DOI: 10.11817/j.ysxb.1004.0609.2020-37579

Cu、Mg含量对2A12铝合金化铣粗糙度的影响

张 鑫,罗兵辉,柏振海,何翠云,唐承璐

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:借助超景深三维显微镜、扫描电镜、能谱分析、透射电镜、X射线物相分析、电化学测试等手段,对比不同Cu、Mg含量对2A12铝合金化铣粗糙度的影响。结果表明:当2A12铝合金中的Cu含量或Mg含量位于成分上限时,化铣后的表面粗糙度达到3.4 μm,合金合理的成分配比为4.02%Cu+1.39%Mg(质量分数),化铣后的表面粗糙度为1.4 μm;θ和S的模拟相在化铣液中的电极电位较之Al基体更正,因而在电化学腐蚀过程中,θ相、S相充当阴极,其周围的Al基体会优先发生腐蚀;合金在化铣时,随着局部不均匀腐蚀的进行,形成相凸起、腐蚀坑等表面形貌特征;尺寸为50 μm左右的大型腐蚀坑是造成表面粗糙度增大的主要原因,晶内小尺寸的弥散T相(Al20Cu2Mn3)对化铣粗糙度的影响较小。

关键词:2A12铝合金;Cu含量;Mg含量;化铣;表面粗糙度;微观组织;模拟相

文章编号:1004-0609(2020)-07-1502-10 中图分类号:TG172.63 文献标志码:A

2A12合金因其优良的综合性能被广泛应用于航空航天领域,如飞机蒙皮结构、螺旋桨元件及其他各种结构件。一些大型结构件的构造较为复杂,一般机械加工难以加工甚至不能加工,机械加工精度有限且不可避免地会引入微变形和切削应力,化铣加工能有效解决上述问题。

化铣加工是一种腐蚀加工,且可选择工件的指定区域进行加工。迄今为止,我国2xxx系铝合金的化铣工艺已经较为成熟。毛大恒等[1]、易慧芝等[2]研究者通过优化化铣液配方研究了2197Al-Li合金的化铣工艺;孟莉莉等[3]研究者在单因素试验基础上考察了化铣液中NaOH、Al3+浓度对化铣表面质量的影响规律;付明等[4]研究者探讨了化铣时间和温度对2A12铝合金化铣速率及表面粗糙度的影响;于芝兰[5]将化铣后表面质量的影响因素归结为合金组织电化学行为的不均匀性;王洪祥等[6]研究者将LY12铝合金厚板化铣时形成的蚀坑归因于稍长的淬火转移时间所导致的沿晶界析出的第二相;张彩碚等[7]研究者通过研究不同热处理制度对LY12铝合金厚板化铣腐蚀坑的影响,认为减轻化铣蚀坑的方法是控制元素偏析。

然而,关于2A12铝合金中成分变化对化铣粗糙度影响规律的研究较少,本文作者在已有研究基础上,从合金成分变化对微观组织的影响着手,探究2A12合金中Cu、Mg含量变化对化铣粗糙度的影响。

1 实验

1.1 实验材料

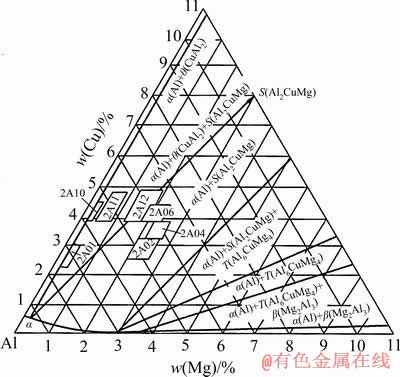

Al-Cu-Mg合金三元相图[8](平衡结晶终了富铝角部分)如图1所示,由于S(Al2CuMg)相中Cu和Mg的质量比为2.61,在相图中位于带箭头的直线上,凡是m(Cu)/m(Mg)<2.61的合金均在该直线右侧,主要强化相是S(Al2CuMg)相,而那些比值大于2.61的合金均位于该直线的左侧,平衡状态下为α(Al)+θ(Al2Cu)+ S(Al2CuMg)三相组成。

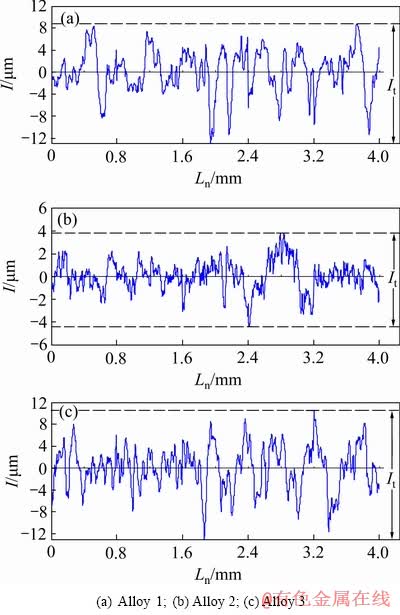

本实验设计了3种成分合金,采用高纯Al、高纯Mg、Al-40Cu、Al-10Mn和Al-5Ti中间合金为原料,在坩埚电阻炉中熔炼,熔炼温度为780℃,原料熔化后,经充分除气扒渣后浇铸,铸锭尺寸为200 mm×150 mm×35 mm。合金成分如表1所列(其中Cu、Mg为实测成分)。

