文章编号:1004-0609(2013)S1-s0781-06

机械球磨-分段烧结制备TiAl基金属间化合物多孔材料

李达人,崔利群,蔡一湘

(广州有色金属研究院 粉末冶金研究所,广州510650)

摘 要:采用粉末冶金工艺,利用传统元素反应烧结合成TiAl基金属间化合物多孔材料。研究机械球磨对制备TiAl基多孔材料的影响,并研究低温烧结和高温烧结两个不同阶段中Ti、Al原材料粉末配比和Al粉颗粒度对制备TiAl基多孔材料的影响。结果表明:随球磨时间延长,坯料的孔隙度降低,未球磨粉末的颗粒分散性较差,对于细粉容易造成组织不均匀。n(Ti):n(Al)=1:2的坯料低温烧结后,再进行高温烧结,反应更加完全。Al粉粒度在40μm左右时,低温烧结成形能获得所需的比较好的闭孔隙形态。

关键词:TiAl合金;多孔材料;机械球磨;烧结;孔隙率

中图分类号:TG146.2 文献标志码:A

Preparation of TiAl intermetallic porous material by mechanical milling-segmented sintering

LI Da-ren, CUI Li-qun, CAI Yi-xiang

(Department of Powder Metallurgy, Guangzhou Research Institute of Non-ferrous Metals, Guangzhou 510650, China)

Abstract: TiAl intermetallic porous material was prepared by powder metallurgy process. The influence of mechanical milling on the preparation of TiAl porous material was investigated. The effects of powder ratio of raw materials and Al powder particle size on the preparation of TiAl porous material by sintering at low temperature and high temperature were studied, respectively. The results show that porosity reduces with increasing the milling time, the powders dispersion property is worse without milling and fine powder is easy to cause non-uniform microstructure. The chemical reaction of sample with n(Ti):n(Al)=1:2 is more completely by segmented sintering. The Al powder with particle size of about 40 μm can form better close pore by sintering at low temperature.

Key words: TiAl alloy; porous material; mechanical milling; sintering; porosity

金属多孔材料是20世纪80年代后期国际上迅速发展起来的,由刚性骨架和内部的孔洞组成,是具有优异的物理特性和良好的力学性能的新型工程材料。金属多孔材料具备的优异物理性能,如密度小、刚度大、比表面积大、吸能减振性能好、消音降噪效果好、电磁屏蔽性能高,使其应用领域已扩展到航空、电子、医用材料及生物化学领域等[1-5]。TiAl基合金在反应烧结过程中由于元素偏扩散造成Kirkendall效应,能生成大量的孔隙,且难以完全被消除。这种由于化学反应生成孔隙的现象,十分有利于金属多孔材料的制备。经过预成形的坯料再经反应烧结用于具有特殊截面的TiAl基多孔型材的制备,其成本低、产量高、工艺简单。国内外TiAl基合金的研究主要集中在结构材料方面,而对于TiAl基多孔功能材料的研究在国内外也已经有了部分报道[6-12],但主要集中在新型过滤材料和固体电解电容器阳极材料两方面的应用上,对于TiAl基多孔绝热材料的研究在国内外几乎是空白。彭超群等[13]制备的TiAl合金过滤材料的最可几孔径可达2.56 μm。HE等[14]利用Kirkendall 效应制备的开孔TiAl多孔过滤材料不仅孔隙大小可调节,并且耐腐蚀抗氧化。WANG等[15]采用元素粉末冶金法制备的Ti-48Al-6Nb多孔材料在800 ℃的热导率仅为3.42 W·m-1·K-1。

本文作者采用粉末冶金工艺,利用传统元素反应烧结合成TiAl基金属化合物,并开展对TiAl基多孔材料制备工艺和孔隙特征的研究。

1 实验

实验采用的Ti粉的颗粒尺寸小于50 μm,纯度为99.5%;Al粉的颗粒尺寸范围在20~800 μm之间,纯度为99.8%,并采用了5种不同的Ti、Al成分配比n(Ti):n(Al)=3:1,2:1,1:1,1:2,1:3)来混合粉末。将Ti粉和颗粒尺寸小于80μm的Al粉按摩尔比1:1混合,在球磨机中进行球磨。不同球磨时间、不同成分配比以及不同颗粒度的Ti/Al复合粉末经冷压制坯,然后对粉体坯料进行低温无压真空反应烧结和高温烧结,将Ti/Al机械混合物组织转变为TiAl基合金组织。烧结坯的密度通过阿基米德排水法测量,并计算理论密度和孔隙率。试样通过XRD分析确定烧结后各相的组成,采用金相观察来分析坯料的显微组织与孔隙形态。

