文章编号: 1004-0609(2005)12-2028-06

含铜金矿的压力氧化浸出及其机理

邱廷省1, 聂光华2, 张 强1, 陈景河3, 邹来昌3

(1. 北京科技大学 土木与环境工程学院, 北京 100083; 2. 江西理工大学 环境与建筑学院, 赣州 341000;

3. 福建紫金矿业集团股份有限公司, 上杭 364200)

摘 要: 含铜金矿在氧气分压为0.45MPa、 温度约为110℃条件下于高压釜中氧化一定时间, 浸出铜后, 渣氰化浸金, 获得的铜、 金浸出率分别为90.3%和96.55%。 通过分析X射线衍射谱及CuFeS2-H2SO4-NaCl-H2O体系在25℃下的φ-pH图, 确定了载金矿物的氧化机理, 分析了浸出体系的酸度、 温度及氯化钠浓度对含铜金矿预氧化及浸出过程的影响规律。 结果表明: 硫化矿的氧化溶解首先是磁黄铁矿, 其次是铜的次生硫化矿, 再次是黄铜矿, 最后是黄铁矿; 载金黄铜矿的氧化首先是铁从黄铜矿的晶格中氧化溶解出来, 生成中间产物CuS2和CuS; 较高的酸度和氯化钠浓度有利于单质硫的生成、 三价铁的水解和铜的浸出, 进而有利于金浸出率的提高。

关键词: 含铜金矿; 压力氧化; 浸出 中图分类号: TF803.21

文献标识码: A

Mechanism of oxidation and leaching for

copper-bearing gold ores

QIU Ting-sheng1, NIE Guang-hua2, ZHANG Qiang1, CHEN Jing-he3, ZOU Lai-chang3

(1. School of Civil and Environmental Engineering,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Environmental and Architectural Engineering,

Jiangxi University of Science and Technology, Ganzhou 341000, China;

3. Fujiian Zijin Mining Industry Co. Ltd., Shanghang 364200, China)

Abstract: The copper-bearing gold ores were extracted from copper-leaching residues under the conditions of the partial oxygen pressure of 0.45MPa and the temperature of 110℃ oxidated for some time in the autoclave. The results show that the extraction rate of gold is 96.55% and the rate of copper extraction is 90.3%. By XRD patterns and φ-pH diagram of CuFeS2-H2SO4-NaCl-H2O system at 298K under pressure of 101.325kPa, the oxidizing process and mechanism of the gold mineral were identified. The effects, such as the acidity of leaching system, the temperature and the concentration of the sodium chloride, on oxidation and leaching of copper-bearing gold ores were analyzed. The results show that the sequence of sulfide ores oxidized and dissolved are pyrrhotite firstly, sulphide secondly, then chalcopyrite, pyrite lastly. The high acidity and concentration of the sodium chloride are propitious to produce sulphur, hydrolyse of Fe3+ and leaching of copper, and furthermore, the rate of gold extraction can be improved dramatically.

Key words: copper-bearing gold ore; pressure oxidation; leaching

含铜金矿石是较典型的难处理矿石, 也是我国重要的黄金资源。 含铜金矿因铜含量较高, 铜在氰化浸金过程中消耗大量的氰化物而致使金浸出率不高或使浸出成本上升, 造成提金在经济上的不可行性, 同时铜离子会与CN-形成铜氰络离子影响后续作业, 因此含铜难处理金矿在氰化浸出前, 必须采取必要的措施去除铜的影响[1, 2]。 预氧化浸铜方法是最好的除铜措施, 目前主要的氧化预处理方法有焙烧氧化、 细菌氧化、 加压氧化, 其中前两种方法在国内有较多的研究和应用, 含硫和砷难处理金矿石的加压氧化预处理工艺也比较成熟, 在国外也有不少工业实践对硫化铜矿物的加压氧化浸出进行研究[3, 4]。 而采用加压氧化预处理特别是通过添加氯化物实现较低温度和较低压力下氧化酸浸预处理含铜金矿, 浸出铜后的渣再进行氰化浸金工艺在国内外的研究较少, 该工艺不仅能大大地降低工艺对设备材质的要求, 还可以综合回收多金属矿物中的铜、 金、 银、 硫等[5, 6]。 因此, 开展该工艺的研究对难处理的含铜金矿的开发利用具有十分重要的意义。 本文作者采用在硫酸-氯化钠水溶液体系中、 较低温度和压力下氧化酸浸预处理含铜金矿, 并在此研究的基础上, 分析了载金矿物的氧化历程、 热力学过程以及体系的酸度、 温度及氯化钠浓度对载金矿物预氧化浸出的影响。