结合相图(见图1)可知:1号合金成分位于α(Al)+ S(Al2CuMg)两相区;2号、3号合金成分均位于α(Al)+ θ(Al2Cu)+S(Al2CuMg)三相区内,但2号合金成分很接近两相区。

图1 部分Al-Cu-Mg合金三元相图

Fig. 1 Partial Al-Cu-Mg alloy ternary phase diagram

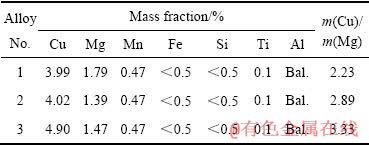

表1 合金的成分表

Table 1 Chemical composition of investigated alloys

铸锭经过切头和铣面后,依次进行均匀化退火、热轧、成品退火。其中均匀化退火工艺为495 ℃、12 h,随炉冷却,热轧前进行430 ℃、2 h保温,经过6道次轧至5 mm(变形量约为83%,为防止板材开裂,第4道次开轧前进行430 ℃、10 min的加热处理),成品退火工艺为380 ℃、2 h,空冷。

1.2 合金的化铣工艺

化铣样品为成品退火态,其尺寸为30 mm×25 mm×5 mm,分别对应轧制方向(RD)、短横向(TD)、厚度,2A12合金化铣工艺流程如图2(a)所示:

其中,化铣液配方:170 g/L NaOH、45 g/L TEA、19 g/L Na2S、19 g/L Al,无添加剂;表面预处理:40% NaOH(质量分数)溶液室温浸蚀5 min,浸入水中1 min,然后浸入30% HNO3 (质量分数)溶液2 min,取出水洗;采用HH968-2可剥涂料浸涂作为保护涂层;在合金表面涂保护层后悬挂固化24 h后用手术刀片刻形,剥去合金待化铣表面的涂层,如图2(b)所示;刻形完成后在温度为90 ℃的化铣液中(恒温油浴锅加热)化铣10 min后取出,在70 ℃水中清洗1 min,浸入冷水中2 min,而后取出浸入30%HNO3溶液2 min,再取出浸入冷水2 min,最后取出干燥;使用JB-4C型表面粗糙度仪测量各试样的表面粗糙度。

1.3 合金组织与表面形貌观察

化铣后表面形貌特征用VHX1000超景深三维显微镜观察;合金组织特征在Sirion 200扫描电镜下观察,第二相的成分用配套的Energy Dispersive X-ray (EDX)进行分析;透射电镜样品用双喷仪进行双喷减薄,双喷液为硝酸和甲醇的混合溶液(硝酸、甲醇体积比为1:3),温度控制在-25 ℃左右,电压为20 V,在FEI TecnaiG220透射电镜上观察晶内析出相的形态,工作电压为200 kV。

1.4 模拟相的制备

采用高纯Al,高纯Mg,Al-40Cu中间合金作为原料熔炼模拟相。考虑到θ(Al2Cu)相是二元相,故直接根据Al2Cu的化学成分配比配料,熔铸模拟θ相,熔铸温度为780 ℃,而后进行498 ℃、12 h退火。通过查阅相关文献[9],在Al-Cu-Mg三元相图液相面S(Al2CuMg)单相区内取成分点冶炼是可以得到S单相材料的,确定成分点51Al-33Cu-16Mg(质量分数,%),熔铸模拟S相,熔铸温度780 ℃,查阅文献[10],确认退火工艺为420 ℃、12 h。

图2 化铣工艺流程图以及刻形后合金表面宏观形貌

Fig. 2 Diagram of chemical milling process(a) and surface morphology of alloy before chamical milling(b)

模拟相制备完成后,在D/max2550型X射线衍射仪上进行物相分析,Cu作为靶材,波长λ=1.5406  的Cu Kα射线作为X射线源,其工作电压为40 kV,工作电流为250 mA,扫描范围(2θ)为10°~90°,扫描速度为8 (°)/min。

的Cu Kα射线作为X射线源,其工作电压为40 kV,工作电流为250 mA,扫描范围(2θ)为10°~90°,扫描速度为8 (°)/min。

1.5 极化曲线测试

样品在IM6eX型电化学工作站进行动电位极化曲线测试,腐蚀液为浓度为2.5%(质量分数)的化铣液,测试步长为2 mV/s,电位测试范围因样品而异,测试结果用软件Nova进行分析。

