基于DEFORM-3D的7050铝合金动态再结晶

元胞自动机模拟

易幼平,刘超,黄始全

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:通过热模拟实验与金相实验建立7050铝合金流变应力模型与动态再结晶的元胞自动机模型(CA模型),该模型综合考虑动态回复、位错密度以及形核率等因素对动态再结晶的影响。应用DEFORM-3D有限元软件模拟7050铝合金自由锻过程与微观组织演变,研究工艺参数与锻件变形程度对微观组织的影响。研究结果表明:变形充分的中心区域先发生动态再结晶,拔长工艺对动态再结晶影响明显,经过拔长可得到均匀细化的组织;经过自由锻工艺后动态再结晶体积分数为40%左右,平均晶粒尺寸为20 μm左右。模拟结果与工业实验结果吻合。

关键词:7050铝合金;动态再结晶;微观组织;元胞自动机

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2010)05-1814-07

Simulation of dynamic recrystallization for 7050 aluminium alloy on platform of DEFORM-3D using cellular automaton

YI You-ping, LIU Chao, HUANG Shi-quan

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The cellular automaton (CA) model of dynamic recrystallization (DRX) for 7050 aluminium alloy was established by thermal-mechanical simulation test and the metallurgical experiment, in which the effects of dynamic recovery, dislocation density and nucleation rate on the DRX were considered. The process of free forging and the law of microstructure evolution for 7050 aluminium alloy were investigated on the software platform of DEFORM-3D. The simulated results show that the DRX occurs sufficiently at the center area of the forging with sufficient deformations. The stretching progress has a great influence on DRX, which can refine the grains and improve the microstructure. By means of multiple-stretching process, the refined and uniform DRX grains can be obtained. Through the free forging the recrystallization volume fraction changes to 40% and the average grain size changes to 20 μm. The simulation results agree well with the industrial results.

Key words: 7050 aluminium alloy; dynamic recrystallization; microstructure; cellular automaton

7050铝合金是一种具有高强度、高韧性的结构材料,被广泛用于飞机制造业,其优良的力学性能取决于材料热变形过程形成的微观组织。自由锻造是构件模锻成形前改善材料内部组织、减少和消除铸造缺陷的必要手段,通过合理的热变形工艺优化、控制材料热变形过程的动态再结晶行为可实现对材料微观组织的调控。然而,目前国内对于新型飞机结构件锻造工艺设计仍依赖于传统的高成本、长周期的工业实验,这制约了航空制造业的发展。计算机数值模拟技术的发展为解决锻件成形工艺设计提供了一种有效途径,国内外学者在此领域进行了大量实验与理论研究。Rollett等[1]采用Monte Carlo方法对动态再结晶的微观组织演化进行了模拟,但他们只考虑了形核率和不同变形条件下存储能的影响。Peczak等[2-5]将Monte Carlo方法与KM模型结合,模拟了加工硬化及动态回复对动态再结晶微观结构的影响,但由于Monte Carlo的局限性,无法考察晶粒的生长动力学特征。近年来,采用元胞自动机(Cellular automaton,CA)模拟材料成形过程微观组织演变规律受到普遍关注。李殿中等[6-7]采用CA法对金属凝固成形过程的再结晶过程进行了模拟。Hesselbarth等[8]建立了基于元胞自动机法的初次再结晶模型,但他们并没有对动态再结晶进行模拟。Goetz等[9]在Hesselbarth等[8]的基础上对动态再结晶进行了模拟研究,但他们的模型没有与热加工过程的实际参数建立关系,因而无法直接考察变形条件对动态再结晶动力学的影响。总体来说,CA作为一种时间、空间、状态都离散的网格动力学模型,目前已应用于凝固结晶的形核生长、再结晶和相变等过程的模 拟[10-13],但对于锻造过程中的动态再结晶的模拟还很少。Deform-3D是目前用于材料热成形过程模拟的大型商用软件,其中的CA模块可用于模拟材料热成形过程的微观组织演变规律分析。本文作者利用DEFORM-3D软件平台与CA模块对7050铝合金锻件自由锻工艺进行仿真分析,利用热力模拟实验确定7050铝合金高温流变方程与再结晶模型,建立7050铝合金CA仿真模型,研究锻造工艺参数对材料内部组织的影响规律,以便为7050铝合金自由锻工艺设计提供依据。

