DOI: 10.11817/j.ysxb.1004.0609.2020-37779

锻造高Nb-TiAl合金高温蠕变与损伤行为

张顺科1,2,田素贵1,2,田宁2,吕晓霞1,焦泽辉3,晋芳伟2,李德元1

(1. 沈阳工业大学 材料科学与工程学院,辽宁 110870;

2. 贵州工程应用技术学院,毕节 551700;

3. 航空材料检测与评价北京市重点实验室,先进高温结构材料国防科技重点实验室,中航工业北京航空材料研究院,北京 100095)

摘要:通过组织形貌观察和蠕变曲线测定,研究了锻造高Nb-TiAl合金的蠕变与损伤行为。结果表明,铸态高Nb-TiAl合金经等温锻造,层片晶团的平均尺寸由507μm减小到56.7μm。锻造态高Nb-TiAl合金在蠕变期间的变形主要发生在γ片层和等轴γ晶中,位错运动至相界/晶界受阻,可形成位错缠结或位错列,提高位错运动的阻力;其中,等轴γ晶粒中的位错缠结可发生束集促进动态再结晶,形成细小亚晶结构。柏氏矢量为[ 10]和[101]的位错分别在不同{111}面滑移形成位错网,γ相中的蠕变位错运动至位错网,与其相互作用,可改变原来的运动方向,促进其攀移。蠕变后期,孔洞首先在等轴γ晶区域产生,并在该区域聚集、长大和扩展,直至发生合金的蠕变断裂,是高温蠕变期间的变形与损伤机制。

10]和[101]的位错分别在不同{111}面滑移形成位错网,γ相中的蠕变位错运动至位错网,与其相互作用,可改变原来的运动方向,促进其攀移。蠕变后期,孔洞首先在等轴γ晶区域产生,并在该区域聚集、长大和扩展,直至发生合金的蠕变断裂,是高温蠕变期间的变形与损伤机制。

关键词: 锻造态高Nb-TiAl合金,组织结构,蠕变,变形机制,损伤特征

中文类图书号:TG146.2 文献标志码:A

1.引言

近年来,TiAl基金属间化合物已在汽车工业和航空航天工业领域得到应用,并成为工业领域中最具发展潜力的新型高温结构材料之一[1,2]。特别是高Nb-TiAl合金,具有优异的高温力学性能和抗高温氧化能力。因此,高Nb-TiAl合金的研发已得到国内外研究者们的高度关注[3,4]。

随着高温合金的服役温度不断升高,要求合金具有更好的抗蠕变性能。诸多研究表明,TiAl基合金在蠕变过程中的主要变形机制为位错的滑移和攀移以及孪生,位错通常在相界处产生并在应力和热激活的共同作用下向基体中的γ相运动[5-7]。合金的蠕变寿命主要与γ相与α2相的体积分数、层片取向与尺寸、晶粒的大小以及晶界形貌等微观组织参数有关[8,9]。另外,层片界面析出的颗粒状相也对合金的高温性能有重要影响,如碳化物、硅化物和B2 相等。因此,通常通过合理的微观结构设计来改善合金的塑韧性和蠕变强度。

采用铸造工艺制取的TiAl基合金,具有较好的断裂韧性和抗高温蠕变性能,但室温及高温延展性较差。通常采用热机械变形使合金中的粗大晶粒尺寸减小,常用的热机械变形方法包括:等温锻造、包套锻造、多向锻造、热挤压、轧制等[10-15],其中,锻造是TiAl基合金普遍使用的热加工工艺。

锻造工艺虽然提高了高Nb-TiAl基合金的诸多力学性能,但并不能有效改善合金的高温蠕变性能。因此,为了得到综合力学性能良好的高Nb-TiAl基合金,需进一步深入研究锻造态合金在蠕变期间的变形及断裂机制。据此,本文通过对铸态高Nb-TiAl基合金进行等温锻造,探究了热变形对该合金组织的影响。并通过蠕变曲线测定和组织观察,研究锻造态TiAl- Nb基合金在蠕变期间的变形与损伤机制,以为进一步提高高Nb-TiAl基合的高温力学性能提供理论基础。

2.实验材料和方法

采用真空凝壳熔炼炉,将成分为Ti-44Al-8Nb-0.2W-0.2B-0.1Y(质量分数%)的母合金制备成铸坯,再经真空自耗电弧炉重复熔炼3次,得到合金锭坯,并在1250℃对合金锭坯进行等温锻造。实施等温锻造工艺时,首先将模具加热至锻造温度以上,再将合金锭坯置于模腔中同时加热至锻造温度,并在低应变速率下施压至80%变形量,再经线切割将合金样坯加工成横断面为4.5 mm × 2.5 mm,标距为20 mm的工字型蠕变试样。

