文章编号:1004-0609(2011)11-2744-07

深过冷Fe-Mo合金中初生α-Fe相的快速生长

张 波, 鲁晓宇, 代富平, 阮 莹

(西北工业大学 应用物理系,西安 710072)

摘 要:采用落管无容器处理技术实现Fe-8%Mo和Fe-26%Mo合金的深过冷快速凝固。结果表明:大尺寸Fe-8%Mo合金液滴的凝固组织由α-Fe枝晶晶粒组成,溶质Mo主要富集于晶界处。随着合金粒子直径的减小,α-Fe相组织形态由粗大枝晶向等轴晶转变并显著细化,同时α-Fe相的微观偏析逐渐减弱。当粒子直径减小到约100 μm时,发生显著的溶质截留效应,过冷度和冷却速率的增大抑制了溶质Mo的扩散。大尺寸Fe-26%Mo合金液滴的快速凝固组织由残余α-Fe相和层片共析组织(μ+α-Fe)组成,且随着粒子直径的减小,凝固组织由层片状逐渐转变为颗粒状。理论计算表明,随着过冷度的增大,α-Fe枝晶发生由溶质扩散控制生长向热扩散控制生长的转变。发生该转变所需的临界过冷度随合金中Mo含量的增大而增大。

关键词:深过冷;快速凝固;溶质截留;枝晶生长;落管

中图分类号:TG113.12 文献标志码:A

Rapid growth of primary α-Fe phase from undercooled Fe-Mo alloys

ZHANG Bo, LU Xiao-yu, DAI Fu-ping, RUAN Ying

(Department of Applied Physics, Northwestern Polytechnical University, Xi’ an 710072, China)

Abstract: Rapid solidification of Fe-8%Mo and Fe-26%Mo alloys was investigated by drop tube technique. The results show that for Fe-8%Mo alloy, the rapid solidification product is α-Fe dendrite in large droplet, a mount of solute Mo distributes at the grain boundaries. The grain refinement effect occurs and it displays a morphological transition of “coarse dendrite-equiaxed grain” with the decrease of droplet diameters, meanwhile, the microsegregation inside the α-Fe dendrite is suppressed. The solute trapping effect occurs when the droplet diameter reduces to approximately 100 μm. For Fe-26%Mo alloy, the solidification microstructure is composed of residual α-Fe dendrite and lamellar eutectoid structure (μ+α-Fe) in large droplet. When the droplet diameter decreases to a certain degree, the microstructure changes into the granular eutectoid structure (μ+α-Fe). Theoretical analysis indicates that the rapid dendritic growth of α-Fe transforms from “solute diffusion controlled” into “thermal diffusion controlled” growth with the enhancement of undercooling. The critical undercooling for this transition increases with the rise of Mo content in the alloy.

Key words: undercooling; rapid solidification; solute trapping; dendrite growth; drop tube

金属的深过冷快速凝固目前是凝聚态物理和材料科学领域的热点课题[1-4],而空间材料科学作为其重要分支越来越引起人们的重视。作为实现深过冷的一种有效途径,落管无容器处理技术可以有效模拟空间环境“超高真空、微重力和无容器”的状态,避免与容器壁接触而诱发异质形核,从而促使液态合金获得较大的过冷度并实现快速凝固[5-7]。 深过冷条件改变了熔体凝固过程中的晶体形核和传质传热规律,金属在液固相变过程中远远偏离平衡态,使生成相的形核次序、生长方式、组织形态和溶质分布等出现新的规律,对新材料、新工艺的发展及相关基础理论的研究具有重要意义。深过冷技术为非平衡条件下的枝晶生长研究提供了实验基础。枝晶是材料凝固过程中最常见的显微组织,其形貌特征直接影响合金的物理化学性能。近年来有关枝晶快速生长的研究,包括理论[8-10]、实验[11-13]以及数值模拟[14-16]都取得了显著成果。

Fe-Mo合金作为优良的高温材料受到了研究者们的青睐,相关的凝固研究主要集中于分析合金发生包晶反应时的相组成及微观组织特征[17-18]。例如,LEONHARDT等[17]通过电磁悬浮中的再辉现象研究了深过冷Fe-Mo多种成分合金的快速凝固。α-Fe枝晶是Fe-Mo合金中重要的凝固组织组成物,但是迄今为止,有关Fe-Mo合金中初生α-Fe枝晶的快速生长研究还鲜有报道。事实上,研究Fe-Mo合金体系中初生α-Fe相的快速凝固,有助于更好地理解二元合金中晶体的快速生长机制和Fe-Mo合金的快速凝固特征。

