DOI: 10.11817/j.issn.1672-7207.2018.04.031

孔板波纹填料热源塔的热质传递性能

吕珍余,梁彩华,黄世芳,张小松

(东南大学 能源与环境学院,江苏 南京,210096)

摘要:提出一种采用大比表面积、表面冲有网孔的塑料孔板波纹填料的热源塔,并通过构建横流式热源塔实验系统,开展风量密度和淋液密度等对孔板波纹填料热源塔热质传递性能的研究,并与常规人字波纹填料热源塔热质传递性能进行实验对比。研究结果表明:孔板波纹填料表面的网孔结构促进液膜在填料两侧的交叉流动及液膜表面的扰动;相比人字波纹填料,当风量密度为2.5 kg/(m2·s)时,孔板波纹填料的传热系数提高9.5%,换热量为人字波纹填料的2倍,为热源塔热质传递强化及紧凑化提供参考。

关键词:热源塔;孔板波纹填料;传热;传质

中图分类号:TU831.6 文献标志码:A 文章编号:1672-7207(2018)04-1003-08

Heat and mass transfer performance of porous corrugated packing in heat-source tower

L Zhenyu, LIANG Caihua, HUANG Shifang, ZHANG Xiaosong

Zhenyu, LIANG Caihua, HUANG Shifang, ZHANG Xiaosong

(School of Energy and Environment, Southeast University, Nanjing 210096, China)

Abstract: A plastics porous corrugated plate packing was proposed which had large specific surface area and was punched with holes on its surface. Cross-flow heat-source tower experiment system was established. The influence of air mass flow flux, liquid desiccant mass flow flux on the heat and mass transfer performance of porous corrugated packing was studied and compared with that of herringbone corrugated packing under the same conditions. The results show that the mesh structure of the porous corrugated packing promotes liquid film’s crossflow on the both sides of the packing and perturbation of liquid film surface. When the air mass flow flux is 2.5 kg/(m2·s), the heat transfer coefficient of porous corrugated packing is 9.5% larger than that of herringbone corrugated packing and porous corrugated packing’s heat transfer is 2 times larger than that of herringbone corrugated packing, which gives reference to enhance the heat and mass transfer and to reduce the volume of heat-source tower.

Key words: heat-source tower; porous corrugated packing; heat transfer; mass transfer

热源塔作为一种新型的热质交换设备,是热源塔热泵系统的核心部件之一。在夏季工况下,热源塔利用部分冷却水的蒸发将机组冷凝热排放到环境中;在冬季工况时,热源塔依靠低温溶液从空气中吸收热量作为热泵的低位热源[1-2]。热源塔热泵系统兼顾了常规水冷冷水机组夏季高运行效率的优势[3-5],同时在冬季可替代锅炉进行供暖,一次能源利用效率高。相比空气源热泵,热源塔热泵系统不存在结霜问题[6-8],可在较低的环境温度下稳定工作;相比水/地源热泵,热源塔热泵系统不受地理地质条件限制[9-10]。热源塔夏季换热以潜热为主,冬季换热则以显热为主,夏季散热量大于冬季吸热量[11]。为了保证热泵系统冬季稳定工作,热源塔需按冬季工况设计。如使用常规冷却塔填料,势必造成热源塔体积过大,使得存在在一些场合因场地受限而不能应用的问题。根据热源塔的传热传质原理可知,为减小热源塔体积,可通过增大热源塔填料的比表面积以获得更大的气液接触面积及提高填料热质传递系数来实现。目前,填料的研究主要集中在通过表面改性和表面微结构改造来提高填料表面的润湿性。填料的宏观结构,如填料排列方式及波纹片几何尺寸等,决定了气体和液体的基本流动方式;填料的微观结构,如凸点、沟槽、小孔、小波纹等,则主要促进液体流动中液膜的铺展、湍动及液相的径向分布[12]。液体在规整填料表面的流动形式主要以膜状流为主[13],李洪等[14]对5种不同的波纹规整填料进行研究,发现依靠渗流作用的波纹规整填料具有更好的热质传递性能。近年来,HOFFMANN等[15-17]通过数值模拟方法,研究了规整填料表面液膜流体动力学特性。谭丽媛等[16]利用计算流体力学中的VOF多相流模型,对液体在两相邻规整填料特征单元上的分布进行三维仿真模拟,发现液体在高比表面积、填料表面有波纹的规整填料上分布较好。虽然前人对填料方面进行了很多研究,但对于结合热源塔传热传质特性的填料优化涉及较少。为此,本文作者提出一种采用大比表面积(500 m2/m3)、表面冲有网孔的塑料孔板波纹填料的横流热源塔,所采用的塑料孔板波纹填料具有规整填料的特性,且比表面积大、表面润湿性能好,结构上利于气液两相充分接触及液膜流动。同时,通过构建横流热源塔实验系统和热源塔数学模型,深入研究孔板波纹填料热源塔传热传质性能并与常规人字波纹填料热源塔进行对比。