2 实验结果

2.1 化铣表面粗糙度

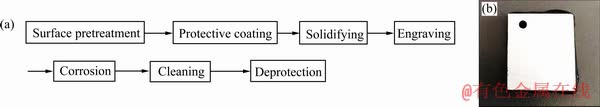

使用表面粗糙度仪测量化铣后各合金的表面粗糙度,用轮廓算数平均偏差Ra来表征,分别沿RD、TD两个方向测量5次求平均值。测试过程中,当仪器触针直接在被测合金表面上轻轻划过一个评定长度Ln,由于被测表面轮廓存在峰谷起伏,触针将在垂直于被测轮廓表面方向上产生上下移动,通过将这种移动信号加以放大,而后输出表面粗糙度的相关数据和图形。

图3所示为展示了3种合金的测试结果,观察了3种合金中峰值(I)的变化。从图3中可以看出,3种合金表面轮廓的峰谷起伏均在0 μm基线附近振荡变化,在图示的评定长度Ln内均存在多个波峰波谷,最大的峰谷垂直距离It分别为21.959、8.242和23.577 μm,对应的Ra分别为3.095、0.980和3.071 μm。

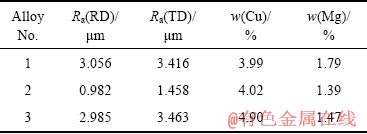

3种成分合金化铣表面粗糙度数据Ra如表2和图4所示,可知合金中Cu含量相近时(1号、2号),Mg含量更多的合金Ra更大(1号);Mg含量相近时(2号、3号),Cu含量更多的合金Ra更大(3号);此外,同种合金沿轧制方向(RD)的Ra低于沿短横向(TD)的Ra。

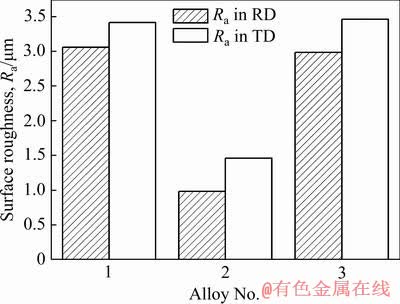

图5所示为3种合金化铣后表面形貌的超景深三维显微图像。图中直观地展现了选区合金表面的高低起伏,表现为区域颜色的改变,红色区域较高,蓝色区域较低,选区内高点与低点的高度差用表面高度参数z值表征,z值越小,表示该选区表面的相对高度变化越小。由图可知:1号、2号、3号合金选区的z值分别为26.73、9.068和24.87 μm,这表明2号合金表面高低起伏更小,表面更平整,这与图3所示的It值21.959、8.24和22.20 μm有一定对应关系。