采用DX2700型X射线衍射仪对研磨至2000#的原始样品进行测定。蠕变样品经机械研磨后,使用GWT504型高温蠕变试验机测定不同条件的蠕变曲线。将原始样品和蠕变断裂后样品进行研磨和抛光并腐蚀,然后使用S-3400型扫描电子显微镜(SEM)对样品进行组织形貌观察,腐蚀液成分为5mL HF + 10mL浓HNO3+ 85mL H2O。通过双喷工艺制备透射样品,并使用TECNAI-G20型透射电子显微镜(TEM)观察不同状态合金的组织形貌,混合双喷液的成分为160mL甲醇 + 75mL正丁醇 + 15mL高氯酸。

3.实验结果与分析

3.1 合金的组织结构

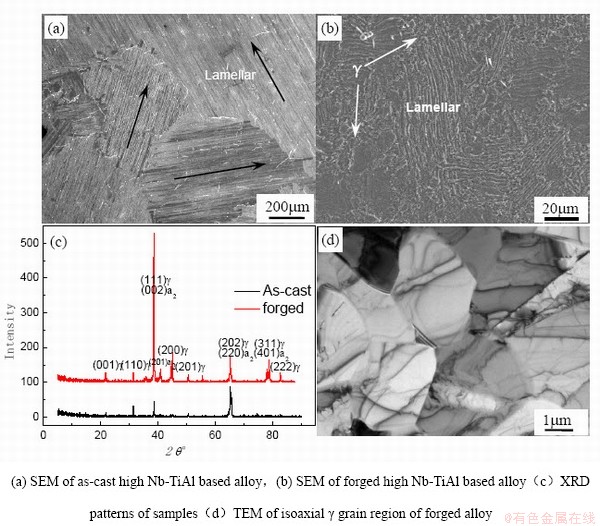

不同状态高Nb-TiAl合金的组织形貌如图1所示。图1(a) 为铸造态合金的组织形貌,可见合金主要由层片晶团组成,层片晶团中交替排列的两相分别为γ-TiAl及α2-Ti3Al [16],不同层片晶团中不同取向的层片如图中黑色箭头所示。锻造态合金的组织形貌如图1(b)所示,其组织结构由不同取向的层片晶团与等轴γ晶粒构成。图1(c) 为两种不同状态合金的XRD图谱,测量铸造态合金的衍射峰半高宽,根据谢乐方程计算合金的平均晶粒尺寸:

其中,Size为晶粒尺寸,K为Scherrer常数,λ是X射线的波长(nm),FW(S)是衍射峰半高宽,θ则是布拉格衍射角(Rad)。

可得铸造态高Nb-TiAl合金的平均层片晶团尺寸为507μm。由于锻造态合金为层片晶团与等轴晶的混合组织,通过XRD只能测量二者的平均尺寸。故取10个如1(b)区域的SEM图片,统计层片晶团的尺寸大小为56.7μm。取10个如1(d)的等轴晶区域的TEM图片,统计等轴晶的平均尺寸大小为4.7μm。可见,等温锻造可明显降低合金层片晶团的平均尺寸。

图1 铸造态与锻造态高Nb-TiAl合金的组织形貌及XRD图谱

Fig. 1 Microstructure of as-cast and forged high Nb-TiAl based alloy

3.2 合金的蠕变性能

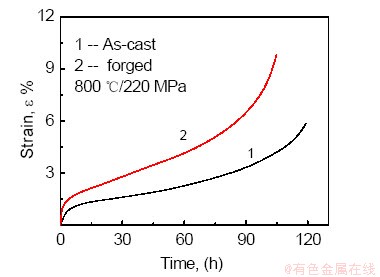

锻造态与铸造态高Nb-TiAl合金在800℃/220MPa条件下的蠕变曲线如图2所示,可见经过锻造的高Nb-TiAl合金蠕变寿命减小,蠕变应变增加。表明锻造工艺提高了合金的高温塑性,但未能改善合金的高温蠕变性能。

图2 铸造态与锻造态高Nb-TiAl合金在800℃/220MPa条件下的蠕变曲线

Fig.2 Creep curves of forged and as-cast high Nb-TiAl alloy at the conditions of 800℃/220MPa

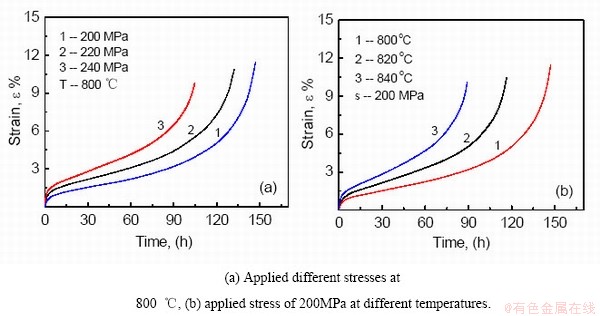

锻造态高Nb-TiAl合金在800℃分别施加200MPa、220MPa、240MPa应力测定的蠕变曲线,如图3(a)所示。由图中曲线1可知,当施加应力为200MPa时,合金在蠕变初期的应变较小,蠕变中期的平均应变速率测定为7.31E-8/s,蠕变寿命为143h。在施加220MPa应力下,合金蠕变初期的应变增大,蠕变中期的平均应变速率测定为9E-8/s,蠕变132h发生断裂。而在施加240MPa应力下,如图2(a)中曲线3所示,合金在蠕变中期的平均应变速率为1.3 E-7/s,蠕变寿命仅为105h。

