挤压次数对Mg-Zn-Zr-Re合金组织和性能的影响

张振栋1,刘楚明1,常亚喆1, 2,李慧中1,王 荣3,周海涛1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中国空空导弹研究院,河南 洛阳,471009;

3. 中国兵器科学研究院 宁波分院,浙江 宁波,315103 )

摘 要:研究一次与二次挤压变形对添加稀土元素Nd和Y的ZK60镁合金显微组织及力学性能的影响。对加稀土元素Nd和Y的ZK60镁合金在5 MN立式挤压机上进行一次与二次挤压,并在国产CSS-44100电子万能拉伸机上进行拉伸试验,采用光学显微镜观察其铸态与变形态显微组织,并在KYKY-2800扫描电镜上观察断口形貌。研究结果表明:经一次挤压后,加入稀土Nd和Y后ZK60镁合金发生动态再结晶晶粒细化,力学性能显著提 高,但伸长率较低(在10%以下);经二次挤压后,在不显著降低合金强度的条件下,其塑性得到明显提高(均在10%以上)。

关键词:镁合金;挤压;二次挤压;第二相

中图分类号:TG146.2 文献标识码:A 文章编号:1672-7207(2008)02-0228-06

Effect of number of extrusion times on microstructure and properties of Mg-Zn-Zr-Re alloys

ZHANG Zhen-dong1, LIU Chu-ming1, CHANG Ya-zhe1, 2, LI Hui-zhong1, WANG Rong3, ZHOU Hai-tao1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. China Airborne Missile Academy, Luoyang 471009, China;

3. Ningbo Branch of Ordnance Science Institute of China, Ningbo 315103, China)

Abstract: The effects of single and double extrusion processes on microstructure and properties of ZK60 alloys added with Nd and Y were investigated. The single and double extrusions of ZK60 alloys added with Nd and Y were extruded on 5 MN vertical extruding machine and the specimens were tested on CSS universal electronic material testing machine. The microstructures of as-cast and as extruded specimens were analyzed by an optic microscopy and the fractographs of specimens were analyzed with the KYKY-2800 scanning electron microscope. The results show that after hot extrusion the alloy added with Nd and Y is greatly refined through dynamic recrystallization, and its tensile strength is improved, but its elongation is low and below 10%. The double extrusion can improve the alloys’ plasticity, the elongation is beyond 10%, and the strength is not obviously descended.

Key words:magnesium alloy; extrusion; double extrusion; the second phase

镁合金具有密度低,比强度和比刚度高,阻尼性能好,电磁屏蔽效果优异及易回收利用等优点,在电子、电器、交通、航空、航天等领域具有重要的应用价值和广阔的应用前景,被誉为21世纪最具发展前途的金属结构材料[1-3]。但是,由于镁具有密排六方(hcp)

的晶体结构,可开动的滑移系比面心立方(fcc)和体心立方(bcc)的少,因而镁合金的室温塑性较低,限制了镁合金的推广应用[4-5]。ZK60镁合金作为Mg-Zn-Zr系变形镁合金的典型代表,具有较高强度,良好的塑性和耐蚀性能,应用范围较广,但与其他合金相比也存在室温力学性能较低等缺点[6]。因此,为了提高ZK60镁合金的强度,许多研究者在ZK60镁合金中添加稀土合金元素Nd和Y[7-8]。如A. Singh等[9-10]研究稀土Y对ZK60镁合金组织和力学性能的影响,指出稀土元素Y可在ZK60镁合金中形成Mg3Zn2Y(W相)和Mg3Zn6Y相(I相),这些相具有较高硬度,良好的耐热性、耐腐蚀性能,较低的界面能,从而大大提高镁合金的室温和高温强度,但合金的伸长率较低[9-13]。