1 实验

1.1 原料

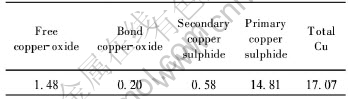

矿样为某矿山浮选含铜金精矿, 矿石中的金属矿物主要为黄铜矿, 其次是黄铁矿、 褐铁矿、 磁黄铁矿, 少量其它硫化矿、 金和银。 脉石主要为石英, 少量方解石、 长石、 云母等。 其多元素分析及铜矿物物相分析结果如表1和2所示。 矿石中铜、 金、 银是主要的有价金属, 黄铜矿是主要的铜矿物, 自然金主要以显微、 次显微富存于黄铜矿等硫化矿中。

1.2 方法

氧化预处理实验在FCH型2L钛衬高压釜中进行。 在矿物粒度、 搅拌强度、 起始酸度、 起始NaCl浓度、 矿浆固液比及浸出时间条件的前期探索实验的基础上, 本文作者重点进行了氧气分压、 氧化温度对预处理含铜金矿金属浸出率的影响实验, 优化预氧化条件获得最佳的铜和金的浸出指标。 对实验预先氧化浸出液和渣进行化验分析, 对渣进行X射线衍射分析、 电镜扫描分析, 查清各种条件下的产物及其结构, 从而分析出氧化反应过程, 根据反应的热力学过程及氧化体系的φ-pH图分析氧化过程及规律, 同时考察了预氧化对金浸出的影响。

表1 矿物多元素的成分

Table 1 Chemical compositions of samples (mass fraction, %)

表2 试样中铜矿物的物相

Table 2 Cu composition of samples (mass fraction, %)

矿石在烧杯中按实验条件调浆后, 加入高压釜中。 进行了加压氧化处理后, 在XTLZ型多用真空过滤机中过滤, 液体送化验, 渣洗涤干燥后, 部分制样送化验分析, 部分用于测试, 其他样进行氰化浸出实验。 氰化浸出实验在锥型瓶中进行, 渣和水按一定液固比加入, 用碱调浆至pH为10~12后, 加入NaCN和活性碳, 在HY-8型调速振荡机上摇瓶浸出。 浸出液送化验, 渣淋洗烘干制样送化验分析。

2 结果及讨论

2.1 加压氧化结果

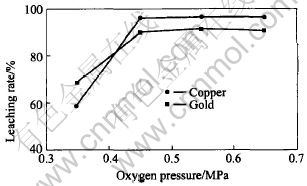

在各条件前期探索实验的基础上, 重点考察了氧气分压、 氧化温度对铜、 金浸出的影响。 在温度为110℃、 氧气分压为0.45MPa、 氧化时间为2.5h、 90%矿物的粒度小于45μm、 搅拌速度为750r/min、 起始酸度为100g/L、 起始NaCl浓度为40g/L和矿物液固比为5g/L的条件下, 获得了较佳的铜、 金浸出指标, 铜、 金浸出率分别为90.3%和96.55%。 实验结果同时表明, 较细的矿物粒度和较高的起始酸度对预处理效果起积极作用。 而氧气分压和温度对预氧化效果的影响较为明显, 其对铜、 金浸出率的影响如图1和2所示。

2.2 矿物的氧化历程

通过对浸出液和渣的化学分析表明, 当实验温度为70~120℃时, 低温矿物中的Fe主要氧化成Fe2+以及少量Fe3+, 存在于浸出液体中; 而高温时, Fe则主要以三价铁的矾类沉淀于浸渣中, 部分Fe3+和少量Fe2+存在于浸出液体中。 铜氧化以Cu2+存在于浸出液中, 大部分硫氧化为单质硫存在于渣中, 只有极少部分氧化为SO2-4生成。 矿物中的金基本上不被浸出而仍存在于浸铜渣中。 主要硫化矿的氧化化学反应如表3所列。