图3 锻造态合金在不同条件测定的蠕变曲线

Fig. 3 Creep curves of forged alloy at various conditions

锻造态高Nb-TiAl合金在800℃、820℃及840℃施加200MPa测定的蠕变曲线,示于图3(b)。当施加温度为820℃时,合金在初始蠕变期间的应变较小,蠕变中期的平均应变速率测定为1.1E-7/s,测定的蠕变寿命是116h。当温度提高到840℃,合金在初始蠕变期间的应变增大,蠕变中期的平均应变速率为1.33E-7/s,蠕变寿命降低至88h。

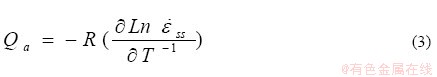

在高温条件下,当锻造高Nb-TiAl合金施加载荷时,产生瞬时应变,合金基体中激活大量位错,随蠕变进行,位错密度增大,其高密度位错阻碍位错运动的作用,可降低合金的应变速率,即:产生形变硬化现象。随蠕变进行,热激活促使合金中位错发生滑移和攀移,可持续增加合金的应变,使合金进入蠕变中期阶段。在蠕变中期,合金的应变速率服从Dorn定律[17],其表达式为:

-蠕变中期的平均应变速率,A-与材料组织有关的常数,σA -外加应力,n-应力指数,R-气体常数,T-绝对温度,Qa-蠕变激活能。

-蠕变中期的平均应变速率,A-与材料组织有关的常数,σA -外加应力,n-应力指数,R-气体常数,T-绝对温度,Qa-蠕变激活能。

在恒应力条件下简化上式可得:

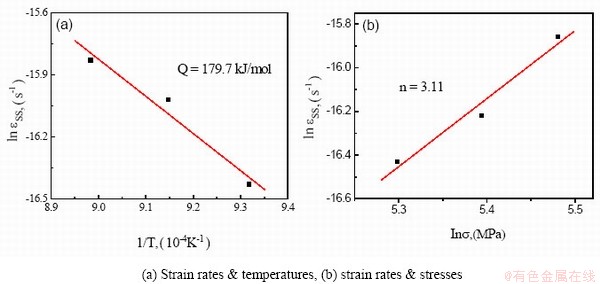

根据图2中蠕变曲线数据及(2)(3)式,在施加温度和应力范围内,测算出锻造态合金蠕变中期平均应变速率与施加温度和应力之间的关系,如图4(a)和(b)所示。据此,测算出该合金在蠕变中期的表观蠕变激活能与表观应力指数分别为:Q = 179.7 kJ/mol和n =3.11。由此,可定量表明合金在蠕变中期的变形机制是位错的滑移。

图4 锻造态合金在近800℃中期蠕变期间应变速率与施加温度、应力的关系

Fig. 4 Dependence of strain rates of forged alloy in the middle period of creep on temperatures and stresses

3.3 蠕变期间的变形特征

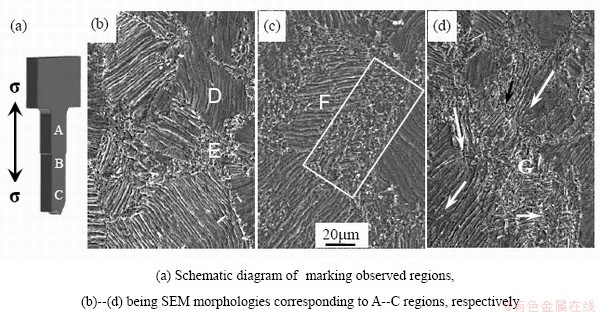

在800℃/220MPa条件下,锻造态样品蠕变断裂后不同区域的组织形貌,如图5所示,施加应力方向和观察区域的示意图,示于图5(a)。在样品不同区域呈现不同的变形特征,如图5(b)、(c)和(d)所示。在远离断口的区域A,合金中层片晶团仍由黑白相间的层片状γ/α2两相组成,且大部分层片状组织仍保持平直特征,仅局部区域发生轻微弯曲变形,如图5(b)中区域D所示。层片晶团间仍为等轴γ晶组织,如图5(b)的区域E所示,等轴γ晶组织的体积分数未见明显增加。

