DOI:10.19476/j.ysxb.1004.0609.2017.09.05

热处理过程中Mg-8Gd-3Y-1Nd-0.5Zr合金的组织演变及性能

冯 艳,李晓庚,王日初,彭超群

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用透射电镜、扫描电镜、能谱分析、X射线衍射及力学性能等测试手段,研究热处理工艺对水冷铸造的Mg-8Gd-3Y-1Nd-0.5Zr(质量分数)合金显微组织、力学性能和耐腐蚀性能的影响。合金铸态显微组织由α-Mg、Mg(Gd,Y)相、富Zr小颗粒相和β-Mg24Y5网状共晶组成。在520 ℃固溶24 h后,合金中共晶相固溶进基体,固溶演变过程为α-Mg+β-Mg24Y5相+ Mg(Gd,Y)→过饱和α-Mg固溶体+Mg(Gd,Y)相。225 ℃时效,合金的析出序列为 Mg(S.S.S.S)→β″(DO19)→β′(CBCO)→β1(FCC)→β(FCC),时效24 h达到峰时效态,合金的室温抗拉强度达到 231 MPa,伸长率为 3.4%。时效处理能提高合金耐腐蚀性能,225 ℃时效72 h时合金析出稳定β(FCC)相,平均析氢速率最小,为0.22 mL/(cm2·h),合金的耐腐蚀性能最强。

关键词:Mg-8Gd-3Y-1Nd-0.5Zr合金;固溶处理;显微组织;力学性能;析出序列

文章编号:1004-0609(2017)-09-1794-09 中图分类号:TG146 文献标志码:A

镁合金在室温下具有较好的力学性能,逐渐成为一种新兴的工业结构材料,然而,在高温下的力学性能差成为制约轻质镁合金应用的关键问题[1-2]。近年来,为了扩大镁合金的应用范围,国内外研究人员对高强耐热镁合金进行了深入研究[3-4]。稀土镁合金是研究较多的高强耐热镁合金,由于稀土元素Gd、Y、Nd、Zr等对镁合金具有除氢脱氧、细化晶粒和弥散强化作用,能很好地提高镁合金的室温及高温力学性能[5-6]。同时,稀土元素能在镁合金表面生成稀土转化膜,提高镁合金的耐腐蚀性能[7-8],使得该合金在航空航天、汽车、军工产品中具有广阔的应用前景[9]。

Mg-Gd系镁合金作为高强耐热镁合金的代表性合金系之一,是当前国内外镁合金研究的热点,NEGISHI等[10]通过研究Mg-Gd-Nd合金的富Mg区相图,得出了这一合金系的时效析出序列为Mg(S.S.S.S)→β″(DO19)→β′(BCO)→β(FCC)。NIE等[11]在对Mg-Y-Nd合金系时效过程研究时,首次观察到了β1亚稳定相,确定了其析出序列为Mg(S.S.S.S)→ β″(DO19)→β′(BCO)→β1(FCC)→β(FCC)。APPS等[12]对Mg-7Gd-2Nd-Zr合金做了研究,发现该合金在250 ℃时效析出序列为Mg(S.S.S.S)→β″(DO19)→ β′(CBCO)→β1(FCC)→β(FCC),汤伊金等[13]研究Mg-Gd系合金时效析出序列与之前合金一致。谢中柱等[14]研究Mg-2.8Gd-0.3Nd合金在极限服役温度300 ℃等温时效状态下析出相的形成和生长,确定了300 ℃等温时效析出序列为Mg(S.S.S.S)→β1(FCC)→ β(FCC),未见常规服役温度时效初期亚稳相β′。李慧中等[15]的研究表明,经过变形和200 ℃时效20 h处理,Mg-10Gd-4.8Y-0.6Zr合金的常温力学性能有较大的提高,均匀化后合金抗拉强度达到242.6 MPa,挤压变形后抗拉强度达到304.5 MPa,挤压态Mg-8Gd-4.8Y- 0.4Zr合金经过220 ℃时效21 h,合金屈服强度达到最高值,达330 MPa,抗拉强度较挤压态提高 29%~ 39%[16]。由此可以看出,对于Mg-Gd-RE系的镁合金,其热处理制度与组织演变和添加合金元素有关,对于合金成分不同的合金,其组织演变和力学性能存在一定差异,需要分别进行研究,并且合金热处理工艺对耐腐蚀性能影响的研究较少,为此,本文作者研究热处理过程中Mg-8Gd-3Y-1Nd-0.5Zr合金的组织演变规律,通过观察组织变化,测试力学性能及析氢测试耐腐蚀性能的方法得出热处理对该合金组织、力学性能及耐腐蚀性能的影响。从而为制备性能优良的Mg-8Gd-3Y-1Nd-0.5Zr合金提供帮助。

