DOI: 10.11817/j.issn.1672-7207.2015.10.003

难选赤褐-菱铁矿离析焙烧-弱磁选提铁研究

肖军辉1, 2,张裕书1, 3,冯启明2,陈超1, 3

(1. 国土资源部 钒钛磁铁矿综合利用重点实验室,四川 成都,610041;

2. 西南科技大学 环境与资源学院,四川 绵阳,621010;

3. 中国地质科学院 矿产综合利用研究所,四川 成都,610041)

摘要:针对重庆綦江沉积型赤褐-菱铁矿,提出离析焙烧-弱磁选工艺实现提铁。矿石与氯化钙、焦炭混匀后置入焙烧炉中进行离析焙烧,铁从弱磁性矿物转变为强磁性矿物后,焙烧矿采用弱磁选回收铁。研究结果表明:焙烧矿中产生了以磁铁矿(Fe3O4)、金属铁(Fe)为主的新矿相及少量的氧化亚铁(FeO)新矿相,实现了铁与其他杂质的有效分离。在离析焙烧温度为950 ℃、离析焙烧时间为60 min、氯化钙和焦炭质量分数分别为4%和15%、弱磁选磁场强度H为0.10 T、弱磁选磨矿细度小于0.038 mm的铁精矿质量分数为95%的综合工艺条件下,得到了铁品位为72.02%,硫和磷质量分数分别为0.080%和0.053%,铁回收率为82.09%的铁精矿分选指标,提铁效果显著。

关键词:菱铁矿;赤褐铁矿;离析焙烧;弱磁选

中图分类号:TD951;TF17 文献标志码:A 文章编号:1672-7207(2015)10-3573-07

Upgrading iron of refractory hematite and limonite-siderite ores using segregation roasting-low intensity magnetic separation

Xiao Junhui1, 2, Zhang Yushu1, 3, Feng Qiming2, Chen Chao1, 3

(1. Key Laboratory of Vanadium-titanium Magnetite Comprehensive Utilization,

Ministry of Land and Resources, Chengdu 610041, China;

2. School of Environment and Resources, Southwest University of Science and Technology, Mianyang 621010, China;

3. Institute of Multipurpose Utilization of Mineral Resources, Chengdu 610041, China)

Abstracts: For the sedimentary pattern hematite and limonite-siderite ores in Qijiang of Chongqing, a segregation roasting-low intensity magnetic separation flowsheet was proposed to upgrade iron. Ores, calcium chloride and coke were mixed and put into roasting furnace to undergo segregation roasting. After being transferred from weak to strong magnetic mineral, iron was recovered by low intensity magnetic separation from roasting ores. The results show that in the roasting ores, new ore phases dominated by magnetite (Fe3O4), metallic iron (Fe) and a few ferrous oxide (FeO) are generated, and effective separation of iron minerals as well as other impurities can be achieved. The iron concentrate separation characterized by 72.02% of iron grade, 0.080% of sulfur mass fraction, 0.053% of phosphorus mass fraction, 82.09% of iron recovery can be obtained under segregation roasting temperature of 950 ℃, segregation roasting time of 60 min, calcium chloride mass fraction of 4%, coke mass fraction of 15%, low intensity magnetic field intensity of 0.10 T and iron ore concentrates mass fraction of 95% of grinding fineness less than 0.038 mm. The effect of upgrading iron is obvious.

Key words: siderite; hematite-limonite; segregation roasting; low intensity magnetic separation

钢铁工业持续稳定的发展迫切需要稳定、足量、优质的铁矿原料供给。2012年,我国国产铁矿石13.09亿t,进口铁矿石7.44亿t,预计2015年我国钢产量8亿t,生铁产量7.44亿t,国产铁矿石16亿t,进口铁矿石(7.3~7.5)亿t,铁矿石对外依存度仍将达到60%左右。在渝东地区,蕴藏着丰富的沉积型赤褐铁矿。其中,巫山地区以宁乡式高磷鲕状赤褐铁矿为主,綦江地区为綦江式沉积型赤褐-菱铁矿。前者预计资源总量在3亿t以上,后者预计资源总量也在3亿t左右。该2种沉积型铁矿石中,存在矿物嵌布粒度很小、种类繁多、结构复杂及品位低等缺陷,被世界选矿界公认为难选矿石,至今未能大规模开发利用[1-5]。针对渝东地区的綦江沉积型难选冶铁矿石,本文作者采用离析焙烧-弱磁选工艺进行提铁研究,以便得到处理该难选冶混合铁矿石的综合工艺条件及离析焙烧铁矿物矿相演变的基本规律。