1 热源塔的数学模型

在横流热源塔中,空气沿水平方向进入填料,溶液从填料顶部流下,两者在填料表面完成热质交换,溶液吸收空气中的显热及潜热,温度升高。针对热源塔内溶液与空气间热质传递过程的特征,提出以下假设:1) 传热与传质系数在整个填料中保持一致;2) 填料表面的传热与传质面积相同;3) 流动方向的导热可以忽略;4) 填料在二维方向润湿均匀。

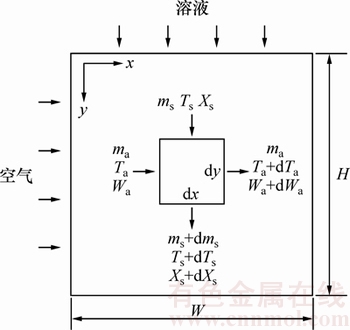

横流热源塔中,填料的长×宽×高为W×L×H。任取图1中1个微元体dV为研究对象。在溶液与湿空气的热质交换过程中,遵循能量守恒、质量守恒(包括水分质量守恒和溶质质量守恒)及对流传热传质关系式。

图1 横流热源塔模型

Fig. 1 Model of crossflow heat-source tower

能量守恒:

(1)

(1)

水分质量守恒:

(2)

(2)

溶质质量守恒:

(3)

(3)

式中:ma和ms分别为空气和溶液的质量流量,kg/s;ha为空气焓,J/g;Ts为溶液温度,K;wa为湿空气含湿量,g/kg;Xs为溶液质量分数,%; 为溶液比定压热容,kJ/(kg·K)。

为溶液比定压热容,kJ/(kg·K)。

对流传热方程为

(4)

(4)

对流传质方程为

(5)

(5)

式中: 为干空气比定压热容,kJ/(kg·K);

为干空气比定压热容,kJ/(kg·K); 为水蒸气比定压热容,kJ/(kg·K);Ta为空气温度,K;hc为传热系数,W/(m2·K);aw为填料比表面积,m2/m3;V为填料体积,m3;hd为湿差传质系数,kg/(m2·s);ws为溶液等效含湿量,g/kg。

为水蒸气比定压热容,kJ/(kg·K);Ta为空气温度,K;hc为传热系数,W/(m2·K);aw为填料比表面积,m2/m3;V为填料体积,m3;hd为湿差传质系数,kg/(m2·s);ws为溶液等效含湿量,g/kg。

其中,空气的焓变化量

,经过一系列推导,得到热源塔内部传热传质的控制方程:

,经过一系列推导,得到热源塔内部传热传质的控制方程:

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

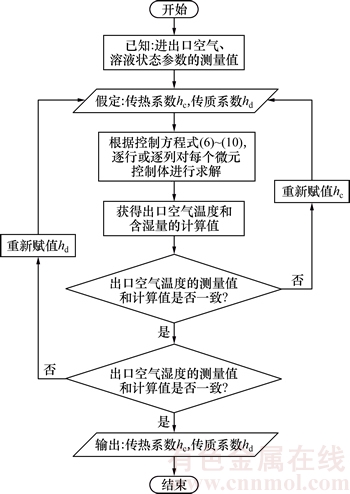

通过对上述控制方程的差分离散,再结合溶液与空气的物性参数,可得到热源塔中各个微元内空气与溶液的参数。实验测得空气与溶液的进出口参数,根据这些参数可推算出填料的传热传质系数。具体计算流程如图2所示:假定传热和传质系数,根据热源塔的进口空气和溶液参数,利用差分离散求解方法,求出热源塔出口参数。通过校核出口空气温度的计算值与测量值,修正传热系数;校核出口空气含湿量的计算值和测量值,修正传质系数,如此循环往复,直到达到一定精度,输出相应的传热系数和传质系数。根据实验测得的空气与溶液的进出口参数,由式(11)和式(12)分别求得热源塔的总换热量和潜热换热量:

(11)

(11)

(12)

(12)

式中:Q为总换热量,kW;QL为潜热换热量,kW;ha,in和ha,out分别为热源塔进出口的空气焓,J/g;ρa为空气的密度,kg/m3;Va为空气体积流量,m3/h;wa,in和wa,out分别为热源塔进出口空气的含湿量,g/kg;r为水蒸气的汽化潜热,J/g。

图2 热源塔传热传质系数计算流程图

Fig. 2 Calculation flow chart of heat and mass transfer coefficient

2 实验台简介

2.1 实验装置

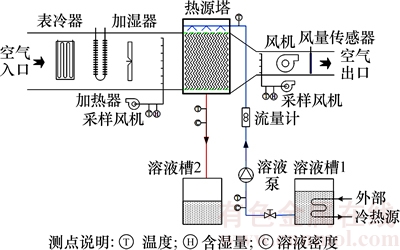

热源塔实验系统如图3所示,主要包括热源塔、空气处理系统、溶液系统和数据采集模块。空气处理系统包括表冷器、加热器、加湿器、风机等,溶液系统包括流量计、泵、溶液槽和外部冷热源。

图3 热源塔实验系统

Fig. 3 Schematic diagram of heat-source tower experiment

实验过程中,溶液槽1中配制好的溶液被外部冷热源处理到设定温度后,由溶液泵抽出,经过调节阀、流量计后送入热源塔顶部的布液装置。溶液在热源塔中润湿填料并与来流空气进行热质传递,吸热后的溶液流入溶液槽2中。热源塔中空气和溶液的流量均采用变频器控制,溶液选用的是质量浓度为24.2%的乙二醇溶液。

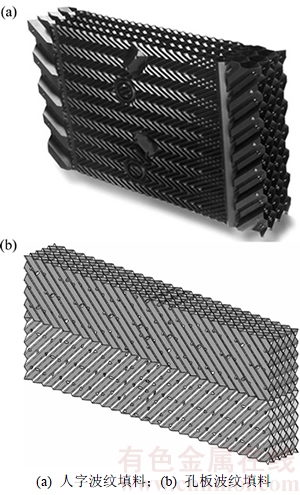

2.2 热源塔填料结构

热源塔为实验台的核心设备,分别采用人字波纹填料和孔板波纹填料,填料长×宽×高均为280 mm×430 mm×700 mm,比表面积分别为172 m2/m3和500 m2/m3,片间距分别为15 mm和6.3 mm。

人字波填料表面有连续的人字形通道(如图4(a)所示),液体流动路线较长,空气流经人字波纹填料时有良好的扰动性。孔板波纹填料的表面冲有网孔结构(如图4(b)所示),自由下降的液体可在填料上形成稳定的降膜流动,网孔结构促进液膜在填料两侧的交叉流动,可有效增加填料表面利用率,加强气液界面上液膜的湍动程度,提高传热效果。孔板波纹填料的材质是聚丙烯,化学稳定性好,耐酸、碱及有机溶剂的腐蚀。同时,相同材质的填料在化工领域已有使用,具有工程应用价值。实验中使用的孔板波纹填料单片横向安装形成一层,填料层与层之间纵向排布,相邻两层交错90°安装。填料长×宽×高为280 mm×430 mm×700 mm,每层填料高度为100 mm,共7层。