2 结果与分析

2.1 机械球磨对烧结制备多孔材料的影响

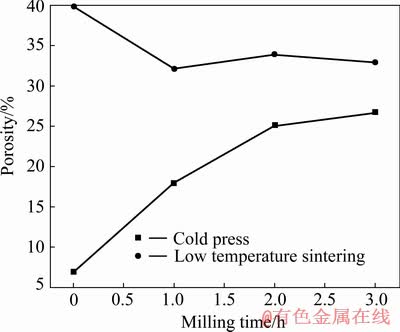

图1所示为低温烧结孔隙度随球磨时间变化曲线。由图1可知,未球磨粉末烧结后孔隙度最大,而随着球磨时间的延长,孔隙度逐渐减小。这是因为在高能球磨Ti/Al粉末中,Ti和Al组元形成层片结构,同时随着球磨时间的延长层片间距迅速减小[16]。从而Al组元被细化后,在烧结过程中向Ti组元扩散反应完全后所留下的孔隙也减小,孔隙度也随之逐渐降低,由未球磨时的39.8%降低到球磨3h后的32.9%。

图1 低温烧结孔隙度随球磨时间变化曲线

Fig.1 Changing curves of porosity by low temperature sintering with milling time

对不同球磨时间(0、1、2和3 h) 的复合粉体热压坯料在620 ℃、4 h的低温无压真空反应烧结后,再进行1200℃、2h高温烧结,测出高温烧结后的密度。试样通过XRD分析确定烧结后各相的组成。

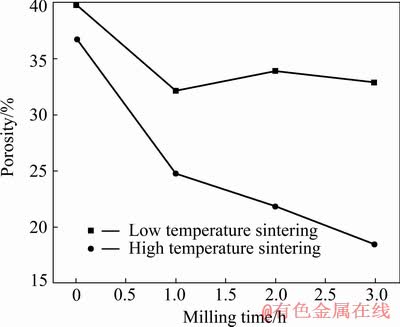

在经过低温烧结后,为了使反应充分进行,促进平衡相的形成,并形成冶金结合,进行高温烧结,在1200 ℃高温烧结2 h。坯料经过高温烧结后,体积与低温烧结后相比均有不同程度的收缩,孔隙度较低温烧结后,坯料的孔隙度有了明显的降低。从图2中可以看到,坯料的孔隙度随着球磨时间的延长而逐渐降低。这说明机械球磨对高温烧结致密过程有明显促进作用,主要是因为机械球磨促进了粉末细化,使烧结过程中扩散更易于进行。而且由于Al组元的细化,偏扩散留下的孔隙大多非常细小,在高温烧结过程中更容易闭合。这显然对于制备高孔隙率的多孔材料是不利的。

图2 高温烧结孔隙度随球磨时间变化曲线

Fig.2 Changing curves of porosity by high temperature sintering with milling time

2.2 分段烧结中Ti、Al原材料粉末配比对多孔材料的影响

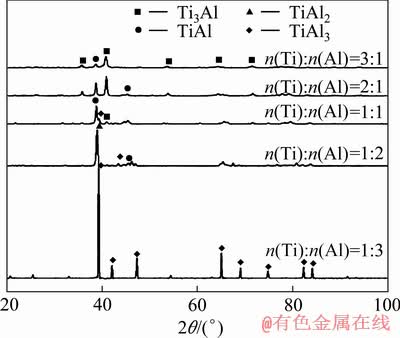

图3所示为不同成分配比坯料低温烧结后的XRD谱。从图3可以明显看出,对于n(Ti):n(Al)=3:1的坯料,主要相组成是Ti3Al,没有富铝相的存在。而对于n(Ti):n(Al)=2:1的坯料,主要相组成为Ti3Al和TiAl,这主要是因为Ti2Al与Ti3Al、TiAl相比,属于一种不稳定相,在常规条件下很难单独生成,充分反应后平衡产物为后两者。对于n(Ti):n(Al)=1:1的坯料,主要相成分为TiAl以及平衡反应的过渡产物Ti3Al和TiAl3,这说明低温烧结对于Ti含量比较高的坯料而言,扩散反应还是进行的不完全,还没有完全达到相平衡。而对于富铝的配比坯料(n(Ti):n(Al)=1:2),Al基本完成了扩散,主要相为TiAl2,以及少量残留的TiAl和TiAl3。n(Ti):n(Al)=1:3的坯料基本上完全形成了TiAl3。这说明低温下Al相的反应比较完全。