图1 氧气分压对铜、 金的浸出的影响

Fig.1 Effects of oxygen pressure on leaching rate of copper and gold

图2 温度对铜、 金浸出率的影响

Fig.2 Effects of temperature on leaching rate of copper and gold

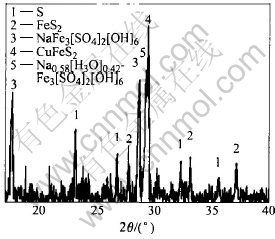

从上述计算的标准吉普斯自由能及标准平衡电位可以看出, 根据氧化电位的高低可推算出各硫化物的理论氧化先后顺序为FeS[FY]CuFeS2[FY]FeS2[FY]CuS2[FY]CuS。 对不同温度下预氧化铜浸出渣进行了化学分析和物相分析, 结果表明, 在H2SO4-O2-NaCl低温水溶液体系中, CuS2和CuS比CuFeS2和FeS2先被氧化溶解完全。 这是由于在此实验条件下, CuS2、 CuS比黄铜矿、 黄铁矿呈现更大的反应动力学趋势, 且CuS2、 CuS含量低也是重要原因。 含铜金矿在氧气分压为0.45MPa于不同温度下氧化2.5h时浸出渣的X射线衍射谱如图3和4所示。 由图3和4可看出, 当温度为90℃时, 渣中主要残余的硫化矿为黄铜矿和黄铁矿, 其他硫化矿已经基本氧化溶解; 当温度为110℃时, 渣中主要残余硫化矿为CuS2和CuS, 黄铁矿和黄铜矿基本已经氧化分解。 表明氧化预处理过程中首先是赤铁矿等氧化矿溶解, 其次磁黄铁矿和铜的次生硫化矿溶解, 再次是黄铜矿, 最后是黄铁矿。 而在黄铜矿的氧化过程中, 首先是铁从黄铜矿的晶格中氧化分离出来, 生成CuS2和CuS, 当pH值小于-0.7时, 反应方程为

CuFeS2+2H+=CuS+Fe2++H2S(1)

2CuS+2H++2e=Cu2S+H2S(2)

pH大于-0.7时, 反应方程为

Cu2S+2Fe2++3S0+4e=2CuFeS2(3)

CuS+Fe2++S0+2e=CuFeS2(4)

CuS2和CuS再进一步氧化为二价铜离子和单质硫。

表3 298K和101.325kPa时主要硫化矿的氧化化学反应过程

Table 3 Major oxidation reaction of sulphides ores at 298 K under pressure of 101.325 kPa

图3 363K时含铜金矿氧化浸出渣的X射线衍射谱

Fig.3 XRD pattern of solid residues at 363K

图4 383K时含铜金矿氧化浸出渣的X射线衍射谱

Fig.4 XRD pattern of solid residues at 383K

2.3 浸出渣及氧化过程分析

用X射线衍射和显微镜分析了不同产物。 结果表明, 在较低温度或较短时间内, 渣中产物主要为未反应的黄铜矿和黄铁矿, 随着氧化的进一步深入, 渣中硫含量逐渐升高, 同时铁的矾类沉淀也增加。 由图3可看出, 当温度90℃时, 浸出的铁离子已经开始以三价铁的黄钠铁矾(NaFe3(SO4)2-(OH)6)大量沉淀于浸出渣中, 由图4可看出, 黄钠铁矾和草黄铁矾(H3OFe3(SO4)2(OH)6)沉淀含量较大, 化学分析也表明在110℃氧化条件下, 铁基本沉淀于浸出渣中。

CuFeS2-H2SO4-NaCl-H2O体系对黄铜矿进行氧化浸出时, 从不同条件下的化学分析结果可发现: 铁首先从其晶格中溶解出来, 并生成CuS2和CuS, 最后被氧化成Cu2+和单质硫。 虽然硫在较低电位下就会氧化成HSO-4, 但在实验中发现, 只要温度低于120℃, 单质硫将不会进一步氧化成HSO-4, 而是很稳定地存在于渣中, 这与文献[7-9]所表明的在120℃的氧化体系内硫化矿的氧化产物主要是单质硫的结果基本一致。

