含铁炉料在高炉各区的冶炼特性

赵改革,范晓慧,陈许玲,袁礼顺,甘敏

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘 要:为了掌握不同含铁炉料在高炉冶炼过程的行为特性以及炉料之间的相互反应性,通过模拟高炉各区的温度和气氛条件,系统研究不同含铁炉料(烧结矿、球团矿和块矿)及综合炉料的冶炼特性,分析综合炉料冶金性能与单一炉料冶炼特性的关系。研究结果表明:烧结矿的低温还原粉化性能较差,球团矿较好,粒径大于3.15 mm的球团矿还原指数达到92%以上;烧结矿的还原性较好,还原度都在80%以上,球团矿的还原性次之,块矿的还原性较差;综合含铁炉料的还原性和低温还原粉化性能存在叠加性,综合炉料的高温软熔性能不存在叠加性;高炉炉料结构的合理性由含铁炉料的自身性能和炉料间反应性决定。

关键词:高炉炉料;炉料结构;还原性;低温还原粉化性;软熔性

中图分类号:TF52 文献标志码:A 文章编号:1672-7207(2010)06-2053-07

Metallurgical properties of ferrous burdens in blast furnace

ZHAO Gai-ge, FAN Xiao-hui, CHEN Xu-ling, YUAN Li-shun, GAN Min

(School of Minerals Processing & Bioengineering, Central South University, Changsha 410083, China)

Abstract: In order to understand the behavior features of iron burdens and reactivity among burdens in the blast furnace, the metallurgical properties of sinters, pellets, lumps and mixed burdens were studied by simulating temperature and atmosphere of blast furnace. On this presupposition, the relationship between single burden and mixed burden was analyzed. The results show that the reduction disintegration of sinter is the worst, the best one is pellets, and their low temperature reduction degradation indexes (+3.15 mm) reach above 92%. The reducibility of sinters is better than that of pellets, and their reduction indexes reach above 80%. The reducibility of lump is the worst. It is superimposed for mix burden in reducibility and reduction disintegration, but not for softening and melting. Therefore, the reasonable burden structure is determined by two factors, one is the single burden characters, and the other is the reactivity among burdens.

Key words: blast furnace burden; burden structure; reducibility; reduction disintegration; softening and melting

钢铁是人类社会使用最主要的结构材料和产量最大的功能材料,是现代社会最重要的原材料之一[1]。目前,世界钢铁工业所需的生铁主要是由高炉生产的,高炉炼铁主导现代炼铁工艺[2-3],高炉炼铁系统的能耗占钢铁生产能耗的70%以上[4],如何在高炉炼铁生产中降低燃耗、节约成本,已是现代钢铁企业十分关注的重大课题。而高炉炼铁生产指标的改善和技术进步主要是基于含铁炉料质量的改善与高炉炉料结构的合理化[5]。国内外高炉炼铁实践同样说明:炉料结构影响生铁产量和焦比,对高炉炼铁成本的影响起主导作用[6-8]。因此,研究高炉合理炉料结构具有重要的现实意义和实用价值。高炉生产所用含铁炉料包括烧结矿、球团矿和块矿[8-9],国内外高炉炼铁的炉料结构没有固定的模式[9],每个高炉都是根据本企业所能获得自然资源的条件(品级和价格)、铁矿石的冶金性能、物理性能、化学成分以及高炉炼铁成本等因素来选择合适的炉料结构[10]。所以,在高炉投产以前或炉料发生变化时,都要对高炉炉料结构进行优化。高炉炉料结构优化不仅包括对含铁炉料搭配模式的优化,还应该包括各种含铁炉料自身性能的优化[11-14]。

1 试验方法与原料性能

1.1 试验方法

还原性能试验采用GB/T 13241—91“铁矿石还原性的测定方法”,以温度为900 ℃、还原时间为180 min时的还原度作为考核指标。

低温还原粉化性能试验采用GB/T 13242—91“铁矿石低温粉化试验静态还原后使用冷转鼓的方法”,以在500 ℃还原转鼓30 min后,粒度大于3.15 mm的含铁炉料含量为考核指标。