图3 不同成分配比时坯料低温烧结后的XRD谱

Fig.3 XRD patterns of low temperature sinter with different composition ratios

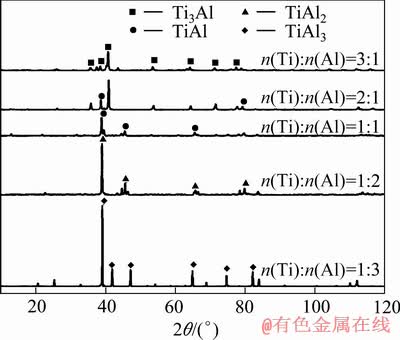

图4所示为不同成分配比坯料高温烧结后的XRD谱。从图4可以看出,经过高温烧结后,在富钛的坯料内部,过渡相TiAlx都已经消耗完毕,产物基本为Ti3Al和TiAl的混合物。对于富铝的坯料,n(Ti):n(Al)= 1:2坯料的反应更加完全,生成了稳定的TiAl2相;而对于n(Ti):n(Al)=1:3的坯料,与低温烧结的谱线差别不大,还产生了一些杂峰。这主要是因为高温烧结设备的真空度不高,有C元素混入(以CO2等的形式)造成的,在所有坯料的内部,都产生了微量的碳化物。

2.3 分段烧结中Al粉颗粒度对多孔材料孔隙率的影响

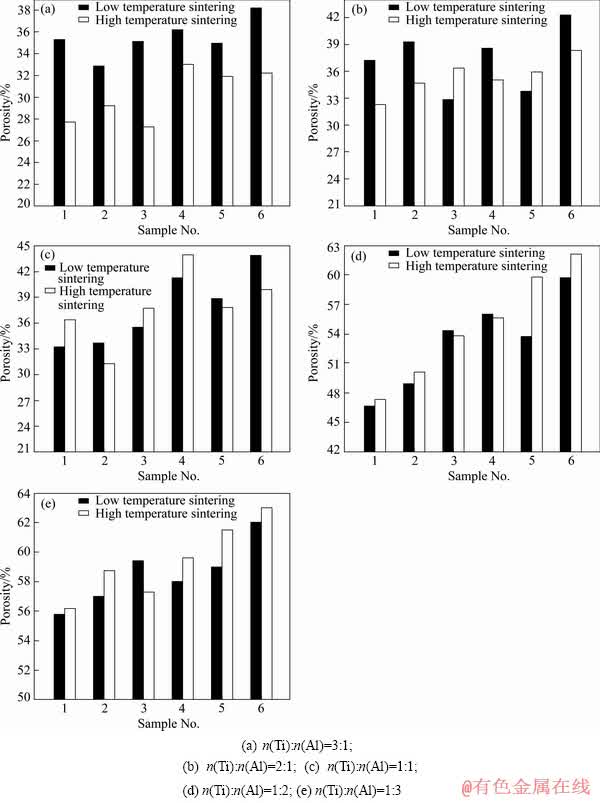

图5所示为不同Al粉粒度坯料低温烧结高温烧结孔隙度变化柱状图。可以看出,对于n(Ti):n(Al)=3:1的坯料(见图5(a)),不同Al粉颗粒度坯料经过高温烧结以后孔隙度都有所下降,这主要是由高温烧结力驱动下一些细小的孔隙闭合造成的,对于Al粉颗粒度比较大的坯料,即孔隙度比较大的坯料,其收缩程度比较小,孔隙度降低的幅度比较小。

图4 不同成分配比时坯料高温烧结后的XRD谱

Fig.4 XRD patterns of high temperature sinter with different composition ratios

图5 不同Al粉颗粒度坯料低温烧结高温烧结的孔隙度变化柱状图

Fig.5 Changing histograms of low and high temperature sinter porosity with Al powder particle size

