文章编号: 1004-0609(2005)07-1075-06

纳米磨料硬度对超光滑表面抛光粗糙度的影响

陈志刚, 陈杨

( 江苏工业学院 材料系, 常州 213016)

摘 要: 通过均相沉淀法制备了纳米CeO2和Al2O3粉体, 研究了在相同抛光条件下纳米CeO2、 Al2O3和SiO2磨料对硅片的抛光效果, 用原子力显微镜观察了抛光表面的微观形貌并测量其表面粗糙度。 结果表明: 纳米CeO2磨料抛光后表面具有更低的表面粗糙度, 在5μm×5μm范围内表面粗糙度Ra值为0.240nm, 而且表面的微观起伏更趋向于平缓; 考虑了纳米磨料在抛光条件下所发生的自身变形, 其变形量相当于一部分抵消了纳米磨料嵌入基体材料的切削深度, 而这个切削深度最终决定了抛光表面的粗糙度; 分析指出这个变形量与纳米磨料的硬度成反比, 硬度低的纳米磨料由于自身变形量大, 导致切削深度小, 抛光后表面的粗糙度值低。 解释了在相同的抛光条件下不同硬度的纳米磨料具有不同的抛光表面粗糙度的原因。

关键词: 纳米磨料; 硬度; 粗糙度; 超光滑表面; 抛光 中图分类号: TG356.28

文献标识码: A

Effect of hardness of nano-sized abrasives on roughness of polished super-smooth surface

CHEN Zhi-gang, CHEN Yang

(Department of Materials and Engineering, Jiangsu Polytechnic University, Changzhou 213016, China)

Abstract: Nano-powder of CeO2 and Al2O3 were prepared via homogenous precipitation, and the different polishing behavior of nano-CeO2, nano-Al2O3 and nano-SiO2 abrasives under the same polishing condition were studied by atomic force microscopy (AFM). The surface roughness of the wafer polished by nano-CeO2 is lower than that polished by the nano-Al2O3 and nano-SiO2, and its surface undulation is smaller. The influence of the deformation of the abrasive particle on polishing mechanism is considered for the first time. The deformation of the abrasive counteracts part of the cutting depth which determines the roughness of the polished surface. The deformation amount is in proportion to the hardness of the abrasives. The reason why the abrasives with different hardness has different polishing behavior is analyzed.

Key words: nano-sized abrasives; hardness; roughness; super-smooth surface; polishing

随着光学领域和微电子学领域及其相关技术的发展, 对所需材料的表面质量的要求越来越高, 从此产生了超光滑表面的概念。 所谓超光滑表面[1-3]主要是针对被加工表面的粗糙度而言的, 它具有以下主要特征: 表面粗糙度小于1nm(Ra)、 尽可能小的表层和亚表层损伤、 表面残余应力极小、 晶体表面具有完整的晶体结构。 超光滑表面的加工手段有抛光和超精密机械加工等, 而抛光应用得最为广泛。 磨料作为抛光介质在材料的去除过程中发挥极其重要的作用, 磨料自身的性质极大地影响抛光表面质量。 对于超光滑表面抛光而言, 使用纳米级的磨料已经是必然的发展趋势[4]。

在现有的抛光接触模型[5-8]中都认为磨料相对于工件材料是硬质的, 以及在传统的硬度测试中都认为是磨料(压头)是刚性的, 即在外力作用下自身不发生变形。 同时在目前使用的纳米磨料的抛光模型中, 从纳米磨料的机械去除角度出发, 不能解释在相同的抛光条件下, 不同硬度的纳米磨料会有不同的抛光表面质量的原因。