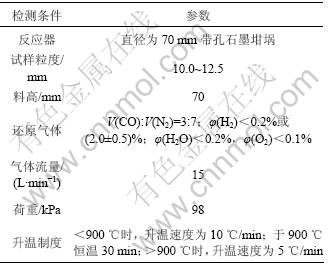

高温软熔性能目前还没有统一的检测标准。本研究的试验条件如表1所示。分别以炉料收缩率达到10%和40%所对应的温度作为软化开始温度(ts)和软化结束温度(te);以压差达到1 kPa时的温度作为炉料熔化温度tm;以炉料渣铁开始滴落时的温度作为炉料的滴落温度td;炉料软化温度区间Δts=te-ts;炉料熔化温度区间Δtm=td-tm;软熔区间为Δts-d=td-ts。

1.2 原料性能

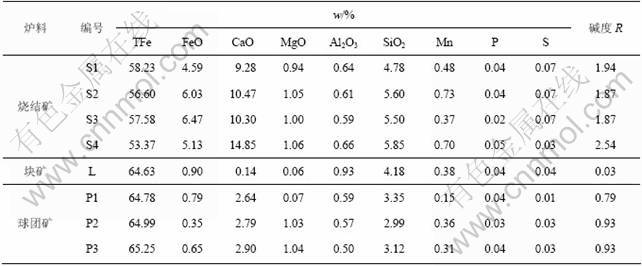

本文以巴西某钢铁公司的8种含铁炉料为研究对象,包括4种高碱度烧结矿、3种熔剂性球团矿和1种块矿。各原料的化学成分(质量分数)如表2所示,物理性能如表3所示。

表1 软熔性能试验参数

Table 1 Parameters of softening and melting test

从表2可以看出:4种烧结矿中S4碱度最高(2.54),其余烧结矿的碱度为1.90左右,均属于高碱度烧结矿;SiO2的含量为4.70%~5.90%,MgO含量为1.00%左右,Al2O3含量为0.60%左右,含少量的Mn。3种球团矿的铁品位都较高,均在64.00%以上;FeO含量较低,都在1.00%以下;SiO2,P和S的含量较低;块矿的铁品位也较高,达到64.63%,脉石成分含量较低。