图4 2种填料结构示意图

Fig. 4 Schematic diagram of two types of packing

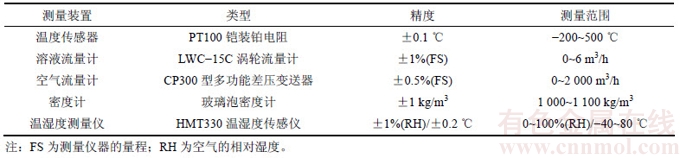

2.3 测试装置

实验测量的空气参数主要有空气流量、热源塔进出口空气的干球温度和含湿量。溶液参数主要有热源塔进出口溶液流量、温度以及浓度。实验测量装置及精度如表1所示。

3 实验结果分析与讨论

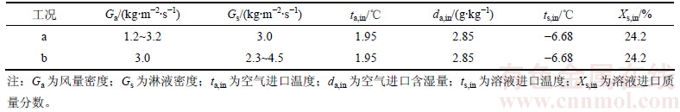

为得到运行参数对2种填料热质传递性能的影响规律,实验通过对溶液与空气间的传热传质过程进行变工况研究,获得不同运行工况下(表2)热源塔的进出口状态参数,然后基于模型对实验数据进行处理,得到该过程不同填料的热质传递系数和换热量。

3.1 实验测试误差分析

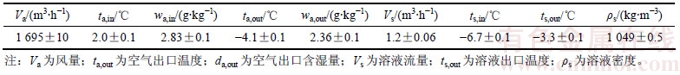

根据间接测量的误差传递原理,以典型工况为例,对实验数据结果进行误差分析,典型工况直接测量值见表3。

表1 实验测试测量装置

Table 1 Specifications of different measuring devices

表2 热源塔热质传递性能实验进口参数

Table 2 Inlet parameters in heat and mass transfer process of heat-source tower

表3 典型工况直接测量值

Table 3 Directly measured values of typically experimental condition

总换热量的绝对误差为

(13)

(13)

总换热量的最大相对误差为

(14)

(14)

从以上的数据误差分析可知,本研究所得总换热量最大相对误差符合实验要求。

3.2 风量密度对热源塔热质传递性能的影响

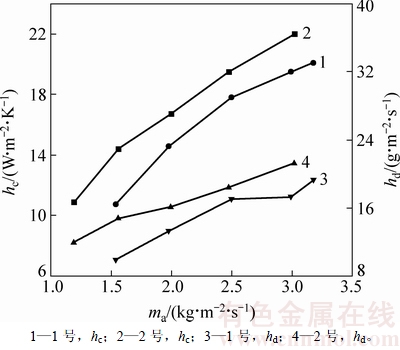

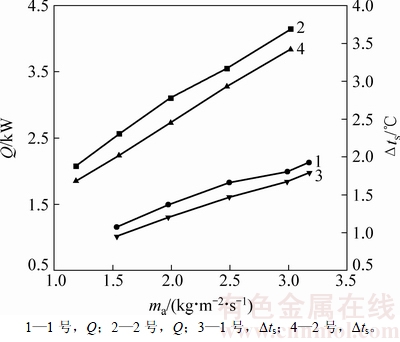

当热源塔在如表2中工况a所示进口参数条件下,调节风量密度从1.2 kg/(m2·s)变化到3.2 kg/(m2·s),分析2种填料的热质传递性能随风量密度的变化规律,其变化曲线如图5~8所示。为方便表示,人字波纹填料和孔板波纹填料在图中分别用1号和2号代替。

图5所示为风量密度对2种填料传热传质系数的影响规律。从图5可知:2种填料的传热传质系数均随着风量密度的增大而增大。由于风量密度的增加,溶液表面与空气主流的扩散渗透增强,同时溶液液膜也会在加大的空气流速下产生较强烈的扰动,从而使系数增加。随着风量密度的增加,孔板波纹填料的平均传热系数比人字波纹填料提高5%,而孔板波纹填料的平均传质系数比人字波纹填料提高7.2%。其原因主要是孔板波纹填料表面的网孔结构能增强液膜的渗流效应及液膜表面的扰动,溶液与空气之间的热质传递更为剧烈。相比于人字波纹填料,在相同运行条件下,孔板波纹填料布液更为均匀,表面润湿更充分。