1 相关模型与理论分析

1.1 CA模型

CA(Cellular automata)是一种用来描述复杂系统在离散空间-时间上演化规律的数学算法,CA模型由元胞空间、邻居类型、边界条件和元胞状态4个基本要素组成,它具有5个特性:(1) 元胞均匀排列;(2) 元胞的状态随时间演变;(3) 元胞的数值是有限的;(4) 元胞状态的演化规则是确定的或随机的;(5) 每个元胞的演化规则是局部的,仅与周围的元胞有关系。本模型将模拟区域划分为200×200(长×宽)的四边形元胞空间,所模拟的区域为1 mm×1 mm的实际样品;采用周期性边界模拟无限大区域;元胞的状态根据转换规则由邻居元胞的状态决定;采用Moore邻居,如图1所示,其中黑色区域代表中心元胞,灰色区域代表其邻居元胞。

图1 Moore邻居

Fig.1 Moore neighbourhood

1.2 流变应力模型

在高温塑性变形条件下,流变应力、应变速率和温度之间的关系可用Sellars和Tegart提出的包含变形激活能Q和温度T的双曲正弦形式表示[14]:

(1)

(1)

式中: 为应变速率;A,n和

为应变速率;A,n和 为常数;Q为变形激活能;R为摩尔气体常数;σ为峰值应力;T为热力学温度。

为常数;Q为变形激活能;R为摩尔气体常数;σ为峰值应力;T为热力学温度。

对上述方程取对数转换为线性问题,再利用热力模拟实验数据用线性回归的方法得出方程中的系 数[15-16]:

(2)

(2)

1.3 位错密度模型

金属的塑性变形源于位错的移动。而在加工过程中,位错密度是不断变化的,在DEFORM-3D中,将位错密度表示成如下增量形式(此模型为DEFORM-3D软件自带模型,参数值根据实验数据进行线性回归得到):

(3)

(3)

(4)

(4)

(5)

(5)

式中: 为位错密度;

为位错密度; 为应变;h为位错应力场作

为应变;h为位错应力场作

用范围高度;r为位错应力场作用范围半径;m为速率敏感度,一般m取0.2; 为应变速率;

为应变速率; 为未发生动态的应变速率。

为未发生动态的应变速率。

1.4 回复模型

动态回复是加工变形金属的另一软化效应,伴随着位错密度的降低,DEFORM-3D中采用的是Goetz等[13]提出的回复模型,即每一时间步随机选取一定数量的元胞N,使其位错密度降低一半:

(6)

(6)

这样,就使得各个元胞的位错密度分布不均匀。N由下式确定:

(7)

(7)

式中:M为CA模型中总元胞数;K为常数,取6 030; 为位错密度增长速率。

为位错密度增长速率。

1.5 动态再结晶形核和长大模型

研究表明动态再结晶的形核与位错密度的累积有关。随着应变量的不断增大,位错密度 以一定的速率增长;当位错密度达到一定的临界值

以一定的速率增长;当位错密度达到一定的临界值 时,动态再结晶晶粒开始在晶界处开始以一定的形核速率

时,动态再结晶晶粒开始在晶界处开始以一定的形核速率 开始形核。形核速率与应变速率

开始形核。形核速率与应变速率 密切相关,一般认为两者呈线性关系[17]:

密切相关,一般认为两者呈线性关系[17]:

(8)

(8)

式中 :C和 为常数,通常

为常数,通常 取0.9,C=200。

取0.9,C=200。

当位错密度达到一定的临界值时,发生动态再结晶,在原晶粒的晶界开始形成新的晶粒。对于新晶粒,初始应变和位错密度为0,并随着变形的继续而逐渐增加。由于再结晶晶粒和原晶粒之间存在着位错密度 差,为新晶粒的生长提供了驱动力,使新晶粒不断长大,直至驱动力减小至0,新晶粒停止生长,或与其他新晶粒相接触,在相接触部分均停止生长。若新晶粒的位错密度达到动态再结晶的临界值,则动态再结晶将继续在新晶粒的晶界上形核和长大。动态再结晶晶粒的生长速度与单位面积上的驱动力成正比[17]:

(9)

(9)

(10)

(10)

其中:b为柏格斯矢量模量;D为扩散系数;Qb为边

界移动激活能; 动态再结晶晶粒的位错密度;

动态再结晶晶粒的位错密度; 为与之相邻晶粒的位错密度;

为与之相邻晶粒的位错密度; 为线位错能;

为线位错能; 为界面能。

为界面能。

(11)

(11)

(12)

(12)

式中: 为再结晶晶粒的晶粒取向;

为再结晶晶粒的晶粒取向; 为相邻晶粒的晶粒取向;