1 实验

1.1 试样性质

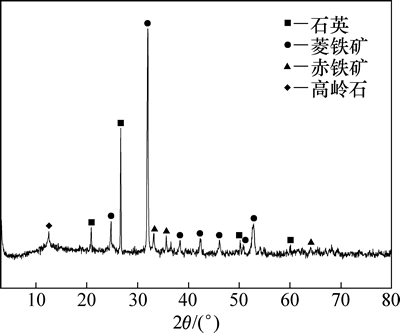

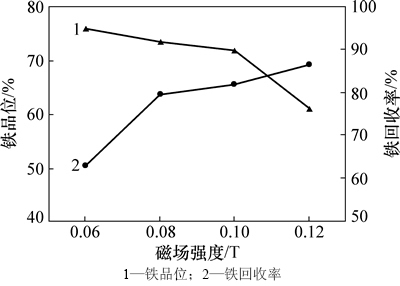

本次试验试样来自渝东地区的綦江,该地区的难选铁矿石中铁主要以菱铁矿为主,其次为褐铁矿为主,原矿Fe品位为36.170%,P和S质量分数分别为0.118%和0.370%,属于低品位难选冶铁矿石。矿石中,菱铁矿多呈粒状、棱角状、形态不规则,嵌布粒度为0.06~2.00 mm,具明显双反射色,表面有星点状褐铁矿分布,部分颗粒被后期褐铁矿交替包围;褐铁矿呈细粒状或浸染状分布于菱铁矿的表面,同时有少量分布在黄铁矿颗粒边缘,为后期的氧化产物;有害元素硫以黄铁矿为主,多呈粒状或浸染状分布,嵌布粒度极不均匀,一般为0.03~0.20 mm,个别为0.50 mm,多被交替溶蚀,边缘呈港湾状,具骸晶结构,有少量与褐铁矿相互交替。试样X线衍射(XRD)主要矿物物相分析结果如图1所示、主要化学成分分析结果如表1所示、铁物相分析结果如表2所示。

结合图1、表1和表2分析可知:綦江混合铁矿石原矿铁品位为36.17%,硅酸盐矿物质量分数较大;矿石中有价金属铁主要以菱铁矿和赤褐铁矿为主,分别占全铁的50.68%和44.68%,属于典型难选冶矿种。常规的选矿很难得到理想的铁精矿分选指标,有害元素磷的质量分数不超标,有害元素硫的质量分数超标0.370%,在分离提取铁的同时需要降低精矿中有害元素硫的质量分数。