本文作者使用了3种尺寸、 形状和粒径分布相差不大的纳米磨料, 对硅晶片进行了超光滑表面化学机械抛光, 分析了不同硬度的纳米磨料抛光后具有不同表面粗糙度值的原因。

1 实验

1.1 纳米CeO2和Al2O3粉体的制备

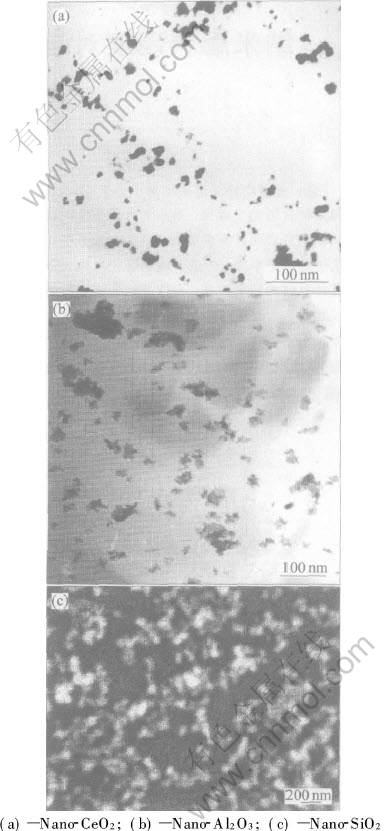

称取一定量的Ce(NO3)3·6H2O和六亚甲基四胺配成浓度比为1∶5的混合液, 将该溶液放入75℃恒温水箱中水浴保温1h后, 放置在室温环境下陈化。 用离心法分离沉淀, 将沉淀物洗涤, 然后在80℃真空干燥箱中烘干, 即可得到纳米CeO2超细粉体。 图1(a)所示为CeO2粉体的TEM照片, CeO2粉体的粒径在10nm左右, 形状为近球形, 大小分布均匀。

根据湿化学法[9]制备超细粉体原理, 再称取一定量的硫酸铝铵和碳酸氢铵配成一定浓度的溶液, 先将碳酸氢铵溶液缓慢滴入硫酸铝铵溶液中至饱和后加入表面活性剂, 然后再雾化加入碳酸氢铵溶液至沉淀完全。 反应过程中控制溶液的pH值并加以机械搅拌, 反应结束后在60℃下陈化一定时间。 用离心法分离沉淀, 将沉淀物洗涤、 干燥, 再将制得的前驱体在分别230℃下保温30min、 1200℃下煅烧1h, 即可得到纳米α-Al2O3超细粉体。 图1(b)所示为Al2O3粉体的TEM照片, 可见制备出10nm左右的近球状α-Al2O3超细粉体。

纳米SiO2粉体是由美国Cabot公司经气相法制得, 型号为M-5。 其SEM照片如图1(c)所示, 可以看出该粉体为球状, 粒径10nm左右, 且分布很均匀。

图1 3种纳米粉体的TEM和SEM照片

Fig.1 TEM and SEM micrographs of different nano-powders

1.2 抛光实验

将3种纳米粉体分别配制成质量分数为1%的抛光液, 用氨水将抛光液pH值调至9。 在一定抛光压力(2N)、 转速(200r/min)和时间(30min)下, 使用美国Buehler Phoenix Beta型抛光机进行抛光实验。 实验材料为硅晶片P型(111)。

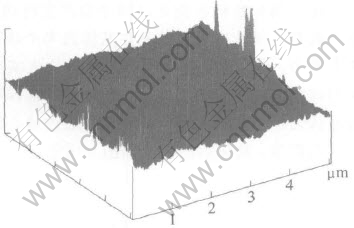

在抛光实验前, 在一定的抛光条件下使用5μm棒状CeO2磨料(长径比为10∶1)和0.3μm球状CeO2磨料对硅晶片进行预抛光, 用原子力显微镜[10, 11](AFM, Nanoscope Ⅲa, Mutimode SPM, 美国DI公司, 纵向分辨率为0.1nm, 横向分辨率为0.01nm)观察抛光表面。 AFM针尖材料是单晶硅(silicon), 针尖半径小于10nm。 预抛光表面在5μm×5μm范围的微观形貌如图2所示, 在5μm×5μm范围内的粗糙度Ra值为0.310nm, 粗糙度均方根(RMS)值为0.403nm。 在本研究中所有微观形貌图在垂直方向上的单位高度都是10nm。

