT samples, the microhardness tends to increase by hot rolling. However, slight increase by 9% in CC sample and significant increase by 49% in CCCNT sample could be obtained. The main reason of increase in electrical conductivity was contributed to the decrease in the scattering surfaces for the conduction electrons by effective densification after hot rolling process especially in Cu-Cr-CNT nanocomposite (CCCNT sample). Furthermore, it can be observed that the electrical conductivity of hot-rolled CCCNT sample (68% (IACS)) is higher than that of hot-rolled CC sample (62% (IACS)). This is related to the lower porosity in CCCNT sample.

fig. 6 Effect of hot rolling on microhardness (a) and electrical conductivity (b) of CC and CCCNT samples

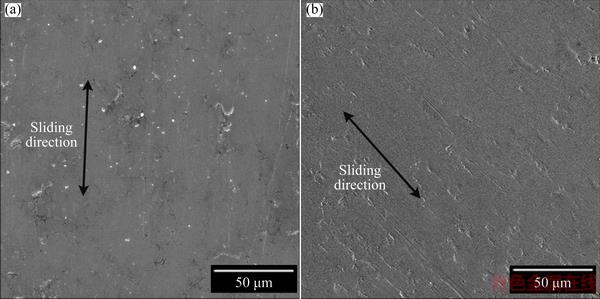

3.4 Wear properties

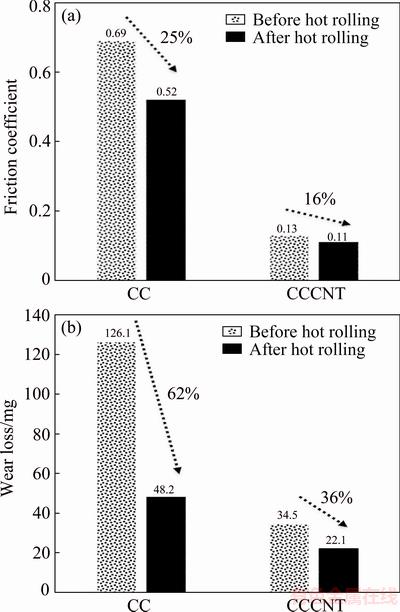

The effects of hot rolling on friction coefficients and the wear losses of CC and CCCNT samples are shown in fig. 7. firstly, it is clear that both friction coefficient and wear loss of the Cu-Cr-CNT nanocomposite (CCCNT sample) are lower than those of Cu-Cr composite (CC sample). Secondly, after hot rolling, both friction coefficient and wear loss of CC sample displayed considerable decrease of 25% and 62%, respectively.

fig. 7 Effect of hot rolling on friction coefficient (a) and wear loss (b) of CC and CCCNT samples

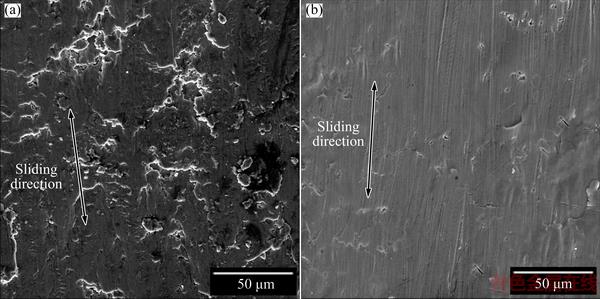

However, for CCCNT sample, friction coefficient and wear loss decreased only 16% and 36%, respectively. The present results are related to the wear mechanisms. To characterize and compare the wear mechanisms in more detail, the SEM micrographs of worn surfaces for CC and CCCNT samples before and after hot rolling are shown in figs. 8 and 9, separately. It is evident that the abrasion is dominant for both samples as can be seen in figs. 8 and 9. figure 8(a) shows severe delamination and excessive fracturing besides abrasion in Cu-Cr composite (CC sample). This may be due to the presence of pores which act as a source of crack nucleation. However, by the increase of relative density and hence hardness after hot rolling, deep scratches and slight delamination with crack initiation at few locations can be noticed in fig. 8(b). On the other hand in figs. 9(a) and (b), the worn surfaces of Cu-Cr-CNT nanocomposites (CCCNT sample) are characterized by the presence of some scattered pits and shallow scratches. This is due to the greater hardness imparted to the composite by the addition of CNT and also its action as a solid lubricant. Furthermore, the morphology of worn surface in CCCNT sample has not changed considerably by hot rolling process. This behavior may be attributed to the lubricating action of CNTs. DONG et al [27] reported that the formation of carbon film in Cu-CNT composite can reduce the friction and wear rate, which is in agreement with the present work. Indeed, as the Cu matrix gradually flaked, CNTs in the matrix near the surface were exposed and became the working film on the worn surface. The worn contacting surfaces were thus changed from the original metal surfaces into metals with a lubricating film of carbon. So, the adhesive between the composite and the counterpart was significantly reduced, which can be seen from wear loss results (fig. 7(b)). Totally, the SEM results are in agreement with friction coefficient and wear loss results discussed above.