1 实验

用普通电阻炉进行Mg-8Gd-3Y-1Nd-0.5Zr合金熔炼,实验用镁为高纯镁锭,稀土元素以Mg-32Gd、Mg-32Y、Mg-25Nd、Mg-33Zr(质量分数,%)的中间合金形式加入。使用电阻炉进行熔炼,熔炼时采用镁覆盖剂隔绝空气,浇注时用硫磺粉末防止合金氧化烧损,熔炼温度为740~780 ℃。浇注使用钢制水冷磨具,尺寸为200 mm×150 mm×20 mm,浇注温度740 ℃左右。铸锭的成分采用等离子化学成分分析,分析结果见表1。

表1 实验合金的化学成分

Table 1 Chemical compositions of the test alloy

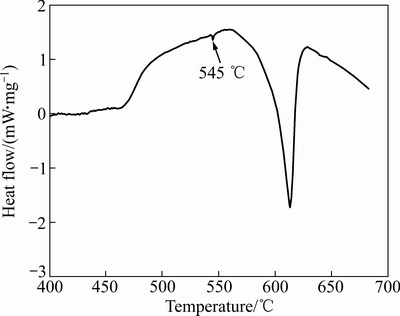

同一高度取样进行固溶处理,保证试样的冷却条件和成分保持一致。在箱式电阻炉内进行固溶处理时,表面涂抹覆盖剂以防止样品氧化和燃烧。确定固溶工艺时,先从铸锭上取样进行DSC分析(见图1)。由图1可以看出,545 ℃以后合金析出相开始熔解,说明固溶温度不能超过545 ℃。保温时间选择工业上能接受的2~30 h作为尝试区间。根据以上所述,采用尝试法研究合金最佳固溶处理工艺,固溶温度选择为500、510、520 ℃;保温时间选择为12、18和24 h,保温结束后用常温水进行淬火。

图1 Mg-8Gd-3Y-1Nd-0.5Zr铸态合金样品DSC曲线

Fig. 1 DSC curves of Mg-8Gd-3Y-1Nd-0.5Zr alloy as cast samples (heating rate of 10 K/min)

试样时效处理在箱式电阻炉内进行,表面涂抹覆盖剂以防止样品氧化和燃烧。时效温度为225 ℃,时效时间为1~96 h,空冷。

用D/max-rA型转靶X射线衍射仪(XRD)对试验样品进行物相分析;用FEI QUANTA-200型扫描电镜(SEM)及其所具备的能谱分析(EDAX)功能对试验样品进行显微组织观察和微区成分半定量分析;用Titan G260-300 with image corrector图像球差校正场发射透射电镜和对样品进行观察与分析,样品制备为机械预减薄后用电解双喷穿孔,电解液为4.5%(质量分数)的高氯酸酒精溶液,双喷加载电压为50 V,双喷温度为-30 ℃;用HB-3000B型布氏硬度计对试验样品进行硬度分析,硬度样品尺寸30 mm×20 mm×15 mm,上下表面用金相砂纸打磨光滑,在上表面距离两边缘5 mm处取4个点,样品中央取1点,共计5点做硬度实验,以防止相互干扰,载荷为2450 N,保压时间30 s,5个点去掉最高最低值后取平均值;常温拉伸试样尺寸依照GB-T 228.1-2010设计,高温拉伸试样尺寸依照GB/T 4338-2006设计,电火花切割制备试样,用瑞格尔RGM-4000全数字化微机控制万能试验机对试验样品进行常温及高温力学性能测试,常温拉伸测试速率为1.5 mm/min,高温测试温度选为200 ℃,保温10 min,拉伸速率为1.0 mm/min,测试3个试样取平均值,拉伸断口放入无水乙醇中保存,并用超声波清洗仪清洗。

耐腐蚀性能测试则利用析氢实验完成,将10 mm×10 mm的试样非工作面用酚醛塑料粉密封,用金相砂纸对工作面逐级打磨,完成后将试样放入室温下,3.5%NaCl(质量分数)中性溶液中,收集腐蚀过程中析出的氢气,计算氢气体积来反映镁合金腐蚀速率。