本文作者采用3 m落管实现Fe-8%Mo与Fe-26%Mo合金在自由落体条件下的深过冷与快速凝固,研究两种合金在凝固过程中的组织形貌特征及演变规律,揭示初生α-Fe相枝晶的快速生长机制。

1 实验方法

两种合金均由高纯(质量分数)Fe(99.999%)和Mo(99.99%)在Ar气保护下采用超高真空电弧炉熔炼配制而成,样品的质量约为1.0 g。

实验过程中,将样品装入底部开有d0.3 mm喷嘴的d16 mm×150 mm石英试管中,然后将试管置于落管顶部加热线圈中,将系统抽真空至10-5 Pa后反充高纯He(99.999%)和Ar(99.999%)的混合气体(体积比为2:3)至0.1 MPa。采用高频感应熔炼装置加热使样品熔化并过热200 K然后保温几分钟,最后向试管内吹入Ar气,使合金熔体通过试管底部的小孔分散成大量不同直径的合金小液滴下落。

实验结束后,对合金粒子按直径筛选后进行镶嵌、抛光和腐蚀,所用腐蚀剂为2.5 g FeCl3+20 mL HCl+100 mL H2O。粒子的凝固组织形貌采用Zeiss Axiovert 200 MAT光学显微镜和FEI Sirion 200场发射扫描电子显微镜(SEM)进行观察,未腐蚀样品中的相组成及溶质分布分别采用Rigaku D/max2500型X射线衍射仪(XRD)和Oxford INCA Energy 300型X射线能谱仪(EDS)进行分析。

2 结果与讨论

Fe-Mo二元合金的部分相图[19]如图1所示,图中标出了Fe-8%Mo与Fe-26%Mo合金的位置。由图1可知,在1 722 K时,Mo在体心立方固溶体α-Fe相中的固溶度达到最大值,为35.7%(质量分数);随着温度的降低,固溶度减小。可以看出,两种合金最终的平衡凝固组织均由α-Fe+λ(Fe2Mo)组成。

图1 Fe-Mo二元合金相图[19]

Fig.1 Equilibrium phase diagram of Fe-Mo binary alloy[19]

2.1 液滴的冷却速率和过冷度

研究合金液滴在下落过程中的冷却速率Rc和过冷度ΔT,对理解合金熔体的形核、生长及组织演变规律具有重要意义。由于合金液滴在落管中下落时处于动态,直接测量冷速非常困难,因此,采用可靠的理论计算获取冷却速率与过冷度的数值。实验中获得的液滴直径介于100~1 200 μm,可以忽略液滴内部的温度梯度。在此基础上,采用牛顿冷却模型[20]与LEE和AHN建立的热传输模型[21],可求得不同直径合金液滴获得的冷却速率和过冷度。图2所示为对Fe-8%Mo合金的计算结果。由图2可知,该合金液滴获得的冷却速率和过冷度均随着液滴直径的减小而增大。其所获得的冷却速率从420.5 K/s增大到4.78×104 K/s,过冷度从46 K增大到281 K(0.18 TL)。Fe-26%Mo合金的冷却速度与过冷度范围分别为425.6~ 4.79×104 K/s与46~284 K(0.19 TL)。

可见,合金液滴获得的冷却速率和过冷度与液滴的尺寸密切相关。直径越小的液滴更容易通过热辐射以及与保护气体进行对流换热同外界进行热交换,致使冷却速率越大;而且液滴尺寸越小含有异质晶核的概率越小,因而获得的过冷度也越大。

图2 Fe-8%Mo合金液滴的冷却速率与过冷度随液滴直径的变化关系

Fig.2 Cooling rate and undercooling versus droplet diameter in Fe-8%Mo alloy

2.2 Fe-8%Mo合金的快速凝固

2.2.1 相组成分析

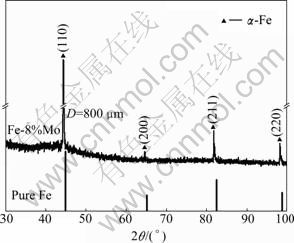

采用落管无容器技术实现了二元Fe-8%Mo合金的深过冷与快速凝固,获得的最大过冷度为281 K(0.18 TL)。合金的相组成由XRD分析确定,图3所示为直径约800 μm的合金粒子的XRD谱。结合图3分析可知,不同直径合金粒子的凝固组织均由单相α-Fe固溶体组成,并未出现平衡凝固中的λ相,即快速凝固抑制了λ相的生成。Fe-8%Mo合金的衍射峰与纯Fe的相比明显向左偏移。这表明Mo的加入引起了Fe晶格的畸变,使固溶体的晶格常数变大。