图3 合金的表面轮廓曲线

Fig. 3 Surface profile curve of different alloys

表2 合金的化铣表面粗糙度

Table 2 Surface roughness of alloys after chemical milling

图4 合金化铣表面粗糙度

Fig. 4 Diagram of alloys surface roughness

图5 合金化铣后表面形貌三维图像

Fig. 5 3D images of alloys’ surface morphology

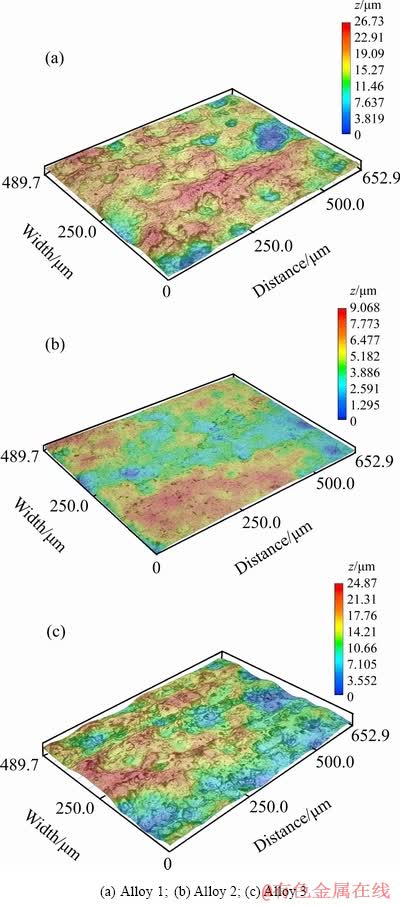

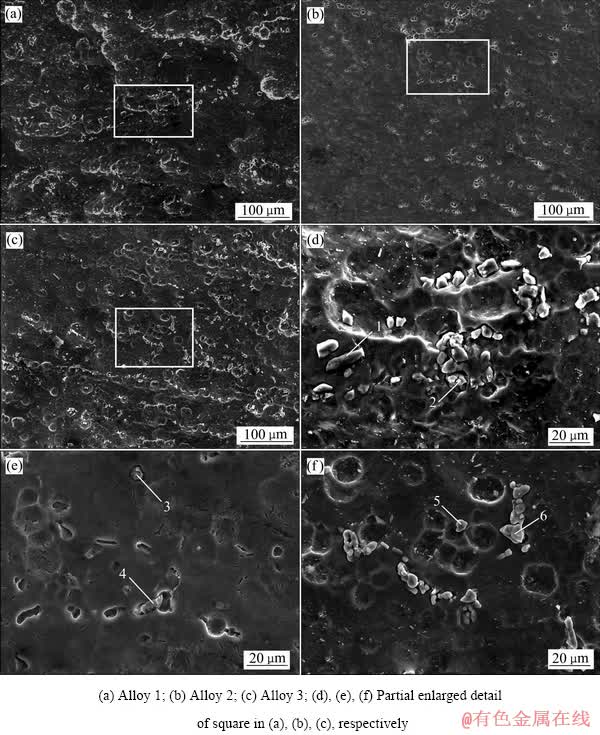

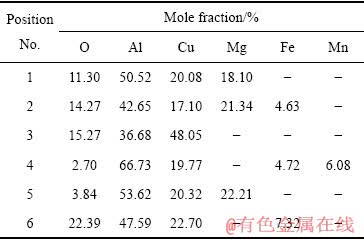

利用SEM像对上述3种合金表面形貌进行观察和能谱分析,结果如图6和表3所示。对比观察3种合金的SEM像,均能观察到形状不规则、尺寸在10~50 μm不等的腐蚀坑,在腐蚀坑周围还能观察到一些衬度较亮、大小不一的粒子。表3所列的能谱结果表明:这些粒子为一些含Al、Cu、Mg的相(原子比接近Al2Cu或Al2CuMg)和一些含Al、Cu、Fe、Mn的相。

不同的是,2号合金(见图6(b))表面腐蚀坑数目较少,分布较为离散,且第二相粒子的数量很少;而1号合金(见图6(a))和3号合金(见图6(c))表面腐蚀坑密度明显更大,均存在多个腐蚀坑的聚集,3号合金表面腐蚀坑分布有一定线性规律,此外,二者表面第二相粒子数量更多,粒子的分布亦存在偏聚现象,这显然会造成合金表面微观尺度的严重不平整;相比之下,2号合金表面质量更好,这与表面粗糙度的测试结果相对应。

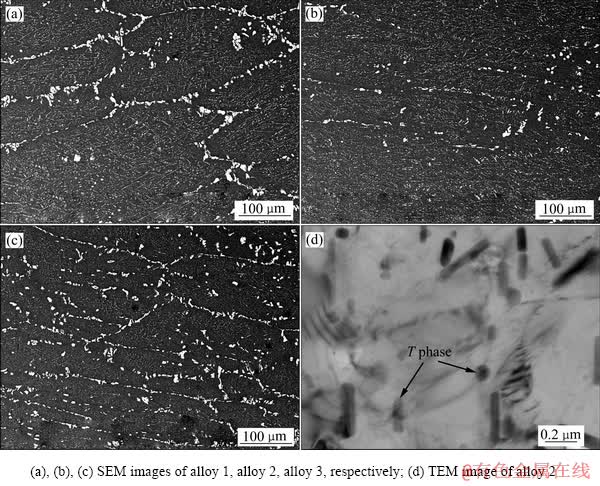

2.2 合金组织观察

图7所示为合金成品退火态组织图像。从图7(a)、(b)、(c)中可以看出,3种合金的晶粒均沿轧制方向被拉长,由于变形量较大,白色衬度的第二相被破碎,大致沿拉长晶界分布,这些第二相是均匀化退火过程中未能回溶基体的粗大结晶相,尺寸在5~40 μm不等,主要包括Al2Cu、Al2CuMg相及一些含Fe的杂质相,如AlCuMnFe、Al7Cu2Fe相等[11-12]。对比3种合金的组织,图7(b)所示的2号合金结晶相数目明显更少,断续分布于晶界上;而1号(见图7(a))、3号(见图7(c))合金组织中结晶相较多,沿晶界连续分布,且部分大尺寸相的破碎不充分;这主要是由于合金成分的不同所致。

此外,3种合金晶内均能观察到微米级别的细长条状相,文献[13]表明是S相,这是因为在均匀化退火随炉冷却过程中,由于冷速缓慢,已经溶解的S相会重新形核析出,并有充分的时间长大,有的一维尺寸甚至达到了20 μm左右,其仍属于结晶相范畴;另外,晶内还存在更细小的点状粒子,文献[14]中提到其可能是T相(Al20Cu2Mn3),T相在透射电镜下能被清楚地观察到,如图7(d)所示的短棒状相和椭圆点状相,尺寸约为0.05~0.5 μm。

