Al-Zn-Mg-Sc-Zr合金板材制备过程中组织性能的演变

周向1,尹志民1,段佳琦1,赵凯1,何振波1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 东北轻合金有限责任公司,黑龙江 哈尔滨,150060)

摘要:采用拉伸力学性能、硬度、电导率测试以及X线衍射(XRD)物相分析和电子显微分析技术研究Al-Zn-Mg-Sc-Zr合金板材在制备过程中的组织性能演变。研究结果表明:铸态合金在350 ℃/8 h单级均匀化处理过程中析出细小弥散的Al3(Sc,Zr)粒子,但同时也析出大量粗大T相,合金过饱和度降低,强度下降;在350 ℃/8 h+470 ℃/24 h双级均匀化第二级过程中,T相回溶入基体,而Al3(Sc,Zr)粒子特性基本上没有发生变化;由于Al3(Sc,Zr)粒子的抑制再结晶作用,合金热轧、退火以及冷轧后固溶状态下为纤维状变形组织;时效后合金析出大量细小弥散分布的η′相,具有很强的强化效果。

关键词:Al-Zn-Mg合金;Al3(Sc,Zr)粒子;热处理;组织性能

中图分类号:TG146.21 文献标志码:A 文章编号:1672-7207(2011)12-3680-06

Microstructure and properties evolution of Al-Zn-Mg-Sc-Zr alloy sheet in different treat conditions during preparation process

ZHOU Xiang1, YIN Zhi-min1, DUAN Jia-qi1, ZHAO Kai1, HE Zhen-bo1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd., Harbin 150060, China)

Abstract: The Microstructure and properties evolution of Al-Zn-Mg-Sc-Zr alloy sheet in different treat conditions during preparation process were studied by hardness, tensile tests, electric conductivity measurement, X-ray diffraction (XRD) and electronic microscopy analysis. The results show that though fine dispersed Al3(Sc,Zr) particles precipitated in single homogenization treated at 350 ℃ for 8 h, the strength of the alloy decreases on account of the decline of supersaturation because of the precipitation of T phase. During two-step homogenization, treated at 350 ℃ for 1 h followed by 470 ℃ for 24 h treatment, T phase dissolves into the matrix again, while Al3(Sc,Zr) particles remain almost the same as the size in the second step. Deformation microstructure is observed in rolling, annealing and solution state due to the resistance effect to recrystallization by Al3(Sc,Zr) particles. During the aging process, the strength increases significantly owing to the fine dispersed η′ phases precipitated from the solid solution.

Key words: Al-Zn-Mg alloy; Al3(Sc,Zr) particle; heat treatment; microstructure and properties

Al-Zn-Mg合金具有较高的强度、良好的塑性和可焊性、优良的耐腐蚀性能,被广泛应用于各种飞机的结构件和其他要求强度高的高应力焊接结构件,是目前许多军用和民用飞机、交通运输工具中不可缺少的重要结构材料。在Al-Zn-Mg合金的基础上,俄罗斯全俄轻合金研究所与全俄复合材料研究院合作,复合添加合金元素钪和锆,开发出了新型中强可焊Al-Zn-Mg-Sc-Zr合金 [1]。目前,国内外对含Sc的Al-Mg和Al-Zn-Mg(-Cu)合金进行了研究。Ocenasek等[2]研究了添加Sc和Zr对Al-Mg合金再结晶行为的抑制作用。Yin等[3-4]研究了含Sc,Zr的Al-Mg和Al-Zn-Mg合金组织与性能,认为合金中Sc,Zr主要以初生Al3(Sc,Zr)和次生Al3(Sc,Zr) 2种形式存在,初生Al3(Sc,Zr)粒子可强烈细化合金的铸态晶粒组织,次生Al3(Sc,Zr)粒子能有效抑制合金加工和热处理过程中的再结晶。Norman等[5]证实了Sc对7000系合金焊接性能的改善作用。Li等[6-7]还研究了微量Sc和Zr对Al-Zn-Mg-Cu合金组织性能的影响。在此,本文作者研究Al-Zn-Mg-Sc-Zr合金板材制备过程中的组织性能演变,旨在为该合金的工程化生产和应用提供理论和实验依据。

