文章编号:1004-0609(2011)06-1265-07

Mo、V和Ag对粉末冶金Ti-5Al合金组织与力学性能的影响

肖代红,杨宝刚,申婷婷,袁铁锤,贺跃辉,王守仁

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用元素混合法制备粉末冶金Ti-Al-Mo-V-Ag合金,通过金相观察、扫描电镜及力学性能测试等方法研究Mo、V和Ag的添加及烧结温度对Ti-5Al合金的烧结行为、显微组织与力学性能影响,并对其作用机制进行探讨。结果表明:1 350 ℃烧结时,V与Mo的添加能改善烧结合金的压缩强度,单独添加Ag时,则降低基体合金的综合性能,但当Ag与Mo、V同时添加到基体合金中时,改变合金的显微组织,提高烧结合金的致密度与抗压缩强度,致密度能达到96%,抗压缩强度达到1 782 MPa。同时,烧结温度不同时,相同成分的粉末冶金Ti-5Al合金的显微组织与性能也表现出不同的特征。

关键词:钛合金;微合金化;烧结温度;显微组织;力学性能

中图分类号:TG 146.23 文献标志码:A

Effects of Mo, V and Ag additions on microstructure and mechanical properties of powder metallurgy Ti-5Al alloy

XIAO Dai-hong, YANG Bao-gang, SHEN Ting-ting, YUAN Tie-chui, HE Yue-hui, WANG Shou-ren

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The powder metallurgy (P/M) Ti-Al-Mo-V-Ag alloys were processed by powder metallurgy using the blended elemental (BE) technique. The effects of Mo, V and Ag additions and sintering temperature on the microstructures and mechanical properties of the Ti-5Al alloys were investigated using optical microscope, scanning electron microscope and mechanical properties tests. The results show that adding Mo or V elements improves the compression strength of the based alloys after sintering at 1 350 ℃, and Ag element addition decreases the properties of Ti-5Al alloy. However, adding Ag element with Mo and V elements increases the density and compressive strength of P/M Ti-5Al alloy. The relative density and compressive strength of the Ti-5Al-4Mo-4V-5Ag alloy are 96% and 1 782 MPa, respectively. Moreover, the sintering temperature also affects the microstructures and properties of the PM Ti-5Al based alloys.

Key words: titanium alloys; microalloying; sintering temperature; microstructure; mechanical properties

钛合金具有密度低、比强度高、屈强比高、塑韧性良好、耐腐蚀性好等优点,在军工和民用等领域具有广阔的应用[1-2]。扩大钛合金市场的瓶颈是钛的提取、熔炼、机加工很难,从而导致生产成本高[3-4]。粉末冶金技术由于在零部件近净形方面具有优势,能大大提高材料利用率,降低加工成本,并能获得均匀细小的显微组织,因此成为降低钛合金成本的重要技 术[3-6]。粉末冶金钛合金的研究主要集中在混合元素法((BE)、预合金法(PA)和快速凝固法(RS)等3种方法上,其中混合元素法无论是经济效益、成分选择及微观组织设计上,都比其它两种方法优越[7-8]。BE法钛合金产品的主要应用是工业钛过滤器、叶轮或整体叶盘等形状复杂的零件,如俄罗斯的伊尔114飞机发动机高压压气离心机叶轮和发动机轴支撑件。由于铝具有密度低、在钛中的固溶度大(质量分数超过6%)等特点,使得其成为钛合金中主要合金化元素之一。

目前已研制的低铝含量(2%~6%)粉末冶金钛合金因具有较高强度、良好耐热抗蠕变性能,而受到广泛的关注[9-12]。由于合金化元素对粉末冶金钛合金具有重要影响[13],为此,本文作者拟采用元素混合法制备Ti-5Al基合金,通过低压烧结,研究Mo、V和Ag等的添加及不同烧结温度对基体合金的组织与性能影响,为实际工业生产提供可行性参考。