图1 试样XRD物相分析结果

Fig. 1 XRD phase analysis results of sample

1.2 方法

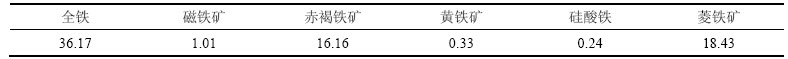

由于綦江混合铁矿石中,铁以菱铁矿和赤褐铁矿为主,呈假鲕碎屑状、粒状、砂状等结构,假鲕碎屑结构比较普遍,呈单一或复合体形式。假鲕碎屑矿物组成主要有赤铁矿、菱铁矿、磁铁矿、绿泥石、石英等,粒径为0.03~0.20 mm不等且嵌布粒度较细,常规的物理选矿方法较难获得理想的铁精矿分选指标[6-9]。本文采用离析焙烧-弱磁选工艺处理该难选冶铁矿石,即:将试样与氯化钙、焦炭按照一定比例混匀后置入焙烧炉中进行离析焙烧后,为防止焙烧产品与空气接触而氧化;采用水淬方式冷却,使铁从菱铁矿、赤褐铁矿的弱磁性矿物转变为以磁铁矿、金属铁为主的强磁性矿物,实现铁与其他杂质的初步分离;离析焙烧产品经水萃冷却进入磨矿机后,采用弱磁选回收铁得到铁精矿。试验工艺流程如图2所示,试验研究主要的仪器设备为XRD仪、扫描电镜(SEM)、电子探针、马弗炉、磁选管、湿式鼓式磁选机、锥形球磨机、分级筛;主要化学试剂及原料为氯化钙、焦炭等。

表1 试样主要化学成分分析结果(质量分数)

Table 1 Main chemical composition analysis results of sample %

表2 试样铁物相分析结果(质量分数)

Table 2 Iron phase analysis results of sample %

图2 离析焙烧-弱磁选试验工艺流程

Fig. 2 Segregation roasting-low intensity magnetic separation test flowsheet

2 结果与讨论

2.1 离析焙烧温度的影响试验

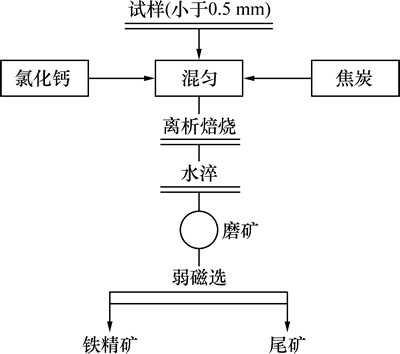

离析温度是决定氯化剂能否分解,有价金属铁能否被氯化的关键因素之一[10-13]。为此,在焦炭(粒度小于0.2 mm)质量分数为15%、氯化钙质量分数为5%、焙烧时间为60 min的焙烧条件下进行离析温度对铁精矿分选指标的影响试验,弱磁选磁场强度H为 0.08 T,磨矿细度小于0.074 mm的铁精矿质量分数为95%,结果如图3所示。

从图3可知:离析温度对铁精矿分选指标的影响效果比较明显,温度升高,铁品位呈先升高后降低的趋势变化,铁回收率呈一直升高的规律变化;当温度为950 ℃时,铁品位出现最大值为65.22%,铁回收率为81.58%。经综合考虑,离析焙烧温度为950 ℃比较合适。

2.2 还原剂用量的影响试验

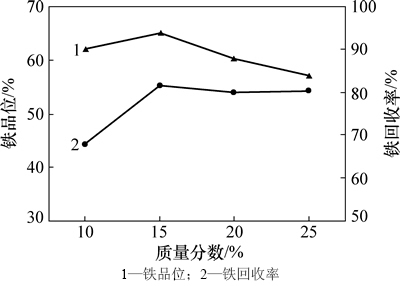

在离析焙烧过程中,焦炭作为还原剂起着提供还原性气氛和提供氯化物吸附载体的双重作用。还原剂用量过多,容易导致其他元素的还原影响铁精矿分选指标;反之,还原剂用量过少,不能有效地还原和吸附铁的氯化物,同样也会影响铁精矿分选指标[14-17]。在离析温度为950 ℃、氯化钙质量分数为5%、焙烧时间为60 min焙烧条件下进行焦炭用量对铁精矿分选指标的影响试验,弱磁选磁场强度H为0.08 T,磨矿细度为小于0.074 mm的铁精矿质量分数为95%,结果如图4所示。

图3 离析焙烧温度对铁精矿品位及回收率的影响

Fig. 3 Effects of segregation roasting temperature on ore grade and recovery of iron ore concentrates

图4 焦炭质量分数对铁精矿品位及回收率的影响

Fig. 4 Effects of mass fraction of coke on ore grade and recovery of iron ore concentrates