图5 传热传质系数hc和hd随风量密度ma的变化

Fig. 5 Heat and mass transfer coefficient vs air mass flow flux

图6所示为风量密度对2种填料换热量和进出口溶液温差的影响规律。由图6可知:2种填料的换热量、溶液温升均随着风量密度的增加而增加;当风量密度从1.2 kg/(m2·s)上升至3.1 kg/(m2·s)时,孔板波纹填料的换热量从2.08 kW上升至4.15 kW,溶液温升也增加至原来的2.00倍。由于风量密度增加导致填料换热系数增大,进而促使换热量和溶液温升增加;当风量密度均为2.5 kg/(m2·s)时,孔板波纹填料的换热量为人字波纹填料的2.00倍。这主要是因为孔板波纹填料的比表面积和热质传递系数均比人字波纹填料的大。

图6 换热量Q和进出口溶液温差△ts随风量密度ma的变化

Fig. 6 Heat transfer and solution temperature difference vs air mass flow flux

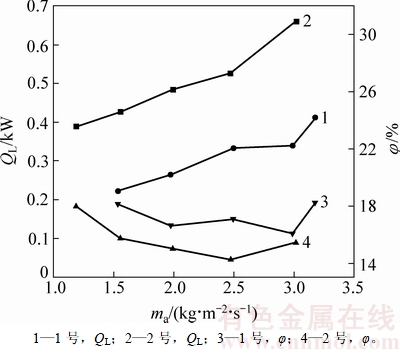

图7所示为风量密度对2种填料潜热换热量和潜热百分比的影响规律。从图7可知:2种填料的潜热换热量随着风量密度增加而增加,而风量密度对2种填料的潜热百分比的影响较小。风量密度的增加提高了传热传质系数,溶液与空气之间的显热和潜热换热量均提高,导致潜热百分比无明显变化。由于孔板波纹填料的比表面积和热质传递系数均比人字波纹填料的大,所以,当风量密度均为2.5 kg/(m2·s)时,孔板波纹填料的潜热换热量是人字波纹填料的1.57倍,而孔板波纹填料的潜热百分比略比人字波纹填料的低。

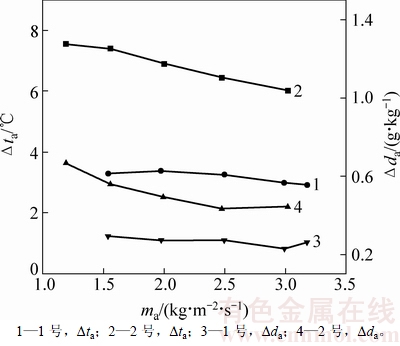

图8所示为风量密度对2种填料的进出口空气温差和含湿量差的影响规律。由图8可知:2种填料的进出口空气温差和含湿量差均随着风量密度的增加而增加;随着风量密度的增加,孔板波纹填料的进出口空气温差下降为原来的80%,进出口空气含湿量差下降到原来的66%。这是因为风量密度的增加导致与溶液接触的空气的总量增大,但空气与溶液之间的接触较之前不够充分。当风量密度均为2.5 kg/(m2·s)时,孔板波纹填料的进出口空气温差是人字波纹填料的2.00倍,孔板波纹填料的进出口空气含湿量差是人字波纹填料的1.60倍。

图7 潜热换热量QL和潜热百分比φ随风量密度ma的变化

Fig. 7 Latent heat and latent heat percentage vs air mass flow flux

图8 进出口空气温差△ta和含湿量差△da随风量密度ma的变化

Fig. 8 Air temperature and humidity difference vs air mass flow flux

3.3 淋液密度对热源塔热质传递性能的影响

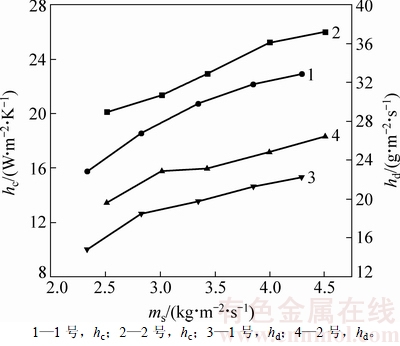

当热源塔在如表2中b所示进口参数条件下,调节淋液密度从2.3 kg/(m2·s)变化到4.5 kg/(m2·s),分析2种填料的热质传递性能随风量密度的变化规律,其变化曲线如图9~12所示。为方便表示,人字波纹填料和孔板波纹填料在图中分别用1号和2号代替。