1 实验

试验用钛合金的名义成分如表1所列,原料为钛粉、钼粉、铝粉、银粉、铝-钒中间合金粉,平均晶粒尺寸分别为48、1.5、2.6、0.7及74 μm。按照配比称量粉末后,在行星式球磨机中通过氩气保护进行湿磨24 h后,在真空干燥箱中干燥处理。干燥后的粉末采用钢模压制成型,压力为300 MPa。压坯在5 MPa 氩气环境中进行低压烧结,烧结温度分别为1 150、 1 250和1 350 ℃。烧结后样品密度采用阿基米德排水法测量。试样抛光后采用Kroll试剂腐蚀并进行金相观察。压缩测试的样品尺寸采用d 6 mm×7 mm,加载速率为1 mm/min。断口观察在FEI-Nano230型场发射扫描电镜上进行。

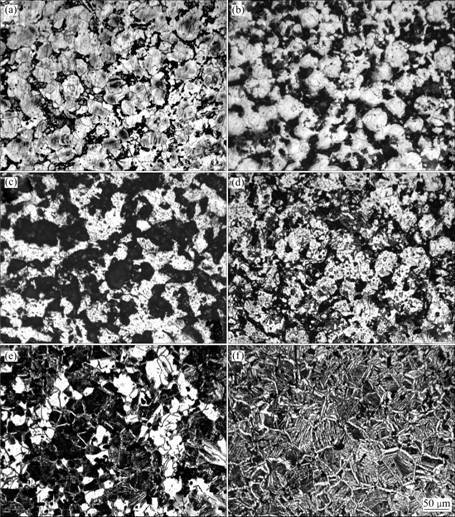

表1 试验合金的名义成分

Table 1 Nominal composition of samples

2 结果与分析

2.1 合金的显微组织

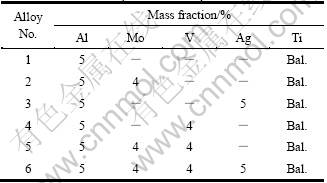

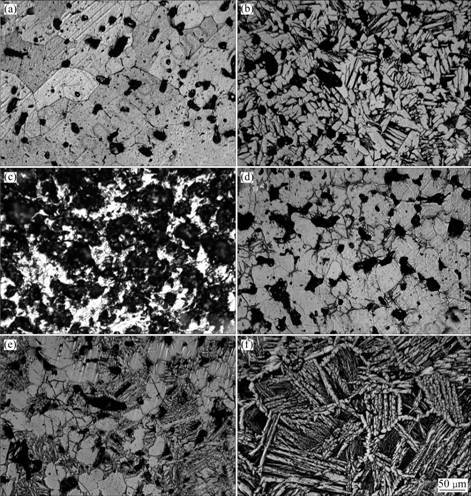

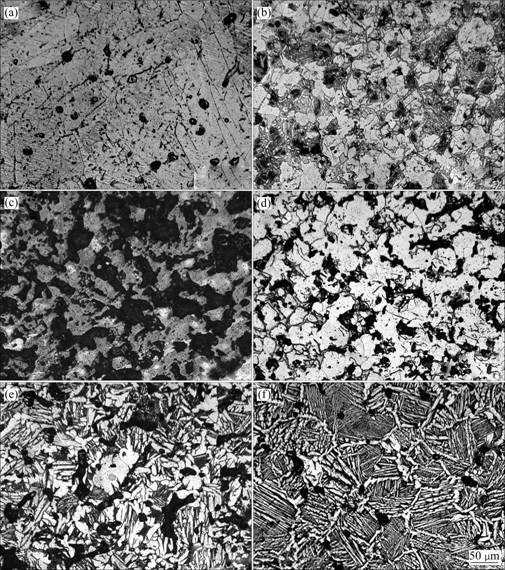

3种不同烧结温度下的金相显微组织如图1、2及3所示。很明显,在相同烧结温度下,不同成分的Ti-5Al基合金的组织明显不同。经1 350 ℃烧结后(见图1),随着添加合金元素的不同,合金中孔隙数量及显微组织明显不同,合金1为α型合金;而添加Mo的合金2,显微组织由原始β晶粒及粗大片状α相组成。含Ag合金3中,孔隙数量较多且粗大,合金4的主要组织为等轴α相及少量β相,而合金5是典型的α+β双态组织,由等轴α相、原始β晶粒、β晶粒内的片状α相及α晶团组成。当同时含Mo、V、Ag时,合金6的组织为魏德曼组织(Widmanstaetten structure),这种组织由原始β晶粒、片状α相及α晶团组成。经1 250 ℃烧结后(见图2),合金1为α型合金,合金3中孔隙数量较多且粗大,合金2与4的主要组织为等轴α相及少量β相,合金5是典型的α+β双态组织,而合金6的组织为魏德曼组织。当降低烧结温度至 1 150 ℃后(见图3),合金1与2为α型合金,合金3中孔隙数量较多且粗大,合金4的主要组织为等轴α相及少量β相,合金5是典型的α+β双态组织,而合金6的组织为魏德曼组织。

