文章编号: 1004-0609(2005)08-1248-05

渗流法制备高孔隙率多孔铝

张伟开, 李乃哲, 何德坪

(东南大学 材料科学与工程系, 南京 210096)

摘 要: 采用负压渗流铸造法, 通过控制铝熔体浇铸量, 制备了高孔隙率(70%~90%)、 高通孔度(25%~50%)的多孔铝; 研究了渗流驱动压力、 铝熔体浇铸温度及模具预热温度对渗流过程的影响; 测试了多孔铝的渗透系数, 并分析了孔结构对渗透系数的影响。 结果表明: 通过正交实验选择渗流参数, 可以降低多孔铝在渗流方向上的孔隙率梯度; 多孔铝的渗透系数与其孔结构密切相关: 对于相同孔径的多孔铝, 渗透系数随孔隙率增大而提高; 在孔隙率相同的条件下, 随着孔径增大, 表面积减小, 摩擦阻力减小, 渗透系数相应增大。

关键词: 多孔铝; 高孔隙率; 渗流铸造; 渗透系数 中图分类号: TG146.2

文献标识码: A

Preparation of porous Al with high porosity by infiltration method

ZHANG Wei-kai, LI Nai-zhe, HE De-ping

(Department of Materials Science and Engineering, Southeast University, Nanjing 210096, China)

Abstract: Porous Al with high porosity (70%-90%) and high degree of pore-opening(25%-50%) was obtained by controlling the quantity of molten Al. The effects of infiltration pressure, casting temperature and preform particles temperature on the preparation process were analyzed. The infiltration property was studied through measuring the infiltration coefficient, which is significant to the application of porous Al. The results show that the main infiltration parameters can be selected by orthogonal test, which will modify the porosity gradient variation of porous Al. The infiltration coefficient of porous Al has close relevance to its pore structure. With the same pore size, infitration coefficient increases while its porosity increases. The specific surface declines with the increase of pore size, which results in the improvement of infitration coefficient.

Key words: porous Al; high porosity; infiltration casting; infiltration coefficient

以通孔和闭孔两类孔结构为特征的超轻型金属结构, 实现了结构材料轻质多功能化, 有着广泛的高技术应用前景, 正成为21世纪热点研究材料之一[1-12]。 以往一直以闭孔泡沫铝作为关注重点, 但近年来在各种高技术应用需求的牵引下, 具有通孔结构的多孔铝(以下简称为多孔铝)引起了人们广泛的重视, 它可用于消声、 分离、 过滤、 布气、 电化学过程和热交换等与流通性能有关的场合[1-4]。

采用占位颗粒渗流法制备多孔铝, 由于受堆积致密度的限制, 尽管采用了多种手段来提高孔隙率, 如振动紧实法[7, 8]、 附加孔隙率调节法[7, 9, 10]、 占位颗粒预制块烧结法[11]和附加载体处理法[12]等, 但效果都不大, 在满足孔隙均匀的前提下很难得到高于70%的孔隙率。 为获得较高的流通性能, 本文通过控制铝熔体浇铸量, 获得了高孔隙率(70%~90%)的多孔铝, 并研究了渗流驱动力Δp、 铝熔体浇铸温度tAl及模具预热温度tp对渗流过程的影响; 此外, 还研究了与多孔铝应用有关的流通性能及其影响因素。

1 实验

1.1 多孔铝孔隙率的构成

采用渗流法制备多孔铝, 其孔隙率P由三部分组成[7, 13]:

占位颗粒在模具中的排列, 并不像原子在金属晶体中排列得那样整齐, 尤其是在模具的横截面上, 因为没有重力的挤压作用, 颗粒的堆垛十分松散。 随占位颗粒孔径、 密度和表面粗糙度的不同, Pd在45%~ 60%范围内变化。

1.2 高孔隙率多孔铝的形成

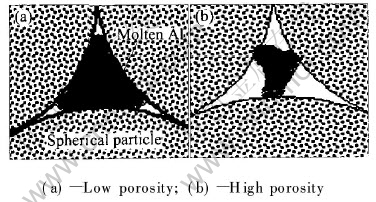

严格控制铝熔体浇铸量, 选择合适的渗流参数, 使有限的熔体均匀地分布在占位颗粒的间隙中, 通过大幅度提高Pa 获得了高孔隙率多孔铝。 图1所示为铝熔体在占位颗粒间隙中的分布示意图。

图1 铝熔体在占位颗粒间隙中的分布

Fig.1 Distribution of molten Al among stuffing particles

高孔隙率多孔铝的形成过程如下:

1)计算铝熔体浇铸量m:

m=(1-P)ρAlπR2L(2)