结合图3所示的合金表面轮廓曲线和图6所示的表面形貌分析,可以推断,合金组织中存在的那些大尺寸结晶相粒子是造成化铣后表面粗糙度增大的主要原因,而晶内小尺寸的弥散T相(Al20Cu2Mn3)对化铣后粗糙度的影响较小。

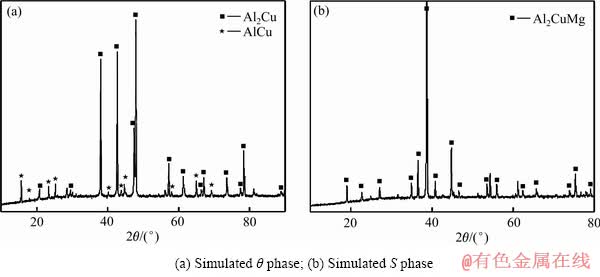

2.3 XRD测试

图8所示为模拟第二相的XRD谱。其中,图8(a)所示为模拟θ(Al2Cu)相,可以看出,模拟θ相的衍射峰与标准库中衍射相相符合,除θ相的峰以外仅存在一些AlCu相的峰,样品制备符合实验要求,可用于替代合金中存在的θ相进行相关研究;图8(b)所示为模拟S(Al2CuMg)相,可以看出,模拟S相的衍射峰与Al2CuMg的标准衍射图谱匹配良好,且杂峰较少,样品纯度较高,可用于替代合金中的S相进行相关研究。

图6 合金化铣后的表面形貌

Fig. 6 Surface morphologies of alloys after chemical milling

表3 图6中粒子的能谱分析结果

Table 3 EDS analysis of particles in Fig. 6

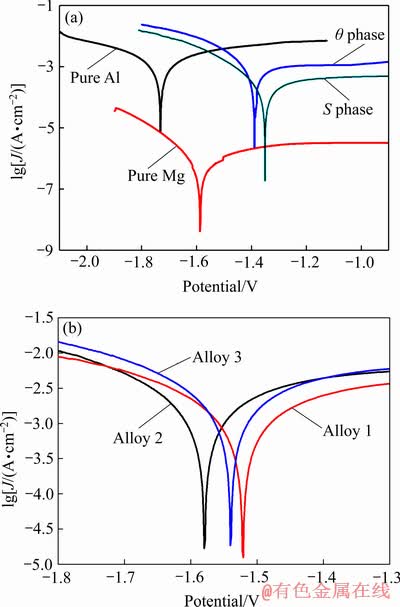

2.4 极化曲线测试

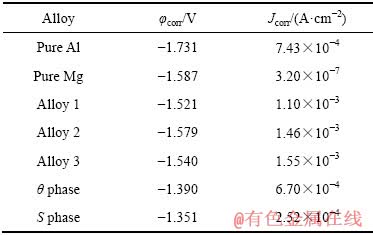

为了研究合金化铣过程中的腐蚀行为,对3种合金、纯Al、纯Mg及模拟θ相、S相进行了极化曲线测试。测试结果如图9所示,极化曲线相关参数列于表4。

图7 合金的显微组织

Fig. 7 Microstructures of alloys

图8 合金模拟相的XRD谱

Fig. 8 XRD patterns of simulated phases of alloys

从图9(a)可以看出,纯金属和模拟相的腐蚀电位大小依次为纯Al、纯Mg、模拟θ相、模拟S相。这是因为Al是两性金属,它可以跟碱发生化学反应,而Mg与碱不反应,故在化铣液中,Mg的活性比Al低,因而Mg的电极电位比Al基体正;此外,θ相和S相中均含有不活泼元素Cu,故它们的电极电位较之Al基体更正,因此在局部碱腐蚀中,含Cu的θ相和S相一般作为阴极相,发生电化学腐蚀时,导致它们附近作为阳极的Al基体优先溶解。

从图9(b)可以看出,3种合金的腐蚀电位大小依次为2号、3号、1号。三者的电位均介于Al基体和两种第二相之间,其中2号合金电极电位更靠近Al基体,这是因为2号合金组织(见图7(b))中第二相数目更少,合金在碱性溶液发生电化学腐蚀时,第二相与基体之间形成的腐蚀原电池数目少,其电位更负;1号、3号合金较之2号合金,由于Cu元素或Mg元素含量的增多,二者组织(见图7(a)和(c))中第二相的数量增多,导致二者电位正移。

图9 合金的极化曲线

Fig. 9 Potentiodynamic polarization curves of alloys

表4 极化曲线相关参数

Table 4 Parameters of potentiodynamic polarization curves

3 分析与讨论

2A12合金的化铣过程包含化学腐蚀和电化学腐蚀过程。化学腐蚀主要是Al在NaOH溶液中的的溶解过程,分两步进行:Al合金表面致密氧化物薄膜Al2O3的溶解;氧化膜被溶解掉以后,Al与NaOH发生反应,两个反应的化学方程式如下[15]:

Al2O3+2NaOH=2NaAlO2+H2O (1)

2Al+2NaOH+2H2O=2NaAlO2+3H2↑+Q (2)

此外,由于Al基体和第二相在化铣液中存在电极电位的差异,因此,电化学腐蚀也是化铣过程中另一种重要的腐蚀形式,主要表现为合金中的Al基体和第二相之间形成腐蚀原电池,造成局部的优先腐蚀。

化学腐蚀是化铣过程中必然发生的反应,Al基体在碱性介质中的均匀腐蚀对化铣是有利的;但是电化学腐蚀会对化铣产生不利影响,腐蚀原电池的存在造成了合金的不均匀腐蚀,产生腐蚀坑和残余粒子凸起等形貌,导致合金微观表面的严重不平整。

在Al合金的腐蚀研究中,相关文献[16]表明,在碱性条件下,Al7Cu2Fe、Al3Fe等含Fe的杂质相粒子均能作为有效的局部阴极,这是由于Fe元素的存在,使得它们在高pH情况下稳定;另外,含Cu的Al2Cu及其它的Al-Cu相粒子也是阴极相;比较特殊的是Al2CuMg相,由于同时含有Cu元素和Mg元素,Al2CuMg相有强烈的“去合金化”倾向[17-19],SHI等[20]学者认为在腐蚀初期,富Mg部分的化学溶解是去合金化的主要形式:

Mg+2H2O=Mg2++2OH-+H2↑ (3)

随着腐蚀的进行,Mg的溶解导致了Cu元素的富集,Cu的富集致使Al2CuMg相的电位正移,在后续的电化学腐蚀进程中,富Cu的Al2CuMg相作为阴极,导致其边缘的Al基体发生阳极溶解。

然而在本实验中,化铣液中的大量存在的OH-离子显然会强烈抑制反应(3)的发生,进而抑制Al2CuMg相的“去合金化”,图6所示为残余Al2CuMg粒子就能在一定程度上佐证这一点;此外,BIRBILIS等[16]的研究也表明:金属间化合物Al2CuMg随着pH的增大,其活泼性减小,电位正移。

综上所述,可以对上述两种腐蚀形貌特征作出解释,在电化学腐蚀过程中,2A12合金中各第二相均为阴极相,它们周围的Al基体发生优先腐蚀,随着腐蚀的进行,第二相粒子周围开始发生环形凹陷,粒子渐渐裸露出来,如图6中所示的白色衬度粒子,能谱分析结果也证实了这一点;而当继续腐蚀到一定程度,这些第二相粒子失去了Al基体的支撑后发生了脱落,留下了图6中所示的腐蚀坑。

上述两种形貌特征均会不同程度地影响合金的化铣粗糙度,结合合金表面轮廓变化曲线(见图3)及化铣后合金表面形貌(见图6)分析,可以认为:那些尺寸为50 μm左右的大型腐蚀坑是造成合金表面不平整的最主要原因;由上文分析可知,大尺寸腐蚀坑是由于那些尺寸同样粗大的第二相在化铣过程中发生脱落所引起的,故合金组织中大尺寸的第二相数量越多、分布越不均匀,合金化铣后的表面粗糙度越大;由图7可知,在合金成品退火组织中,粗大的第二相显然是那些沿晶界分布的未溶结晶相,相对而言,晶内小尺寸的T相(Al20Cu2Mn3)对合金化铣后表面粗糙度的影响较小。

众所周知,材料的成分差异是导致其微观组织变化的最根本原因;文献[8]显示:Al-Cu-Mg合金在500 ℃时,Cu、Mg元素在Al中的溶解度分别为3.9%和1.8% (质量分数);本实验中,1号合金Cu、Mg含量均处于该极限固溶度附近,3号合金虽然Mg含量有所降低,但Cu含量较之在Al中的极限固溶度已超出1%,因此,二者在凝固时形成了更多粗大的结晶相。相比之下,2号合金的Cu、Mg含量配比更合理(4.02%Cu+ 1.39%Mg,质量分数),在相同的均匀化退火工艺下(495 ℃, 12 h),其未回溶的粗大结晶相数目更少,故2号合金化铣后的表面粗糙度最小。

4 结论

1) 在(495 ℃, 12 h)均匀化、(380 ℃, 2 h)成品退火条件下,高Cu或高Mg的2A12铝合金组织中未回溶的粗大结晶相数量较多,合金化铣后的表面粗糙度达到3.4 μm;合金合理的成分配比为4.02%Cu+1.39%Mg,化铣后的表面粗糙度为1.4 μm。

2) θ相、S相在化铣液中的电极电位较Al基体更正,合金在化铣时,第二相粒子周围Al基体发生优先腐蚀,粒子失去Al基体包裹渐渐裸露出来;随着腐蚀的继续进行,第二相粒子脱落,留下腐蚀坑。

3) 粗大结晶相脱落形成的尺寸为50 μm左右的大型腐蚀坑是造成合金化铣后表面粗糙度增大的主要原因,相对而言,晶内小尺寸的弥散T相(Al20Cu2Mn3)对化铣粗糙度的影响较小。

REFERENCES

[1] 毛大恒, 张 灿, 周亚军, 韩德夫. 2197铝锂合金化学铣切工艺的探讨[J]. 材料保护, 2010, 43(10): 33-35.