图5 蠕变断裂后,样品不同区域的组织形貌

Fig. 5 Microstructure in different regions of sample after creeping fracture

区域B的组织形貌示于图5(c),可以看出,层片晶团的组织无明显变化,但尺寸明显减小,如图中F区域所示。层片晶团间仍为等轴γ晶区域,体积分数明显增加,如图中白色方框所示。

近断口区域C的组织形貌,示于图4(d),可以看出,部分晶粒中的层片状组织仍保持平直特征且相互平行,其晶粒中层片状的取向如图4(d)中白色长箭头所示。由于该区域的形变量较大,区内层片组织已发生明显的弯曲变形,晶界区域等轴晶组织的体积分数进一步增大,表明,蠕变已使合金的组织形貌发生明显变化。晶内与施加应力轴近垂直方向存在较小尺寸的层片晶团,如图4(d)中黑色箭头所示。以上观察表明,蠕变断裂样品中,随观察点离断口距离减小,层片晶团的变形量增加,层片晶团边缘的组织转化为等轴γ晶,使层片晶团的尺寸减小,体积分数降低。等轴γ晶的体积分数增大。

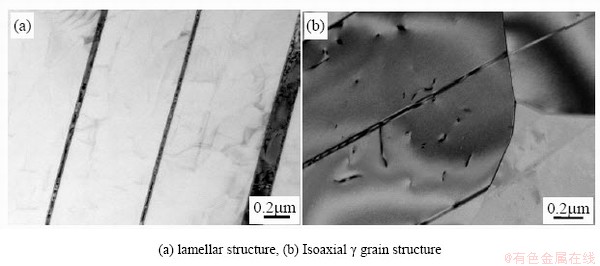

锻造态合金蠕变前的TEM形貌如图6所示,可见锻造态合金由γ/α2层片晶团和等轴γ晶组成,与图1中观察到的组织形貌一致。图6(a)为层片晶团的组织形貌,亮色衬度为γ相,暗色衬度为α2相,可见两相的层片宽度不同,组织中位错密度较小。图6(b)为等轴γ晶组织,可见等轴γ晶中位错密度也较小,且在等轴γ晶中存在孪晶。

图6 锻造态合金的组织形貌

Fig. 6 Microstructure of forged alloy

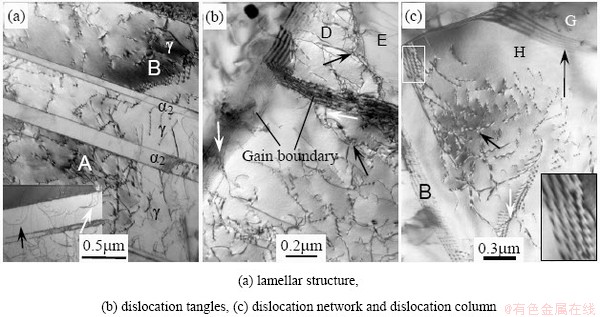

该合金经800℃/220MPa蠕变132h断裂后,其微观变形特征的TEM观察,示于图7。7(a)为合金层片晶团区域的组织形貌,γ相与α2相交替排列如图中标注所示。其中γ片层中的位错密度较高,位错的形态及取向各异,并在局部形成位错缠结,如图中A区域和B区域所示,α2片层中仅有少量位错。该样品的另一形貌示于图左下角,可见在γ/α2界面有U型迹线特征,为位错弓出的形态,如图中倾斜黑色短箭头所示,可见位错由γ/α2界面产生,并在γ相中滑移。部分位错交滑移使迹线呈现具有近90°折线特征,示于图5(a)的白色箭头。且大量位错在γ相中滑移和塞积,可产生应力集中。以上观察表明,蠕变期间位错主要在γ片层发生滑移、交滑移和剪切。

图7 锻造态合金经800℃/220MPa蠕变断裂后的组织形貌

Fig. 7 Microstructure of forged alloy after crept up to fracture at 800 ℃/200 MPa

图7(b)为合金等轴γ晶区域的组织形貌,照片左侧的暗色组织和近水平方向的黑色组织为晶界。可见等轴γ晶区域位错密度较大,且滑移位错的形态及取向各异,呈现缠结的特征。当位错在等轴γ晶中滑移至晶界,该位错可通过晶界,剪切进入另一等轴γ晶,如图7(b)中的白色箭头所示。另外,位错相互缠结形成位错胞,如图中黑色箭头所示,位错胞在蠕变后期可演变为亚晶界,这是合金发生动态再结晶的主要原因。