图3 Fe-8%Mo合金和纯Fe的XRD谱

Fig.3 XRD patterns of Fe-8%Mo alloy and pure Fe

2.2.2 快速凝固组织特征

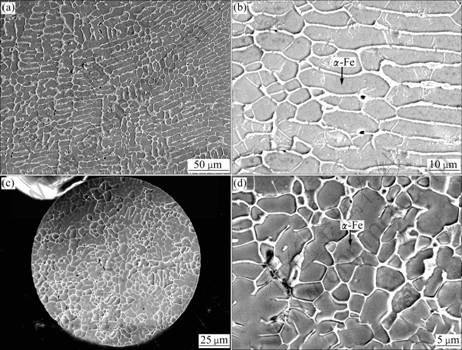

深过冷条件下Fe-8%Mo合金的凝固组织均由α-Fe相组成。图4所示为不同直径Fe-8%Mo合金粒子的凝固组织形貌。图4(a)和4(c)对应的直径分别为950 μm和140 μm,其中图4(b)和4(d)分别为图4(a)和4(c)的局部放大。由图4可以看出,当粒子直径D=950 μm时,由于凝固放热和溶质分凝等原因改变了热场和浓度场等凝固条件,致使在大直径合金的凝固组织中形成了较多的粗大枝晶;随着直径的减小,凝固组织由枝晶转变为等轴晶。这主要是由于直径较小的合金液滴获得的过冷度较大,α-Fe相的生长速度较大,而与此同时大量结晶潜热的快速释放使合金液滴的温度回升并导致α-Fe相枝晶发生重熔碎断;当粒子直径减小为D=140 μm时,如图4(c)和4(d)所示,生长形貌变为细碎的等轴晶。

图4 不同直径Fe-8%Mo合金粒子的组织形貌

Fig.4 Solidification microstructures of Fe-8%Mo alloy at different diameters: (a) D=950 μm; (b) D=950 μm; (c) D=140 μm; (d) D=140 μm;

图5(a)给出了α-Fe相的平均晶粒尺寸L随粒子直径D的变化趋势。 当粒子直径从950 μm减小到85 μm时, α-Fe相的平均晶粒尺寸由9.45 μm减小到3.46 μm。可见,随着粒子直径的减小,α-Fe相发生由粗大枝晶向碎断等轴晶的形貌转变,并且组织逐渐细化。

图5 α-Fe相的平均晶粒尺寸与Mo在其中的固溶度随粒子直径的变化关系

Fig.5 Mean size of α-Fe phase and solid solubility of Mo in α-Fe phase versus droplet diameter: (a) Size of α-Fe phase; (b) Solid solubility of Mo in α-Fe phase (A—Intergranular; B—At grain boundary)

2.2.3 α-Fe相中Mo的分布

采用EDS方法对Fe-8%Mo合金中α-Fe相的成分进行了测定。图5(b)所示为该合金凝固组织α-Fe相中Mo的固溶度与粒子直径的关系。其中A和B分别表示晶粒内部与晶界处α-Fe相中Mo的固溶度。由图 5(b)可知,直径较大的粒子中α-Fe相在晶界处成分发生扩展,微观偏析非常明显,晶界处Mo的固溶度介于13%~15%,远高于晶粒内部Mo的固溶度6.56%~7.06%。大量的Mo富集于晶界处,溶质的微观偏析现象较为严重。随着直径的减小,α-Fe相中Mo的固溶度在晶界处快速减小,而在晶粒内部逐渐增加,偏析程度逐渐减弱。当粒径达到约100 μm时,两处α-Fe相中Mo的固溶度都趋于8%,即合金的原始成分。这表明快速凝固导致了显著的溶质截留效应。