然而,目前镁合金力学性能仍不高,为了提高镁合金的力学性能,本文作者主要研究挤压次数对添加稀土元素Nd和Y的ZK60镁合金显微组织及力学性能的影响。

1 实 验

1.1 合金的制备

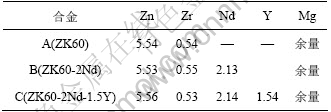

采用纯Mg、纯Zn和Mg-Zr,Mg-Nd,Mg-Y中间合金制备的实验合金,合金在电阻炉中进行熔 炼,采用SF6和CO2气体进行保护。合金的化学成分如表1 所示。

表1 合金化学成分

Table 1 Chemical composition of alloy w/%

1.2 挤压工艺

挤压前铸锭用感应炉加热,在5 MN立式挤压机上挤压,用石墨油润滑剂润滑。一次挤压的温度为 613 K,挤压比为20,挤压速度为0.5~2.0 m/min,挤压后空冷至室温。在CSS电子万能拉伸试验机上进行拉伸实验。

对合金B和合金C进行二次挤压,先将合金的直径从90 mm挤至32 mm,二次挤压前要对合金进行充分加热保温,保温时间为4 h,挤压比为10。

1.3 材料表征方法

合金显微组织采用Polyva-MET金相显微镜观察,用60 mL乙二醇+20 mL醋酸+19 mL蒸馏水+1 mL浓硝酸作浸蚀剂。在D/MAS-ⅢA X射线衍射仪上进行相分析。拉伸试验在国产CSS-44100电子万能拉伸机上进行,拉伸试样断口在KYKY-2800扫描电镜下观察断口形貌。

2 结果及分析

2.1 铸态显微组织分析

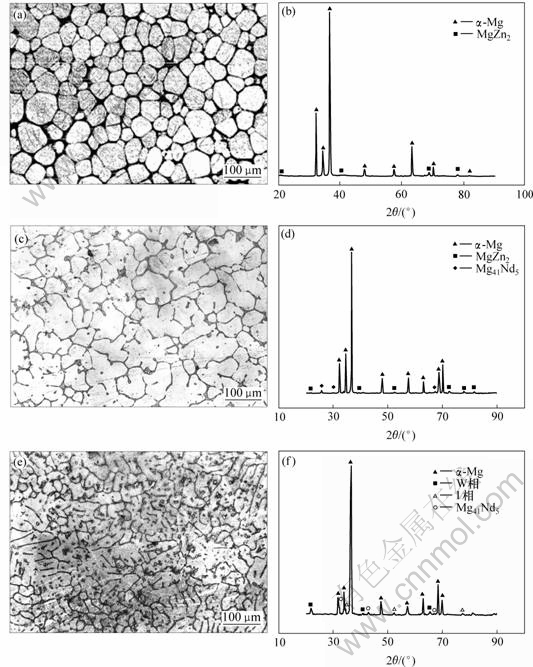

图1所示为合金的铸态显微组织。从图1可以看出,添加稀土元素Nd和Y后,合金的显微组织发生了显著的变化。随着稀土元素的加入,合金的晶粒粒径明显细化。其中ZK60镁合金的原始晶粒粒径约为90 μm,添加稀土元素Nd后,其晶粒粒径约为60 μm,同时加入Nd和Y后合金的晶粒粒径减小到约40 μm。由图1还可以看出,随着稀土元素的加入,合金中第二相逐渐增加,在晶内晶界处均有分布,以晶界处第二相较多。经过X射线衍射分析可知,在合金A中,只存在着α-Mg和MgZn2 2种相,而在合金B中,添加稀土元素Nd,除了存在α-Mg和MgZn2,还形成了Mg41Nd5第二相。在合金C中,稀土元素Y与Mg和Zn分别形成了W(Mg3Zn2Y)相和准晶I(Mg3Zn6Y)相。