2 结果与分析

2.1 铸态Mg-8Gd-3Y-1Nd-0.5Zr合金显微组织及相分析

图2所示为铸态Mg-8Gd-3Y-1Nd-0.5Zr合金的SEM像。由图2可知,铸态合金组织由α-Mg基体、晶界骨骼状第二相、固溶于α-Mg基体中的颗粒状第二相和方块状第二相组成,X射线衍射分析结果见图3,对第二相的能谱成分分析见表2。由图3和表2的检测结果可知,B相沿晶界形成呈现明显网状特征,由Mg、Gd、Y和Nd元素组成,稀土元素含量高,为非平衡凝固产生的镁稀土相,结合XRD分析,Mg-RE相为β-Mg24Y5。研究表明,β-Mg24Y5相中的Y原子可以被Gd和Nd等原子取代[12],故该相中Gd、Nd元素含量较高。C相分布在基体与B相附近,呈明显方块状,其中的Gd和Y的含量高于Mg元素的含量,结合能谱和XRD分析,为游离的稀土元素固溶体相(α-RE、Mg(Gd,Y)),在铸态组织中数量不多。D相经检测为富锆粒子,富锆粒子的这种分布有利于细化镁合金铸锭的晶粒尺寸[17],由扫描照片可以看出,实验中的Mg-8Gd-3Y-1Nd-0.5Zr合金的晶粒尺寸<100 μm,一般Mg-Gd-Y合金的晶粒尺寸约为1000 μm[18],符合添加Zr元素的规律。

图2 Mg-8Gd-3Y-1Nd-0.5Zr铸态合金的SEM像

Fig. 2 SEM image of as-cast Mg-8Gd-3Y-1Nd-0.5Zr alloy

表2 Mg-8Gd-3Y-1Nd-0.5Zr合金第二相粒子成分分析

Table 2 Composition measurements of second phase particles in Mg-8Gd-3Y-1Nd-0.5Zr alloys shown in Fig. 2

图3 Mg-8Gd-3Y-1Nd-0.5Zr合金铸态和520 ℃、24 h固溶处理的XRD谱

Fig. 3 XRD patterns of Mg-8Gd-3Y-1Nd-0.5Zr alloy

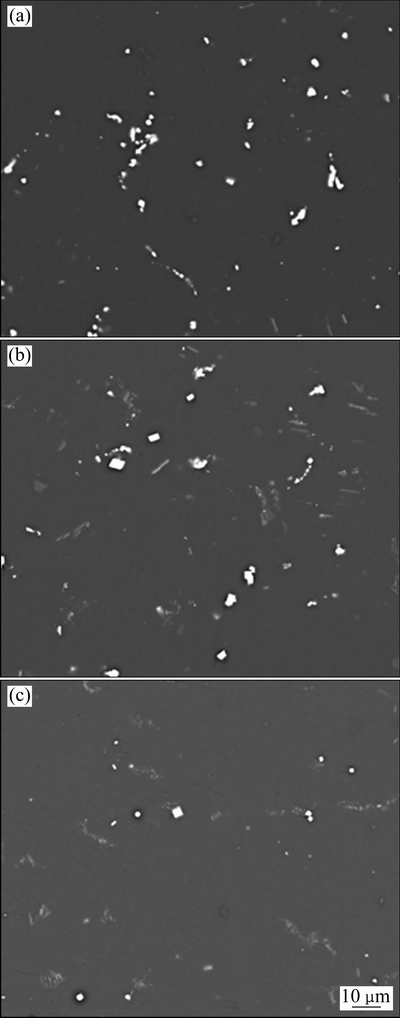

图4 铸态组织在500、510、520 ℃下保温24 h后的SEM像

Fig. 4 SEM images of Mg-8Gd-3Y-1Nd-0.5Zr alloy at 500 ℃ (a), 510 ℃ (b) and 520 ℃ (c) for 24 h

2.2 固溶处理对合金显微组织及力学性能的影响

2.2.1 固溶处理对合金显微组织的影响

图4所示为Mg-8Gd-3Y-1Nd-0.5Zr合金进行不同

固溶温度保温24 h后的SEM像。从图4可以看出,合金进行固溶处理以后,Mg-RE共晶组织减少,对于500 ℃与510 ℃而言,到24 h时,仍有部分Mg-RE共晶相未溶解完成。经520 ℃固溶24 h以后,Mg-RE共晶相大部分固溶进基体,仅剩少量块状Mg(Gd,Y)相存在。研究表明[19],Mg(Gd,Y)相在保温时间延长至72 h后仍然存在。由此可以得出,Mg-8Gd-3Y-1Nd- 0.5Zr合金在固溶过程中的显微组织演变为α-Mg+β-Mg24Y5相+Mg(Gd,Y)→过饱和α-Mg固溶体+Mg(Gd,Y)相。