而对于n(Ti):n(Al)=2:1、n(Ti):n(Al)=1:1的坯料,不同Al粉颗粒度坯料的孔隙度本身波动就比较大,烧结过程中相成分变化比较复杂,再加上烧结变形的影响,其高温烧结收缩和孔隙度的降低不十分明显。而对于n(Ti):n(Al)=1:2和n(Ti):n(Al)=1:3的坯料,其经过高温烧结后的相变化很小,没有致密的富钛相生成,因此其孔隙度没有产生明显的下降,而且在Al粉颗粒度比较大的 时候,孔隙度还产生了明显的上升。从图中还可以看出,不同Al粉颗粒度坯料低温烧结后,随着粉末颗粒尺寸的增大,不同配比的坯料的孔隙度基本上也随之增大。

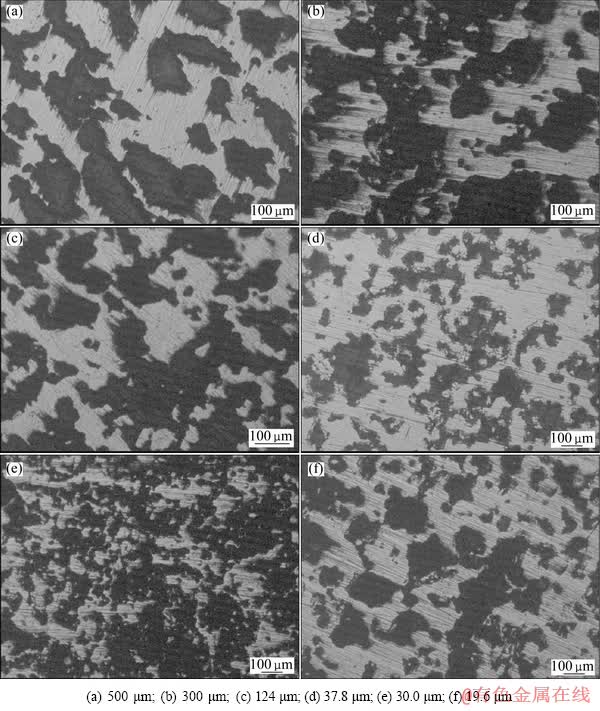

图6所示为不同Al粉粒度低温烧结坯料(n(Ti):n(Al)=1:1)金相组织。从图6可以看出,对于Al粉颗粒度比较大的坯料(见图6(a)、(b)和(c)),单个孔隙的尺寸都比较大,而且孔隙之间容易产生连接形成更大尺寸的连通孔,其中大于500 μm的Al粉反应后形成的孔隙为明显的长条状孔。对于Al粉颗粒度为37.8 μm的坯料(见图6(d)),孔隙分散性相对较好,孔径尺寸也比较均匀,闭孔隙较多,实验效果好。Al粉颗粒度再减小后,Al粉颗粒在制坯过程中容易产生团聚,在随后的低温烧结成型过程中形成的孔隙出现明显的大小分布不均匀。综上所述,Al粉粒度在40 μm左右低温烧结成形能获得所需的比较好的闭孔隙形态。

3 结论

1) 机械球磨Ti/Al复合粉末经过低温烧结,孔隙度随着球磨时间的增长而减小,孔隙度由未球磨时的39.8%降低到球磨3 h后的32.9%。低温烧结坯料经高温烧结,孔隙率有所降低,孔隙度的降低幅度随着球磨时间的延长而增大。

2) 低温烧结对于富铝的配比坯料反应比较完全。经过高温烧结后,在富钛的坯料内部,产物基本为Ti3Al和TiAl的混合物;对于富铝的坯料,n(Ti):n(Al)=1:2坯料的反应更加完全。

3) 不同Al粉颗粒度坯料低温烧结后,随着粉末颗粒尺寸的增大,不同配比的坯料的孔隙度基本上是随之增大的,经高温烧结以后孔隙度都有所下降低。Al粉粒度在40 μm左右低温烧结成形能获得所需的比较好的闭孔隙形态。

图6 不同Al粉粒度低温烧结坯料的金相组织

Fig.6 Microstructures of samples with different Al powder particle sizes sintered at low temperature

REFERENCES

[1] BANHART J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 559-632.