在近断口的另一局部区域,由于形变量较大,已有高密度位错剪切进入层状相,如图7(c)所示,其中,位错在γ层片中可发生滑移和交滑移,并在相界面存在位错网,示于图7(c)的白色方框中,其放大形貌示于照片的右下方。其位错列切入γ层片的形貌,如图7(c)中白色箭头所示,位错列中滑移位错的迹线方向相互平行。由于随高温蠕变时间延长,合金中γ/α2两相发生粗化,使其两相形成半共格界面,其半共格界面中形成的界面位错网,如图7(c)中的区域B,其中,照片左上方有滑移位错与位错网相邻。特别是有大量位错剪切该γ层片,并在γ层片内形成位错缠结,如图7(c)中黑色短箭头所示。分析认为,随蠕变进行,γ相内位错缠结可发生束集,形成亚晶,使该区域成为具有较小尺寸的亚晶结构,如图7(b)中区域D、E所示。并在G、H亚晶之间存在倾斜亚晶界,在倾斜亚晶界的等倾条纹相互平行,示于图7(c)中黑色长箭头所示。

综上表明,该合金蠕变过程中产生的大量位错可在γ层片和等轴γ晶中滑移和交滑移,位错运动至相界或晶界受阻,塞积于γ层片和等轴γ晶中,可形成位错网或位错列。蠕变过程中,滑移位错与相界和晶界相互作用,可增加位错运动的阻力,提高合金的抗蠕变性能。加之,蠕变期间位错在γ/α2两相中滑移相遇,形成的位错网可促进位错的攀移。另外,α2片层仅有少量位错产生,对合金的变形机制贡献可以忽略不计。

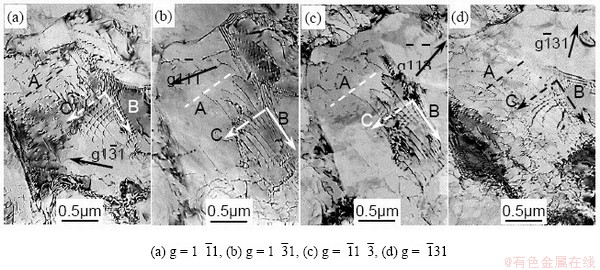

该合金经800℃/220MPa蠕变断裂后的位错组态,示于图8,鉴定出图8中位错较多的区域为γ相,图中左侧区域存在大量与黑色虚线平行的位错,标注为A,而位错B和位错C是两组相互垂直的位错网,且每组位错的迹线相互平行,如图8(a)所示。当衍射矢量为g1 1和g

1和g 31时,位错A出现衬度,如图8(a)和(d)所示,当衍射矢量为g1

31时,位错A出现衬度,如图8(a)和(d)所示,当衍射矢量为g1 和g

和g

时,位错A衬度消失,如图8(b)、(c)所示。根据位错不可见判据,确定位错A的柏氏矢量为bA=g1

时,位错A衬度消失,如图8(b)、(c)所示。根据位错不可见判据,确定位错A的柏氏矢量为bA=g1 × g

× g

= a[110]。图6(a)可以看出,位错A的迹线与[

= a[110]。图6(a)可以看出,位错A的迹线与[ 12]方向平行,因此,确定出位错A的滑移面为bA×μA = (

12]方向平行,因此,确定出位错A的滑移面为bA×μA = ( 11)。

11)。

图8 合金经800℃/220MPa蠕变断裂后的位错组态

Fig. 8 Dislocation configuration of forged alloy after crept up to fracture at 800 ℃/200 MPa

图8右侧互相垂直的两组位错中,竖直迹线和水平迹线方向的位错,分别记为B和C,如图8中虚线箭头所示。当衍射矢量为g1 1、g1

1、g1 1和g

1和g

时,位错B显示衬度,如图8(a)、(b)、(c)所示,当衍射矢量为g

时,位错B显示衬度,如图8(a)、(b)、(c)所示,当衍射矢量为g 31时,位错B失去衬度,示于图8(d)。由此,确定出位错B的柏氏矢量为bB = a[101],由于位错B的线矢量是μB = [12

31时,位错B失去衬度,示于图8(d)。由此,确定出位错B的柏氏矢量为bB = a[101],由于位错B的线矢量是μB = [12 ],因此,确定出位错B的滑移面为bB×μB= (

],因此,确定出位错B的滑移面为bB×μB= ( 11)。当衍射矢量为g1

11)。当衍射矢量为g1 1时,位错B和C显示衬度,如图8(a)所示。当衍射矢量为g1

1时,位错B和C显示衬度,如图8(a)所示。当衍射矢量为g1 1时,位错C失去衬度,如图8(b)所示,由此,确定出位错C的柏氏矢量为bC = a[011]。进一步,根据位错C的线矢量为μC= [

1时,位错C失去衬度,如图8(b)所示,由此,确定出位错C的柏氏矢量为bC = a[011]。进一步,根据位错C的线矢量为μC= [ 21],确定出位错C的滑移面为bC×μC = (11