(a), (b) 合金A; (c), (d) 合金B; (e), (f) 合金C

图1 合金铸态组织和 X射线衍射图谱

Fig.1 Microstructures in as-cast alloys and XRD patterns of tested alloys

2.2 力学性能分析

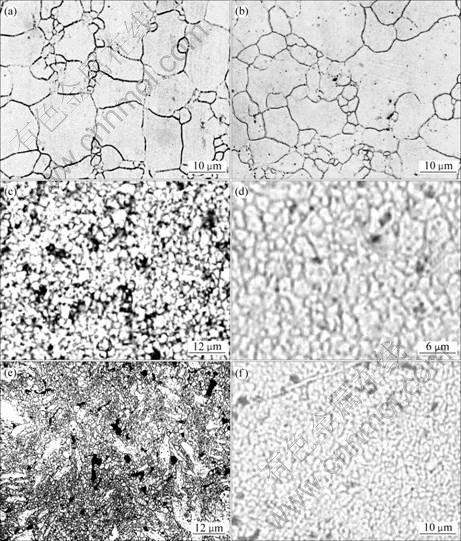

图2所示为合金挤压态显微组织形貌。从图2可以看出,合金在热挤压过程中发生了明显的动态再结晶,在未添加稀土元素的ZK60合金中再结晶晶粒明显长大,长大的晶粒粒径有的可达到20 μm左右。在添加了稀土元素Nd和Y的合金中再结晶晶粒并未长大,这是由于稀土元素的加入,形成多种耐热稀土相,提高了合金的再结晶温度。合金B和合金C经挤压后晶粒细化明显,且合金B晶粒粒径可达到5 μm左右,合金C晶粒粒径可到达4 μm左右。这一方面是由于稀土元素Nd和Y具有晶粒细化作用,另一方面,Nd和Y可以与Mg形成的多种耐热相(Mg41Nd5、W(Mg3Zn2Y)相和准晶I(Mg3Zn6Y)相)可以阻碍在热变形过程中再结晶晶粒的长大。同时,从图中还可以看出,与一次挤压相比,二次挤压后,合金晶粒更加细小,合金C晶粒粒径可达到3 μm左右。细小的晶粒有利于提高合金的抗拉强度和伸长率。

(a) 合金A一次挤压组织(横向);(b) 合金A一次挤压组织(纵向);(c) 合金B一次挤压组织;(d) 合金B二次挤压组织;(e) 合金C一次挤压组织;(f) 合金C二次挤压组织

图2 合金挤压态组织

Fig.2 Microstructures of as-extruded alloys

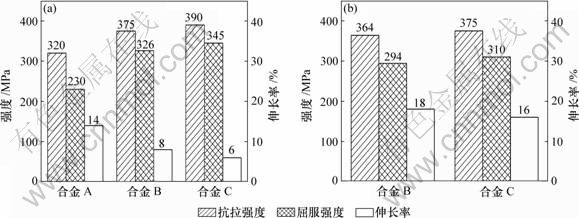

图3所示为合金力学性能图。从图3可以看出,

加入稀土元素Nd和Y后,经挤压变形后,与ZK60镁合金相比,合金B和C的抗拉强度和屈服强度明显提高,这是由于合金中加入稀土元素后,晶粒明显细化,由Hall-Petch公式可知[7]

K为常数;d为晶粒粒径。可知,材料晶粒得到细化,其屈服强度提高,相应的抗拉强度也得到明显提高。合金B和C经挤压后发生动态再结晶,晶粒明显细化,与ZK60镁合金相比晶粒细化明显,因此,其强度比ZK60镁合金的高。此外,合金中加入稀土元素Nd和Y后,合金中含有大量的第二相,对合金有较强的第二相弥散强化作用。

(a) 一次挤压;(b) 二次挤压

图3 试验合金的力学性能

Fig.3 Tensile properties of tested alloys

从图3还可以看出,与一次挤压相比,二次挤压对合金强度的提高并不明显,但伸长率却大幅度提高。二次挤压后合金的伸长率均在10%以上。这是由于合金经过二次挤压后,晶粒细化更明显,晶界总面积增加,阻碍裂纹扩展的能力增强,且使晶界上杂质浓度降低,避免产生沿晶脆性断裂。从图2还可以看 出,经二次挤压后,再结晶较完全,使晶粒细化,晶粒粒径均匀,合金变形趋于均匀、协调;且经过二次挤压后,第二相分布比较弥散,未在晶界处大量聚集,使得在晶界前塞积的位错数减少,有利于降低应力集中,从而避免脆性断裂。