从图4可知:焦炭质量分数对铁精矿的铁品位及回收率的影响主要表现为:随着焦炭质量分数的增加,铁品位及回收率呈先升高后降低的规律变化;当焦炭质量分数为15%时,铁品位及回收率出现极大值,分别为65.17%和81.45%。这与焦炭在离析焙烧过程中所起的作用有较大关系。焦炭主要起提供还原性气体CO、H2和作为吸附挥发性FeCl2的载体的双重作用,质量分数过多容易产生过还原现象,质量分数过少,不能有效地还原FeCl2和吸附金属铁粒子,均会影响铁的离析效果。故焦炭质量分数为15%比较合适,在此条件下,可以得到铁品位为65.17%,铁回收率为81.45%的铁精矿分选指标。

2.3 氯化剂用量的影响试验

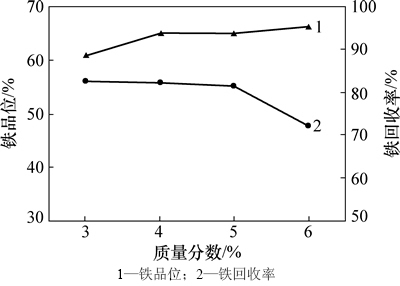

氯化钙作为氯化剂在离析焙烧过程中,与矿石中的SiO2,Al2O3等酸性氧化物及H2O反应生成氯化氢气体,部分有价金属铁与氯化氢发生氯化反应生成FeCl2,由于FeCl2属于不稳定体系,在焦炭表面上被还原和吸附[18-19];同时,氯化氢气体也会与其他元素发生氯化反应,质量分数过多,可能导致副反应的进行;质量分数过少,生成的FeCl2量过少,主要影响铁精矿的回收率。故在离析温度950 ℃、焦炭质量分数为15%、焙烧时间为60 min的焙烧条件下进行氯化钙质量分数对铁精矿分选指标的影响试验,弱磁选磁场强度H为0.08T,磨矿细度为小于0.074 mm的铁精矿质量分数为95%,结果如图5所示。

从图5可知:氯化钙质量分数增加,铁精矿的铁品位逐渐升高,铁回收率呈降低的规律变化,同时质量分数增大易使其他元素被氯化,易导致精矿质量的下降。因此,在确保铁品位大于65%的前提下,氯化钙质量分数为4%比较合适;铁品位为65.21%,铁回收率为82.24%。

图5 氯化钙质量分数对铁精矿品位及回收率的影响

Fig. 5 Effects of mass fraction of calcium chloride on ore grade and recovery of iron ore concentrates

2.4 离析焙烧时间的影响试验

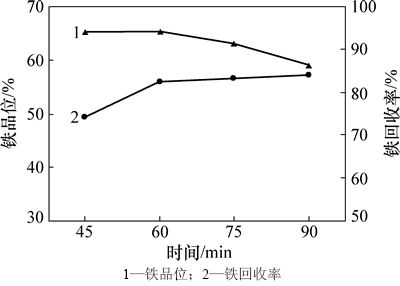

离析焙烧过程主要分为分解反应过程、氯化反应过程、还原反应过程,但分解、氯化、还原等反应不是机械的先后反应过程,而是各种化学反应的交叉[20]。离析焙烧时间决定整个离析焙烧过程反应进行的程度,延长离析焙烧时间,反应相对越完全;但离析焙烧时间过短,又不能实现较好的离析效果。在离析焙烧温度为950 ℃、焦炭质量分数为15%、氯化钙质量分数为4%的焙烧条件下进行离析焙烧时间对铁精矿分选指标的影响试验,弱磁选磁场强度H为0.08 T,磨矿细度为小于0.074 mm的铁精矿质量分数为95%,结果如图6所示。

图6 离析焙烧时间对铁精矿品位及回收率的影响

Fig. 6 Effects of segregation roasting time on ore grade and recovery of iron ore concentrates

从图6可知:延长离析焙烧时间,有利于提高铁的综合回收率,但当离析焙烧时间超过60~75min时,铁精矿的铁品位降低比较明显。这要是由于离析焙烧增加,反应相对越彻底,但同时带来部分副反应;铁回收率增加,但铁品位有所降低。因此,离析焙烧时间为60 min比较合适。在此条件下,可以得到铁品位为65.21%,铁回收率为82.24%的铁精矿分选指标。