2.3 Fe-26%Mo合金的快速凝固

2.3.1 快速凝固组织特征

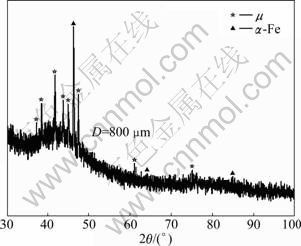

图6所示为直径约400 μm的合金粒子的XRD谱。结合图6分析可知,不同直径合金粒子的快速凝固组织均由α-Fe相和μ(Fe7Mo6)相组成,并非平衡时的α-Fe相和λ相。这表明在快速凝固条件下,随着温度的降低,Fe-26%Mo合金只发生了共析转变(R→α-Fe+μ),而包析转变(α-Fe+μ→λ)受到抑制。

图 6 Fe-26%Mo合金的XRD谱

Fig.6 XRD pattern of Fe-26%Mo alloy

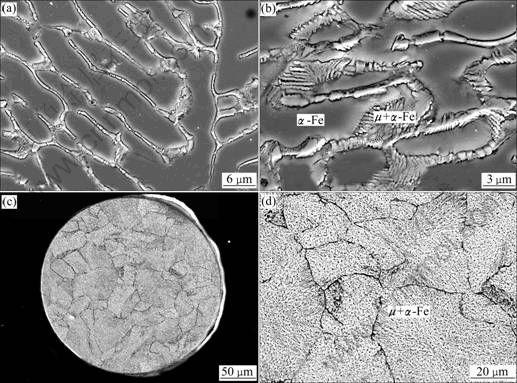

深过冷条件下Fe-26%Mo合金的凝固组织如图7所示,其中图7(b)和7(d)分别为图7(a)和7(c)的局部放大,图中灰色相为固溶体α-Fe相,白色相为μ相。研究发现,微观组织随直径变化呈现不同的生长形态。当粒子直径D大于400 μm时,如图7(a)所示,初生α-Fe相表现为粗大的枝晶组织形态,一次枝晶主干和二次分枝十分发达,具有明显的方向性;共析组织(μ+α-Fe) 则多以层片状的形态分布在初生α-Fe相主干枝晶之间,形成层片共析结构,如图7(b)所示。当粒子直径D小于400 μm时,凝固组织均为共析组织,且组织形貌由层片状向颗粒状转变,如图7(c)和7(d)所示。

图7 不同直径Fe-26%Mo合金粒子的组织形貌

Fig.7 Solidification microstructures of Fe-26%Mo alloy with different diameters: (a) D=920 μm; (b) D=920 μm; (c) D=250 μm; (d) D=250 μm

2.3.2 快速凝固机制

结合微观组织形态与XRD分析结果可知,合金在快速凝固过程中经历了两次明显的相变,分别为初生α-Fe相的快速生长和共析转变(R→α-Fe+μ)的发生。

不同直径的合金液滴在下落过程中热力学与动力学条件的差异使两相的生长形态发生改变。随液滴直径的减小,初生α-Fe相和共析组织(μ+α-Fe)均显著细化,且发生了复杂的形貌转变,这主要是深过冷条件下α-Fe相的快速形核与生长的结果。α-Fe相的快速形核导致其晶粒密度增加,快速生长则加剧枝晶的重熔和碎断,而碎断的枝晶经过熟化最终形成细化组织。随液滴直径的减小,合金熔体获得的过冷度与冷却速率较大,致使凝固过程越来越偏离平衡状态,抑制了初生α-Fe相的生长,这是引起小尺寸液滴的共析组织均匀分布的主要原因,如图7(c)和7(d)所示。

另外,随粒子直径的减小,共析组织发生由层片状向颗粒状的转变。这可能有两方面原因:第一,层片状的共析组织具有较高的表面能,转变为颗粒状组织后系统的表面能降低,稳定性更好;第二,层片状共析组织的尖角处固溶度高于平面处的固溶度,使得周围α-Fe相与共析组织尖角接触处的Mo浓度高于平面接触面处的Mo浓度,因而引起Mo的扩散。扩散破坏了界面Mo浓度的平衡,为了恢复平衡,共析组织尖角处将进一步溶解,其平面将向外长大,如此不断进行,最终形成颗粒状的共析组织。