为相邻晶粒的晶粒取向; 为晶界成为大角度晶界时的界面能,

为晶界成为大角度晶界时的界面能, 可由如下公式得出:

可由如下公式得出:

(13)

(13)

其中: 为泊松比。

为泊松比。

1.6 动态再结晶体积分数和再结晶晶粒尺寸

动态再结晶体积分数和再结晶晶粒尺寸方程的表达式如下(此模型是由DEFORM-3D软件自带模型,参数值由实验数据进行线性回归得到):

(14)

(14)

(15)

(15)

(16)

(16)

式中:a1, a2, a3, h1, h2, n1, n2, m1, c1和c2为常数;d0为原始晶粒尺寸,本模型中d0为90 μm; 为应变速率;

为应变速率; 为动态再结晶体积分数;

为动态再结晶体积分数; 为动态再结晶体积分数为50%时对应的应变;drex为动态再结晶晶粒尺寸;

为动态再结晶体积分数为50%时对应的应变;drex为动态再结晶晶粒尺寸; 为峰值应变;Q1为晶粒长大激活能;Q2为再结晶激活能。

为峰值应变;Q1为晶粒长大激活能;Q2为再结晶激活能。

为获得上述方程中的系数,对以上方程取对数转换为线性问题,再利用热力模拟实验数据用线性回归的方法得出方程中的系数,得出以下方程 :

(17)

(17)

(18)

(18)

(19)

(19)

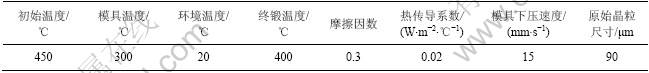

表1所示为7050铝合金材料基本参数[14-15],表2所示为在DEFORM-3D平台上模拟时的基本参 数[14-15]。

表1 材料基本参数

Table 1 Basic parameters of the material

表2 仿真模拟基本参数

Table 2 Basic parameters in simulation

2 模拟结果与分析

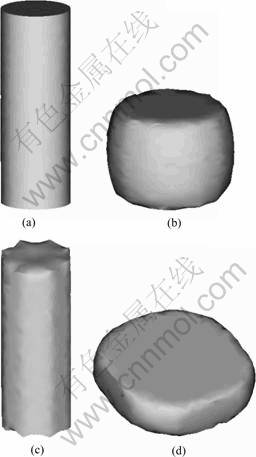

将热力模拟实验获得的材料系数与CA模型在DEFORM-3D平台上对7050铝合金大锻件自由锻过程进行仿真模拟。CA法采用均匀的网格划分,每一时刻基元的状态用有限的值加以描述,初始晶粒采用等轴长大方式形成。为了用有限的空间代替无限的空间,采用了周期性边界条件,所取的平面区域划分为200×200个网格,代表1 mm×1 mm的实际样品,所选的材料为7050铝合金。模拟的自由锻过程包括镦粗、拔长和平整等工艺,如图2所示。

图3所示为原始坯料的剖面图与微观组织。本文微观组织模拟的区域为中心区域(P1)。P2所示为坯料端部,用来与中心区域的再结晶过程相比较。原始晶粒尺寸为设置值90 μm。

图4所示为经过镦粗后的平均晶粒尺寸、再结晶体积分数与微观组织。在模拟过程中将坯料高度从 1 000 mm镦粗到280 mm。从模拟结果可以看出:中心部位由于变形量大,位错密度达到动态再结晶的临界值。发生动态再结晶时,晶粒便细化,平均晶粒尺寸为40 μm左右,再结晶体积分数为30%左右。而端部由于变形量较小,未发生动态再结晶,晶粒尺寸仍为90 μm。

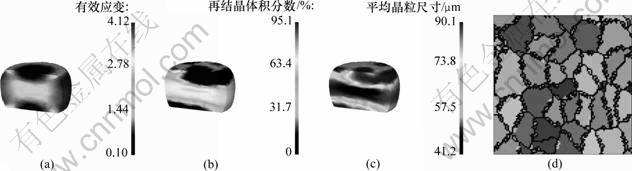

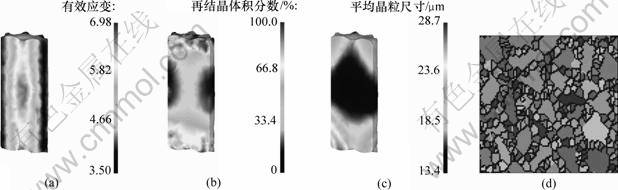

图5所示为经过拔长后的平均晶粒尺寸、再结晶体积分数与微观组织,在模拟过程中将坯料从280 mm拔长到800 mm。从模拟结果可以看出:经过一轮拔长后,有效应变增加非常明显,坯料各部位都有再结晶现象的发生,晶粒得到进一步细化,中心部位平均晶粒尺寸为15 μm左右,再结晶体积分数为50%左右,平均晶粒尺寸为25 μm左右,再结晶体积分数为40%左右,这是因为经过一轮拔长后,锻件各部位得到充分变形,大部分区域的位错密度都达到了再结晶的临界值,发生了动态再结晶。由此可见:拔长工艺对晶