2.2.2 固溶处理对合金力学性能的影响

图5所示为520 ℃固溶处理不同时间的Mg-8Gd-3Y-1Nd-0.5Zr合金布氏硬度变化曲线。图6所示为520 ℃固溶处理不同时间Mg(Gd, Y)方块相的分布情况。由图5可知,固溶4 h之前,合金的硬度下降,这是由于β-Mg24Y5相开始固溶进镁基体,枝晶偏析逐渐消除,导致合金硬度下降,随着固溶时间增加,β-Mg24Y5相中Gd、Y、Nd等稀土元素在镁基体中的大量固溶产生了固溶强化,导致合金硬度上升, 8 h左右,大量Mg(Gd, Y)方块相生成,导致合金固溶强化作用有所下降,硬度上升变缓;到12 h后,Mg(Gd,Y)方块相开始固溶至基体中,固溶强化效果恢复,合金硬度再次快速上升,随着时间延长,固溶过程结束,合金硬度趋于稳定。在520 ℃固溶24 h时,第二相几乎能全部溶入α-Mg基体,Mg(Gd,Y)相数量较少,合金达到较好的固溶效果。

图5 Mg-8Gd-3Y-1Nd-0.5Zr合金520 ℃固溶处理不同时间的布氏硬度变化曲线

Fig. 5 Hardness change curves of Mg-8Gd-3Y-1Nd-0.5Zr alloy at 520 ℃ for different solution-treated time

图6 520 ℃下保温不同时间Mg(Gd,Y)相分布

Fig. 6 Mg(Gd,Y) phase distribution at 520 ℃ for different holding time

表3所列为Mg-8Gd-3Y-1Nd-0.5Zr合金经过不同固溶处理后的室温拉伸力学性能和200 ℃高温拉伸力学性能。由表3可以看出,合金经过520 ℃固溶处理24 h以后,晶界处第二相固溶进镁基体,合金塑性提高,而且在固溶强化的作用下,样品抗拉强度有所上升,伸长率明显提高。

2.3 时效处理对合金的组织及力学性能的影响

2.3.1 时效析出分析

图7所示为合金经过225 ℃不同时效时间后的TEM形貌及衍射斑点。图7(a)~(b)所示为225 ℃、4 h时效试样TEM明场像和选区电子衍射花样。从图7(a)和(b)中可以看出,合金组织中含有薄板状析出相,且薄板长度为几十纳米,结合衍射斑点分析,此薄板状组织与Mg-RE系合金中的β″相一致,具有DO19结构,晶格参数为a=2aMg=0.64 nm,c=cMg=0.52 nm,在1/2{0110}α处产生额外衍射斑点[20]。由图9(c)和(d)可以发现,在时效时间延长至24 h后,合金中有新相生成,新相为细小颗粒状,尺寸约为几纳米,多个小颗粒相构成沿同一方向排列的链状结构,链长约为100~150 nm左右,结合电子衍射斑点分析,析出相为β′相,具有底心正交结构(CBCO),晶格参数a=2aMg=0.64 nm,b=2.2 nm,c=cMg=0.52 nm,该相在1/2{0110}α、1/4{0110}α和3/4{0110}α处产生额外衍射斑点[21]。

表3 不同热处理状态下Mg-8Gd-3Y-1Nd-0.5Zr合金的力学性能

Table 3 Mechanical properties of Mg-8Gd-3Y-1Nd-0.5Zr alloy with different heat treatments

经过225 ℃、30 h时效后,试样中出现β1相,如图7(e)和(f)所示,β1相为独特的梭形形状,其中两头与β′相相连,标定电子衍射斑点可以得出,β1相为面心立方结构(FCC),a=0.73 nm,与Mg3Nd同构[22]。继续时效至72 h,合金中开始出现板条状相,如图7(g)所示,且板条状粗化至长度达1 μm,厚度为100 nm,有电子衍射斑点标定(见图7(h))可知,该相为面心立方结构(FCC),a=2.22 nm,与Mg5Gd同构,与Mg-RE合金中的β相一致。

TEM表征结果表明,Mg-8Gd-3Y-1Nd-0.5Zr合金在经过225 ℃时效过程中经过了4个时效析出序列过程:Mg(S.S.S.S)→β″→β′→β1→β,与Mg-Gd系合金析出序列一致[11]。

图8所示为Mg-8Gd-3Y-1Nd-0.5Zr合金时效试样的XRD谱。由图8可看出,衍射峰随着时效状态的不同发生明显变化,除了α-Mg基体和Mg(Gd,Y)方块相衍射峰以外,其他各峰对应物相都做了标定,到达24 h时,有明显的β峰值出现,30 h时出现了β1的衍射峰值,但还存在部分β′相,72 h时,出现β物相峰,结果与TEM表征结果相同。