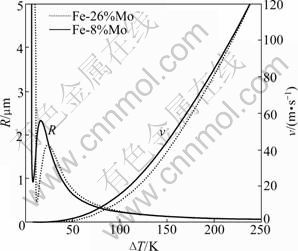

2.4 α-Fe枝晶的快速生长

利用LKT-BCT[8-10]快速枝晶生长模型,对Fe-8%Mo和Fe-26%Mo合金过冷熔体中α-Fe相的枝晶生长速率v、枝晶顶端半径R与过冷度ΔT的关系进行了理论计算,结果如图8所示。由图8可知,随着过冷度的增大,枝晶顶端半径急剧减小,在10~50 K之间出现起伏,产生了一个极大值。一般认为,顶端半径出现起伏是由于枝晶发生由溶质扩散控制生长向热扩散控制生长的转变,而极大值所对应的过冷度就是发生转变的临界过冷度[8-10]。因此,可推知α-Fe枝晶在Fe-8%Mo和Fe-26%Mo合金中均发生了由溶质扩散控制生长向热扩散控制生长的转变,且前者所需的临界过冷度小于后者的。

图8 不同合金中α-Fe枝晶的生长速率和顶端半径随过冷度的变化关系

Fig.8 Calculated growth velocity and tip radius of α-Fe dendrite in undercooled Fe-Mo alloys

经过对比发现,在相同的过冷条件下,α-Fe枝晶在Fe-8%Mo合金中的生长速率略大于在Fe-26%Mo合金中的生长速率。当过冷度增大至一定程度时,合金成分对枝晶生长速率的影响变小。值得注意的是,在落管实验中,特殊的实验环境以及冷却速率的影响,使得小尺寸Fe-26%Mo合金液滴的快速凝固路径完全偏离平衡凝固,共析组织直接从液相中生成,α-Fe枝晶的生长被抑制。将两合金中α-Fe枝晶的顶端半径曲线进行比较,发现Fe-8%Mo合金曲线的极大值明显大于Fe-26%Mo合金曲线的极大值,且前者中枝晶发生由溶质扩散控制生长向热扩散控制生长转变所对应的临界过冷度小于后者的。

3 结论

1) Fe-8%Mo合金液滴的凝固组织由单相α-Fe固溶体组成;Fe-26%Mo合金的相组成则为残余α-Fe相和共析组织μ+α-Fe相,或者完全的共析组织μ+α-Fe相。

2) 随着过冷度和冷却速率的增大,Fe-8%Mo合金的凝固组织由枝晶演化为等轴晶,溶质Mo从大量富集于晶界处转变为均匀分布,快速凝固导致了显著的溶质截留效应。小尺寸Fe-26%Mo合金液滴的凝固组织中初生α-Fe相的生长被抑制,共析组织由层片状向颗粒状转变且显著细化,凝固路径显著偏离平衡状态。

3) 计算表明,Fe-8%Mo和Fe-26%Mo合金的过冷度范围分别为46~281 K(0.18 TL)和46~284 K(0.19 TL);冷却速率分别为420.5~4.78×104 K/s和425.6~4.79×104 K/s。

4) 在相同的过冷条件下,熔体中Mo的含量越低,α-Fe枝晶生长越快。随着过冷熔体中Mo含量的增高,α-Fe枝晶发生由溶质扩散控制生长向热扩散控制生长的动力学转变所需的临界过冷度增大。

致谢

感谢王伟丽、宋瑞波、鄢振麟、李志强和泰伟业等同事在实验及分析过程中给予的帮助和建议。

REFERENCES

[1] KNOCH K G, REINSCH B, PETZOW G. Nd2Fe14B: Its region of primary solidification[J]. Zeitschrift Fuer Metallkunde, 1994, 85(5): 350-353.

[2] VANDYOUSSEFI M, KERR H W, KURZ W. Two-phase growth in peritectic Fe-Ni alloys[J]. Acta Materialia, 2000, 48(9): 2297-2306.

[3] TRIVEDI R, PARK J S. Dynamics of microstructure formation in the two-phase region of peritectic systems[J]. Journal of Crystal Growth, 2002, 235(1/4): 572-588.

[4] ARAI Y, EMI T, FREDRIKSSON H, SHIBATA H. In-situ observed dynamics of peritectic solidification and δ/γ transformation of Fe-3 to 5 at. pct Ni alloys[J]. Metallurgical and Materials Transactions A, 2005, 36(11): 3065-3074.

[5] 姚文静, 杨 春, 韩秀君, 陈 民, 魏炳波, 过增元. 微重力条件下Ni-Cu合金的快速枝晶生长研究[J]. 物理学报, 2003, 52(2): 448-453.