(a) 坯料; (b) 镦粗; (c) 拔长; (d) 平整

图2 自由锻工艺

Fig.2 Process of free forging

(a) 剖面图; (b) 微观组织

图3 原始坯料剖面图及其微观组织

Fig.3 Section and its microstructure of workpiece

粒的细化作用明显,经过多次拔长可得到均匀细化的再结晶组织。

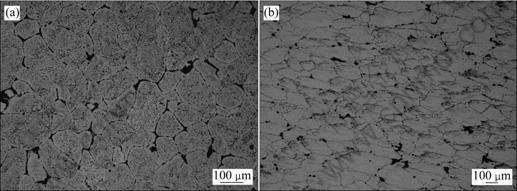

3 工业实验结果

本次实验原料为工业7050铝合金铸锭与锻件,采用Leica DMI5000M智能型金相显微镜对不同变形条件下的压缩试样进行观察分析。采用电解法对7050铝合金铸锭与锻件进行金相实验,所有试样均采用线切割方法切取,再分别用粗细砂纸和金相砂纸进行粗磨、细磨和精磨,最后用Cr2O3微粉悬浮液进行机械抛光。抛好后用浸蚀剂(配比为:H2O 20 mL,H2SO4 14 mL,H3PO4 57 mL,CrO3 9 g)对其进行电解浸蚀,电解浸蚀电压为16~20 V,电流为0.3~0.5 A,电解浸蚀时间为4 min。

图6所示为工业7050铝合金原始铸锭与锻件的微

(a) 有效应变; (b) 再结晶体积分数; (c) 平均晶粒尺寸; (d) 微观组织

图4 镦粗后的模拟结果

Fig.4 Simulation results in upsetting

(a) 有效应变; (b) 再结晶体积分数; (c) 平均晶粒尺寸; (d) 微观组织

图5 拔长后的模拟结果

Fig.5 Simulation results after stretching

(a) 原始铸锭; (b) 锻件

图6 7050铝合金原始铸锭与锻件的显微组织

Fig.6 Microstructures of ingot casting and forging for 7050 aluminium alloy

观组织。从图6(a)可见:原始铸锭晶粒较小,呈规则的等轴状,晶界较直,且晶粒分布较为均匀,原始铸锭平均晶粒尺寸为90 μm左右。图6(b)显示,由于经过了镦粗、拔长和滚圆等工艺,晶粒被拉长,晶界细小,并且由于在锻造过程中位错密度不断增加,在达到了7050铝合金发生动态再结晶的临界值时,发生了动态再结晶现象,在晶界处有动态再结晶组织,再结晶晶粒较少,且呈零散分布,形成的再结晶晶粒较为细小。工业锻件晶粒平均晶粒尺寸为20 μm左右,再结晶体积分数为40%左右,与模拟结果较吻合。

4 结论

(1) 在DEFORM-3D软件平台上,通过热力模拟实验与金相实验建立了7050铝合金热变形过程的流变应力模型与材料动态再结晶模型,研究了7050铝合金锻件微观组织的演变规律。

(2) 在保证一定锻造比的情况下,有效应变较大的中心区域先发生动态再结晶,而两端则较慢发生再结晶;经过拔长后得到的组织较好,晶粒得到了进一步细化,有效地消除了铸造缺陷,并且经过多次拔长可得到均匀细化的再结晶组织。

(3) 实验与模拟所得到的动态再结晶体积分数与平均晶粒尺寸较吻合,经过自由锻工艺后动态再结晶体积分数为40%左右,平均晶粒尺寸为20 μm左右。

参考文献:

[1] Rollett A D, Luton M J, Srolvoitz D J. Microstructural simulation of dynamic recrystallization[J]. Acta Metall Mater, 1992, 40(1): 43-55.

[2] Peczak P, Luton M.The effect of nucleation models on dynamic recrystallization Ⅰ: Homogeneous stored energy distribution[J]. Phi Mag B, 1993, 68(1): 115-144.