2.3.2 时效态合金的力学性能

图9所示为固溶后的合金硬度随时间变化规律曲线。由图9可知,合金在225 ℃下具有较为明显的时效硬化效果。时效初期(0~4 h),合金硬度增加不明显;当时间增长到6~18 h时,合金硬度迅速上升,时效时间为20~30 h时,合金硬度显示出相当长的硬度平台,24 h左右到达峰值104.4 HBS,之后,随着时效时间的增长,合金硬度有所下降。利用TEM对合金时效析出行为进行研究,选取时效硬化曲线中的典型的时间点进行研究(4 h、24 h、30 h、72 h)。

表4所示为Mg-8Gd-3Y-1Nd-0.5Zr铸态合金经过520 ℃、24 h固溶处理,225 ℃时效不同时间后的力学性能,可以看出在时效状态下合金的抗拉强度上升,而伸长率与固溶状态相比有所下降,在峰时效225 ℃、24 h时,抗拉强度最高,比铸态合金高出80 MPa。

Mg-8Gd-3Y-1Nd-0.5Zr铸态合金经过520 ℃、24 h固溶,225 ℃时效处理,组织和性能发生改变。时效初期,晶内析出β″相,合金硬度稍有增加。随着时效时间的增加,达到峰时效时,晶内主要析出相为β′相,当合金进入过时效阶段时,β1相逐渐产生,不断粗化,消耗了β′相而形成平衡相β,导致晶内的β′相体积分数降低,从而使得合金的硬度下降。

β′相能够显著提高合金强度是因为它与基体共格、长轴垂直于基面的椭球形状、和相互链接的密集分布、β′相周围的产生应变场能够阻碍位错的运动[23]。β′椭球呈链状排列,相互交联,形成对位错基面滑移的良好阻碍[24]。

时效初期产生的细小板条状β″相也对合金强化起重要作用,但由于太过细小,容易被位错切过[23],所以强化作用有限。过时效阶段产生的β1相与β相,本身尺寸过于粗大,在单个晶体内数量密度有限,其强化作用不如初期的亚稳定析出相。

2.3.3 时效态合金的耐腐蚀性能

图10所示为不同状态下Mg-8Gd-3Y-1Nd-0.5Zr合金析氢量与浸泡时间的关系。从图10中可以看出,热处理对合金的耐腐蚀性能影响较为明显。铸态合金析氢量最高,平均析氢速率为2.48 mL/(cm2·h)。由于铸态合金中的晶界第二相较多,与基体形成电偶腐蚀,β-Mg24Y5相和Mg(Gd,Y)相在腐蚀过程中作为阴极相,导致其边缘的α-Mg基体优先发生腐蚀,合金耐腐蚀性能不佳[25]。固溶态合金的平均析氢速率为0.79 mL/(cm2·h),合金耐腐蚀性能显著提高。由于固溶态合金中晶界Mg24Y5相固溶进镁基体,阴极相明显减少,腐蚀原电池的驱动力降低导致合金的耐腐蚀性能提高。

图7 Mg-8Gd-3Y-1Nd-0.5Zr合金的TEM明场像及选区电子衍射花样

Fig. 7 TEM images and SAED patterns of Mg-8Gd-3Y-1Nd-0.5Zr alloy aged for different time

表4 225 ℃时效不同时间Mg-8Gd-3Y-1Nd-0.5Zr合金的力学性能

Table 4 Mechanical properties of Mg-8Gd-3Y-1Nd-0.5Zr alloy aged at 225 ℃ for different time

图8 Mg-8Gd-3Y-1Nd-0.5Zr合金时效试样的XRD谱

Fig. 8 XRD patterns of aged Mg-8Gd-3Y-1Nd-0.5Zr alloy specimens

图9 Mg-8Gd-3Y-1Nd-0.5Zr合金时效硬化曲线

Fig. 9 Age-hardening curve of Mg-8Gd-3Y-1Nd-0.5Zr alloy

225 ℃时效使Mg-8Gd-3Y-1Nd-0.5Zr合金的耐腐蚀性能继续提高。随着时效时间的延长,合金内的析出相发生变化,影响了合金的析氢速率。时效4 h后,合金基体内密集析出尺寸约为15 nm的亚稳β″相,合金耐腐蚀性能提高,平均析氢速率为0.56 mL/(cm2·h);时效16 h后,合金内弥散析出尺寸约为0.2 μm的亚稳β′相,β″相数量减少(消失),合金的耐腐蚀性能下降,平均析氢速率为0.64 mL/(cm2·h),与时效4 h相比略有上升;时效24 h后,合金达到峰时效状态,合金内亚稳β′相数量达到最高(形状由弥散的块状变成线条状),合金的耐腐蚀性能提高,平均析氢速率下降到0.40 mL/(cm2·h)。时效72 h后,合金进入过时效阶段,合金内大量生成稳定第二相β,合金耐腐蚀性能提高,平均析氢速率最小,为0.22 mL/(cm2·h)。由时效态Mg-8Gd-3Y-1Nd-0.5Zr合金的耐腐蚀性能可知,当镁基体处于过饱和的热力学不稳定状态时,镁基体中合金元素容易析出,此时析出的第二相为亚稳相,合金的耐腐蚀性能较低,当镁基体中析出稳定第二相时,镁基体处于热力学相对稳定的状态,有益于提高镁合金的耐腐蚀性能提高。