1 材料与实验方法

1.1 实验材料

实验用Al-Zn-Mg-Sc-Zr合金由东北轻合金有限责任公司提供,合金成分(质量分数)见表1。合金采用半连续铸造,铸锭在350 ℃/8 h单级均匀化和350 ℃/8 h+470 ℃/24 h双级均匀化后经热轧、中间退火、冷轧成板材,冷轧板经470 ℃/1 h固溶后水淬,于120 ℃/24 h时效后得到成品板材。

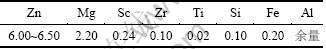

表1 合金的化学成分

Table 1 Chemical composition of experimental alloy %

1.2 实验方法

采用HBE-3000硬度计和D60K数字金属电导率测量仪对不同处理状态合金试样进行硬度和电导率进行测试。拉伸力学性能测试在CSS电子万能试验机上进行,拉伸速度为2 mm/min。X线衍射(XRD)物相分析在日本理学D/max-2500/PC型X线衍射仪上进行。采用扫描电镜背散射电子成像技术和TECNAIG2 20透射电镜(加速电压为200 kV)对合金显微组织进行观察。

2 实验结果

2.1 不同处理状态合金拉伸力学性能、硬度和电导率

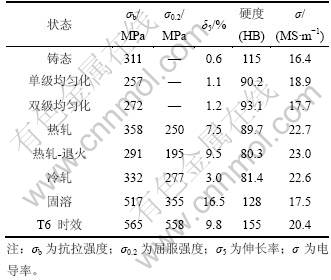

Al-Zn-Mg-Sc-Zr合金板材制备过程中不同处理状态合金拉伸力学性能、硬度和电导率测试结果见表2。

表2 不同处理状态合金拉伸力学性能、硬度和电导率

Table 2 Tensile properties, Brinell hardness and conductivity of experimental alloy

从表2可知:铸态合金经均匀化后,抗拉强度和硬度下降,但双级均匀化态的下降幅度较小,伸长率和电导率都略有升高;双级均匀化态合金经热轧后抗拉强度、伸长率和电导率都升高;热轧板材退火后,合金强度、硬度降低,伸长率升高;在随后的冷轧过程中,合金强度、硬度升高,伸长率则显著降低;冷轧板经470 ℃/1 h固溶后,抗拉强度、屈服强度、硬度和伸长率都有了显著提高,而电导率则大幅度降低;于120 ℃/24 h时效后,合金强度、硬度继续增加,伸长率降低,而电导率则较固溶态时有所提高。