图9所示为淋液密度对2种填料传热和传质系数的影响规律。从图9可知:2种填料的传热和传质系数均随着淋液密度的增加而增加,随着淋液密度的增加,孔板波纹填料的平均传热系数比人字波纹填料提高15%,孔板波纹填料的平均传质系数比人字波纹填料提高18%。其主要原因是孔板波纹填料表面的网孔结构促进了液膜在填料两侧的交叉流动,有效增加了填料表面利用率,加强了气液界面上液膜湍动程度,提高了传热效果。同时,高比表面积的孔板波纹填料相比于人字波纹填料布液更均匀。

图9 传热传质系数hc和hd随淋液密度ms的变化

Fig. 9 Heat and mass transfer coefficient vs solution mass flow flux

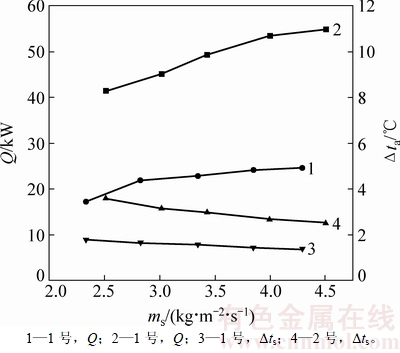

图10所示为淋液密度对2种填料换热量和进出口溶液温差的影响规律。由图10可知:2种填料的换热量随着淋液密度的增加而增加,而溶液温差则随着淋液密度的增加而减少;当淋液密度从2.5 kg/(m2·s)上升至4.5 kg/(m2·s)时,孔板波纹填料的换热量从 41.5 kW上升至55.0 kW,上升至原来的1.30倍,进出口溶液温差则下降为原来的70%。由于淋液密度的增加导致填料的热质传递系数增大,促使溶液与空气之间的换热量上升;随着淋液密度的增加,孔板波纹填料的平均换热量约为人字波纹填料的2.20倍,平均进出口溶液温差约为人字波纹填料的1.90倍。这是孔板波纹填料的传热传质系数和比表面积均比人字波纹填料的大所导致的。

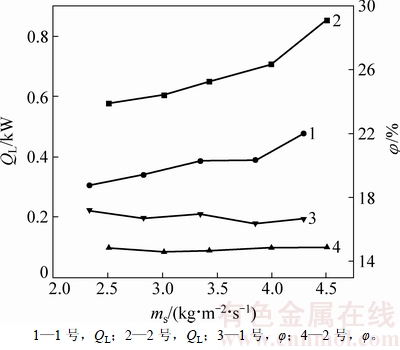

图11所示为淋液密度对2种填料的潜热换热量和潜热百分比的影响规律。从图11可知:2种填料的潜热换热量均随淋液密度的增加而增加,而淋液密度对填料的潜热百分比影响不大;当淋液密度从2.3 kg/(m2·s)增加至4.5 kg/(m2·s)时,孔板波纹填料的潜热换热量上升至原来的1.47倍。淋液密度的增加提高了填料的热质传递系数,促使溶液与空气之间的显热和潜热均增加,导致潜热百分比变化不大;随着淋液密度的增加,孔板波纹填料的平均潜热换热量是人字波纹填料的1.78倍,而孔板波纹填料的潜热百分比比人字波纹填料的略低。

图10 换热量Q和溶液温差△ta随淋液密度ma的变化

Fig. 10 Heat transfer and solution temperature difference vs solution mass flow flux