图10 不同状态下Mg-8Gd-3Y-1Nd-0.5Zr合金析氢量与浸泡时间的关系

Fig. 10 Relationship between hydrogen evolution volumes and immersion time of Mg-8Gd-3Y-1Nd-0.5Zr alloy anodes under different conditions

3 结论

1) Mg-8Gd-3Y-1Nd-0.5Zr铸态合金显微组织主要由α-Mg、β-Mg24Y5、富Zr颗粒和Mg(Gd,Y)方块相组成。

2) Mg-8Gd-3Y-1Nd-0.5Zr合金固溶组织演变过程为:α-Mg+β-Mg24Y5相+Mg(Gd,Y)→过饱和α-Mg固溶体+Mg(Gd,Y)相。时效析出序列为Mg(S.S.S.S)→ β″→β′→β1→β,主要时效增强相为β′相。

3) Mg-8Gd-3Y-1Nd-0.5Zr合金在520 ℃、24 h固溶后力学性能增强,常温抗拉强度为181.6 MPa,伸长率为6.1%;200 ℃、24 h处理后,抗拉强度为169.1 MPa,伸长率为6.5%;经过225 ℃、24 h时效处理后,常温抗拉强度为231.3 MPa,伸长率为3.4%;200 ℃、24 h处理后,抗拉强度为210.5 MPa,伸长率为3.9%。

4) 时效热处理提高Mg-8Gd-3Y-1Nd-0.5Zr合金的耐腐蚀性能。时效初期,镁合金析出亚稳第二相β″和β′,基体处于热力学不稳定状态,合金的耐腐蚀性能较低,当镁基体中析出稳定第二相β时,镁基体处于热力学相对稳定的状态,此时平均析氢速率最小,为0.22 mL/(cm2·h),合金的耐腐蚀性能最强。

REFERENCES

[1] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 512-513.

LI Wen-xian. Magnesium and Magnesium alloys[M]. Changsha: Central South University Press, 2005: 512-513.

[2] 李元元, 张卫文, 刘 英, 陈维平, 倪东惠. 镁合金的发展动态和前景展望[J]. 特种铸造及有色合金, 2004(1): 14-17.

LI Yuan-yuan, ZHANG Wei-wen, LIU Ying, CHEN Wei-pin, NI Dong-hui. Developing tendency and future prospects of Mg alloy[J]. Special Casting & Nonferrous Alloys, 2004(1): 14-17.

[3] ZHENG L, LIU C M, WAN Y C, YANG P W, SHU X. Microstructure and mechanical properties of Mg-10Gd-6Y- 2Zn-0.6Zr(wt%)alloy[J]. Journal of Alloys and Compounds, 2011, 509(35): 8832-8839.

[4] 刘静安, 温育智. 稀土在有色金属工业中的开发与应用前景[J]. 四川有色金属, 2003, 32(2): 20-27.

LIU Jing-an, WEN Yu-zhi. Exploitation and application prospect of rare earth in non-ferrous metals industry[J]. Sichuan Nonferrous Metals, 2003, 32(2): 20-27.

[5] 王敬丰, 周 海, 宋鹏飞, 秦德昭, 潘复生. 一种高强度Mg-Gd-Y-Zn-Mn合金:中国, CN 201210164316.5[P]. 2012.

WANG Jin-feng, ZHOU Hai, SONG Peng-fei, QIN De-zhao, PAN Fu-sheng. A high-strength Mg-Gd-Y-Zn-Mn alloy: China, CN201210164316.5[P]. 2012.

[6] GAO L, CHEN R S, HAN E H. Effect of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys[J]. Journal of Alloys and Compounds, 2009, 481: 379-384.

[7] 刘文娟. Mg-Al系镁合金及稀土元素(Ce,La)合金化后微观结构和腐蚀行为的研究[D]. 杭州: 浙江大学, 2012: 145-154.

LIU Wen-juan. Investigation of microstructure and corrosion behavior of Mg-Al series magnesium alloy with/without rare earth element (Ce, La) addition[D]. Hangzhou: Zhejiang University, 2012: 145-154.