2.2 不同处理状态合金显微组织

2.2.1 SEM显微组织和能谱分析

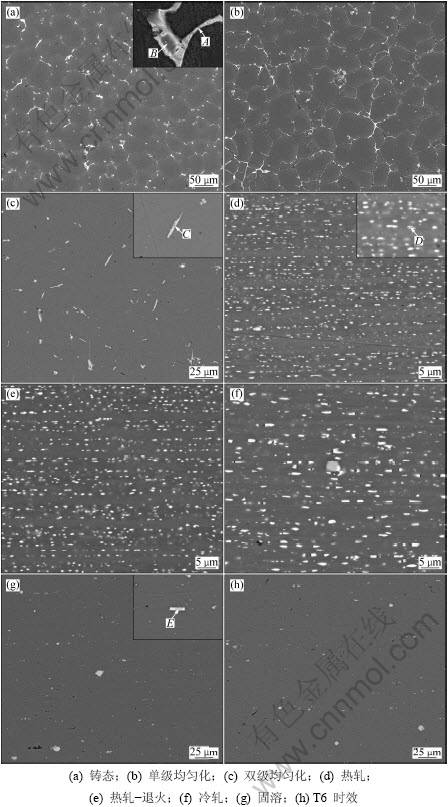

Al-Zn-Mg-Sc-Zr合金板材制备过程中不同处理状态下合金SEM显微组织如图1所示。

由图1可知:铸态合金为细小均匀的等轴晶,主要由α(Al)固溶体及晶界上的低熔点共晶相组成,能谱分析和后续XRD分析表明晶界上主要为T相(Mg32(Al,Zn)49)和富Fe、Mn的杂质相。铸态合金单级均匀化后,T相并没有消除;双级均匀化后,T相回溶到基体之中。热轧态、热轧-退火态和冷轧态板材铝基体上分布着大量第二相颗粒, 沿轧制方向排布;能谱和后续XRD物相分析表明,该第二相颗粒为热轧过程中析出的T相。于470 ℃固溶1 h后,热轧过程中析出的T相几乎完全固溶入基体,合金中只残留少量的Fe和Mn杂质相。经T6时效处理后合金SEM显微组织主要由铝基体和Fe和Mn杂质相组成。

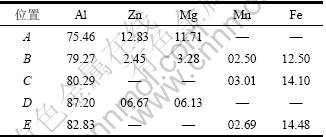

图1中A~E各点EDS能谱分析(原子数分数)见表3。

图1 Al-Zn-Mg-Sc-Zr合金SEM微观形貌

Fig.1 SEM images of Al-Zn-Mg-Sc-Zr alloy

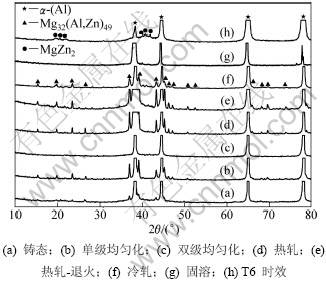

2.2.2 XRD物相分析

Al-Zn-Mg-Sc-Zr合金板材制备过程中不同处理状态合金的XRD物相分析结果如图2所示。

由图2可知:铸态和单级均匀化合金主要由α(Al)基体和在T相(Mg32(Al,Zn)49)组成,但单级均匀化态T相衍射峰较铸态更明显。而双级均匀化态合金主要由α(Al)基体组成,并没有发现T相。轧制后T相衍射峰再次出现,热轧态、热轧-退火态和冷轧态合金XRD图谱并无太大差别。合金经470 ℃固溶1 h后,T相完全溶入基体中;于120 ℃时效24 h后,合金XRD图谱中出现MgZn2的衍射峰。

表3 图1中A~E各点EDS结果

Table 3 EDS analysis results of points marked in Fig.1 %

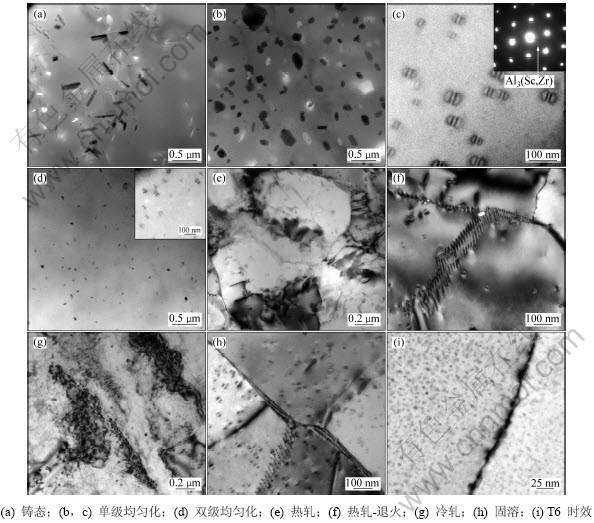

2.2.3 TEM显微组织

Al-Zn-Mg-Sc-Zr合金板材制备过程中不同状态合金板材透射电镜显微组织如图3所示。由图3可知:铸态合金晶内除基体外还存在一些分布不均匀棒状T相。铸态合金经350 ℃/8 h单级均匀化后晶内棒状T相较铸态分布更均匀,并且析出了大量与基体共格的马蹄状Al3(Sc, Zr)粒子;经350 ℃/8 h+470 ℃/24 h双级均匀化后,晶内第二相几乎全部回溶到铝基体中。热轧态合金主要由大量胞状组织构成,胞壁位错密度高,胞内位错密度低。热轧板经370 ℃/2 h退火后,胞状组织规整化,胞壁位错密度降低,亚晶界位错墙明显。冷轧态合金中有大量密集的位错缠结。冷轧板经470 ℃/1 h固溶后,位错缠结消失,亚晶清晰可见,还可以看到大量细小弥散分布的Al3(Sc,Zr)粒子。于120 ℃/24 h时效后,晶粒内部析出大量细小弥散η′相,晶界处有连续链状η平衡相析出。