21],确定出位错C的滑移面为bC×μC = (11 )。组织观察表明,两组相互垂直的位错不在同一滑移面,故未发生位错反应。

)。组织观察表明,两组相互垂直的位错不在同一滑移面,故未发生位错反应。

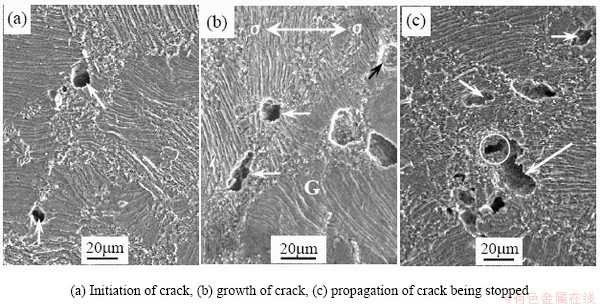

3.4 裂纹的萌生与扩展

锻造态合金经800℃/220 MPa蠕变132 h断裂后,近断口区域裂纹沿晶界萌生与扩展的形貌,示于图9,白色双向箭头表示施加的应力方向。蠕变后期,合金中激活的位错数量增加,其中,等轴γ晶中的位错缠结,如图7 (b)所示。随蠕变进行,热激活可使等轴γ晶中位错缠结发生束集,形成亚晶结构,如图7(b)中区域D、E所示,促进动态再结晶的产生,从而使等轴γ晶的数量增加且尺寸减小,如图5(d)中区域G所示。

随蠕变进行,合金的应变进一步增大,并在等轴γ晶出现孔洞,如图9(a)中细小箭头所示,该形貌可视为蠕变期间裂纹萌生。样品近断口区域的组织形貌,如图9 (b)所示。由于形变量较大,该区域层片组织已发生弯曲变形,如区域G所示。晶内垂直于应力轴方向的细小等轴γ晶,为蠕变后期发生的动态再结晶所致。特别是裂纹的萌生主要发生在等轴γ晶区域,与图9 (a)相比,孔洞的数量增加,尺寸增大,如图9 (b)中箭头所示。

随蠕变进行,细小等轴晶区中孔洞数量进一步增多,孔洞之间相互连接与合并,可逐渐形成较大尺寸的孔洞,如图9 (c)中倾斜长箭头所示。并且较大孔洞,可向基体内部逐渐渗透,如图中白色圆圈所示。随着孔洞的相互连接可形成较大裂纹,当大尺寸裂纹继续扩展,超过临界尺寸,则合金失去蠕变抗力,进而发生合金的蠕变断裂。

图9 锻造态合金经800°C/220 MPa蠕变断裂后,裂纹沿晶界的萌生与扩展

Fig. 9 Initiation and propagation of micro-crack in the forged alloy after crept up to fracture at 800℃/200MPa

4.讨论

经过锻造工艺,铸造态合金由层片晶团构成的全层片组织转变为层片晶团与等轴γ晶共同构成的双态组织,晶粒尺寸明显减小。在施加温度和应力的范围内,合金在蠕变期间的主要变形发生在γ片层和等轴γ晶中。随蠕变进行,合金中发生多系滑移,其中,柏氏矢量为 [ 10]的位错在(111)面滑移,而柏氏矢量为[101]的位错和柏氏矢量为[011]的位错在(

10]的位错在(111)面滑移,而柏氏矢量为[101]的位错和柏氏矢量为[011]的位错在( 11)面上滑移,可形成位错网络。当高密度位错在γ片层中滑移和交滑移至晶界或相界受阻时,可塞积于近晶界和相界区域,形成位错缠结,增加位错运动的阻力,改善合金的蠕变抗力。加之,形变位错与位错网相遇,可因位错反应而改变其运动方向,促进位错的攀移[18]。

11)面上滑移,可形成位错网络。当高密度位错在γ片层中滑移和交滑移至晶界或相界受阻时,可塞积于近晶界和相界区域,形成位错缠结,增加位错运动的阻力,改善合金的蠕变抗力。加之,形变位错与位错网相遇,可因位错反应而改变其运动方向,促进位错的攀移[18]。

此外,在蠕变过程中,层片晶团边缘的层片组织在温度和应力的作用下,转化为等轴γ晶组织。使γ/α2层片晶团的体积分数减小,相应的等轴γ晶组织体积分数增加。另外,等轴γ晶组织可通过动态再结晶进一步转化为细小的组织。由于α2-Ti3Al相为强化相,γ/α2层片晶团的强度优于等轴γ晶组织,因此该组织转变对合金的蠕变抗力产生不利的影响。而γ相的变形能力优于α2相,且随着蠕变的进行,轴γ晶组织中位错缠结形成亚结构,进而促使动态再结晶的进一步可发生,使晶界数量增加,晶界与位错的交互作用加剧,从而提高合金的高温变形能力。

分析认为,γ片层和等轴γ晶均为锻造态合金蠕变强度的薄弱环节。但由于γ/α2层片晶团中的γ片层受到α2层片的强化作用,孔洞和裂纹首先在等轴γ晶区域形成,并长大和扩展,直至合金的蠕变断裂。