fig. 8 SEM images of worn surfaces of CC sample before (a) and after (b) hot rolling

fig. 9 SEM images of worn surfaces of CCCNT sample before (a) and after (b) hot rolling

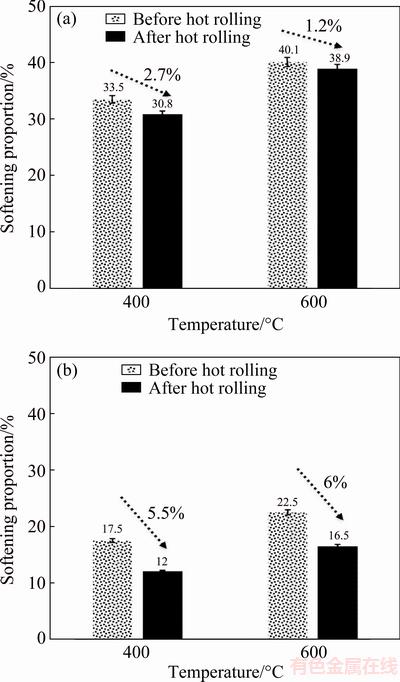

3.5 High temperature softening

To examine the thermal stability, figs. 10(a) and (b) show the effect of hot rolling on the softening after 50 h high temperature (400 and 600 °C) exposure on CC and CCCNT samples, respectively. It should be mentioned that, the softening percent was determined according to the results of hardness measurements before and after holding the materials for 50 h at these temperatures. firstly, higher temperature exposure at 600 °C led to more softening effect on both CC and CCCNT samples. Secondly, the softening percent of CC sample is approximately two times higher than that of CCCNT sample. The retained enhanced microhardness during high temperature exposure suggests good thermal stability of CCCNT sample. This can be ascribed to the CNTs reinforcements which may have contributed to retarding the grain growth. It seems that excessive growth of Cr precipitates and grains in CC sample results in higher hardness reduction. This result is in a good agreement with some earlier results that thermal stability can be expected to increase more considerably if a ceramic second phase such as CNT is added to the copper matrix in order to promote grain boundary pinning [28]. Indeed, the stability of metallic Cr precipitates was decreased because of higher diffusion rate at higher temperature. Thirdly, hot rolling process was more effective on softening resistance increment of Cu-Cr-CNT nanocomposite (CCCNT sample) at high temperature compared to Cu-Cr composite (CC sample). This is possibly due to the considerable densification of Cu-Cr-CNT nanocomposite by hot rolling, as mentioned above. This means that lower hardness of CCCNT sample before hot rolling is related to the higher porosity. Therefore, considerable densification and hence hardness increase of this sample by rolling were more effective on the hardness compared to the softening due to the grain growth.

fig. 10 Effect of hot rolling on softening after 50 h high temperature (400 and 600 °C) exposure on CC (a) and CCCNT (b) samples

4 Conclusions

1) Cu-1%Cr and Cu-1%Cr-5%CNT nano- composites were produced using a combination of mechanical alloying, powder consolidation and hot rolling process. A comparative evaluation of the effect of hot rolling on Cu-Cr and Cu-Cr-CNT nanocomposites was investigated.

2) The hot rolling process had varying effects on the properties of Cu-Cr and Cu-Cr-CNT nanocomposites. The higher relative density (98%), microhardness (HV 175) and electrical conductivity (68% IACS) were achieved in Cu-Cr-CNT nanocomposites.

3) The improvement of densification by hot rolling had the greatest contribution to different properties of nanocomposites.

4) Compared to the slight densification of Cu-Cr sample, the introduction of CNTs led to a larger increase in relative density.