图2 不同处理状态Al-Zn-Mg-Sc-Zr合金XRD物相分析

Fig.2 XRD patterns of Al-Zn-Mg-Sc-Zr alloy

图3 Al-Zn-Mg-Sc-Zr合金板材透射电镜显微组织

Fig.3 TEM images of Al-Zn-Mg-Sc-Zr alloy

3 分析与讨论

3.1 均匀化过程中合金组织性能的演变

Mondolfo等[8-9]指出Zn/Mg为0.14%~0.40%(质量分数)的铝合金中,T相倾向于在较高的温度下析出,而MgZn2平衡相则倾向于在低温下析出。在半连续铸造过程中,由于熔体结晶后的铸锭冷却速度很快,铸态组织通常为非平衡凝固共晶组织。研究合金铸态组织主要为亚稳的过饱和固溶体以及凝固过程中形成的T相。由于单级均匀化的温度没有达到T相的溶解温度,T相并不溶入基体;另一方面,亚稳的过饱和固溶体在单级均匀化过程中会分解析出粗大的T相和细小弥散分布的Al3(Sc,Zr)粒子。在双级均匀化过程中,由于第2级均匀化温度很高,第1级均匀化过程中析出的T相在第2级均匀化过程中又逐渐回溶入基体固溶体中,而Al3(Sc,Zr)粒子因热稳定性高而不回溶。

合金的强度和硬度与基体的过饱和程度、第二相的粒度、粒形和物相结构密切相关。单级均匀化处理过程中,弥散的Al3(Sc,Zr)粒子和大量粗大T相析出。一方面,弥散的Al3(Sc,Zr)粒子有利于提高强度和硬度;但另一方面,由于析出温度较高,析出粗大的T相,同时过饱和度降低,导致合金强度、硬度大幅度下降。双级均匀化过程中,T相又回溶到基体中,使过饱和度增大,但双级均匀化态的过饱和度仍小于铸造时激冷的过饱和度。因此,双级均匀态合金强度和硬度比单级均匀化态要高,但较铸态有所降低。

合金的电阻率与组织结构有关。按Mathiessen的理论[10],合金的电阻率可以表示如下:

ρ=ρ0+Δρ固溶+Δρ析出+Δρ空位+Δρ位错+Δρ晶界

式中:ρ为合金的电阻率,ρ0为纯铝的电阻率;Δρ固溶为添加合金元素形成固溶体引起的电阻率变化值; Δρ析出为过饱和固溶体分解析出引起的电阻率变化值;Δρ空位,Δρ位错和Δρ晶界分别为空位、位错和晶界变化引起的电阻率变化值。

研究表明,在多组元合金中,对电阻率影响最大的是Δρ固溶,其次为Δρ析出[10]。合金中有第二相粒子析出时,电阻率变化的主要因素有2个方面:一是过饱和固溶体的分解,固溶度减小,晶格正常化,使合金电阻率下降,电导率上升;其次是第二相粒子从过饱和固溶体中析出,阻碍电子运动,增大散射概率,且合金结构由单相变为复相,电导率下降。

研究合金在单级均匀化过程中第二相粒子析出,固溶度减小引起的电导率上升比第二相粒子对电子的附加散射引起的电导率下降作用要大,因此,单级均匀化过程中合金的电导率提高。双级均匀化第2级均匀化中,T相回溶入基体,固溶度增大,因此,双级均匀化电导率较单级均匀化态小。