图11 潜热换热量QL和潜热百分比φ随淋液密度ms的变化

Fig. 11 Latent heat and latent heat percentage vs solution mass flow flux

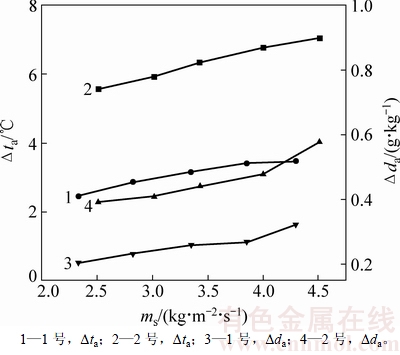

图12所示为淋液密度对2种填料的进出口空气温差和含湿量差的影响规律,由图12可知:2种填料的进出口空气温差和含湿量差均随着淋液密度的增加而增加;当淋液密度从2.5 kg/(m2·s)上升至4.5 kg/(m2·s)时,孔板波纹填料进出口空气温差上升为原来的1.26倍,而进出口空气含湿量差上升为原来的1.47倍;随着淋液密度的增加,孔板波纹填料的平均进出口空气温差为人字波纹填料的2.10倍,而平均进出口空气含湿量差为人字波纹填料的1.78倍。这主要是因为淋液密度的增加导致2种填料的传热传质系数均增加,潜热和显热换热量随之增加,而孔板波纹填料的比表面积和传热传质系数均比人字波纹填料的大,故其进出口空气温差和含湿量差均比人字波纹填料的大。

图12 进出口空气温差△ta和含湿量差△da随淋液密度ms的变化

Fig. 12 Air temperature and humidity difference vs solution mass flow flux

在热源塔中,空气与溶液发生传热传质,空气侧和溶液侧相互影响。风量密度增加导致溶液在热源塔中滞留时间增加,而空气和溶液交界面处溶液的扰动也更为剧烈,强化了溶液侧的换热。同时,淋液密度的增加提升了空气与溶液界面处溶液的更新速度,单位体积的空气与溶液接触更充分,强化了空气侧的换热。

4 结论

1) 采用孔板波纹填料,相比于传统的人字波纹填料,其具有较大的比表面积,孔板波纹填料表面的网孔结构增强液膜的渗流效应以及液膜表面的扰动,溶液与空气之间的热质传递更为剧烈。在相同运行条件下,孔板波纹填料布液更均匀,表面润湿更充分。

2) 随着风量密度的增加,孔板波纹填料的传热系数从10.9 W/(m2·K)上升至22 W/(m2·K),换热量从2.08 kW上升至4.15 kW。而淋液密度的增加使孔板波纹填料的传热系数从20.2 W/(m2·K)上升至26.0 W/(m2·K),换热量上升至原来的1.30倍。

3) 当风量密度为2.5 kg/(m2·s)时,孔板波纹填料的平均传热系数比人字波纹填料提高9.5%,换热量为人字波纹填料的2.00倍,潜热换热量是人字波纹填料的1.57倍。

4) 随着淋液密度的增加,孔板波纹填料的平均传热系数比人字波纹填料提高15%,平均换热量为人字波纹填料的2.20倍,平均潜热换热量是人字波纹填料的1.78倍。

参考文献:

[1] LI Nianping, ZHANG Wenjie, WANG Lijie, et al. Experimental study on energy efficiency of heat-source tower heat pump units in winter condition: Measuring Technology and Mechatronics Automation (ICMTMA)[C]//2011 Third International Conference on, IEEE, 2011: 135-138.

[2] WEN Xiantai, LIANG Caihua, ZHANG Xiaosong. Experimental study on heat transfer coefficient between air and liquid in the cross-flow heat-source tower[J]. Building and Environment, 2012, 57: 205-213.

[3] CHEN Qun, WANG Yifei, XU Yunchao. A thermal resistance-based method for the optimal design of central variable water/air volume chiller systems[J]. Applied Energy, 2015, 139: 119-130.

[4] CHEUNG H, BRAUN J E. Empirical modeling of the impacts of faults on water-cooled chiller power consumption for use in building simulation programs[J]. Applied Thermal Engineering, 2016, 99: 756-764.

[5] LO C, TSAI S, LIN B. Economic dispatch of chiller plant by improved ripple bee swarm optimization algorithm for saving energy[J]. Applied Thermal Engineering, 2016, 100: 1140-1148.

[6] JANG J Y, BAE H H, LEE S J, et al. Continuous heating of an air-source heat pump during defrosting and improvement of energy efficiency[J]. Applied Energy, 2013, 110: 9-16.