5) The addition of CNTs and their lubricating action can change the wear mechanism. Hence, after hot rolling, both friction coefficient and wear loss of Cu-Cr sample displayed more considerable improvements compared to Cu-Cr-CNT nanocomposite.

6) Hot rolling process was more effective on softening resistance increment of Cu-Cr-CNT nanocomposite at high temperature compared to Cu-Cr composite.

Acknowledgments

The authors would like to acknowledge the financial support of University of Tehran for this research. Also, financial supports of Iran Nanotechnology Initiative Council are gratefully acknowledged.

References

[1] NUNES R, ADAMS J H. ASM metals handbook [M]. Ohio: ASM International, 1990.

[2] MALLIKARJUNA H M, RAMESH C S, KOPPAD P G, KESHAVAMURTHY R, KASHYAP K T. Effect of carbon nanotube and silicon carbide on microstructure and dry sliding wear behavior of copper hybrid nanocomposites [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 3170-3182.

[3] CORREIA J B, DAVIES H A, SELLARS C M. Strengthening in rapidly solidified age hardened Cu-Cr and Cu-Cr-Zr alloys [J]. Acta Materialia, 1997, 45: 177-190.

[4] JIN Y, ADACHI K, TAKEUCHI T, SUZUKI H G. Aging characteristics of Cu-Cr in situ composite [J]. Journal of Materials Science, 1998, 33: 1333-1341.

[5] GAO N, HUTTUNEN-SAARIVIRTA E, TIAINEN T, HEMMILA M. Influence of prior deformation on the age hardening of a phosphorus-containing [J]. Materials Science and Engineering A, 2003, 342: 270-278.

[6] SHEIBANI S, HESHMATI-MANESH S, ATAIE A. Influence of Al2O3 nanoparticles on solubility extension of Cr in Cu by mechanical alloying [J]. Acta Materialia, 2010, 58: 6828-6834.

[7] SHEIBANI S, HESHMATIMANESH S, ATAIE A. Structural investigation on nano-crystalline Cu-Cr supersaturated solid solution prepared by mechanical alloying [J]. Journal of Alloys and Compounds, 2010, 495: 59-62.

[8] HARRIS P. Carbon nanotube composites [J]. International Materials Reviews, 2004, 49: 31-34.

[9] JIN Y, ZHU L, XUE W D, LI W Z. Fabrication of superaligned carbon nanotubes reinforced copper matrix laminar composite by electrodeposition [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2994-3001.

[10] APRAKASH K S, THANKACHAN T, RADHAKRISHNAN R. Parametric optimization of dry sliding wear loss of copper-MWCNT composites [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 627-637.

[11] PAK J, KIM G, HWANG S, KIM B, NOH J, HUH S. Mechanical properties of Cu matrix composite fabricated by extrusion process [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 2679-2686.

[12] CHU K, JIA C, JIANG L K, LI W S. Improvement of interface and mechanical properties in carbon nanotube reinforced Cu-Cr matrix composites [J]. Materials and Designs, 2013, 45: 407-411.

[13] MASROOR M, SHEIBANI S, ATAIE A. Effect of milling energy on preparation of Cu-Cr/CNT hybrid nano-composite by mechanical alloying [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1359-1366.

[14] KIM B J, OH S Y, YUN H S, KI J H, KIM C J, BEIK S, LIM B S. Synthesis of Cu-CNT nanocomposite powder by ball milling [J]. Journal of Nanoscience and Nanothechnology, 2009, 9: 7393-7397.

[15] TRINH P V, TRUNG T B, THANG N B, THANG B H, TINH T X, PHUONG D D, MINH P N. Calculation of the friction coefficient of Cu matrix composite reinforced by carbon nanotubes [J]. Computational Materials Science, 2010, 49(S): s239-s241.

[16] KIM H T, CHA S, HONG S H, HONG S H. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites [J]. Materials Science and Engineering A, 2006, 430: 27-33.

[17] ULLBRAND J M, CORDOBA J M, TAMAYO-ARIZTONDO J, ELIZALDE M R, NYGREN M, MOLINA-ALDAREGUIA J M, ODEN M. Thermomechanical properties of copper-carbon nanofibre composites prepared by spark plasma sintering and hot pressing [J]. Composites Science and Technology, 2010, 70: 2263-2268.