式中 P为多孔铝的目标孔隙率; ρAl为铝的密度; R为模具的内径; L为堆积体长度。

2)将可溶性占位颗粒直接堆积于模具中, 将模具放入电阻炉中, 设定预热温度tp、 铝熔体温度tAl、 渗流驱动压力Δp。

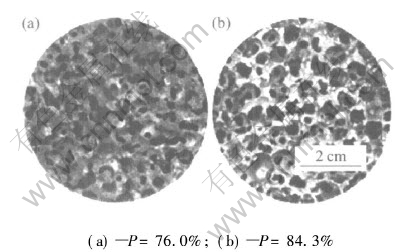

3)将模具从炉中取出, 放置在渗流装置的吸盘底座上; 将铝熔体浇注到模具中, 打开真空阀门, 使铝熔体均匀分布在占位颗粒堆积体的空隙中; 铝熔体凝固后, 形成占位颗粒-铝复合体, 去除占位颗粒即得到高孔隙率多孔铝, 如图2所示。 它具有较高的通孔度(通孔度I=r/d。 其中, d为多孔铝孔径, r为孔隙间的通道尺寸)。

图2 高孔隙率多孔铝的横截面

Fig.2 Cross-section morphologies of porous Al with different pore structures

2 渗流参数的确定

2.1 驱动压力对渗流过程的影响

图3所示为渗流压力对多孔铝形貌的影响。 L=140mm; Pd=45.5%; d=4mm; 目标孔隙率P=80%; tP=570℃; tAl=705℃。

图3 渗流压力对高孔隙率多孔铝形貌的影响

Fig.3 Effect of infiltration pressure on pore structure of porous Al

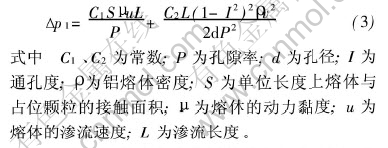

1) 要使铝熔体到达占位颗粒堆积体底部, 必须施加一定的驱动压力Δp1, 以克服沿程粘滞阻力和由弯曲通道造成的局部阻力。 Δp1可以表示为[13, 14]

2) 占位颗粒在各个位置的堆积方式不同, 空隙的分布也不同。 采用渗流压力Δp1, 铝熔体虽然可以到达堆积体底部, 但会选择空隙较大的最优路径, 从而造成铝熔体的不均匀分布(见图3(b))。 所以要选取高于Δp1的渗流压力, 设为Δp2。

3) 渗流压力过高会造成多孔铝孔隙率在渗流方向上的梯度分布: 定量铝熔体在压力驱动下渗入并填充到堆积体底部, 导致底部孔隙率较低; 熔体流过顶部占位颗粒, 黏附在颗粒表面, 形成孔隙率较高的薄层骨架结构(见图3(d))。

所以, 应在满足渗流长度和孔结构均匀的基础上尽可能选择较低的渗流驱动压力。

2.2 铝熔体温度及颗粒预热温度的确定

1)铝熔体黏度μ与温度T基本符合以下关系[11, 15] :

熔体温度升高, 其黏度降低, 根据式(3), 渗流驱动压力Δp1略微减小。

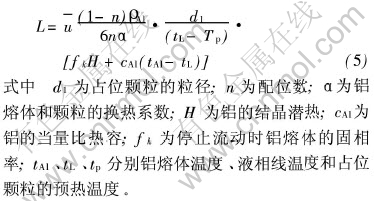

2)渗流过程中, 熔体与占位颗粒之间以及模具与外界环境之间不断发生热交换, 在渗流压力一定的情况下, 如果熔体温度过低, 就会因迅速凝固而无法渗入堆积体底部。 渗流长度可以用如下公式表示[11, 16]:

可见, 渗流长度随占位颗粒温度tp和铝熔体温度tAl的升高而增大, 应采用足够高的tp和tAl, 以保证铝熔体的渗流长度。

2.3 渗流参数的优化

1)多孔铝的孔隙率梯度

采用负压渗流法制备高孔隙率多孔铝, 由于渗流驱动压力及重力在渗流方向上的梯度分布, 会造成其孔隙率沿长度方向的变化。 将圆柱形多孔铝试样(d58mm×140mm)沿渗流方向从下至上切割成长度ΔL=10mm的试块, 标号为1~14号, 采用称量质量法分别测量其孔隙率P(i), 通过如下公式确定孔隙率梯度gradp:

2) 正交实验设计

影响多孔铝形成的各种因素互相影响和作用, 难以从理论上推导出最佳的渗流参数, 故以孔隙率梯度和渗流长度为考察对象, 通过正交实验来确定渗流参数。 为制备孔径4mm, 孔隙率80%, 长度为140mm的多孔铝, 采用的正交实验如下:

第一次实验, 采用正交表L9(34)(第4列不用): 预热温度tp分别为500、 550、 600℃; 铝熔体温度tAl分别为680、 710、 740℃; 渗流驱动压力Δp分别为0.5、 2.0、 3.5kPa。 第一次实验的最优水平组合tp=550℃、 tAl=710℃、 Δp=2.0kPa, 通过实验测得其孔隙率梯度为7.3%/dm。

第二次实验, 采用正交表L9(34) (第4列不用): tp分别为540、 570、 600℃; tAl分别为690、 705、 720℃; Δp分别为1.2 、 1.8、 2.4kPa。 第二次实验的最优水平组合tp=570℃、 tAl=705℃、 Δp=1.8kPa, 其孔隙率梯度为5.5%/dm。

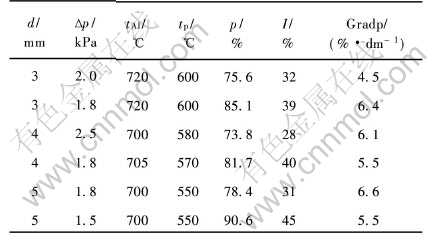

通过两次正交实验, 得到各参数的大致范围, 在制备过程中还可根据经验进行适当的调整, 从而得到较优的渗流参数, 见表1。

表1 高孔隙率多孔铝负压渗流参数

Table 1 Main parameters of porous Al by infiltration casting

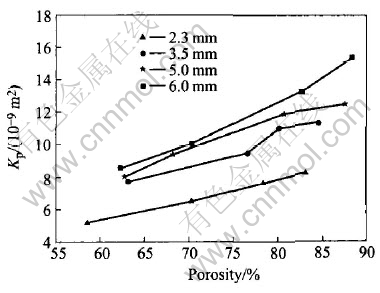

3 多孔铝的流通性能

多孔铝在吸湿、 干燥、 消声、 散热和过滤等方面的用途, 都与流体在其中的流通有关, 多孔铝的流通性能可以用渗透系数来表征。 渗透系数表示在一定的渗流驱动力下, 流体通过多孔材料的难易程度, 其数值只与多孔材料的结构与性质有关。 渗透系数测试装置如图4所示, 测试结果如图5所示。

图4 多孔铝渗透系数测试系统

Fig.4 Experimental set-up to measure permeability coefficient of porous Al

图5 不同孔径多孔铝的渗透系数

Fig.5 Permeability coefficient of porous Al with different pore structures

流体速度较小时(u=0.5~2.5m/s), 它服从稳态层流Darcy定律宏观表达式[13]:

多孔铝的渗透系数与流动阻力有关, 流动阻力越小, 渗透系数越高。 由于流体在多孔介质中受到的局部阻力种类很多, 影响因素复杂, 目前尚无法从理论上求得其精确解, 因而难以确定渗透系数与多孔铝特征结构参数(P、 d、 I、 S)的关系式, 本文定性地分析了各种参数对渗透系数的影响。

流体运动时与壁面发生摩擦, 会造成一定的能量损失, 其值随多孔铝内表面积S、 流体流速u和流体黏度μ的增大而增大[13, 14]。 流体在改变流动方向或流速大小时产生漩涡与碰撞, 也会形成较集中的能量损失, 其值随弯曲通道的数量n及通孔度I的增大而增大[14, 17]。

根据高孔隙率多孔铝的形成原理, 对于相同孔径的多孔铝, 随着孔隙率P的提高, 其通孔度I增大, 表面积S减小, 其渗透系数相应提高。 在相同孔隙率下, 随着孔径d增大: 一方面, 单位长度上的孔穴数n减少, 漩涡区减少, 局部阻力损失降低, 渗透系数相应增大; 另一方面, 表面积S减小, 内摩擦阻力减小, 渗透系数增大。

4 结论

1) 在负压渗流铸造法的基础上, 控制铝熔体浇铸量, 选择合适的渗流参数, 使铝熔体均匀分布在占位颗粒的间隙中, 获得了高孔隙率(70%~90%)、 高通孔度(25%~50%)的多孔铝。

2) 渗流驱动压力Δp、 铝熔体浇铸温度tAl、 模具预热温度tp是主要的渗流参数: 采用足够高的tp和tAl, 以保证铝熔体的渗流长度; 应在满足渗流长度和孔结构均匀的基础上选择较低的渗流驱动压力Δp; 通过正交实验对渗流参数进行优化, 可以减小多孔铝在渗流方向上的孔隙率梯度。

3) 多孔铝的渗透系数KP与其孔结构密切相关: 对于孔径相同的多孔铝, KP随孔隙率P增大而提高; 在孔隙率相同的条件下, 随着孔径d的增大, 表面积S减小, 摩擦阻力减小, KP相应增大。

REFERENCES

[1] Gibson L J, Ashby M F. Cellular Solids: Structure & Properties[M]. New York: Cambridge University Press, 1997. 18-41.

