煤粉锅炉膜法富氧局部助燃技术

张家元,周孑民,闫红杰

(中南大学 能源科学与工程学院,湖南 长沙,410083)

摘 要:针对150 t/h煤粉动力锅炉存在结焦、热效率低及NOx排放浓度高等问题,在冷态动力场试验的基础上,借助计算机仿真技术,应用k-ε-g湍流燃烧模型及煤的双挥发反应热解模型对炉内流动及燃烧过程进行数值计算,开发局部富氧助燃技术,设计膜法富氧局部助燃系统,并将局部富氧助燃技术应用于煤粉锅炉的工业试验。实践结果表明:局部富氧助燃技术的应用,能有效地解决炉膛结焦和高温腐蚀问题;提高低负荷不投油稳燃能力;燃用贫煤时,可以在50%额定负荷下断油稳燃;大渣及飞灰可燃物含量降低,排烟热损失减少1.2%,锅炉实测热效率比常规运行方式下的热效率提高2.5%以上;锅炉NOx排放量在120~150 t/h负荷下为627~768 mg/m3。

关键词:煤粉锅炉;膜法富氧;局部助燃技术;节能;数值仿真

中图分类号:TK224.1+1;TK229.6+3 文献标识码:A 文章编号:1672-7207(2007)05-0857-06

Technology of local supporting-combustion by membrane oxygen-enrichment for pulverized coal boiler

ZHANG Jia-yuan, ZHOU Jie-min, YAN Hong-jie

(School of Energy Science and Engineering, Central South University, Changsha 410083, China)

Abstract: To solve the problems such as slag bonding, low thermal efficiency and high NOx emission of a 150 t/h pulverized coal boiler, based on the experiment of the cold dynamical field and computer simulation, the flowing field and combustion of pulverized coal were simulated by k-ε-g turbulence combustion model for gas phase and two competing reactions for the coal devolatilization. Furthermore, the technology of local enriched-oxygen supporting combustion was opened up and a system of membrane oxygen-enrichment was designed and applied to industrial practice for the first time. The results of the practice show that slag bonding and high temperature corrosion can be effectively prevented; the low load stable burning can be improved up to 50%; the carbon content in slag and fly ash are obviously lowered; and the thermal efficiency of the boiler enhances by above 2.5%; NOx emission is 627-768 mg/m3 under the load of 120-150 t/h.

Key words: pulverized coal boiler; membrane oxygen-enrichment; local combustion-supporting technology; energy saving; numerical simulation

四角切圆煤粉燃烧方式是我国煤粉锅炉普遍采用的一种燃烧方式[1],随着浓淡燃烧、分级燃烧及富氧燃烧等先进技术的应用,为四角切圆煤粉锅炉注入了新的活力[2-3]。然而,针对我国动力用煤的具体特点,现有的切圆燃烧技术仍有许多需要改进和完善之 处[4]。但是,对于切圆燃烧锅炉存在的问题,目前的燃烧技术并不能较好地予以解决[5]。在此,本文作者针对某公司热力厂6号锅炉运行中存在的高温腐蚀、结焦、经济性差及无油助燃低负荷稳燃能力差等问题,在浓淡燃烧技术的基础上,借助计算机数值模拟技术,开发局部富氧助燃技术,设计膜法富氧局部助燃系统,并成功应用于工业生产。

1 锅炉概况

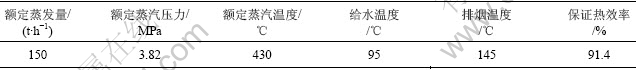

某公司热力厂6号锅炉是北京锅炉厂生产的中温中压煤粉锅炉,设计煤种为:75%(质量分数)义马煤,15%鹤壁煤和10%大同煤。近年来燃用75%义马煤,掺烧25%当地小窑贫煤。锅炉采用中间仓储式钢球磨制粉系统,乏气送粉。采用四角布置切圆燃烧方式,假想切圆直径为365 mm,每角一、二次风从上到下布置形式为二一二一二,即3个二次风夹2个一次风,燃烧器为浓淡燃烧器。6号锅炉的主要设计参数见表1。