2.5 离析焙烧产品弱磁选条件的影响试验

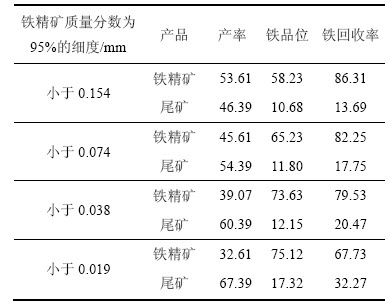

通过离析焙烧条件试验得到了綦江难选混合铁矿石的离析焙烧条件如下:离析焙烧温度为950 ℃,离析焙烧时间为60min,氯化钙和焦炭质量分数分别为4%和15%。为进一步提高铁精矿的分选指标,对离析焙烧产品进行弱磁选条件的影响试验。弱磁选过程中影响铁品位及回收率的主要因素为磨矿细度和磁场强度,因此,在所得到的综合焙烧条件下,进行扩大离析焙烧试验,每次焙烧矿样质量增加至1 kg,将重复试验的离析焙烧样品混合后作为弱磁选条件影响试验物料,首先进行磨矿细度对铁精矿品位及回收率的影响试验,结果如表3所示。

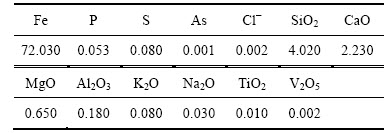

从表3可知:提高磨矿细度,矿物的单体解离程度提高,在磁选过程中有利于提高精矿的铁品位,但磨矿细度过高,精矿的铁回收率降低比较明显。在磁选过程中磁性矿物主要受到磁场力、重力、机械力等的共同作用,而粒度变小时,在分选过程中受到外力的影响就更加明显,要提高分选指标需要改变弱磁选磁场强度。当磨矿细度小于0.038 mm的铁精矿质量分数为95%时,铁品位提高至73.63%,属于高品质铁精矿,故进一步进行磁场强度对铁分选指标的影响试验,结果如图7所示。

表3 磨矿细度对铁精矿品位及回收率的影响(质量分数)

Table 3 Effects of grinding fineness on ore grade and recovery of iron ore concentrates %

图7 磁场强度对铁精矿品位及回收率的影响

Fig. 7 Effects of magnetic field intensity on ore grade and recovery of iron ore concentrates

从图7可知:磁场强度降低,铁品位提高幅度较大,但回收率降低幅度也比较大;当磁场强度为0.14 T时,铁精矿的铁品位降低至61.22%。经综合考虑,磁场强度H为0.10 T比较合适。在此条件下,可以得到铁品位为72.02%,铁回收率为82.09%的铁精矿分选指标,该铁精矿的铁品位接近磁铁矿的理论品位72.41%,属于高纯优质铁精矿。

2.6 讨论

采用离析焙烧-弱磁选工艺处理重庆綦江难选冶赤褐-菱铁矿混合铁矿石,得到了铁品位为72.02%,铁回收率为82.09%铁精矿,提铁效果比较明显。铁精矿主要化学成分分析结果如表4所示。

表4 铁精矿主要化学成分分析结果(质量分数)