5.结论

1)经等温锻造后,高Nb-TiAl合金的晶粒尺寸由507μm减小到56.7μm,组织结构由γ/α2层片晶团和等轴γ晶组成。

2)锻造态高Nb-TiAl合金在800℃-840 ℃/200 MPa-240 MPa蠕变期间的变形机制是位错在层片状γ相及等轴γ晶中的运动,位错滑移至晶界、相界受阻,可塞积在近界面区域,形成位错列和位错缠结,增加位错运动的阻力。蠕变期间,等轴γ晶中的位错缠结可发生束集从而促进动态再结晶,使等轴γ晶进一步细化。

3)柏氏矢量为[ 10]和[101]的位错分别在不同{111}面滑移,形成位错网,在层片状γ相中的蠕变位错滑移至位错网,与其发生反应,而改变原来的运动方向,可促进位错攀移,可改善合金的蠕变抗力。

10]和[101]的位错分别在不同{111}面滑移,形成位错网,在层片状γ相中的蠕变位错滑移至位错网,与其发生反应,而改变原来的运动方向,可促进位错攀移,可改善合金的蠕变抗力。

4)蠕变后期,孔洞首先出现在等轴γ晶区域,并在该区域发生孔洞的聚集、长大、及裂纹的萌生与扩展,直至蠕变断裂,是合金在高温蠕变后期的变形与损伤机制。

参考文献

[1] APPEL F, CLEMENS H, FISCHER F D. Modeling concepts for intermetallic titanium aluminides[J]. Progress in Materials Science, 2016, 81: 55-124.

[2] KIM Y W, KIM S L. Advances in gammalloy materials–processes–application technology: successes, dilemmas, and future[J]. JOM, 2018, 70: 553-560.

[3] Wang W, Z W D, Sun Y L. Zhou H X , Liang X B. Microstructure, Tensile, and Creep Behaviors of Ti-22Al-25Nb (at.%) Orthorhombic Alloy with Equiaxed Microstructure[J], Materials, 2018, 11(7): 1-13.

[4] 关红,邰清安,汪大成,朱春雷,王红卫.TiA合金锻造工艺试验与验证[J]. 锻造与冲压, 2020, 07: 23-28.

GUAN Hong, TAI Qing-an, WANG Da-cheng, ZHU Chun-lei, Wang Hong-wei. The forging process test and verification of earthy alloy[J]. Forging & Metalforming, 2020, 07: 23-28.

[5] 张熹雯, 王红卫, 朱春雷, 李胜, 张继. C含量对铸造TiAl合金组织和力学性能的影响[J]. 稀有金属材料与工程, 2020, 49(1): 138-146.

ZHANG Xi-wen, WANG Hong-wei, ZHU Chun-lei, LI Sheng, ZHANG Ji. Effect of Carbon Content on Microstructure and Mechanical Properties of Cast TiAl Alloys [J]. Rare Metal Materials and Engineering, 2010, 49(1): 138-146.

[6] 项宏福,李惠,王冀恒,崔玉友. TiAl基铸造合金的蠕变行为研究[J]. 热加工工艺, 2010, 39(5): 4-7.

XING Hong-fu, LI Hui, WANG Ji-heng, CUI Yu-you. Study on Creep Behavior of TiA1 Casting Alloy [J]. Hot Working Technology, 2010, 49(1): 138-146.

[7] 刘自成, 李书江, , 林均品, 陈国良, 张卫军. 一种高铌TiAl合金的蠕变性能[J].稀有金属材料与工程, 2002, 31(1): 31-36.

LIU Zi-cheng, LI Shu-jiang, , LIN Pin-jun, CHEN Guo-liang, ZHANG Wei-jun. The creep properties of high niobium containing TiAl alloy[J]. Rare Metal Materials and Engineering, 2002, 329/331(1): 649-652.

[8] 周兰章, 郭建亭, V.Lupinc, M.Maldini. Ti-47Al-2W-0.5Si抗蠕变合金的高温力学行为和变形机制[J]. 金属学报, 2001, 37(8):785-790.

ZHOU Lan-zhang, GUO Jian-ting, V.Lupinc, M.Maldini. High-temperature mechanical behavior and deformation mechanism of ti-47al-2w-0.5si creep-resistant alloy [J]. Acta Metallurgica Sinica, 2001, 37(8):785-790.

[9] 林建国, 张永刚, 陈昌麒.γ-TiAl 合金的显微组织对其蠕变性能的影响[J]. 北京航空航天大学学报,1998(06):3-5.

LIN Jianguo, ZHANG Yonggang, CHEN Changqi, ZHANG Wei-jun. Effects of the Microstructure of γ-TiAl Alloys on the Creep Behavior [J]. Journal of Beijing University of Aeronautics and Astronautics, 1998(06):3-5..