3.2 变形过程中合金组织性能的演变

由实验结果可知Al-Zn-Mg-Sc-Zr合金在均匀化处理过程中析出次生Al3(Sc,Zr)粒子,粒子细小、均匀、弥散,呈蹄印状且与基体共格,满足阻碍再结晶的要求(粒子间距λ<1 μm,粒子直径d<0.3 μm)[11]。因此,热轧板为非再结晶组织,而且在热轧板高温退火过程中,基体位错密度有所降低,而Al3(Sc,Zr)粒子并无明显变化,仍与基体保持共格关系,钉扎亚晶界和位错,阻碍晶界的迁移和亚晶粒的长大[12-13],变形组织得以保留。在合金热轧过程中,引入了一定量的空位和位错等缺陷,这些缺陷成为新相形核的有利位置,使得T相的形核能降低,T相又重新析出,因此,合金的电导率升高。退火后合金中位错密度较热轧态有所降低,冷轧后有重新引入了较多的位错缠结。在退火和冷轧过程中,由于没有明显固溶度变化,因此,对电导率的影响不大。

3.3 固溶时效过程中合金组织性能的演变

Al-Zn-Mg合金主要通过固溶-时效析出而强化,获得高过饱和度的固溶体,是时效析出强化的前提。实验结果表明,冷轧板经470 ℃固溶1 h后,热轧过程中重新析出的T相充分固溶入基体,基体过饱和度增大固溶强化效果明显。因此,固溶态合金较冷轧态强度和硬度有显著提高,电导率大幅度降低。在固溶过程中并未发生明显的再结晶现象,仍然保持纤维状的加工组织。这是由于在均匀化过程中,析出的Al3(Sc,Zr)粒子能强烈钉扎亚晶界和位错,阻碍晶界的迁移和亚晶粒的长大[12-13]。

Al-Zn-Mg合金沉淀相的析出序列为:αsss (过饱和固溶体)→GP区→η′过渡相(亚稳态MgZn2)→η平衡相(MgZn2)[14-15]。合金在时效过程中的强度和硬度的变化主要由GP区、η′和η等沉淀相的数量和分布所决定。本实验所研究的合金经120 ℃/24 h时效后,过饱和固溶体中析出大量细小弥散与基体有较好的共格关系的η′相,对合金有很强的强化效果。弥散η′相粒子对合金屈服强度的贡献可以用奥罗万(Orowan)绕过机制[16]来解释:

式中:Δτ为使位错线通过粒子所需的临界切应力;G为剪切模量;φ为质点体积分数;r为质点半径;b为柏氏矢量;r0为位错芯半径。绕过机制的强化效果随质点体积分数增大和尺寸的减小而增大。由于位错每绕过1次粒子就留下1个位错环,位错环的存在使粒子间距减小,后续的位错绕过粒子更加困难。因此,与固溶态相比,合金时效后强度和硬度升高。

4 结论

(1) Al-Zn-Mg-Sc-Zr铸态合金单级均匀化后,过饱和固溶体分解析出T(Mg32(Al,Zn)49)相和细小弥散的Al3(Sc,Zr)相;在双均级均匀化第2级过程中,T相回溶到基体,而Al3(Sc,Zr) 粒子由于热稳定性高不回溶。

(2) 由于Al3(Sc,Zr)粒子的存在,合金热轧后为纤维状未再结晶组织,热轧板退火后,基体位错密度有所降低,Al3(Sc,Zr)粒子并无明显长大。

(3) 在固溶过程中,T相溶解但细小弥散的Al3(Sc,Zr)粒子仍然存在,合金依然为纤维状未再结晶组织,时效后合金析出大量弥散细小的η′相,具有很强的强化效果。

(4) 于120 ℃/24 h时效态Al-Zn-Mg-Sc-Zr合金成品板材抗拉强度、屈服强度、伸长率和电导率分别为565MPa,558 MPa,9.8%和20.4 MS/m。

参考文献:

[1] 尹志民, 潘青林, 姜峰, 等. 钪和含钪合金[M]. 长沙: 中南大学出版社, 2007: 425.