表1 6号锅炉主要设计参数

Table 1 Principal design parameters of boiler No.6

2 膜法富氧系统设计

助燃用的富氧风是通过膜分离而获得的O2体积分数为28%~30%的富氧空气。膜法富氧系统采用负压操作流程[6]。空气经过过滤器除去灰尘,在氧氮分离器中通过膜件进行分离,得到富氧和富氮气体,富氮气体经过排废管道由鼓风机排出;富氧气体经过真空泵进入氧气缓冲罐进行脱湿处理,之后由增压风机提供动力经过预热器预热后送入富氧喷嘴助燃。该系统产生的富氧空气技术指标如表2所示。

表2 膜富氧系统设计技术指标

Table 2 Parameters for design of membrane oxygen enrichment system

富氧风喷嘴的形状和安装位置的设计是技术的关键。通过对炉内速度场和温度场的数值仿真及多次冷态和热态工业试验,确定了富氧风喷嘴的形状和安装位置。富氧风喷嘴安装位置示意图如图1(a)所示。富氧风喷嘴安装在炉膛四角,每角设计安装2层,上层位于11.5 m处,下层位于9.3 m处(通过中二次风喷口)。下层富氧风喷嘴出口与炉墙成25?夹角,作为贴壁风,在水冷壁附近形成氧化性气氛,并实现炉膛向火侧欠氧燃烧、背火侧富氧燃烧;上层富氧风作为燃烬风,以降低飞灰碳含量,如图1(b)所示。

(a)纵截面; (b)横断面

1—上富氧风喷嘴; 2—上二次风喷嘴; 3—上一次风喷嘴; 4—中二次风喷嘴、下富氧风喷嘴; 5—下一次风喷嘴; 6—下二次风喷嘴

图1 富氧风喷嘴安装位置示意图

Fig.1 Schematic diagram of oxygen enrichment air burner nozzles arrangement

3 炉内速度场测量

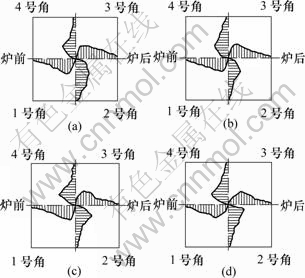

本文的冷态试验主要关注旋转气流的实际切圆大小、切圆是否偏斜和贴壁等情况,特别是测量富氧投入之前(常规操作状态)和投入之后(试验状态)燃烧器区域炉膛断面上气流分布的情况。用速度测量法进行炉内空气动力场测量[7-8]。在炉内燃烧器区拉“十”字坐标线,坐标线上分若干坐标点,用电子风速仪在坐标线上每点进行测量,根据测量数据,绘出相应的速度玫瑰图,确定气流分布情况及切圆直径,结果如图2和图3所示。其中下层为下一次风喷口处(8.9 m层)炉内断面位置,上层为中二次风喷口处(9.3 m层)炉内断面位置。

(a) 未开富氧上层; (b) 未开富氧下层; (c) 开富氧上层; (d) 开富氧下层

图2 炉内冷态动力场速度玫瑰图

Fig.2 Velocity rose charts of cold dynamical field

(a) 未开富氧上层; (b) 未开富氧下层; (c) 开富氧上层; (d) 开富氧下层

图3 炉内冷态动力实际切圆情况

Fig.3 Actual tangential circle diameters of cold dynamical field

由图3可见,常规操作时切圆直径较大,切圆中心略偏向4号角,气流呈逆时针旋向,没有气流和固体颗粒贴壁的情况发生;加入富氧风后,适当调整一、二次配风,炉内切圆有所减小,切圆位置调整适中[9]。二次风切圆直径略大于一次风切圆直径,基本形成“风包粉”的流动状态[10]。