[10]CUI N, KONG F T,WANG X P, CHEN Y Y, ZHOU H T. Microstructure evolution, hot working, and mechanical properties of Ti-43Al-2Cr-2Mn-0.2Y alloy[J]. Materials and Design, 2016, 89: 1020-1027.

[11]TOSHIMITSU T,KENTARO S,SATORU K, MASAO T. Strengthening a high-strength TiAl alloy by hot-forging[J]. Intermetallics, 2003, 679: 299-306.

[12]LIU C T,WRIGHT J L,DEEVI S C. Microstructures and properties of a hot-extruded TiAl containing no Cr [J]. Materials Science and Engineering A, 2002, 329-331: 416-423.

[13]WU Y,PARK Y W,PARK H S, HWANG S K. Microstructural development of indirect- extruded TiAl-Mn-Mo-C intermetallic alloys during aging [J], Materials Science and Engineering A, 2003, 347: 171-179.

[14]JIAN G L , VIOLA L A. Processing gamma-based TiAl sheet materials by cyclic cold roll bonding and annealing of elemental titanium and aluminum foils[J]. Materials Science and Engineering A, 2006, 433 (1-2): 334-342.

[15]TIAN S G, WANG Q, YU H C, SUN H F, L Q Y. Microstructure and creep behaviors of a high Nb-TiAl intermetallic compound based alloy[J]. Materials Science and Engineering A, 2014, 614: 338-346.

[16]CHENG L, LI J S , XUE X Y, TANG B, KOU H C, BOUZY E. Superplastic deformation mechanisms of high Nb containing TiAl alloy with (α2+γ) microstructure[J]. Intermetallics, 2016, 75: 62-71.

[17]TIAN S G., LV X X, YU H C, WANG QI, JIAO Z H, SUN H F. Creep behavior and deformation feature of TiAl-Nb alloy with various states at high temperature[J]. Materials Science and Engineering A, 2016, 651 (10): 490-498

[18]Tian S G, Wang Q, Yu H C, Sun H F, Li Q Y. Microstructure and creep behaviors of a high Nb- TiAl intermetallic compound based alloy[J]. Materials Science and Engineering A, 2014, 614: 338-346.

Deformation and Damage Behavior of high Nb-TiAl Alloy during Creep at High Temperature

ZHANG Shunke1,2, TIAN Sugui1,2,, TIAN Ning2, Lü Xiaoxia1, JIAO Zehui3, JIN Fangwei2, Li Deyuan1

(1. Shenyang University of Technology, Shenyang 110870; China

2. Guizhou University of Engineering Science, Bijie 551700, China

3. Beijing Key Laboratory of Aeronautical Materials Testing and Evaluation, Science and Technology on Advanced High Temperature Structural Materials Laboratory, AVIC Beijing Institute of Aeronautical Materials, Beijing 100095; China)

Abstract: The deformation and damage behavior of the forged high Nb-TiAl alloy during creep are investigated by means of creep properties measurement and microstructure observation. Results show that using isothermal forging technology may diminish the average grain size of the alloy from 573μm to 43.8μm. TThe deformation of forged alloy during creep mainly occurred in γ lamellar and equiaxed γ grain. The dislocations slipping to boundaries and phases interfaces are hindered for piling up, and dislocation tangle or dislocation sequence can be formed to increase the resistance of dislocation motion. Wherein, dislocation tangles in the equiaxed γ grain can generate bundle aggregation to promote dynamic recrystallization and form fine sub-grain structure. The dislocations with Burgers vector of [ 10] and [101] slip on the {111} planes to form the networks. When the creep dislocations in the lamellar γ phases slip to the networks, the ones may react with the networks to change the original moving direction to promote the climbing of dislocations, which may delay the stress concentration and improve the creep resistance of alloy. In the latter stage of creep, the holes or cracks are firstly initiated in the equiaxed γ grain to propagate in the region until creeping fracture, which is the damage and fracture mechanism of alloy during creep at high temperature.

10] and [101] slip on the {111} planes to form the networks. When the creep dislocations in the lamellar γ phases slip to the networks, the ones may react with the networks to change the original moving direction to promote the climbing of dislocations, which may delay the stress concentration and improve the creep resistance of alloy. In the latter stage of creep, the holes or cracks are firstly initiated in the equiaxed γ grain to propagate in the region until creeping fracture, which is the damage and fracture mechanism of alloy during creep at high temperature.

Key words : forged high Nb-TiAl alloy, microstructure, creep, deformation mechanism, damage features

贵州省教育厅青年科技人才成长项目(黔教合KY字[2019] 163);贵州省科技计划项目(黔科合基础[2020]1Y198);毕节市煤磷化工工程技术中心(毕科合字[2015]1号);贵州省普通高等学校特色重点实验室(黔科合字[2019]053)

收到初稿日期:2020—07—08通信作者:田素贵,教授,博士,电话:13889121677: E-mail:tiansugui2003@163.com