YIN Zhi-min, PAN Qing-lin, JIANG Feng, et al. Scandium and its alloys[M]. Changsha: Central South University Press, 2007: 425.

[2] Ocenasek V, Slamova M. Resistance to recrystallization due to Sc and Zr addition to Al-Mg alloys[J]. Materials Characterization, 2001, 47(2): 157-162.

[3] YIN Zhi-min, JIANG Feng, PAN Qing-lin, et al. Microstructures and mechanical properties of Al-Mg and Al-Zn-Mg based alloys containing minor scandium and zirconium[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(3): 515-520.

[4] 肖静, 尹志民, 黄继武, 等. 微量钪对Al-Zn-Mg-Zr合金组织与性能的影响[J]. 中南大学学报: 自然科学版, 2008, 39(5): 975-979.

XIAO Jing, YIN Zhi-min, HUANG Ji-wu, et al. Effects of minor Sc on microstructure and properties of Al-Zn-Mg-Zr alloy[J]. Journal of Central South University: Science and Technology, 2008, 39(5): 975-979.

[5] Norman A F, Hyde K, Costelloet F, et al. Examination of the effect of Sc on 2000 and 7000 series aluminum alloy castings: for improvements in fusion welding[J]. Materials Science and Engineering A, 2003, 354(1/2): 188-198.

[6] LI Wen-bin, PAN Qing-lin, ZOU Liang, et al. Effects of minor Sc on the microstructure and mechanical properties of Al-Zn-Mg-Cu-Zr based alloys[J]. Rare Metals, 2009, 28(1): 102-106.

[7] ZOU Liang, PAN Qing-lin, HE Yun-bin, et al. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 340-345.

[8] Mondolfo L F. The aluminum–magnesium–zinc alloys[M]. Rome: Revere Copper and Brass Inc, 1967: 12.

[9] Charit I, Mishra R S. Low temperature superplasticity in a friction-stir-processed ultrafine grained Al-Zn-Mg-Sc alloy[J]. Acta Materialia, 2005, 53(15): 4211-4223.

[10] 田莳, 李秀臣, 刘正堂. 金属物理性能[M]. 北京: 航空工业出版社, 1994: 36.

TIAN Shi, LI Xiu-Chen, LIU Zheng-tang. Physical properties of metal[M]. Beijing. Aviation Industry Press, 1994: 36.

[11] 谢优华, 杨守杰, 戴圣龙, 等. 含锆超高强铝合金的研究及发展概况[J]. 材料导报, 2002, 16(5): 8-10.

XIE You-hua, YANG Shou-jie, DAI Sheng-long, et al. Research and development of ultra-high strength aluminum alloys containing zirconium[J]. Materials Review, 2002, 16(5): 8-10.

[12] Riddle Y W, Sanders T H. Recrystallization performance of AA7050 varied with Sc and Zr[C]//Murch G E. Mater Sci Forum 331-337. Switzerland: Trans Tech Publications Inc, 2000: 799-803.

[13] Senkov O N, Bhat R B, Senkova S V, et al. Microstructure and properties of cast ingots of Al-Zn-Mg-Cu alloys modified with Sc and Zr[J]. Metall Mater Trans A, 2005, 36(8): 2115-2126.

[14] WU Ling-mei, Seyring M, Rettenmayr M, et al. Characterization of precipitate evolution in an artificially aged Al-Zn-Mg-Sc-Zr alloy[J].Materials Science and Engineering A, 2010, 527(4/5): 1068-1073.

[15] LI Xing-zhong, Hansen V, Gjonnes J, et al. HREM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materialia, 1999, 47(9): 2651-2659.

[16] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 447-478.

ZHEN Zi-qiao. Fundamentals of materials science[M]. Changsha: Central South University Press, 2005: 447-478.

(编辑 赵俊)

收稿日期:2010-12-15;修回日期:2011-03-20

基金项目:国家民口配套项目(JPPT-115-2-948)

通信作者:尹志民(1946-),男,湖南湘乡人,教授,从事铝合金组织与性能的研究;电话:0731-88830262;E-mail:zmyin@163.com