Table 4 Main chemical composition analysis results of iron ore concentrates %

从表4可知:铁精矿中有害元素硫、磷的质量分数均很低,主要杂质元素为硅、钙、镁等,进一步说明所得的综合条件较合适,铁精矿分选指标也较为可靠。

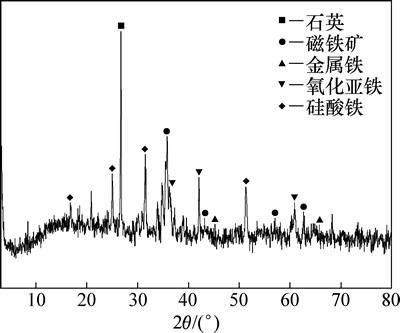

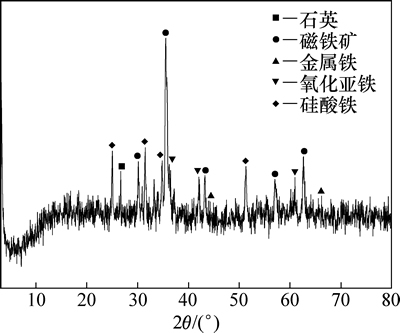

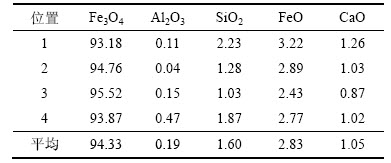

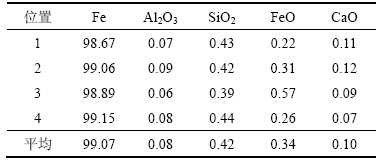

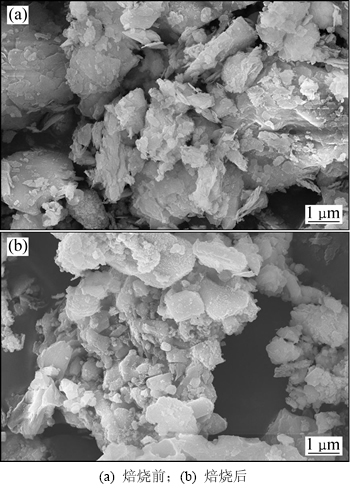

为进一步研究有价金属铁在离析焙烧前后的矿相转变,在工艺条件试验结果的基础上,采用XRD,SEM及电子探针分别对原矿、离析焙烧产品、磁选精矿进行分析检测。XRD物体相分析如图8~9所示、铁矿物的SEM矿相变化如图10所示,电子探针成分分析结果如表5~6所示。

结合图8~10和表5~6可知:离析焙烧前,矿石中的有价金属铁以菱铁矿(FeCO3)、赤褐铁矿(Fe2O3和Fe2O3·nH2O)为主,离析焙烧后铁转变为以磁铁矿(Fe3O4)、金属铁(Fe)为主的新矿相,同时含有少量的氧化亚铁(FeO)的新矿相。金属铁属于铁磁性金属、磁铁矿属于强磁性矿物,二者均具有较大的比磁化系数,采用弱磁选就可以较好地回收铁并得到铁品位较高的铁精矿,进一步验证了离析焙烧-弱磁选工艺处理綦江沉积型赤褐-菱铁矿比较合理,并能够得到显著的提铁效果,同时,铁精矿中的硫、磷、砷等杂质的质量分数也比较低。

图8 焙烧矿XRD物相分析结果

Fig. 8 XRD phase analysis of roasting ores

图9 铁精矿XRD物相分析结果

Fig. 9 XRD phase analysis of sample of iron ore concentrates

表5 焙烧后磁铁矿的电子探针成分分析结果(质量分数)

Table 5 Electronic probe composition analysis results of magnetite after roasting (mass fraction) %

表6 焙烧后金属铁的电子探针成分分析结果(质量分数)

Table 6 Electronic probe composition analysis results of metallic iron after roasting (mass fraction) %

图10 铁矿物相变的SEM图

Fig. 10 SEM images of phase change of iron mineral

3 结论

1) 渝东地区的綦江沉积型赤褐-菱铁矿中,原矿中铁、硫、磷质量分数分别为36.170%,0.370%和0.118%。铁主要以菱铁矿和赤褐铁矿为主;其中,菱铁矿质量占全铁的50.68%,赤褐铁矿质量占全铁的44.68%,两者合计占全铁的95.36%,属于难选冶铁矿石。

2) 在离析焙烧温度为950 ℃,焦炭和氯化钙质量分数分别为15%和4%,离析焙烧时间为60 min,弱磁选磁场强度H为0.10 T,弱磁选磨矿细度小于0.038 mm的铁精矿质量分数95%的综合条件下,可以得到铁品位为72.02%,硫和磷质量分数分别为0.080%和0.053%,铁回收率为82.09%的铁精矿分选指标。