YAO Wen-jing, YANG Chun, HAN Xiu-jun, CHEN Min, WEI Bing-bo, GUO Zeng-yun. Rapid dendritic growth in an undercooled Ni-Cu alloy under the microgravity condition[J]. Acta Physica Sinica, 2003, 52(2): 448-453.

[6] LIU X R, CAO C D, WEI B. Microstructure evolution and solidification kinetics of undercooled Co-Ge eutectic alloys[J]. Scripta Materialia, 2002, 46(1): 13-18.

[7] WANG N, GAO J R, WEI B. Primary phase growth within highly undercooled Cu-Ge eutectic alloys[J]. Scripta Materialia, 1999, 41(9): 959-965.

[8] LIPTON J, KURZ W, TRIVEDI R. Rapid dendrite growth in undercooled alloys[J]. Acta Metallurgica, 1987, 35(4): 957-964.

[9] TRIVEDI R, LIPTON J, KURZ W. Effect of growth rate dependent partition coefficient on the dendritic growth in undercooled melts[J]. Acta Metallurgica, 1987, 35(4): 965-970.

[10] BOETTINGER W J, CORIELL S R, TRIVEDI R. Solute redistribution during rapid solidification [C]//MEHRABIAN R, PARRISH P A. Solidification Processing: Principles and Technologies IV. Baton Rouge: Claitor’s Publishing Division, 1988: 13-24.

[11] WANG H P, YAO W J, WEI B. Remarkable solute trapping within rapidly growing dendrites[J]. Applied Physics Letters, 2006, 89(20): 201905.

[12] CHANG J, WANG H P, WEI B. Rapid dendritic growth with in an undercooled Ni-Cu-Fe-Sn-Ge quinary alloy[J]. Philosophical Magazine Letters, 2008, 88(11): 821-828.

[13] 樊建峰, 杨根仓, 刘新宝, 王锦程, 宋广生. 深过冷Al72Ni12Co16合金的组织演化及单相准晶的生成[J]. 中国有色金属学报, 2003, 13(2): 344-348.

FAN Jian-feng, YANG Gen-cang, LIU Xin-bao, WANG Jin-cheng, SONG Guang-sheng. Microstructure evolution and single phase quasicrystal formation of highly undercooled Al72Ni12Co16 alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 344-348.

[14] SUZUK I T, ODE M, KIM S G, KIM W T. Phase-field model of dendritic growth[J]. Journal of Crystal Growth, 2002, 237/239: 125-131.

[15] DANILOV D, NESTLER B. Dendritic to globular morphology transition in ternary alloy solidification[J]. Physical Review Letters, 2004, 93(21): 215501.

[16] FUNKE O, PHANIKUMAR G, GALENKO P K, CHERNOVA L, REUTZEL S, KOIBE M, HERLACH D M. Dendrite growth velocity in levitated undercooled nickel melts[J]. Journal of Crystal Growth, 2006, 297(1): 211-222.

[17] LEONHARDT M, L?SER W, LINDENKREUZ H G. Phase selection in undercooled peritectic Fe-Mo alloys[J]. Acta Materialia, 2002, 50(4): 725.

[18] L?SER W, LEONHARDT M, LINDENKREUZ H G, ARNOLD B. Phase selection in undercooled binary peritectic alloy melts[J]. Materials Science and Engineering A, 2004, 375/377: 534-539.

[19] MASSALSKI T B, MURRAY J L, BENNETT L H, BAKER H. Binary alloy phase diagrams[M]. Metals Park (OH): American Society for Metals, 1986: 1726-1728.

[20] TKATCH V I, DENISENKO S N, BELOSHOV O N. Direct measurements of the cooling rates in the single roller rapid solidification technique[J]. Acta Materialia, 1997, 45(7): 2821-2826.

[21] LEE E S, AHN S. Solidification progress and heat transfer analysis of gas-atomized alloy droplets during spray forming[J]. Acta Metallurgica et Materialia, 1994, 42(9): 3231-3243.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51001087);陕西省自然科学基础研究计划资助项目(2009JQ6002);西北工业大学基础研究基金资助项目(NPU-FFR-JC201049,G9KY1021)

收稿日期:2010-10-26;修订日期:2011-05-23

通信作者:鲁晓宇,副教授,博士;电话:029-88431669-807;E-mail:xylu@nwpu.edu.cn