图1 试样在1 350 ℃烧结后的金相组织

Fig.1 Optical microstructures of samples after sintering at 1 350℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

图2 试样在1 250 ℃烧结后的金相组织

Fig.2 Optical microstructures of samples after sintering at 1 250 ℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

另外,对相同成分的合金,不同烧结温度下,其显微组织也有明显的不同。对合金1,当烧结温度降低时,合金尽管均为α型合金,但晶粒尺寸减小。而合金2的烧结温度从1 350 ℃降低到1 150 ℃时,其组织也发生了明显的变化,1 350 ℃时,合金的组织由 α相与β相组成,而1 150 ℃时,合金的组织为α相。合金3在不同烧结温度下烧结后,均含有大量的空隙,只是孔隙数量不同。而对合金6,不同烧结下的组织均为魏德曼组织,只是片状α相的厚度不同,1 350 ℃烧结时的α相的厚度较1 150 ℃大。

图3 试样在1 150 ℃烧结后的金相组织

Fig.3 Optical microstructures of samples after sintering at 1 150 ℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

粉末冶金钛合金的显微组织主要受合金成分影响,尽管Mo、V、Ag均为β相稳定元素,但所起的作用却不同。Mo与V元素是同晶型β相稳定元素,它们与β相晶格类型相同,可无限固溶于β相中,无化合物相产生,主要起到固溶强化作用。而Ag元素是一种共析型β相稳定元素,与钛会发生共析转变,生成TiAg化合物相(见图5(f)),较强烈降低(α+β)/β相点,使得合金中易生成片状组织[14]。烧结温度不同时,由于各元素扩散激活能不同,所产生的组织也不同,而高温烧结有助于合金元素的扩散,使β相稳定元素在基体合金中的固溶更为充分,从而在炉冷过程中,得到有效的析出。

2.2 合金的力学性能

对1 350 ℃烧结试样进行密度测试显示(见图4(a)),合金1的相对密度达到了90%;添加4%Mo合金2的相对密度达到了93%;添加5%Ag合金3的密度则降低至79%;而在基体合金中添加4%V时,合金4的相对密度相对合金1的没有明显变化;当同时在基体合金中添加4%Mo和4%V时,合金5的相对密度达到94%;而在合金5的基础上,再添加5%Ag后,合金6的相对密度提高到96%以上。对烧结态合金进行压缩性能测试显示(见图4(b)),基体合金的抗压塑强度达到了1 485 MPa,而含Mo合金2的抗压 缩强度提高到了1 634 MPa,但只添加Ag或V的合金3和4的抗压缩强度分别只有385 MPa和901 MPa。而同时添加Mo和V的合金5的抗压缩强度达到1 531 MPa,当在合金5的基础上进一步添加5%Ag时,合金6的抗压缩强度则达到1 782 MPa。

1 250 ℃烧结后的性能如图4(c)与(d)所示,合金1的致密度为88%,合金2的致密度则为92%,合金3的致密度则降低到78%,合金4的致密度为85%,合金5的致密度提到91%,当同时添加Mo、V和Ag时,合金6的致密度进一步提到94.5%。压缩性能测试显示,合金1、2、5和6的抗压缩强度分别达到了1 356、1 427、1 498和1 601 MPa。

经1 150 ℃烧结后(见图4(e)与(f)),6种合金的致密度分别为85.7%、89.6%、74.5%、82.7%、90.7%和93%;而抗压缩强度分别为1 250、1 332、287、513、1 400和1 580 MPa。1 250 ℃及1 150 ℃烧结后,合金成分对材料的致密度及压缩性能的影响与1 350 ℃时相类似。

上述表明,在Ti-5Al合金中单独添加Mo或V,并不改变基体合金的致密度,而单独添加Ag则降低了基体合金的密度,但Ag与Mo、V同时添加时,基体合金的密度反而得到提高。而抗压缩强度表明,在Ti-5Al基合金中单独添加V或Ag时,合金的抗压缩强度并未提高,但同时添加Mo、V和Ag时,合金的抗压缩强度明显提高,显示出Ag只有通过Mo与V共同添加时,才能发挥其作用。