炉内速度场试验结果表明,局部富氧风投入后,一、二次配风调整合理,四角配风均匀,切圆大小与位置适中。

4 炉内燃烧工况的数值仿真

炉内燃烧工况的数值仿真研究的目的是为了了解炉内煤粉颗粒行径、炉内速度场及温度场的分布,为富氧风喷嘴形状及安装位置的设计提供理论依据。应用k-ε-g模型对该公司热力厂6号锅炉进行数值仿真,将整个炉膛空间作为解析区域,划分为多块非均匀结构化网格,实际计算网格数为38×38×78,共计 112 632个网格,贴壁处采用3层加密网格[11]。应用CFX4.3商业软件,采用混合有限差分格式对炉膛内的多场耦合方程组进行数值计算,速度与压力耦合关系应用SIMPLC算法[12]。

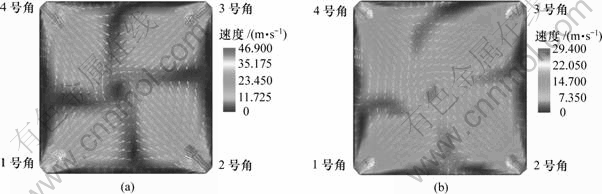

4.1 常规操作工况

图4所示为常规操作工况下炉膛内不同截面的速度分布。由图可见,一、二次风均在炉膛内部形成切圆,切圆圆心偏向4号角,与冷态动力场试验结果相吻合。

(a) 中二次风口处; (b) 上一次风口处

图4 横截面速度矢量分布

Fig.4 Distribution of cross section velocity field

图5所示为常规操作工况下炉膛内的温度分布。由图5(a)可见,由于中二次风风量偏大,导致炉膛内上、下2层火焰有较明显的分层现象,表明一、二次风没有得到及时混合,影响燃烧的稳定性;由图5(b)可见,炉膛内火焰偏向前墙和北侧墙,这将引起高温气流冲刷水冷壁,从而导致结焦和水冷壁高温腐蚀现象,同时表明,炉膛中心燃烧温度较高,使热力型NOx生成量增加[9],对环保不利。

(a) 中心纵截面; (b) 上一次风喷口处横截面; (c) 多个横截面

图5 常规工况下炉膛温度分布图

Fig.5 Temperature distribution of boiler on base case

图6和图7所示分别为常规操作工况下不同直径的煤粉颗粒在炉膛内的运动轨迹及颗粒分布。可见,煤粉在喷入炉膛瞬间,直径较大的煤粉颗粒集中在颗粒群的前面,直径较小的煤粉颗粒则分布在后面;运动到炉膛中心后,由于受到二次风的影响,直径较大的煤粉因动量大反而分布在颗粒群的尾端,聚集在炉膛四角,之后向水冷壁面扩散。结果表明,一次风刚性较差,易产生偏转;一、二次风混合性能差,使燃烧时间延长,大颗粒煤粉不易燃尽,将导致飞灰碳含量升高,锅炉热效率降低。

图6 煤粉颗粒轨迹

Fig.6 Particle trajectory with different diameters

(a) 煤粉喷出瞬间; (b) 煤粉在炉膛中心混合后

图7 不同直径煤粉颗粒瞬时分布

Fig.7 Particle instantaneous distributions with different diameters

4.2 局部富氧运行工况

根据炉内冷态动力场测试及常规操作状态下的仿真结果,确定局部助燃技术参数,对锅炉系统运行操作方式进行适当调整。调整后运行工况温度分布的数值仿真结果如图8所示。可见,炉膛燃烧中心区域一、二次风混合较好,炉膛截面温度趋于均匀,炉膛中心最高燃烧温度比常规工况下的最高燃烧温度降低154 ℃,且避免了火焰冲刷水冷壁的现象。局部富氧助燃运行工况下温度分布的数值仿真结果表明:局部富氧助燃技术改造,改善了炉内煤粉燃烧动力学条件,提高了燃烧的稳定性[13];并且炉膛纵、横截面温度分布趋于合理,炉膛燃烧中心温度的降低有利于抑制NOx的形成[14]。