图2 预抛光后硅晶片表面的AFM微观形貌

Fig.2 AFM morphology of silicon wafer surface after pre-polished

2 实验结果

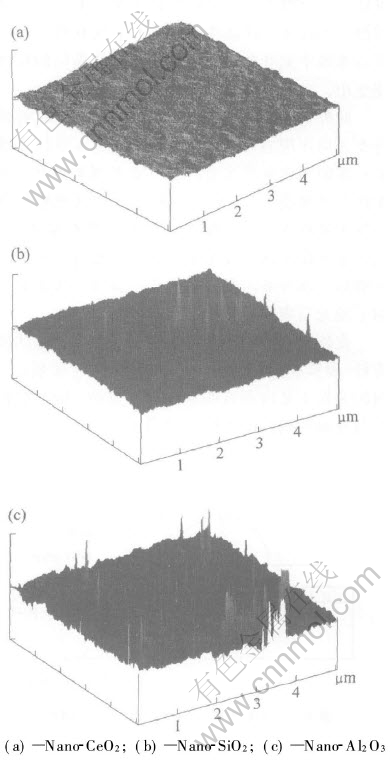

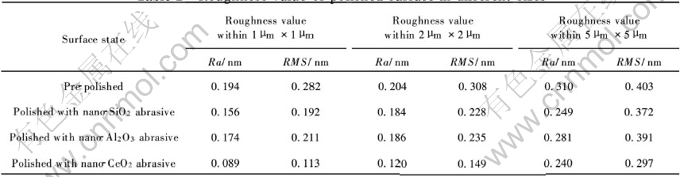

用原子力显微镜观察3种纳米磨料抛光后表面, 在5μm×5μm范围内的AFM微观形貌如图3所示。 从图中可以看出, 经纳米CeO2磨料抛光后硅晶片表面的微凸体的尺寸更加细小, 抛光表面的微观起伏更趋于平缓。 经3种纳米磨料抛光后表面在不同微观范围内的粗糙度值列于表1。

由表1可见, 不同测量范围内的结果均表明使用纳米CeO2磨料抛光后表面具有最低的表面粗糙度值。

3 分析与讨论

由于在抛光过程中纳米磨料与硅晶片局部接触 点处会产生高温高压, 会导致一系列复杂的摩擦化学[12]反应。 在抛光液中碱性物质的作用下, 首先会在硅片表面形成一层腐蚀软质层, 然后再通过磨料的机械作用将其去除, 同时又暴露出新的表面, 材料的去除正是软质层形成与去除的一个动态过程。 有研究表明[13], 在经过亲水处理的硅晶片表面会形成一层厚度小于7nm的氧化膜。 实际上在本实验抛光条件下, 硅晶片表面上的氧化软质层不会象在亲水液中氧化的那么完全, 因而软质层的厚度可能更小。

图3 纳米磨料抛光后硅晶片表面的AFM微观形貌

Fig.3 AFM morphologies of silicon wafer surface after polished with different nano-sized abrasives

表1 抛光后表面不同范围内的粗糙度值

Table 1 Roughness value of polished surface in different sizes

此外, 由于纳米磨料粒子嵌入到基体材料的部分受三向压应力作用, 这样纳米磨料本身就会既产生一定的塑性变形又会产生一定的弹性变形。 由于塑性变形量很小, 所以就近似地认为纳米磨料自身只发生弹性变形, 并假设这个弹性变形量为δ。 事实上正是由于这个变形量的存在, 相当于抵消了纳米磨料一部分嵌入基体材料内的深度, 从而最终影响了抛光后表面的粗糙度。