图4 试样在1 350、1 250及1 150 ℃烧结后的性能比较

Fig.4 Properties comparison of samples after sintering at 1 350 ℃((a), (b)), 1 250 ℃((c), (d)) and 1 150 ℃((e), (f))

同时分析也显示,对相同成分的Ti-5Al基粉末冶金合金,随着烧结温度的降低,合金的致密度与抗压缩强度分别降低。如合金6在1 350 ℃,合金的致密度与压缩强度分别达到96%与1 782 MPa;而经1 150 ℃烧结后,合金的致密度与抗压缩强度分别降低到93%与1 580 MPa。

根据图4的结果可知,不同成分合金的强度与其致密度有一定的关系。DUCKWORTH[15]认为,随着致密度的增大,烧结合金的强度具有呈指数增大趋势。而本研究中,由于合金成分及烧结温度的不同,烧结体的致密度也不同,其中合金3的致密度最低,而合金6的致密度最高,因此,合金6的抗压缩强度也相应最大。

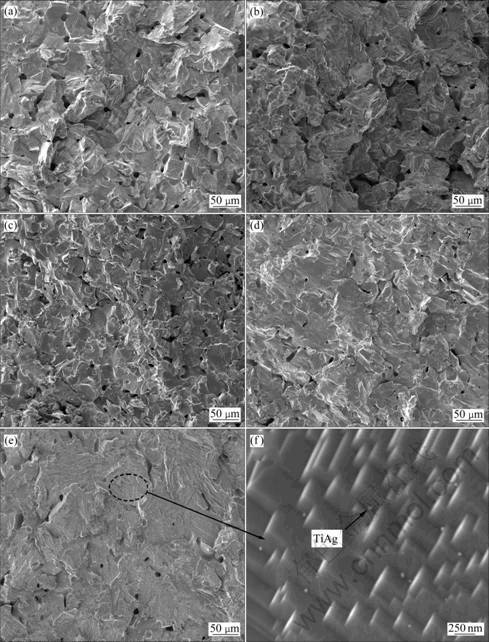

2.3 合金的断口组织

对1 350 ℃烧结后合金的压缩断口进行SEM观察(见图5),合金中均含有孔洞,这是由于烧结过程中,并没有完全致密化所产生的。同时添加Mo、V的合金5(见图5(d))相对合金1(见图5(a))、合金2(见图5(b))和合金3(见图5(c)),孔洞数量减少。而在合金5中添加Ag时,合金6(见图5(e))中的孔洞明显减少。这与图4(a)中合金相对密度的变化一致。从图5中也看到,5种合金的断裂主要都是穿晶断裂与沿晶断裂。但进一步分析显示,在合金2、5及6中,有片状痕迹,特别是合金6中的片状相更为明显,能谱测试显示这些片状相是α相。对合金6中片状相的高倍组织分析表明(见图5(f)),这些片状相由平均尺寸120 nm的层片状组成,在层片之间有纳米级的球状TiAg化合物,这些化合物可起到弥散强化作用。

图5 合金在1 350 ℃烧结后的压缩断口形貌

Fig.5 Compressive fracture surface morphologies of alloys 1(a), 2(b), 4(c), 5(d) and 6((e), (f)) after sintering at 1 350 ℃

3 结论

1) 在Ti-5Al合金中,单独添加5%Ag或4%V时,合金的致密度及抗压缩强度降低,而添加4%Mo则提高了合金的致密度与抗压缩强度。

2) 当5%Ag元素与4%Mo及4%V同时添加时,合金的致密度及抗压缩强度明显得到提高。1 350 ℃烧结后,Ti-5Al-4Mo-4V-5Ag合金的致密度与抗压缩强度分别达到96%与1 782 MPa。

3) Mo、V和Ag的添加改变基体合金的物相组成及显微组织,含4%Mo、4%V和5%Ag的Ti-5Al合金为典型魏德曼组织,片状析出相中含有纳米级的TiAg化合物相。

4) Ti-5Al基合金随着烧结温度的提高,其致密度与抗压缩强度得到提高。

REFERENCES

[1] MOISEYEV V N. Titanium alloys: Russian aircraft and aerospace applications[M]. Wikipedia: Taylor & Francis Group, 2008: 147-153.