MAO Da-heng, ZHANG Can, ZHOU Ya-jun, HAN De-fu. Discussion on chemical milling process of 2197 Al-Li alloy[J]. Materials Protection, 2010, 43(10): 33-35.

[2] 易慧芝, 邓飞跃, 张忠亭. 2197铝锂合金化学铣切工艺研究[J]. 表面技术, 2010, 39(4): 73-76.

YI Hui-zhi, DENG Fei-yue, ZHANG Zhong-ting. Study on chemical milling process of 2197 Al-Li alloy[J]. Surface Technology, 2010, 39(4): 73-76.

[3] 孟莉莉, 朱彦海, 曾元松. 2A97铝锂合金化学铣切工艺探讨[J]. 材料保护, 2016, 49(12): 46-49.

MENG Li-li, ZHU Yan-hai, ZENG Yuan-song. Discussion on chemical milling process of 2A97 Al-Li alloy[J]. Materials Protection, 2016, 49(12): 46-49.

[4] 付 明, 刘 群. 2A12铝合金化学铣切加工工艺探讨[J]. 材料保护, 2018, 51(7): 100-103.

FU Ming, LIU Qun. Discussion on chemical milling process of 2A12 aluminum alloy[J]. Materials Protection, 2018, 51(7): 100-103.

[5] 于芝兰. 铝合金的碱腐蚀-高精度化铣[J]. 轻合金加工技术, 1994, 22(12): 27-31.

YU Zhi-lan. Alkali corrosion of aluminum alloy-High precision chemical milling[J]. Light Alloy Processing Technology, 1994, 22(12): 27-31.

[6] 王洪祥, 葛 蔚. LY12铝合金化铣蚀坑形成机理[J]. 东北大学学报, 1994, 15(5): 538-541.

WANG Hong-xiang, GE Wei. Etch-pit formation mechanism of aluminum alloy LY12 due to chemical milling[J]. Journal of Northeastern University, 1994, 15(5): 538-541.

[7] 张彩碚, 孙 威, 潘 浩. 不同热处理制度对LY12铝合金厚板化铣腐蚀坑的影响[J]. 东北工学院学报, 1987(4): 527-531.

ZHANG Cai-bei, SUN Wei, PAN Hao. Effects of different heat treatments of etch pit formation due to chemical milling on LY12 Al alloy plates[J]. Journal of Northeast University of Technology, 1987(4): 527-531.

[8] 丁惠麟, 辛智华. 实用铝、铜及其合金金相热处理和失效分析[M]. 北京: 机械工业出版社, 2007: 239-241.

DING Hui-lin, XIN Zhi-hua. Metallographic heat treatment and failure analysis of practical aluminum, copper and their alloys[M]. Beijing: Mechanical Industry Press, 2007: 239-241.

[9] 周和荣, 陈明明, 杜翠薇, 马 坚, 揭敢新, 李晓刚. 金属间化合物Al2CuMg的制备[J]. 航空材料学报, 2013, 33(2): 35-40.

ZHOU He-rong, CHEN Ming-ming, DU Cui-wei, MA Jian, JIE Gan-xin, LI Xiao-gang. Synthesis of intermetallic compound Al2CuMg[J]. Journal of Aeronautical Materials, 2013, 33(2): 35-40.

[10] LI Jing-feng, ZHENG Zi-qiao, JIANG Na, TAN Cheng-yu. Localized corrosion mechanism of 2xxx-series Al alloy containing S(Al2CuMg) and θ′(Al2Cu) precipitates in 4.0% NaCl solution at PH 6.1[J]. Materials Chemistry and Physics, 2005, 91: 325-329.

[11] 李培越, 熊柏青, 张永安, 李志辉, 王国军, 王 锋, 朱宝宏. 2D70耐热铝合金显微组织均匀化热处理[J]. 中国有色金属学报, 2010, 20(11): 2101-2105.

LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, WANG Guo-jun, WANG Feng, ZHU Bao-hong. Homogenization treatment and microstructure of semicontinuous cast ingot of 2D70 heat-resistance aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2101-2105.