由表3可知:球团矿粒度分布均匀;球团矿的转鼓强度最高,块矿次之,烧结矿最低;块矿的耐磨指数最高,耐磨性最差。

表2 含铁炉料的化学成分

Table 2 Chemical composition of ferrous burdens

表3 含铁炉料的物理性能

Table 3 Physical characteristics of ferrous burden

2 试验结果与讨论

根据含铁炉料在高炉内的行为以及炉内温度分布的特点,将高炉分为块状区和软熔区。

2.1 含铁炉料在块状区的冶炼特性

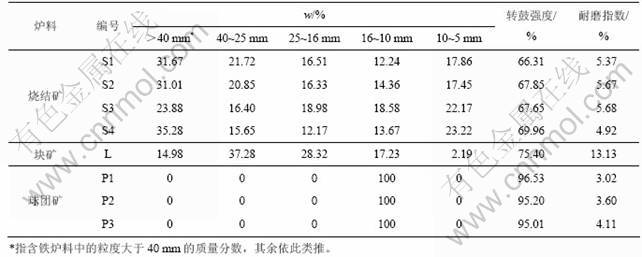

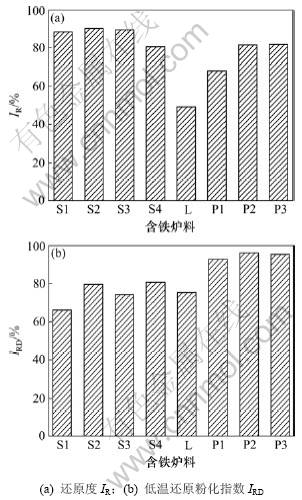

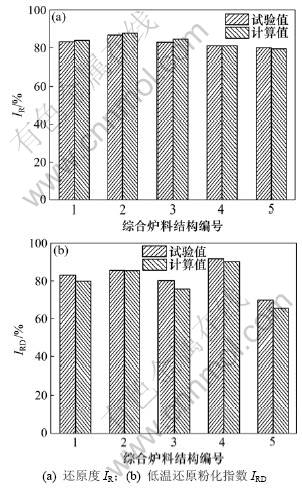

在高炉块状区,影响高炉利用系数和焦比最主要的因素就是含铁炉料的低温还原粉化性和还原度。8种含铁炉料的还原度(IR)和低温还原度粉化指数(IRD)如图1所示。

从图1(a)可以看出:烧结矿的还原性较好,还原度IR都达80.00%以上,最高达90.02%;球团矿次之,还原度都在67.00%以上;块矿的还原性较差,还原度仅为49.18%。

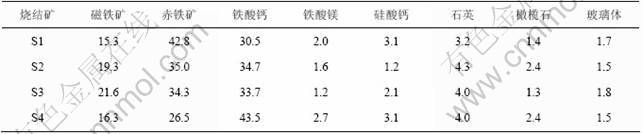

表4所示的烧结矿矿物组成表明:易还原的赤铁矿和铁酸钙的含量占70%左右,难还原的铁橄榄石和玻璃相的含量较少。而且烧结矿是一种多孔集合体,孔隙率较高,可达40.00%~50.00%[10];还原气体可以顺利扩散至反应界面与铁氧化物发生反应,加快了烧结矿的还原速度,所以,烧结矿的还原度较高。

烧结中矿赤铁矿含量较高。在低温还原时,内部的赤铁矿会发生晶型转变,产生体积膨胀,使得赤铁矿与其他矿物连接处容易产生微细裂纹,强度降低;而且烧结矿中的赤铁矿与黏结相交织在一起,当还原进一步进行时,还原气体扩散至微细裂纹后,那些可接触到还原气体的新赤铁矿颗粒被迅速还原,而其附近的黏结相的还原速度较慢,不同矿物还原速度的差异和还原时体积的变化使得烧结矿微细裂纹发展;烧结矿矿物组成的复杂性和其各组分热膨胀性能的差异性,造成烧结矿内应力增大,裂纹继续扩展。虽然低温还原后烧结矿还较完整,但是其内部的龟裂程度比较严重,所以,烧结矿的低温还原粉化指数低。

图1 含铁炉料的还原度IR和低温还原粉化指数IRD

Fig.1 Reducibility and low-temperature reduction disintegration of ferrous burdens

表4 烧结矿主要矿物的含量

Table 4 Contents of main minerals in sinters %

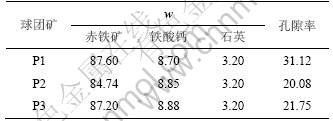

表5所示的球团矿矿物组成表明:球团矿中赤铁矿含量最高,达到84.74%以上。但由于球团矿气孔均是微气孔,比烧结矿的孔隙率低10%~20%,使得球团矿还原时,还原气体的扩散阻力比烧结矿的大,减慢了球团矿的还原速度,导致其还原度略低于烧结矿的还原度。

球团矿的矿物组成相对单一,且赤铁矿晶粒集结在一起,形成集合体,并连接成片,使得球团矿的强度较高;3种球团矿孔隙率为21.75%~31.12%,使其具备抵抗还原时体积的变化能力;P2和P3的IRD高于P1的低温还原粉化指数,这是由于P2和P3含有1%的MgO,MgO固溶于铁矿物晶格中,可以使Fe3O4稳定存在,在还原时抑制了α-Fe2O3向γ-Fe2O3的晶型转变,减弱了该相变引起的体积膨胀,改善了P2和P3的低温还原粉化性能。