[3] Peczak P, Luton M.The effect of nucleation models on dynamic recrystallization Ⅱ: Homogeneous stored energy distribution[J]. Phi Mag B, 1994, 70: 817-849.

[4] Peczak P, Luton M J. A monte carlo study of the influence of dynamic recovery on dynamic recrystallization[J]. Acta Metal Mater, 1993, 41: 59-71.

[5] Peczak P. A monte carlo study of influence of deformation temperature on dynamic recrystallization[J]. Acta Metal Mater, 1995, 43: 1279-1291.

[6] 李殿中, 杜强, 胡志勇. 金属成形过程组织演变的Cellular Automaton模拟技术[J]. 金属学报, 1999, 35(11): 1201-1205.

LI Dian-zhong, DU Qiang, HU Zhi-yong. Simulation of the microstructure evolution in metal forming by using Cellular Automaton[J]. Acta Metallurgia Sinica, 1999, 35(11): 1201-1205.

[7] 李强, 李殿中, 钱百年. 元胞自动机方法模拟枝晶生长[J]. 物理学报, 2004, 53(10): 3077-3081.

LI Qiang, LI Dian-zhong, QIAN Bai-nian. Modeling of dendritic growth by means of cellular automaton method[J]. Acta Physica Sinica, 2004, 53(10): 3077-3081.

[8] Hesselbarth H W, Gobel I R. Simulation of recrystallization by cellular automata[J]. Acta Matal Mater, 1991, 39: 2135-2143.

[9] Goetz R L, Seetharaman V. Modeling dynamic recrystallization using cellular automaton[J]. Scripta Mater, 1998, 38: 405-413.

[10] 张林, 王元明, 张彩碚. Ni基耐热合金凝固过程的元胞自动机方法模拟[J]. 金属学报, 2001, 37(8): 882-888.

ZHANG Lin, WANG Yuan-ming, ZHANG Cai-bei. Modelling solidification process for nickel-based superalloy by cellular automata[J]. Acta Metallurgia Sinica, 2001, 37(8): 882-888.

[11] 张林, 张彩碚, 王元明. 低碳钢奥氏体转变为铁素体的元胞自动机模型[J]. 材料研究学报, 2002, 16(2): 200-204.

ZHANG Lin, ZHANG Cai-bei, WANG Yuan-ming. Modeling the phase transformation from austenite to ferrite of low carbon steels by cellular automaton[J]. Chinese Journal of Materials Research, 2002, 16(2): 200-204.

[12] 张林, 张彩碚, 王元明, 等. 变形、冷却条件下的碳钢铁素体相变的元胞自动机模型[J]. 东北大学学报: 自然科学版, 2002, 23(9): 872-875.

ZHANG Lin, ZHANG Cai-bei, WANG Yuan-ming. Cellular automata to simulate the phase transformation of ferrite for a low carbon steel under deformation and cooling[J]. Journal of Northeastern University: Natural Science, 2002, 23(9): 872-875.

[13] Goetz R L, Seetharaman V. Static recrystallization kinetics with homogeneous and heterogeneous nucleation using a cellular automata model[J]. Metal Meter Trans A, 1998, 29: 2307-2321.

[14] CHEN Hui-qin, CAO Chun-xiao. Hot deformation mechanism and microstructure evolution of TC11 titanium alloy in β field[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1021-1027.

[15] 易幼平, 杨积慧, 蔺永诚. 7050铝合金热压缩变形的流变应力本构方程[J]. 材料工程, 2007(4): 20-22.

YI You-ping, YANG Ji-hui, LIN Yong-cheng. Flow stress constitutive equation of 7050 aluminum alloy during hot compression[J]. Journal of Materials Engineering, 2007(4): 20-22.

[16] YI You-ping, FU Xin, CUI Jin-dong. Prediction of grain size for large-sized aluminium alloy 7050 during hot forming[J]. Journal of Central South University of Technology, 2008, 15(1): 1-5.

[17] Ding R, Guo Z X. Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization[J]. Acta Materialia, 2001, 49(16): 3163-3175.

(编辑 陈爱华)

收稿日期:2009-09-22;修回日期:2009-12-14

基金项目:国家重点基础研究发展计划(“973”计划)项目(2005CB724105)

通信作者:易幼平(1966-),男,湖南长沙人,博士,教授,从事精密锻造成形工艺数字化仿真研究;电话:13319599319;E-mail: yyp@mail.csu.edu.cn