[2] LEYENS C, PETERS M. Titanium and titanium alloys[M]. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2003: 351-368.

[3] 汤慧萍, 刘 咏, 韦伟峰, 陈丽芳. 添加稀土元素对粉末冶金Ti合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2004, 14(2): 244-249.

TANG Hui-ping, LIU Yong, WEI Wei-feng, CHEN Li-fang. Effect of rare-earth element addition on microstructure and mechanical properties of P/M titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 244-249.

[4] HANSON A D, RUNKLE J C, WIDMER R, HEBEISSEN J C. Titanium near net shapes from elemental powder blends[J]. International Journal of Powder Metallurgy, 1990, 26(2): 157-164.

[5] ROBERTSON I M, SCHAFFER G B. Design of titanium alloy for efficient sintering to low porosity[J]. Powder Metallurgy, 2009, 52(4): 311-315.

[6] 汤慧萍, 黄伯云, 刘 咏, 欧阳洪武. 粉末冶金钛合金致密化研究的进展[J]. 稀有金属材料与工程, 2003, 32(9): 677-680.

TANG Hui-ping, HUANG Bai-yun, LIU Yong, OUYANG Hong-wu. Progress in the densification of powder metallurgical titanium alloys[J]. Rare Metal Materials and Engineering, 2003, 32(9): 677-680.

[7] TAKAHIRO F, OGAWA A, OUCHI C, TAJIMA H. Microstructure and properties of titanium alloy produced in the newly developed blended elemental powder metallurgy process[J]. Materials Science and Engineering A, 1996, 213(1/2): 148-153.

[8] SUN F S, OSOURCE Y K. Development of cost effective blended elemental powder metallurgy Ti alloys[C]// ORLANDOF L. Innovations in Titanium Technology. Warrendale (PA): TMS, 2007: 19-27.

[9] 赵 瑶, 贺跃辉, 江 垚.粉末冶金Ti6Al4V合金的研制进展[J].粉末冶金材料科学与工程, 2008, 13(2):70-78.

ZHAO Yao, HE Yue-hui, JIANG Yao. Progress of powder metallurgy Ti6Al4V alloy[J]. Powder Metallurgy Materials Science and Engineering, 2008, 13(2):70-78.

[10] TAMIRISAKANDALA S. BHAT R B, RAVI V A. Powder metallurgy Ti-6Al-4V-xB alloys: processing, microstructure, and properties[J]. JOM, 2004, 56(5): 60-63.

[11] AZEVEDO C R F, RODRIGUES D, NETO F B. Ti-Al-V powder metallurgy (PM) via the hydrogenation dehydrogenation (HDH) process[J]. Journal of Alloys and Compounds, 2003, 353(1/2): 217-227.

[12] IVASISHIN O M, SAVVAKIN D G, FROES F, MOKSON V C. Synthesis of alloy Ti-6Al-4V with low residual porosity by a powder metallurgy method[J]. Powder Metallurgy and Metal Ceramics, 2002, 41(7/8): 382-390.

[13] LIU Yong, CHEN Li-fang, WEI Wei-feng, TANG Hui-ping. Improvement of ductility of powder metallurgy titanium alloys by addition of rare earth element[J]. Journal of Materials Science and Technology, 2006, 22(4): 465-469.

[14] 莫 畏. 钛[M]. 北京: 冶金工业出版社, 2008: 252-257.

MO Wei. Titanium[M]. Beijing: Metallurgical Industry Press, 2008: 252-257.

[15] DUCKWORTH W. Discussion of ryshkewitch paper[J]. Journal of American Ceramics Society, 1953, 36: 68-75.

(编辑 李艳红)

基金项目:国家自然科学基金创新研究群体科学基金资助项目(51021063);国家杰出青年科学基金资助项目(50825102);粉末冶金国家重点实验室创新基金资助项目(PM2010);中国博士后科学基金特别资助项目(200801348);湖南省科技计划博士后专项资助项目(2009RS3025)

收稿日期:2010-06-28;修订日期:2010-09-28

通信作者:肖代红,副教授,博士;电话:0731-88877880;E-mail: xdh0615@163.com