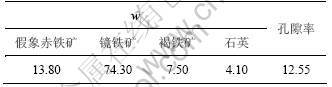

块矿中主要矿物的含量和孔隙率如表6所示。从表6可知:与球团矿相比,块矿的孔隙率更低,为12.55%;块矿FL中,镜铁矿含量达74.30%。镜铁矿为Fe2O3呈细小的叶片状和针状结构连生在一起形成集合体,结构致密,气孔率较低,使得块矿在还原 时,还原气体的扩散受到极大的阻力,降低了块矿的还原度。

块矿的结构致密,孔隙较小,在还原时体积变化使得矿物结构被破坏,造成了块矿的粉化;块矿内含有7.5%的褐铁矿,褐铁矿中的结晶水在200~500 ℃时分解扩散造成块矿破裂。多矿物相的热膨胀性能不同也是其粉化的主要原因。

表5 球团矿主要矿物的质量分数和孔隙率

Table 5 Contents of main minerals and porosity in pellets %

表6 块矿FL中主要矿物的质量分数和孔隙率

Table 6 Contents of main minerals and porosity in lump FL %

为了研究综合炉料在块状区的冶炼特性,设计了5种炉料结构:(1) 72% S2+28% P1;(2) 72% S2+ 28% P2;(3) 50% S3+50% P3;(4) 30% S4+70% P2; (5) 18% L+74% S1+8% P1。5种综合炉料的还原性与低温还原粉化性如图2所示,图中计算值是通过单一炉料的试验结果经加权计算所得。

从图2可知:5种综合炉料的还原度和低温还原粉化指数的计算值与试验值基本相当,说明综合炉料的还原性与低温还原粉化性能具有叠加性。高炉块状区综合炉料的还原性和低温还原粉化性可以由其单种炉料自身的还原性和低温还原粉化性能预测(见式(1)和式(2)),也可以通过控制单个炉料的还原性和低温还原粉化性来优化综合炉料的还原性和低温还原粉 化性。

(1)

(1)

(2)

(2)

式中: 为综合炉料的还原度,%;

为综合炉料的还原度,%; 为第i种炉料的还原度,%;

为第i种炉料的还原度,%; 为综合炉料的低温还原粉化指数,%;

为综合炉料的低温还原粉化指数,%; 为第i种炉料的低温还原粉化指数,%;Xi为第i种炉料的配比,%;n为综合炉料中炉料的 种类。

为第i种炉料的低温还原粉化指数,%;Xi为第i种炉料的配比,%;n为综合炉料中炉料的 种类。

图2 综合炉料的还原度IR和低温还原粉化指数IRD的加权计算值与试验值的比较

Fig.2 Comparison of tested and calculated values for IR and IRD of mix burdens

2.2 含铁炉料在软熔区的冶炼特性

烧结矿、球团矿和块矿的高温软熔性能试验结果如图3所示。从图3可以看出:烧结矿与球团矿和块矿的软熔性能存在明显的差异,烧结矿的软化开始温度与软化结束温度比球团矿和块矿的低,但其软化区间相当,为100~120 ℃;烧结矿的熔化温度高于球团矿和块矿的熔化温度,滴落温度更高,达到1 470 ℃以上,使得烧结矿的软熔区间较宽,透气性较差;2种含镁球团矿P2和P3的软熔开始温度和软化结束温度都较高、熔化温度较高、滴落温度较低,使得其软熔区间较窄,透气性较好。