[7] JIANG Yiqiang, DONG Jiankai, QU Minglu, et al. A novel defrosting control method based on the degree of refrigerant superheat for air source heat pumps[J]. International Journal of Refrigeration, 2013, 36(8): 2278-2288.

[8] 汪峰, 梁彩华, 吴春晓, 等. 疏水性铝翅片表面的结霜/融霜特性[J]. 中南大学学报(自然科学版), 2016, 47(4): 1368-1373.

WANG Feng, LIANG Caihua, WU Chunxiao, et al. Frosting and defrosting characteristics of hydrophobic fin surfaces[J]. Journal of Central South University (Science and Technology), 2016, 47(4): 1368-1373.

[9] LEE C K. Effects of multiple ground layers on thermal response test analysis and ground-source heat pump simulation[J]. Applied Energy, 2011, 88(12): 4405-4410.

[10] REZAEI B. A, KOLAHDOUZ E M, DARGUSH G F, et al. Ground source heat pump pipe performance with Tire Derived Aggregate[J]. International Journal of Heat and Mass Transfer, 2012, 55(11/12): 2844-2853.

[11] 文先太, 梁彩华, 张小松, 等. 填料型叉流热源塔不同运行模式下换热性能实验分析[J]. 重庆大学学报, 2011, 34(S1): 67-71.

WEN Xiantai, LIANG Caihua, ZHANG Xiaosong, et al. Heat transfer performance in a cross flow packing tower under different operational mode[J]. Journal of Chongqing University, 2011, 34(S1): 67-71.

[12]  , SEIBERT A F, FAIR J R. Influence of corrugation geometry on the performance of structured packings: an experimental study[J]. Chemical Engineering and Processing: Process Intensification, 2000, 39(4): 335-342.

, SEIBERT A F, FAIR J R. Influence of corrugation geometry on the performance of structured packings: an experimental study[J]. Chemical Engineering and Processing: Process Intensification, 2000, 39(4): 335-342.

[13] FOURATI M, ROIG V, RAYNAL L. Experimental study of liquid spreading in structured packings[J]. Chemical Engineering Science, 2012, 80: 1-15.

[14] 李洪, 姚跃宾, 王方舟, 等. 液相流动方式对波纹规整填料性能的影响[J]. 化工学报, 2014, 65(12): 4760-4766.

LI Hong, YAO Yuebin, WANG Fangzhou, et al. Effect of liquid flow behaviour on performance of corrugated structured packing[J]. CIESC Journal, 2014, 65(12): 4760-4766.

[15] HOFFMANN A, AUSNER I, REPKE J U, et al. Detailed investigation of multiphase (gas-liquid and gas–liquid–liquid) flow behaviour on inclined plates[J]. Chemical Engineering Research and Design, 2006, 84(2): 147-154.

[16] 谭丽媛, 袁希钢, KALBASSI M A. 规整填料结构对液相分布影响的计算流体力学[J]. 化工进展, 2015, 34(11): 3869-3878.

TAN Liyuan, YUAN Xiang, KALBASSI M A. Effect of structured packing’s structure on liquid distribution by computational fluid dynamics[J]. Chemical Industry and Engineering Progress, 2015, 34(11): 3869-3878.

[17] 李相鹏, 李锋, 张超. 规整填料内气相载荷对液膜流动特性的影响[J]. 中南大学学报(自然科学版), 2015, 46(4): 1239-1246.

LI Xiangpeng, LI Feng, ZHANG Chao, Influences of gas load on hydrodynamics of liquid film flow over structured packings[J]. Journal of Central South University (Science and Technology), 2015, 46(4): 1239-1246.

(编辑 杨幼平)

收稿日期:2017-04-29;修回日期:2017-06-22

基金项目(Foundation item):“十三五”国家重点研发计划项目(2016YFC070030)(Project(2016YFC070030) supported by the National Key Research and Development Program of China during the 13th Five Year Plan Period)

通信作者:梁彩华,博士,教授,博士生导师,从事制冷空调、建筑节能及可再生能源利用研究;E-mail:caihualiang@163.com