(a) 中心纵截面; (b) 上一次风喷口处横截面; (c) 多个横截面

图8 局部富氧工况下炉膛温度分布图

Fig.8 Temperature distributions of boiler on local enriched-oxygen supporting combustion case

5 性能考核试验

2005年3月膜法富氧助燃系统安装调试完成,2005年4月在实炉上进行了冷态动力场和热态燃烧调整工业试验,2005年5月膜法富氧局部助燃系统正式投入运行,在系统运行1 a后于2006年7月18日进行了锅炉性能考核试验。

共进行了8种工况的试验:工况T01,T02和T03为不同负荷下的常规性试验,习惯性操作;工况T04,T05和T06为不同负荷下的富氧风局部助燃性能考核试验;工况T07和T08为锅炉低负荷稳燃性能考核试验。图9所示为各试验工况的热效率(η)和热损失(图中:q2为排烟热损失,q3为固体未完全燃烧热损失,q4为气体未完全燃烧热损失)。由图可见,富氧风助燃使排烟热损失减少1.2%左右,飞灰碳含量明显降低,固体未完全燃烧热损失降低1%左右,锅炉实测热效率比常规运行方式下提高2.5%以上,表明富氧风起到了很好的助燃效果。

图9 各试验工况热效率及热损失图

Fig.9 Thermal efficiency and thermal loss of each case

试验结果还表明,锅炉燃烧稳定性大幅度提高,在燃用挥发分为12.21%,灰分为26.14%的贫煤时,可以在50%额定负荷下断油稳燃;锅炉水冷壁高温腐蚀区域壁面O2的体积浓度大于2.2%,高温腐蚀及结渣得到了有效控制[10];锅炉NOx排放量在120~150 t/h负荷下为627~768 mg/m3,为国内燃用贫煤同类锅炉的最好水平[15]。

6 结 论

a. 根据某公司热力厂6号锅炉实际情况,在冷态动力场测试的基础上,借助计算机仿真技术,设计了膜法富氧系统及其附属设备,开发了煤粉动力锅炉的富氧局部助燃技术。

b. 当局部助燃富氧风率为2.5%左右时,适当调整一次风和二次风配入方式,飞灰碳含量和大渣碳含量明显降低,锅炉热效率达到91.5%,比常规运行热效率提高2.5%以上。

c. 局部富氧助燃技术有利于防范水冷壁高温腐蚀和结焦现象的发生,提高了不投油低负荷稳燃性能,有效地降低了NOx排放浓度,具有很好的经济、环保性能,经济及社会效益显著。

参考文献:

[1] 吕伟业. 中国电力工业发展及产业结构调整[J]. 中国电力, 2002, 35(1): 1-7.

L? Wei-ye. Development and restructuring of electric power industry in China[J]. Electric Power, 2002, 35(1): 1-7.

[2] 沈光林, 牛正东, 陈 勇. 国内局部增氧助燃技术研究及应用进展[J] . 应用科技, 2003, 30(1): 51-54.

SHEN Guang-lin, NIU Zheng-dong, CHEN Yong. Study and application of local oxygen increasing technology for combustion-supporting in China[J]. Applied Science and Technology, 2003, 30(1): 51-54.

[3] 刘泰生. 浓侧一次风反切小切圆燃烧系统的研究[D]. 西安: 西安交通大学能源与动力工程学院, 2001.

LIU Tai-sheng. Study of the tangentially-fired system with the small imaginary-circle and the reverse tangential rich primary-air[D]. Xi’an: School of Energy and Power Engineering, Xi’an Jiaotong University, 2001.

[4] 张晓鲁. 推动电力发展和电力结构调整, 创建国际一流电力企业[J]. 中国电力, 2001, 34(9): 6-7.

ZHANG Xiao-nu. Current situation of and restraints on electric power industry in China[J]. Electric Power, 2001, 34(9): 6-7.