3) 离析焙烧前,矿石中的有价金属铁以菱铁矿(FeCO3)、赤褐铁矿(Fe2O3和Fe2O3·nH2O)为主;离析焙烧后出现了以磁铁矿(Fe3O4)、金属铁(Fe)为主的新矿相,实现了铁从弱磁性矿物到强磁性矿物的转变,即从“难选矿石”到“易选矿石”的转变,也进一步表明离析焙烧-弱磁选处理重庆綦江难选冶赤褐-菱铁矿比较合理。

参考文献:

[1] 王昆, 戴惠新. 菱铁矿选矿现状[J]. 矿产综合利用, 2012(1): 6-9.

WANG Kun, DAI Huixin. Research and application of flotation column in domestic metallic ore beneficiation[J]. Multipurpose Utilization of Mineral Resources, 2012(1): 6-9.

[2] 张宗旺, 李健, 李燕, 等. 国内难选铁矿的开发利用现状及发展[J]. 有色金属科学与工程, 2012, 3(1): 72-77.

ZHANG Zongwang, LI Jian, LI Yan, et al. The development and utilization status of China’s refractory ore[J]. Nonferrous Metals Science and Engineering, 2012, 3(1): 72-77.

[3] 朱庆山, 李洪钟. 难选铁矿流态化磁化焙烧研究进展与发展前景[J]. 化工学报, 2014, 65(7): 2437-2442.

ZHU Qingshan, LI Hongzhong. Status quo and development prospect of magnetizing roasting via fluidized bed for low grade iron ore[J]. CIESC Journal, 2014, 65(7): 2437-2442.

[4] 张凌燕, 杨香风, 王芳, 等. 山西某赤、褐铁矿选矿试验研究[J]. 金属矿山, 2010(3): 53-56.

Zhang Lingyan, Yang Xiangfeng, Wang Fang, et al. Study on the beneficiation technology of a hematite-limonite ore of Shanxi[J]. Metal Mine, 2010(3): 53-56.

[5] 邵安林. 东鞍山含碳酸盐赤铁矿石浮选试验[J]. 中南大学学报(自然科学版), 2013, 44(2): 456-460.

Shao Anlin. Flotation separation of Donganshan carbonates-containing hematite ore[J]. Journal of Central South University (Science and Technology), 2013, 44(2): 456-460.

[6] 王传龙, 杨慧芬, 蒋蓓萍, 等. 云南某褐铁矿直接还原—弱磁选试验[J]. 金属矿山, 2014(5): 74-77.

Wang Chuanlong, Yang Huifen, Jiang Beiping, et al. Experiments on direct reduction-low intensity magnetic separation of a limonite in Yunnan Province[J]. Metal Mine, 2014(5): 74-77.

[7] 罗良飞, 陈雯, 严小虎, 等. 大西沟菱铁矿煤基回转窑磁化焙烧半工业试验[J]. 矿冶工程, 2006, 26(2): 71-73.

Luo Liangfei, Chen Wen, Yan Xiaohu, et al. Pilot plant test of magnetization roasting of Daxigou Siderite Ore by Rotary Kiln[J]. Mining and Metallurgical Engineering, 2006, 26(2): 71-73.

[8] 陈涛, 黄兴远, 刘莉霞. 离析焙烧-磁选法富集磁铁矿尾渣中钴的工艺研究[J]. 稀有金属与硬质合金, 2013, 41(1): 5-7, 12.

Chen Tao, Huang Xingyuan, Liu Lixia. Research on process of cobalt enrichment from magnetite tailings by segregation roasting-magnetic separation[J]. Rare Metals and Cemented Carbides, 2013, 41(1): 5-7, 12.

[9] 王在谦, 唐云, 舒聪伟, 等. 难选褐铁矿氯化离析焙烧-磁选研究[]. 矿冶工程, 2013, 33(2): 81-83, 87.

Wang Zaiqian, TanG Yun, Shu Congwei, et al. Study on chloridizing segregation roasting-magnetic separation for refractory limonite[J]. Mining and Metallurgical Engineering, 2013, 33(2): 81-83, 87.