[18] GHORBANI A, SHEIBANI S, ATAIE A. Microstructure and mechanical properties of consolidated Cu-Cr-CNT nanocomposite prepared via powder metallurgy [J]. Journal of Alloys and Compounds, 2018, 732: 818-827.

[19] PATRA S, GOUTHAMA S, MONDAL K. Densification behavior of mechanically milled Cu-8at%Cr alloy and its mechanical and electrical properties [J]. Progress in Natural Science: Materials International, 2014, 24: 608-622.

[20] YOO S J, HAN S H, KIM W J A. Combination of ball milling and high-ratio differential speed rolling for synthesizing carbon nanotube/copper composites [J]. Carbon, 2013, 61: 487-500.

[21] XIA C, ZHANG W, KANG Z, JIA Y, WU Y, ZHANG R, XU G, WANG M. High strength and high electrical conductivity Cu-Cr system alloys manufactured by hot rolling-quenching process and thermomechanical treatments [J]. Materials Science and Engineering A, 2012, 538: 295-301.

[22] CHO S, KIKUCHI K, KAWASAKI A, KWON H, KIM Y. Effective load transfer by a chromium carbide nanostructure in a multi-walled carbon nanotube/copper matrix composite [J]. Nanotechnology, 2012, 23: 315-705.

[23] CULLITY B D, STOCK S R. Elements of X-ray diffraction [M]. 3rd ed. Delhi: Addision-Westley, 2001.

[24] XUE Z W, WANG L D, ZHAO P T, XU S C, QI J L, FEI W D. Microstructures and tensile behavior of carbon nanotubes reinforced Cu matrix composites with molecular-level dispersion [J]. Materials and Design, 2012, 34: 298-301.

[25] AKBARPOUR M R, FARVIZI M, LEE D J, REZAEI H, KIM H S. Effect of high-pressure torsion on the microstructure and strengthening mechanisms of hot-consolidated Cu-CNT nanocomposite [J]. Materials Science and Engineering A, 2015, 638: 289-295.

[26] DUBE R K, BAGDI P K. Densification and deformation behavior of a porous metal strip during hot rolling [J]. Metallurgical Transactions A, 1993, 24: 1753-1760.

[27] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes [J]. Materials Science and Engineering A, 2001, 313: 83-87.

[28] CARVALHO P, FONSECA I, MARQUES M, CORREIA J, ALMEIDA A, VILAR R. Characterization of copper-cementite nanocomposite produced by mechanical alloying [J]. Acta Materialia, 2005, 53: 967-976.

S. SHAKIB HAMEDAN, M. ABDI, S. SHEIBANI

School of Metallurgy and Materials Engineering, University of Tehran, P. O. Box 11155-4563, Tehran 13145-1318, Iran

摘 要:通过机械合金化制备Cu-1%Cr和Cu-1%Cr-5%CNT(碳纳米管)(质量分数)纳米复合粉体,用热压法将两种复合粉末压制成型,然后将样品在650 °C下热轧,其压下率为50%。分别通过X射线衍射分析(XRD)和扫描电镜(SEM)分析其相组成和显微组织,并检测材料的相对密度、显微硬度、热稳定性、电性能和耐磨性。与Cu-Cr样品相比,热轧后Cu-Cr-CNT 的相对密度从75%提高到几乎全致密的98%。虽然热轧后Cu-Cr和Cu-Cr-CNT样品的电导率和显微硬度均得到提高,但是含有碳纳米管的样品提高的效果更显著。热轧态Cu-Cr-CNT纳米复合材料的显微硬度和电导率分别达到HV 175和68%(IACS)。且与Cu-Cr复合材料相比,热轧对Cu-Cr-CNT纳米复合材料热稳定性的提高更加有效。然而,热轧后,与Cu-Cr-CNT纳米复合材料相比,Cu-Cr样品的摩擦因数和磨损量减少得更多(变化量分别为25%和 62%),这是两种材料的磨损机制不同造成的。

关键词:Cu-Cr;碳纳米管;纳米复合材料;热轧

(Edited by Wei-ping CHEN)

Corresponding author: S. SHEIBANI; Tel: +98-21-61114068; Fax: +98-21-88006076; E-mail: ssheibani@ut.ac.ir

DOI: 10.1016/S1003-6326(18)64848-4