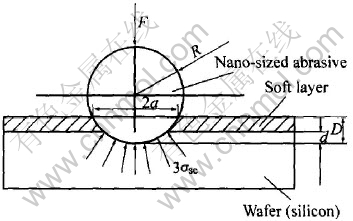

在使用球形纳米磨料抛光硅晶片时, 球状纳米磨料(硬质压头)压入到硅晶片表面产生压痕, 而材料的去除正是由压痕的滑动所造成的。 纳米磨料粒子与硅晶片间的接触模型如图4所示。

图4 纳米磨料粒子与硅晶片间的接触模型

Fig.4 Contacting model between nano-sized abrasive particle and wafer

考虑到纳米磨料自身变形对其嵌入深度的影响, 采用两步走的方法来简化计算: 首先在认为纳米磨料是刚性的、 自身不发生变形, 来求解磨料的嵌入深度D; 再求解纳米磨料的自身弹性变形量δ。

由于切削深度d的平均值与被抛光表面粗糙值Ra值成正比[14], 则:

Ra=Kd

=K(D-d0-δ)

式中 D为纳米磨料嵌入到硅晶片表面所产生的压痕深度(若不考虑其自身变形, 那么相同形貌和尺寸的磨料具有相同的嵌入深度); d0为软质层的厚度; δ为纳米磨料的自身变形量。

由上式可以看出, 抛光后表面粗糙度Ra值与纳米磨料的自身变形量δ成反比。 也就是说, 纳米磨料的自身变形量δ越大, 抛光后表面粗糙度Ra值越小; 反之越大。 同时根据以上的分析可知, 磨料的硬度越小, 纳米磨料的自身变形量δ越大; 反之越小。 因而纳米磨料的硬度越大, 抛光后表面粗糙度Ra值越大。

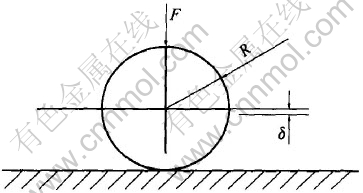

实际上纳米磨料在抛光过程中会产生滑动, 因此纳米磨料只是在嵌入在硅晶片基体内半个球冠的面积上受力, 但由于嵌入深度很小, 这样真实受力方向与球型磨料垂直轴向间的夹角很小。 这样可以近似地认为纳米磨料是球状, 而且受通过球心的垂直压应力作用, 简化后的模型如图5所示。

图5 球形纳米磨料在垂直轴向上的变形示意图

Fig.5 Schematic of vertical deformation of

spherical nano-sized abrasive

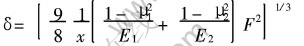

假设这个弹性变形量为δ(即球形磨料垂直轴向上的长度变化), 这样根据弹性力学可知[15]:

式中E1和E2分别为磨料粒子和抛光垫材料的弹性模量; μ1和μ2分别为磨料粒子和抛光垫材料的泊松比; x为球形磨料的直径; F为单个磨料上的作用力。

可以看出, 变形量δ与球形磨料的直径x成反比。 当使用微米级或亚微米级的磨料时, 磨料的自身变形仍然存在, 但由于磨料的粒径x大, 因而δ很小, 这时变形量δ与磨料的嵌入深度以及磨料自身尺寸相比很小, 因而可以忽略。 而在使用纳米磨料抛光时, 由于纳米磨料的尺寸很小, 因而纳米磨料的变形量δ相对比较大, 同时纳米磨料本身的粒径x以及其嵌入深度都很小, 这时候纳米磨料自身微小的变形量就不能被忽略。

由于陶瓷材料的泊松比相近, 可以认为弹性模量E才是决定δ的主要因素。 而且从某种意义上讲弹性模量E和硬度H都反映了材料表层原子间的作用力, 因此可以近似地认为材料的弹性模量E大则硬度H大; 反之则随之变小。 由于δ与磨料的弹性模量E成反比, 可见δ与磨料的硬度Ha也成反比。 也就是说, 纳米磨料的硬度越大, 则纳米磨料自身的变形量越小; 反之纳米磨料的硬度越小, 则纳米磨料自身的变形量就越大。