[12] 陈宇强, 潘素平, 易丹青, 刘文辉, 蔡志华, 唐昌平. 2E12铝合金均匀化过程微观组织演变规律[J]. 中南大学学报(自然科学版), 2017, 48(2): 316-324.

CHEN Yu-qiang, PAN Su-ping, YI Dan-qing, LIU Wen-hui, CAI Zhi-hua, TANG Chang-ping. Microstructure evolutions of 2E12 Al alloy during homogenization[J]. Journal of Central South University(Science and Technology), 2017, 48(2): 316-324.

[13] 刘海全, 许晓嫦, 吴 峰. 2524铝合金均匀化过程中的组织演变[J]. 材料热处理学报, 2015, 36(11): 47-53.

LIU Hai-quan, XU Xiao-chang, WU Feng. Evolution of microstructure of 2524 aluminum alloy during homogenization[J]. Transaction of Materials and Heat Treatment, 2015, 36(11): 47-53.

[14] WANG S C, STARINK M J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys[J]. International Materials Reviews. 2005, 50(4): 193-215.

[15] 《航空制造工程手册》总编委会. 航空制造工程手册—特种加工[M]. 北京: 航空工业出版社, 1993: 622-623.

General editorial committee. Aviation manufacturing engineering handbook—Nontraditional machining[M]. Beijing: Aviation Industry Press, 1993: 622-623.

[16] BIRBILIS N, BUCHHEIT R G. Investigation and discussion of characteristics for intermetallic phases common to aluminum alloys as a function of solution pH[J]. Journal of the Electrochemical Society, 2008, 155(3): C117-C126.

[17] 李劲风, 郑子樵, 任文达. 第二相在铝合金局部腐蚀中的作用机制[J]. 材料导报, 2005, 19(2): 81-83.

LI Jing-feng, ZHENG Zi-qiao, REN Wen-da. Function mechanism of secondary phase on localized corrosion of Al alloy[J]. Material Reports, 2005, 19(2): 81-83.

[18] ZHU Dan-qing, van OOIJ W J. Corrosion protection of AA 2024-T3 by bis-[3-(triethoxysilyl)propyl]tetrasulfide in neutral sodium chloride solution. Part 1: Corrosion of AA 2024-T3[J]. Corrosion Science, 2003, 45: 2163-2175.

[19] YIN Yuan, LUO Bing-hui, JING Hui-bo, BAI Zhen-hai, GAO Yang. Influences of quench cooling rate on microstructure and corrosion resistance of Al-Cu-Mg alloy based on the end-quenching test[J]. Metallurgical and Materials TransactionsB, 2018, 49: 2248-2250.

[20] SHI Hong-wei, TIAN Zhen-huang, HU Tian-hui, LIU Fu-chun, HAN En-hou, TARYBA M, LAMAKA S V. Simulating corrosion of Al2CuMg phase by measuring ionic currents, chloride concentration and pH[J]. Corrosion Science, 2014, 88: 178-186.

Effect of Cu and Mg content on surface roughness of 2A12 Al alloy after chemical milling

ZHANG Xin, LUO Bing-hui, BAI Zhen-hai, HE Cui-yun, TANG Cheng-lu

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of different Cu and Mg content on the surface roughness of 2A12 Al alloy after chemical milling was investigated by ultra-depth three-dimensional microscope, scanning electron microscope with energy dispersive X-ray spectroscopy, transmission electron microscope, X-ray diffraction analysis and electrochemical measurement. The results indicate that, when the Cu or Mg content in the alloy is at the upper limit of the composition, the surface roughness after milling is 3.4 μm. The reasonable distribution ratio of the alloy is 4.02%Cu+1.39%Mg (mass fraction). The surface roughness after milling is 1.4 μm. The corrosion potentials of the simulated θ phase and S phase in chemical milling solution are more positive than that of the Al matrix. During the electrochemical corrosion process, the θ phase and S phase act as cathodic zone and lead the Al matrix around them be preferentially corroded. Besides, the development of local nonuniform-corrosion results in phase protrusion and corrosion pit. The large-scale corrosion pit with a size of about 50 μm is the main cause to increase surface roughness, whereas, the small-sized intragranular dispersoid such as T-phase (Al20Cu2Mn3) has little influence on it.

Key words: 2A12 aluninum alloy; Cu content; Mg content; chemical milling; surface roughness; microstructure; simulated phase

Foundation item: Project(JPPT-Y2017-3) supported by State Administration of Science, Technology and Industry, China

Received date: 2019-07-11; Accepted date: 2020-04-28

Corresponding author: LUO Bing-hui; Tel: +86-13808425282; E-mail: luobinghui@csu.edu.cn

(编辑 李艳红)

基金项目:军工配套项目(JPPT-Y2017-3)

收稿日期:2019-07-11;修订日期:2020-04-28

通信作者:罗兵辉,教授,博士;电话:13808425282;E-mail:luobinghui@csu.edu.cn