[2] 戴长松, 张 亮, 王殿龙, 胡信国. 泡沫材料的最新研究进展[J]. 稀有金属材料与工程, 2005, 34(3): 337-340.

DAI Chang-song, ZHANG Liang, WANG Dian-long, HU Xin-guo. The newest developments of foam materials[J]. Rare Metal Materials and Engineering, 2005, 34(3): 337-340.

[3] 刘培生. 泡沫金属力学性能的若干问题[J]. 稀有金属材料与工程, 2004, 33(5): 473-477.

LIU Pei-sheng. Some problems on mechanical properties of foamed metals[J]. Rare Metal Materials and Engineering, 2004, 33(5): 473-477.

[4] 赵增典, 张 勇, 李 杰. 泡沫金属的研究及其应用进展[J]. 轻合金加工技术, 1998, 26(11): 1-4.

ZHAO Zeng-dian, ZHANG Yong, LI Jie. The study and application progress of porous metal[J]. Light Alloy Fabrication Technology, 1998, 26(11): 1-4.

[5] EVANS A G, HUTCHINSON J W, ASHBY M F. Multifunctionality of cellular metal systems[J]. Progress in Materials Science, 1998, 43(3): 171-221.

[6] KIM J M, KIM J, YOON S H, HYUN S K, KIM M S. Fabrication and compressive properties of porous TiAl-Mn intermetallics by powder metallurgical route[J]. Metals and Materials International, 2013, 19(2): 159-162.

[7] YANG S H, KIM W Y, KIM M S. Fabrication of unidirectional porous TiAl-Mn intermetallic compounds by reactive sintering using extruded powder mixture[J]. Intermetallics, 2003, 11(8): 849-855.

[8] YANG F, LIN J, HE Y, DU H, CHEN G. Innovative fabrication of Ti-48Al-6Nb porous coating by cold gas spraying and reactive sintering[J]. Materials Letters, 2012, 76: 190-193.

[9] HAN Y F, LIN J P, XIAO CH B, ZENG X Q. Effect of Nb addition on the corrosion behavior of porous TiAl based alloys in aqueous environments[J]. Materials Science Forum, 2013, 747/748: 57-62.

[10] FROES F.H., EYLON D. Powder metallurgy of titanium alloys[J]. International Materials Reviews, 1990, 35(3): 162-182.

[11] JHA S K, LARSEN J M, ROSENBERGER A H. The role of competing mechanisms in the fatigue life variability of a nearly fully-lamellar γ-TiAl based alloy[J]. Acta Materialia, 2005, 53(5): 1293-1304.

[12] WU X. Review of alloy and process development of TiAl alloys[J]. Intermetallics, 2006, 14(10/11): 1114-1122.

[13] 彭超群, 江 垚, 贺跃辉, 汤义武, 黄伯云. 元素粉末冷轧成形及反应合成制备TiAl合金过滤材料[J]. 中国有色金属学报, 2006, 14(6): 889-894.

PENG Chao-qun, JIANG Yao, HE Yue-hui, TANG Yi-wu, HUANG Bai-yun. Fabrication of TiAl filter material through elemental powder cold roll forming and reactive synthesis[J]. The Chinese Journal of Nonferrous Metals, 2006, 14(6): 889-894.

[14] HE Y H, JIANG Y, XU N P, ZOU J, HUANG B Y, LIU C T, LIAW P K. Fabrication of Ti-Al micro/nanometer-sized porous alloys through the Kirkendall effect[J]. Advanced Materials, 2007, 19(16): 2102-2106.

[15] WANG Y H, LIN J P, HE Y H, ZU C K, CHEN G L. Pore structure and thermal insulating properties of high Nb containing TiAl porous alloys[J]. Journal of Alloys and Compounds, 2010, 492(1/2): 213-218.

[16] 李达人, 于 洋, 王尔德. 高能球磨Ti/Al复合粉体低温烧结膨胀开裂行为[J]. 材料科学与工艺, 2008, 16(4): 467-470.

LI Da-ren, YU Yang, WANG Er-de. Expansion and dehiscence behaviors during low-temperature reactive sintering of compact Ti/Al composite powders prepared by high-energy ball milling[J]. Materials Science and Technology, 2008, 16(4): 467-470.

(编辑 龙怀中)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:李达人,工程师,博士;电话:020-61086127; E-mail: darenlie@126.com