由以上的分析看出, 在使用纳米级磨料进行抛光时, 除了要考虑抛光工艺参数和纳米磨料的形貌、 粒径及分布的影响之外, 还要考虑磨料本身硬度对切削深度的影响, 这是因为在这种极端的情况下纳米磨料自身在三向压应力的作用下所产生的变形量是不容忽视的。 基于考虑到纳米磨料自身的变形量δ对纳米磨料粒子嵌入材料基体深度的影响, 这里引入了相对硬度ΔH的概念。 即:

ΔH=Ha-H

式中 Ha为纳米磨料的硬度; H为被抛光材料的硬度(也可能是材料的综合硬度), 在相同的抛光条件下, H是个定值。

ΔH越大, 纳米磨料的硬度越高, 纳米磨料自身的弹性变形量δ就越小, 纳米磨料嵌入到被加工基体材料内的深度越大, 因而导致最终抛光表面的粗糙值也就越高。 ΔH越小, 纳米磨料的硬度越低, 纳米磨料自身的弹性变形量δ就越大, 纳米磨料嵌入到被加工基体材料内的深度越小, 因而最终抛光表面的粗糙值也就越低。 这就解释了纳米磨料在形貌、 粒径大小以及粒径分布差别不大的条件下, 不同硬度的纳米磨料对具有不同抛光表面粗糙度的原因。

本实验中, 在相同的抛光条件下使用10nm左右的CeO2、 SiO2和Al2O3磨料对硅晶片进行抛光, 其实验结果列于表1。 正是由于纳米CeO2的磨料硬度最低(莫氏硬度为6), Al2O3的硬度最高(莫氏硬度为9), 而SiO2的硬度居中(莫氏硬度为7), 因而使用纳米CeO2磨料时相对硬度ΔH最小, 纳米CeO2磨料自身的变形量δ最大, 因而纳米CeO2磨料嵌入硅基体材料内的深度就越小, 最终导致抛光表面的粗糙值最小, 抛光表面质量最好。 而使用纳米SiO2和Al2O3磨料时, 由于相对硬度ΔH较大, 导致纳米磨料自身的弹性变形量δ较小, 纳米SiO2和Al2O3磨料嵌入硅基体材料内的深度就相对较大, 最终导致抛光表面粗糙度相对就要大一些。

4 结论

1) 使用自制的纳米CeO2和Al2O3粉体以及SiO2作为磨料对单晶硅片实现了超精密抛光, 3种纳米磨料均有良好的抛光效果。

2) 使用纳米CeO2磨料抛光的单晶硅片, 在1μm×1μm范围内粗糙度Ra值达到了0.089nm, 在相同条件下与使用纳米SiO2和Al2O3磨料相比, 具有最低的表面粗糙度值, 而且表面的微观起伏更趋于平缓。

3) 考虑了在使用纳米磨料抛光时, 纳米磨料自身可能发生变形, 这个变形量相当于一部分抵消了纳米磨料嵌入基体材料的切削深度, 而这个切削深度最终决定了抛光表面的粗糙度。 由分析指出这个变形量与纳米磨料的硬度成反比, 硬度低的纳米磨料由于自身变形量大, 导致纳米磨料的切削深度小, 抛光后表面的粗糙度值低。 这就解释了在相同的条件下不同硬度的纳米磨料具有不同的抛光表面粗糙度的原因, 初步解释了纳米磨料的硬度对切削深度, 以及最终表面粗糙度的影响。

REFERENCES

[1]Asadchikov V E, Kozhevnikov I V, Krivonosov Y S, et al. Application of X-ray scattering technique to the study of supersmooth surfaces[J]. Nuclear Instruments and Methods in Physics Research Section A, 2004, 530(3): 575-595.

[2]Yuan J L, Zhao P, Ruan J, et al. Lapping and polishing process for obtaining super-smooth surfaces of quartz crystal[J]. Journal of Materials Processing Technology, 2003, 138(3): 116-119.