根据脆性塑性断裂转变理论,晶粒粒径d与塑性脆性转变有如下关系[14-15]:

式中等号表示塑性脆性转变的条件,大于号表示呈脆性断裂。可见,合金经过二次挤压后,使得晶粒粒径明显减小,这有利于合金断裂方式向韧性断裂转变。

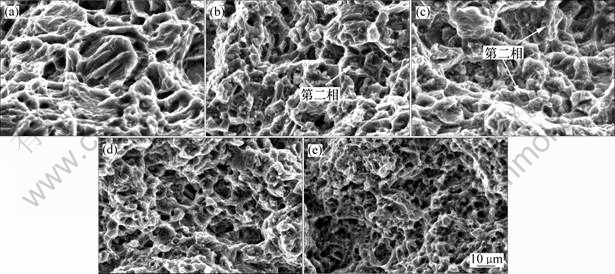

挤压态合金的断口形貌扫描图如图4所示。可以看出,经一次挤压后,合金的断裂方式接近解理断裂。图4(a)所示为合金A断口形貌,断口内部存在少量韧窝,韧窝之间存在着明显的撕裂棱;图4(b)和4(c)所示分别为合金B和合金C经一次挤压后的断口形貌,断口内部存在更少的韧窝,撕裂棱的数目明显增多。在韧窝内部存在着开裂的第二相粒子。如前所述,这些第二相粒子可能为Mg41Nd5和W(Mg3Zn2Y)相或准晶I(Mg3Zn6Y),且多分布在晶界上。在塑性变形时,在颗粒与基体的边界上造成位错塞积,从而产生应力集中,当应力达到一定程度时,在部分颗粒-基体边界发生孔隙,产生微细裂纹,随着应力的增加,这些细裂纹不断长大, 裂纹尖端应力不断增加,当裂纹尖端附近区域内的应力超过材料的断裂强度后,基体发生局部断裂,所以材料的强度得到提高的同时,塑性会有所降低。

图4(d)和4(e)所示分别为合金B和合金C二次挤压后的断口形貌扫描图。从图4(d)和4(e)可以看出,二次挤压后合金的断口中存在大量韧窝,窝间存在少量撕裂棱,且韧窝直径明显增大,合金断裂方式接近于韧性断裂。此外,在韧窝中第二相粒子含量减少。这是由于合金经二次挤压后,第二相粒子分布比较弥散,未在晶界处聚集(见图2(d)和2(f)),从而降低了应力集中,合金变形趋于均匀,从而合金的塑性得到明显提高。

(a) 合金A一次挤压断口形貌;(b) 合金B一次挤压断口形貌;(c) 合金C一次挤压断口形貌;(d) 合金B二次挤压断口形貌;(e) 合金C二次挤压断口形貌

图4 试验合金的断口形貌

Fig.4 Fractographs of tensile fracture of tested alloy

3 结 论

a. 在ZK60镁合金中,添加稀土元素Nd和Y后,铸态晶粒明显细化。在合金B中,形成Mg41Nd5第二相。在合金C中,稀土元素Y与Mg和Zn分别形成了W(Mg3Zn2Y)相和准晶I(Mg3Zn6Y)相。

b. 合金经过一次挤压后,添加稀土元素Nd和Y的合金B和合金C发生动态再结晶,晶粒明显细化,强度明显提高,但伸长率较低,均在10%以下,合金断裂方式为脆性断裂。

c. 合金经过二次挤压后,添加稀土元素Nd和Y的合金B和合金C发生动态再结晶,与一次挤压相比合金晶粒细化更为明显,强度略有降低,但塑性明显提高,伸长率均在10%以上。合金断裂方式为韧性 断裂。

参考文献:

[1] Mordike B T, Ebert T. Magnesium properties applications potential [J]. Mater Sci Eng A, 2001, 302: 37-45.

[2] Aghion E, Bronfin B. Magnesium alloys development towards the 21st century[J]. Mater Sci Forum, 2000, 350: 19-28.