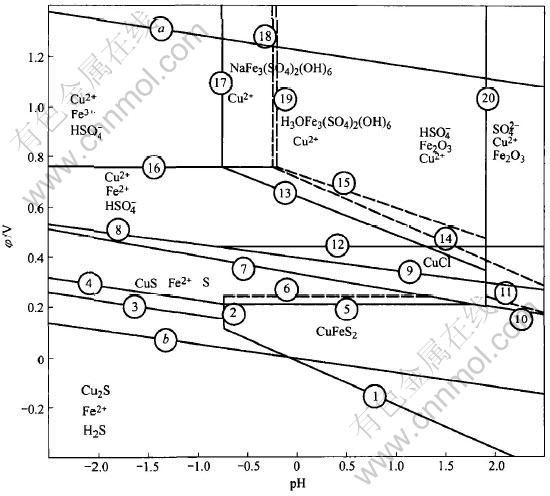

图5所示为CuFeS2-H2SO4-NaCl-H2O体系在标准状态下的φ-pH图[10-16]。 图5中的曲线a和b分别为氧和氢线; 曲线1~12为矿物氧化反应线; 曲线13~19为铁离子氧化和沉淀反应线; 曲线20为HSO-4生成SO2-4的反应线。 由见图5可看出, 在低电位下, 铁主要氧化成二价铁稳定地存在于溶液中, 随着体系电位的提高, 铁氧化为三价, 并生成大量的黄钠铁矾。 Fe3+有较高的氧化能力, 在体系中能氧化铜、 铁的硫化物, 对硫化矿的氧化起到很好的催化作用。 当体系的pH值降低时, 产生草黄铁矾和Fe2O3, 但在实际实验分析中却没有产生Fe2O3, 这主要是由于在CuFeS2-H2SO4-NaCl-H2O体系中, 黄钠铁矾和草黄铁矾具有更大的反应趋势和稳定区, 其主要反应方程为

NaFe3(SO4)2(OH)6+8H+=

3Fe3++Na++2HSO-4+6H2O(5)

Fe2O3+6H+=2Fe3++3H2O(6)

H3OFe3(SO4)2(OH)6+7H+=

3Fe3++2HSO-4+7H2O(7)

同时铁大量水解生成的H+, 会使体系pH值基本维持在0左右, 使Fe2O3难以生成, 并可避免单质硫的氧化和铜离子的水解沉淀。

图5 CuFeS2-H2SO4-NaCl-H2O体系在298K时的φ-pH图

Fig.5 φ-pH diagram of CuFeS2-H2SO4-NaCl-H2O system at 298K

由图5还可发现, Na+、 Fe3+、 HSO-4、 SO4的大量沉淀会伴随H+的大量生成, 这有利于维持体系在较高的酸度。 而体系中Cl-的存在也有利于矿物的氧化溶解, 有关化学反应方程为

2CuCl+HSO-4+7H++8e=

Cu2S+2Cl-+4H2O(8)

CuCl+ Cl-=CuCl-2(9)

Cu2++2Cl-+e=CuCl-2(10)

由上述反应方程可看出, Cl-促进了硫化铜矿的氧化, 生成CuCl沉淀后被Cl-络合溶解后, 再进一步氧化溶解。 同时, Cl-有很强的去极化作用, 它能与铜、 铁等金属离子形成各种络合物, 这也降低了体系中金属离子的活度, 从而有利于浸出反应向金属离子的浸出方向进行, 另外低的铜铁离子浓度也更不容易产生水解沉淀。 因此, 适当的NaCl浓度有利于载金黄铜矿的氧化, 使金裸露, 从而提高浸金效果。

3 结论

1) 在氧气分压为0.45MPa、 温度为110℃的低温低压H2SO4-NaCl-H2O体系下可使含铜金矿实现预氧化浸出, 铜、 金浸出率分别为90.3%和96.55%。 较细的矿物粒度和较高的起始酸度对预处理效果起积极的作用, 氧气分压和氧化温度对预氧化效果影响显著。

2) 矿物中各硫化矿的氧化溶解顺序首先是赤铁矿等氧化矿溶解, 其次磁黄铁矿、 铜的次生硫化矿溶解, 再次是黄铜矿, 最后是黄铁矿。 载金黄铜矿氧化过程首先是铁从黄铜矿的晶格中氧化分离出来, 从而生成CuS2和CuS。 CuS2和CuS再被氧化成铜离子和元素硫, 使金暴露出来, 实现有效浸金。

3) 在110℃时, 较高的酸度和氯化钠浓度有利于单质硫的生成、 三价铁的水解和铜的浸出, 从而有利于载金黄铜矿的氧化预处理。

REFERENCES

[1]姜涛. 提金化学[M]. 长沙: 湖南科学技术出版社, 1998.

JIANG Tao. Chemistry of Extractive Metallurgy of Gold[M]. Changsha: Hunan Science Technology Press, 1998.