[3]Shi X K, Hua M, Cheung E H M, et al. Automatic recognition and evaluation of micro-contaminant particles on ultra-smooth optical substrates using image analysis method[J]. Optics and Lasers in Engineering, 2004, 45(6): 901-917.

[4]陈杨, 陈建清, 陈志刚. 超光滑表面抛光技术[J]. 江苏大学学报, 2002, 22(5): 55-59.

CHEN Yang, CHEN Jian-qing, CHEN Zhi-gang. Ultra-smooth surface polishing techniques[J]. Journal of Jiangsu University, 2002, 22(5): 55-59.

[5]Luo J F, Doronfeld D A. Material removal regions in chemical-mechanical planarization for submicron integrated circuit fabrication: coupling effects of slurry chemicals, abrasive size distribution, and wafer-pad contact area [J]. IEEE Transactions on Semiconductor Manufacturing, 2003, 16(1): 45-56.

[6]Park S S, Cho C H, Ahy Y. Hydrodynamic analysis of chemical mechanical polishing process[J]. Tribology International, 2000, 33(10): 723-730.

[7]Cho C H, Park S S, Ahn Y. Three-dimensional wafer scale hydrodynamic modeling for chemical mechanical polishing[J]. Thin Solid Films, 2001, 389(1-2): 254-260.

[8]Zhao Y W, Chang L. A micro-contact and wear model for chemical-mechanical polishing of silicon wafers[J]. Wear, 2002, 252(3-4): 220-226.

[9]陈雪梅, 陈彩凤, 陈志刚. 超声沉淀法制备纳米Al2O3粉体[J]. 中国有色金属学报, 2003, 13(1): 122-126.

CHEN Xue-mei, CHEN Cai-feng, CHEN Zhi-gang. Al2O3 nanopowder prepared by precipitation under ultrasonic radiation[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 122-126.

[10]吴芳, 王零森. 碳化硼陶瓷的表面形貌和摩擦性能[J]. 中国有色金属学报, 2003, 13(1): 136-140.

WU Fang, WANG Ling-sen. Nano tribology properties of boron carbide ceramics studied by atomic force microscope[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 136-140.

[11]Hu Y Z, Chow T P, Gutmann R J, et al. XPS and AFM study of chemical mechanical polishing of silicon nitride[J]. Thin Solid Films Volume, 1998, 333(1-2): 219-223.

[12]李生华, 周春红, 张瑞军, 等. 摩擦化学进展—化学的地位与作用[J]. 摩擦学学报, 2002, 22(1): 74-79.

LI Sheng-hua, ZHOU Chun-hong, ZHANG Rui-jun, et al. Role of chemistry in tribochemsistry progress[J]. Tribology, 2002, 22(1): 74-79.

[13]何进, 陈星弼, 杨传仁, 等. 直接键合硅片的亲水处理及其表征[J]. 半导体技术, 1999, 24(5): 23-25.

HE jin, CHEN Xing-bi, YANG Chuan-ren, et al. Characterization of silicon surface hydrophilicity treatment[J]. Semiconductor Technology, 1999, 24(5): 23-25.

[14]袁巨龙. 功能陶瓷的超精密加工技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 2000. 40-46.

YUAN Ju-long. Ultraprecision Machining of Functional Ceramics[M]. Harbin: Harbin Institute of Technology Press, 2000. 40-46.

[15]陈国荣. 弹性力学[M]. 南京: 河海大学出版社, 2002. 132-136.

CHEN Guo-rong. Mechanics Elasticity[M]. Nanjing: Hehai University Press, 2002. 132-136.

基金项目: 江苏省自然科学基金资助项目(BK2002010); 江苏省高技术资助项目(BG2004022)

收稿日期: 2005-01-14; 修订日期: 2005-05-31

作者简介: 陈志刚(1955-), 男, 教授.

通讯作者: 陈志刚, 教授; 电话: 0519-3290002; E-mail: czg@jpu.edu.cn

(编辑 陈爱华)