[10] LUO Lingqun, HUANG Hong, YU Yongfu. Characterization and technology of fast reducing roasting for fine iron materials[J]. Journal of Central South University, 2012, 19(8): 2272-2278.

[11] 邹德余, 伍成波, 朱子宗. 贫菱铁预还原矿回转窑生产及高炉冶炼试验[J]. 钢铁, 1997, 32(11): 5-8.

ZOU Deyu, WU Chengbo, ZHU Zizong. Experiment on reducing pretreatment of lean siderite with rotary kiln and blast furnace smelting of prereduced ore[J]. Iron and Steel, 1997, 32(11): 5-8.

[12] 伍喜庆, 程征, 杨平伟. 矿浆pH对表面磁化和菱铁矿-赤铁矿协同磁化的效应[J]. 中南大学学报(自然科学版), 2014, 45(3): 677-683.

WU Xiqing, CHNEG Zheng, YANG Pingwei. Effects of pulp pH on surface magnetization and siderite-hematite synergic magnetization[J]. Journal of Central South University (Science and Technology), 2014, 45(3): 677-683.

[13] McLennan A R, Bryant G W, Bailey C W, et al. Experimental comparison of the ash formed from coals containing pyrite and siderite mineral in oxidizing and reducing conditions[J]. Energy and Fuels, 2000, 14(2): 308-315.

[14] LI Ding, CHEN Luzheng, HUANG Jianxiong, et al. Effect of feed solids on high gradient magnetic separation of cylindrical magnetic matrix[J]. Advanced Materials Research, 2014, 881: 1634-1637.

[15] Singh S, Sahoo H, Rath S S, et al. Separation of hematite from banded hematite jasper (BHJ) by magnetic coating[J]. Journal of Central South University, 2015, 22(2): 437-444.

[16] BAI Shaojun,L Chao, WEN Shuming, et al.Removal of harmful elements and sodium carbonate reinforced carbothermic reduction of siderite ore with high phosphorus and sulphur content[J]. Ironmaking and Steelmaking, 2014, 41(2): 138-146.

Chao, WEN Shuming, et al.Removal of harmful elements and sodium carbonate reinforced carbothermic reduction of siderite ore with high phosphorus and sulphur content[J]. Ironmaking and Steelmaking, 2014, 41(2): 138-146.

[17] Michelin A, Burger E, Leroy E, et al. Effect of iron metal andsideriteon the durability of simulated archeological glassy material[J]. Corrosion Science,2013, 76: 403-414.

[18] 罗立群, 陈敏, 杨铖, 等. 鲕状赤铁矿的磁化焙烧特性与转化过程分析[J]. 中南大学学报(自然科学版), 2015, 46(1): 2-13.

LUO Liqun, CHEN Min, YANG Cheng, et al. Characteristics of magnetic roasting and analysis of phase transformation process of oolitic iron ore[J]. Journal of Central South University (Science and Technology), 2015, 46(1): 2-13.

[19] Logachev G N, Pishnograev S N, Gostenin V A.Influence of roastedsideriteconcentrate in the sintering batch on blast-furnace performance at OAO MMK[J]. Steel in Translation,2012, 42(6): 502-503.

[20] WU Xiqing, XU Pengyun, DUAN Yunfeng, et al.Surface magnetization ofsideritemineral[J]. International Journal of Mining Science and Technology,2012, 22(6): 825-830.

(编辑 罗金花)

收稿日期:2015-01-07;修回日期:2015-03-18

基金项目(Foundation item):中国地质大调查项目(12120113087600);国土资源部钒钛磁铁矿综合利用重点实验室资助项目(KLVMCU-2014-01)(Project (12120113087600) supported by China Geological Big Survey; Project (KLVMCU-2014-01) supported by Key Laboratory of Vanadium-titanium Magnetite Comprehensive Utilization, Ministry of Land and Resources)

通信作者:肖军辉,男,博士(后),副教授,从事选冶理论与工艺研究;E-mail:xiaojunhui33@163.com