[2] Ashby M F, Lu T J. Metal foams: a survey[J]. Science in China B, 2003, 46(4): 521-523.

[3] Banhart J, Fleck N A, Mortensen A. Cellular metals: manufacture, properties and application[A]. International Conference on Cellular Metals and Metals Foaming Technology[C]. Berlin: Verlag MIT, 2003. 13-16.

[4] Ashby M F, Evans A G, Fleck N A, et al. Metal Foams: A Design Guide[M]. Boston: B-H Press, 2000. 11-16.

[5] ZOU Yi, HE De-ping, JIANG Jia-qiao. New type of spherical pore Al alloy foam with low porosity and high strength[J]. Science in China B, 2004, 47(5): 407-413.

[6] 吴照金, 何德坪. 泡沫铝凝固过程中孔隙率的变化[J]. 科学通报, 2000, 45(8): 829-835.

WU Zhao-jin, HE De-ping. Changes of aluminum foam porosity during solidify-cation[J]. Chinese Science Bulletin, 2000, 45(8): 829-835.

[7] YANG Dong-hui, HE De-ping. Porosity of porous Al alloys[J]. Science in China B, 2001, 44(4): 411- 418.

[8] 李乃哲, 陈 策, 何德坪. 多孔铝合金的孔隙率梯度及控制[J]. 中国有色金属学报, 2004, 14(3): 378-384.

LI Nai-zhe, CHEN Ce, HE De-ping. Porosity gradient of porous aluminum alloy and its control[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 378-384.

[9] Mortensen A, Masur L J, Cornie J A, et al. Infiltration of porous preforms by a pure metal [J]. Metallurgical Transactions A, 1989, 20a: 2535-2547.

[10] 陈 锋, 张爱文, 何德坪. 多孔金属通孔度的控制[J]. 材料研究学报, 1999, 13(6): 591-595.

CHEN Feng, ZHANG Ai-wen, HE De-ping. Control of the degree of pore-opening for porous metals[J]. Chinese Journal of Materials Research, 1999, 13(6): 591-595.

[11] 何德坪, 闻德荪, 张 勇, 等. 铝熔体在多孔介质中的渗流过程[J]. 材料研究学报, 1997, 11(2): 113- 119.

HE De-ping, WEN De-sun, ZHANG Yong, et al. The infiltration process of molten Al into porous media[J]. Chinese Journal of Materials Research, 1997, 11(2): 113-119.

[12] 马立群, 何德坪. 新型泡沫铝的制备及其孔结构的控制[J]. 材料研究学报, 1994, 8(1): 11-17.

MA Li-qun, HE De-ping. Fabrication and pore structure control of new type aluminium foams[J]. Chinese Journal of Materials Research, 1994, 8(1): 11-17.

[13] 林瑞泰. 多孔介质传热传质引论[M]. 北京: 科学出版社, 1995. 53-78.

LIN Rui-tai, Introduction to Heat and Mass Transfer in Porous Media[M]. Beijing: Science Press, 1995. 53-78.

[14] 梅 炽. 冶金传递过程原理[M]. 长沙: 中南工业大学出版社, 1987. 70-85.

MEI Chi. Principle of Transport Processes in Metallurgy[M]. Changsha: Central South University of Technology Press, 1987. 70-85.

[15] 康志成, 毛大垣, 邓圭玲. 铝熔体粘度测量的研究[J]. 湖南有色金属, 2001, 17(2): 18-20.

KANG Zhi-cheng, MAO Dao-hong, DENG Gui-ling. The study of measuring molten aluminium viscosity[J]. Hunan Nonferrous Metals, 2001, 17(2): 18-20.

[16] 程桂萍, 陈 锋, 何德坪, 等. 用负压渗流法制备通孔泡沫金属[J]. 东南大学学报(自然科学版), 1997, 27(3): 85-88.

CHENG Gui-ping, CHEN Feng, HE De-ping, et al. Preparation of open-pore metallic foam by negative pressure infiltration process[J]. Journal of Southeast University(Natural Science Edition), 1997, 27(3): 85-88.

[17] 归柯庭, 汪 军, 王秋颖. 工程流体力学[M]. 北京: 科学出版社, 2003. 183-200.

GUI Ke-ting, WANG Jun, WANG Qiu-ying. Engineering Fluid Mechanics[M]. Beijing: Science Press, 2003. 183-200.

基金项目: 国家自然科学基金资助项目(90205005; 50231010)

收稿日期: 2005-01-26;

修订日期: 2005-05-16

作者简介: 张伟开(1978-), 男, 博士研究生.

通讯作者: 何德坪, 教授; 电话: 025-83794119; E-mail: dphe@seu.edu.cn

(编辑 陈爱华)