[3] LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong. Influence of isochronal heat treatment on damping behavior of AZ61 alloy[J]. Journal of Central South University of Technology, 2007, 14(3): 315-318.

[4] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. The theoretical basis and application of magnesium based light weight alloy[M]. Beijing: China Machine Press, 2002.

[5] 刘饶川, 汪凌云, 辜蕾钢. AZ31B镁合金板材退火工艺及晶粒尺寸模型的研究[J]. 轻合金加工技术, 2004, 32(2): 22-25.

LIU Rao-chuan, WANG Ling-yun, GU Lei-gang. Study on annealing technique for wrought magnesium alloy plate and modeling research on the changing law of its grain size[J]. Light Alloy Fabrication Technology, 2004, 32(2): 22-25.

[6] 麻彦龙, 左汝林. 钇对铸态ZK60镁合金晶界析出相形态的影响[J]. 重庆大学学报: 自然科学版, 2005, 28(2): 51-54.

MA Yan-long, ZUO Ru-ling. Effect of yttrium on morphologies of precipitation phases along grain boundary of as-cast ZK60 magnesium alloy[J]. Journal of Chongqing University: Natural Science Edition, 2005, 28(2): 51-54.

[7] 王 斌, 易丹青. 稀土元素Y和Nd对Mg-Zn-Zr系合金组织和性能的影响[J]. 金属热处理, 2005, 30(7): 9-13.

WANG Bin, YI Dan-qing. Influence of Y and Nd on Microstructure and Properties of Mg-Zn-Zr alloys[J]. Heat Treatment of Metals, 2005, 30(7): 9-13.

[8] MA Chun-jiang, LIU Man-ping, WU Guo-hua. Tensile properties of extruded ZK60-RE alloys[J]. Mater Sci Eng A, 2003, 349: 207-212.

[9] Singh A, Nakamura M, Watanabe M. Quasicrystal strengthened Mg-Zn-Y alloys by extrusion[J]. Scripta Materialia, 2003, 49: 417-422.

[10] ZHANG Ya, ZENG Xiao-qin, LIU Liu-fa, et al. Effects of yttrium on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr alloys[J]. Mater Sci Eng A, 2004, 373: 320-327.

[11] 张新明, 彭卓凯, 陈健美, 等. 耐热镁合金及其研究进展[J]. 中国有色金属学报, 2004, 14(9): 1443-1450.

ZHANG Xin-ming, PENG Zhou-kai, CHEN Jian-mei, et al. Heat-resistant magnesium alloys and their development[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1143-1450.

[12] Bae D H, Lee M H, Kim K T. Application of quasicrystalline particles as a strengthening phase in Mg-Zn-Y alloyes[J]. Journal of Alloys and Compounds, 2002, 342: 445-450.

[13] Yi S, Park E S, Ok J B. (Icosahedral phase+α-Mg) two phase microstructure in the Mg-Zn-Y ternary system[J]. Mater Sci Eng A, 2001, 300: 312-315.

[14] 张新明, 石其年. 二次挤压对Al-Li合金挤压织构及力学性能的影响[J]. 中南矿冶学院学报, 1991, 22(2): 174-183.

ZHANG Xin-ming, SHI Qi-nian. Effect of double extrusion processes on extrusion texture and properties of Al-Li alloy[J]. Journal of Central-South Institute of Mining and Metallurgy, 1991, 22(2): 174-183.

[15] 石其年. 二次挤压对Al-Li合金组织及性能的影响[J]. 热加工工艺, 2006, 35(8): 34-39.

SHI Qi-nian. Effect of double extrusion processes on microstructure and properties of Al-Li alloy[J]. Hot Working Technology, 2006, 35(8): 34-39.

收稿日期:2007-06-29;修回日期:2007-08-08

基金项目:国防科工委资助项目(2006年)

通信作者:刘楚明(1960-),男,湖南张家界人,教授,从事镁合金材料性能、组织及加工工艺研究;电话:0731-8877502;E-mail: cmliu@mail.csu.edu.cn