[8] ARDELEAN H, SEYEUX A, ZANNA S, PRIMA F, FRATEUR I, MARCUS P. Corrosion processes of Mg-Y-Nd-Zr alloys in Na2SO4 electrolyte[J]. Corrosion Science, 2013, 73: 196-207.

[9] 吴文祥, 靳 丽, 董 杰, 章帧彦, 丁文江. Mg-Gd-Y-Zr高强耐热镁合金的研究进展[J]. 中国有色金属学报, 2011, 21(11): 2709-2718.

WU Wen-xiang, JIN Li, DONG Jie, ZHANG Zhen-yan, DING Wen-jiang. Research progress of high strength and heat resistant Mg-Gd-Y-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2709-2718.

[10] NEGISHI Y, T NISHIMURA, M KIRYUU. Phase diagrams of magnesiun-rich portion, aging characteristics and tensile properties of Mg-heavy rare earth metal(Gd,Dy)-Nd alloys[J]. Journal of Japan Institute of Light Metals, 1995, 45(2): 57-63.

[11] NIE J F, MUDDLE B C. Characterizations of strengthening precipitate phase in a Mg-Y-Nd alloy[J]. Acta Materialia, 2000, 48(8): 1691-1703.

[12] APPS P J, KARIMZADEH H, KING J F, LORIMER G W. Phase compositions in magnesium-rare earth alloys containing yttrium, gadolinium or dysprosium[J]. Scripta Materialia, 2003, 48(5): 475-481.

[13] 汤伊金, 章桢彦, 靳 丽, 董 杰, 丁文江. Mg-Gd系合金时效析出研究进展[J]. 中国有色金属学报, 2014, 24(1): 8-24.

TANG Yi-jin, ZHANG Zhen-yan, JIN Li, DONG Jie, DING Wen-jiang. Research progress on ageing precipitation of Mg-Gd alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 8-24.

[14] 谢中柱, 许并社, 孙 威. Mg-Gd-Nd合金极限高温时效析出相的研究[J]. 热加工工艺, 2011, 40(2): 170-172.

XIE Zhong-zhu, XU Bing-she, SUN Wei. Study on precipitating phases in Mg-Gd-Nd alloy aged at limiting high temperature[J]. Hot Working Technology, 2011, 40(2): 170-172.

[15] 李慧中, 郭菲菲, 刘楚明, 刘洪挺, 王海军, 梁霄鹏. 热处理及热挤压对Mg-10Gd-4.8Y-0.6Zr组织及常温力学性能的影响[J]. 粉末冶金材料科学与工程, 2010, 15(4): 338-343.

LI Hui-zhong, GUO Fei-fei, LIU Chu-ming, LIU Hong-ting, WANG Hai-jun, LIANG Xiao-peng. Effects of heating treatment and hot extrusion on microstructures and room temperature mechanical properties of Mg-10Gd-4.8Y-0.6Zr alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(4): 338-343.

[16] 万迎春, 刘楚明. 挤压及时效对Mg-8Gd-4.8Y-0.4Zr合金显微组织及力学特性的影响[J]. 兵器材料科学与工程, 2013, 36(5): 13-16.

WAN Ying-chun, LIU Chu-ming. Effect of extrusion and aging on microstructure and mechanical property of Mg-8Gd-4.8Y-0.4Zr alloy[J]. Ordnance Material Science and Engineering, 2013, 36(5): 13-16.

[17] 肖 阳, 张新明, 蒋 浩, 陈部湘. Gd和Y偏析对Mg-9Gd-4Y-0.6Zr和Mg-7Gd-4Y-0.6Zr合金组织性能的影响[J]. 中南大学学报(自然科学版), 2007, 38(1): 24-29.

XIAO Yang, ZHANG Xin-ming, JIANG Hao, CHEN Bu-xiang. Influence of Gd and Y elements segregation on microstructure and mechanical properties of Mg-9Gd-4Y-0.6Zr and Mg-7Gd-4Y-0.6Zr alloys[J]. Journal of Centra South University (Science and Technology), 2007, 38(1): 24-29.

[18] 彭卓凯, 张新明, 陈健美. Mn, Zr对Mg-Gd-Y合金组织与力学性能的影响[J]. 中国有色金属学报, 2005, 15(6): 917-922.

PENG Zhuo-kaiZHANG Xin-mingChen Jian-mei. Effects of Mn, Zr on microstructure and properties of Mg-Gd-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 917-922.