[5] YIN Chun-gen, LUO Zhong-yang, NI Ming-jiang, et al. Investigation of the flow, combustion, heat-transfer and emissions from a 609 MW utility tangentially fired pulverized-coal boiler[J]. Fuel, 2002, 81(3): 997-1006.

[6] 苏得胜. 膜法富氧局部增氧助燃节能技术[J]. 膜科学与技术, 2003, 4(4): 34-37.

SU De-sheng. Membrane process oxygen-enriched local oxygenation combustion adding energy-saving technology[J]. Membrane Science and Technology, 2003, 4(4): 34-37.

[7] 王子延. 热能与动力工程测试技术[M]. 西安: 西安交通大学出版社, 1991.

WANG Zi-yan. Energy and power engineering test technology[M]. Xi’an: Xi’an Jiaotong University Press, 1991.

[8] 黄 革. 锅炉燃烧测试技术[M]. 长沙: 中南工业大学出版社, 1997.

HUANG Ge. Boiler combustion test technology[M]. Changsha: Central South University of Technology Press, 1997.

[9] 秦裕琨, 李争起, 孙 锐, 等. 风包粉煤粉燃烧原理及实验研究[J]. 中国电机工程学报, 2000, 20(5): 59-62.

QIN Yu-kun, LI Zheng-qi, SUN Rui, et al. Study on experiment and the principle of air-surrounding-fuel pulverized-coal combustion[J]. Proceeding of the CSEE, 2000, 20(5): 59-62.

[10] 秦裕琨, 李争起, 孙 锐, 等. 风包粉系列浓淡煤粉燃烧技术的研究[J]. 中国工程科学, 2002, 4(11): 42-49.

QIN Yu-kun, LI Zheng-qi, SUN Rui, et al. Study on bias coal combustion technologies with air-surrounding-fuel[J]. Engineering Science, 2002, 4(11): 42-49.

[11] 董 芫, 李杰伟, 陈晓东, 等. 大型煤粉锅炉炉膛传热工程化数值计算方法的研究[J]. 哈尔滨工业大学学报, 1994, 26(1): 29-32.

DONG Peng, LI Jie-wei, CHENG Xiao-dong, et al. Study on practical numerical method for heat transfer in large pulverized-coal boiler[J]. Journal of Harbin Institute of Technology, 1994, 26(1): 29-32.

[12] 龚光彩. 煤粉锅炉燃烧工况的数值仿真及其优化[D]. 长沙: 中南大学能源与动力工程学院, 1999.

GONG Guang-cai. Numerical investigation of pulverized-coal combustion and optimization of operating model in power station boiler[D]. Changsha: School of Energy and Power Engineering, Central South University, 1999.

[13] 李欣峰. 铜闪速炉数值仿真[J]. 中南工业大学学报: 自然科学版, 2001, 32(3): 262-266.

LI Xin-feng. Numerical simulation of copper flash smelter[J]. Journal of Central South University of Technology: Natural Science, 2001, 32(3): 262-266.

[14] 周 国. 燃煤电站锅炉的低NOx燃烧技术[J]. 节能技术, 2005, 23(129): 43-46.

ZHOU Guo. Low NOx combustion technique for power boiler[J]. Energy Conservation Technology, 2005, 23(129): 43-46.

[15] 兰泽全, 曹欣玉, 赵选桥, 等. 煤粉锅炉沾污防治措施探讨[J]. 锅炉技术, 2003, 34(3): 61-69.

LAN Ze-quan, CAO Xin-yu, ZHAO Xuan-qiao, et al. Discussion on preventing measures of fouling and slagging in pulverized-coal boiler[J]. Boiler Technology, 2003, 34(3): 61-69.

收稿日期:2006-12-28;修回日期:2007-02-05

基金项目:中国博士后基金资助项目(291054)

作者简介:张家元(1968-),男,湖北浠水人,副教授,博士,从事热能与动力工程研究

通信作者:张家元,男,副教授,博士;电话:0731-8876111;E-mail:zjyzhq@mail.csu.edu.cn