[2]Deschenes G. Cyanidation of gold ore bearing copper[J]. J Miner Process, 1997, 50: 127-141.

[3]李俊萌. 难处理金矿石预处理方法研究现状与其发展趋势[J]. 稀有金属, 2003, 27(4): 478-481.

LI Jun-meng. Current situations of refractory gold ores pretreatment method research and its tendency[J]. Chinese Journal of Rare Metals, 2003, 27(4): 478-481.

[4]王力军, 刘春谦. 难处理金矿石预处理技术评述[J]. 黄金, 2000, 21(1): 38-45.

WANG Li-jun, LIU Chun-qian. Overview of pretreatment technique of refractory gold ores[J]. Gold, 2000, 21(1): 38-45.

[5]黄怀国. 从含铜金精矿综合回收金银铜硫的湿法冶金工艺研究[J]. 黄金科学技术, 2004, 12(2): 27-34.

HUANG Huai-guo. Study on hydrometallurgical process for comprehensive recovery Au, Ag, Cu and S form copper-bearing gold concentrate[J]. Gold Science and Technology, 2004, 12(2): 27-34.

[6]谢洪珍, 黄怀国, 江城, 等. 黄铜矿精矿的酸性热压氧化提铜工艺研究[J]. 矿冶工程, 2003, 23(4): 54-56.

XIE Hong-zhen, HUANG Huai-guo, JIANG Cheng, et al. A study on copper extraction from chalcopyrite concentrate by acidic hot-pressure oxidation[J]. Mining and Metallurgical Engineering, 2003, 23(4): 54-56.

[7]周绍銮, 孙全庆, 张晓泓, 等. 难处理金矿石的加压浸出技术[J]. 铀冶金, 1997, 16(4): 337-344.

ZHOU shao-luan, SUN Quang-qing, ZHAO Xiao-hong, et al. Pressure leaching technology of refractory gold ore[J]. Uranium Mining and Metallurgy, 1997, 16(4): 337-344.

[8]黄礼煌. 化学选矿[M]. 北京: 冶金工业出版社, 1990.

HUANG Li-huang. Chemical Ore Dressing[M]. Beijing: Metallurgical Industry Press, 1990.

[9]聂树人, 索有瑞. 难选冶金矿的浸金[M]. 北京: 地质出版社, 1997.

NIE Shu-ren, SUO You-rui. Leaching Gold From Refractory Gold Ore[M]. Beijing: The Geological Press, 1997.

[10]钟竹前, 梅光贵. 化学位图在湿法冶金和废水净化中的应用[M]. 长沙: 中南工业大学出版社, 1986. 27-66.

ZHONG Zhu-qian, MEI Guang-gui. Application of Diagrams of Chemical Potential in Hydrometallurgy and Purification of Waste Water[M]. Changsha: Central South University of Technology Press, 1986. 27-66.

[11]Vracar R Z, Parezanovic I S, Cerovic K P. Leaching of copper(Ⅰ) sulfide in calcium chloride solution[J]. Hydrometallurgy, 2000, 58(3): 261-267.

[12]Dutrizac J E. The leaching of sulphide minerals in chloride media[J]. Hydrometallurgy, 1992, 29: 1-45.

[13]朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003. 605-612.

ZHU Zu-ze, HE Jia-qi. Modern Metallurgy of Copper[M]. Beijing: Science Press, 2003. 605-612.

[14]Hiroyoshi N, Miki H, Hirajima T, et al. A model for ferrous-promoted chalcopyrite leaching[J]. Hydrometallurgy, 2000, 57(1): 31-38.

[15]Hiroyoshi N, Miki H, Hirajima T, et al. Enhancement of chalcopyrite leaching by ferrous ions in acidic sulphate solutions[J]. Hydrometallurgy, 2001, 60: 185-197.

[16]Zhang S W, Tromans D. Temperature and pressure dependent solubility of oxygen in water: a thermodynamic analysis[J]. Hydrometallurgy, 1998, 48(3): 327-342.

基金项目: 江西省自然科学基金资助项目(0350076)

收稿日期: 2005-05-31; 修订日期: 2005-08-19

作者简介: 邱廷省(1962-), 男, 博士研究生, 教授

通讯作者: 邱廷省, 教授; 电话: 0797-8312351; E-mail: qiutingsheng@163.com

(编辑李艳红)