[19] LI D J, ZENG X Q, DONG J, ZHAI C Q, DING W J. Microstructure evolution of Mg-10Gd-3Y-1.2Zn-0.4Zr alloy during heat-treatment at 773K[J]. Journal of Alloys and Compounds, 2009, 468(1/2): 164-169.

[20] APPS P J, KARIMZADEH H, KING J F, LORIMER G W. Precipitation Reactions in magnesium-rare earth alloys containing Yttrium, Gadolinium of Dysprosium[J]. Scripta Materialia, 2003, 48(8): 1023-1028.

[21] 李慧中, 郭菲菲, 刘楚明, 刘洪挺, 王海军, 梁霄鹏, 赵家彦. Mg-10Gd-4.8Y-0.6Zr合金在520 ℃下的固溶处理行为[J]. 粉末冶金材料科学与工程, 2011, 16(3): 323-328.

LI Hui-zhong, GUO Fei-fei, LIU Chu-ming, LIU Hong-ting, WANG Hai-jun, LIANG Xiao-peng, ZHAO Jia-yan. Behavior of Mg-10Gd-4.SY-0.6Zr alloy during solution heat treatment at 520 ℃[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(3): 323-328.

[22] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, Ding W J. Precipitation in a Mg-10Gd-3Y-0.4Zr (wt.%) alloy during isothermal ageing at 250 ℃[J]. Journal of Alloys and Compounds, 2006, 421(1/2): 309-313.

[23] HOMMA T, OHKUBO T, HONO K, KAMADO S. Chemistry of nanoscale precipitates in Mg-2.1Gd-0.6Y-0.2Zr (at.%) alloy investigated by the atom probe technique[J]. Materials Sciences and Engineering A, 2005, 395(1): 301-306.

[24] NIE J F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys[J]. Scripta Materialia, 2003, 48(8): 1009-1015.

[25] 刘 俊, 陈明安, 马聪聪, 黄宇迪, 张新明, 邓运来. 第二相粒子在Mg-Gd-Y-Nd-Zr合金局部腐蚀中的作用机制[J]. 中国有色金属学报, 2013, 23(1): 15-21.

LIU Jun, CHEN Ming-an, MA Cong-cong, HUANG Yu-di, ZHANG Xin-ming, DENG Yun-lai. Effect of second phase particles on localized corrosion of Mg-Gd-Y-Nd-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 15-21.

Microstructure evolution and performance of Mg-8Gd-3Y-1Nd-0.5Zr alloy during heat treatment

FENG Yan, LI Xiao-geng, WANG Ri-chu, PENG Chao-qun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of heat treatments on the microstructures and properties of the Mg-8Gd-3Y-1Nd-0.5Zr alloy were studied. The cast Mg-8Gd-3Y-1Nd-0.5Zr alloy consists α-Mg, Mg(Gd,Y) second phases and eutectic phases of Zr-rich particle phase and β-Mg24Y5 reticular. After solid solution treatment at 520 ℃ for 24 h, the microstructure evolution of the alloy follows this sequence, α-Mg+β-Mg24Y5 phase + Mg(Gd,Y)→oversaturated α-Mg solid solution +Mg(Gd,Y) phase. After aged at 225 ℃, the second phases in the Mg-8Gd-3Y-1Nd-0.5Zr alloy precipitate following this sequence, Mg(S.S.S.S)→β″(DO19)→β′(CBCO)→β1(FCC)→β(FCC). The peak aging state occurs when the alloy is aged at 225 ℃ for 24 h. The room temperature tensile strength gets 231 MPa and the elongation rate gets 3.4%, respectively. Moreover, aging treatment improves the corrosion resistance of the alloy. After aged at 225 ℃ for 72 h, stable β(FCC) phase precipitates in the Mg-8Gd-3Y-1Nd-0.5Zr alloy, which express the best corrosion resistance. The lowest average hydrogen precipitation rate is 0.22 mL/(cm2·h).

Key words: Mg-8Gd-3Y-1Nd-0.5Zr alloy; solid solution treatment; microstructure; mechanical property; precipitation sequence

Foundation item: Project(2015JC3004) supported by the Science and Technology Plan Projects of Hunan Province, China; Project(2016JJ2147) supported by the National Science Foundation of Hunan Province, China

Received date: 2016-04-20; Accepted date: 2017-01-11

Corresponding author: WANG Ri-chu; Tel: +86-731-88836638; E-mail: rcwcsu@163.com

(编辑 李艳红)

基金项目:湖南省科技计划项目(2015JC3004);湖南省自然科学基金项目(2016JJ2147)

收稿日期:2016-04-20;修订日期:2017-01-11

通信作者:王日初,教授,博士;电话:0731-88836638;E-mail:rcwcsu@163.com