烧结矿还原性较强,但是,烧结矿的SiO2含量较高,还原形成的FeO与SiO2可形成低熔点的橄榄石,使得烧结矿的软化温度较低;随着还原的进一步进行,其表层还原形成金属铁壳。由于金属铁的熔点为 1 540 ℃,高碱度的烧结矿中Ca2+含量较高,Ca2+扩散渗透到固相浮士体晶格内,渣相的熔点升高,所以,烧结矿的滴落温度较高。球团矿主要矿物为赤铁矿和SiO2,且P2和P3都含有1% MgO,MgO可以与FeO形成无限固溶体,并使熔点提高。渣相中MgO含量增加后,使SiO2活度降低,不利于与FeO反应形成低熔点的橄榄石,所以,球团矿P2和P3的高温软熔性能要优于不含MgO的P1的软熔性能。块矿结构致密,还原性较差,还原速度较慢,还原形成的FeO易与SiO2反应,形成橄榄石等低熔点物质,使得其软化温度和熔化温度都较低。

图3 含铁炉料高温软熔性能

Fig.3 High-temperature softening and melting properties of ferrous burdens

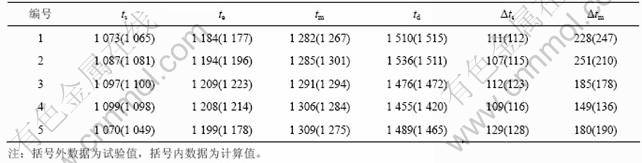

5种综合炉料的高温软熔性能试验结果和由单一含铁炉料软熔性能加权计算结果如表7所示。对比图3与表7所示结果,可以发现:

(1) 综合炉料的高温软熔性能与单一炉料相比,软化性能相当,熔化性能改善。如综合炉料72% S2+28% P1的高温软熔性能与单一S2和P1的相比,综合炉料熔化温度比球团矿的熔化温度提高98 ℃,滴落温度提高143 ℃,而熔化温度和滴落温度与烧结矿的相比分别降低17 ℃和62 ℃;从2~5号炉料结构的试验结果也可以发现综合炉料比单一炉料高温软熔性能较优。可见:综合炉料可以弥补烧结矿和球团矿高温性能的缺点,改善炉料在高炉软熔区的高温软熔特性。

表7 综合炉料软熔性能计算值与试验值的比较

Table 7 Comparison of tested and calculated results for softening and melting properties of mix burdens ℃

(2) 综合炉料的高温软熔特性与按单一炉料加权计算的结果不一致,而且有的比计算值高,有的比计算值低,说明综合炉料的高温软熔性能不具备叠加性,需进一步研究综合炉料的炉料间反应对其高温软熔性能的影响。

在高温反应过程中,烧结矿、球团矿和块矿的软熔特性通过料层的收缩率来表征。为了分析各综合炉料与单一炉料软熔特性之间的关系,可用炉料间的反应性指数Y来说明综合炉料与单一炉料收缩率的差 异[15]:

(3)

(3)

式中:Y为炉料间反应性指数; 为综合炉料在温度t时的收缩率,%;

为综合炉料在温度t时的收缩率,%; 为第i种炉料在温度t时的收缩率,%;Xi为第i种炉料的配比,%;n为综合炉料中炉料的数目。

为第i种炉料在温度t时的收缩率,%;Xi为第i种炉料的配比,%;n为综合炉料中炉料的数目。

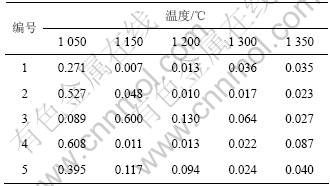

由式(3)可以看出:Y越远离0,说明炉料间的反应性越好,发生反应的程度就越高。5种综合炉料在不同温度下的炉料间反应性指数见表8。从表8可以看出:综合含铁炉料在升温还原过程中的收缩率变化与单一炉料的收缩率变化不同,说明在不同温度下,烧结矿、球团矿和块矿炉料间反应程度不同;不同含铁炉料和配比对炉料间反应性指数的影响不同,3号炉料结构的反应性指数在1 150 ℃时最高,达到0.600,其他温度下炉料间反应性指数都在0.150以下,说明S3和P3是1 150 ℃时反应程度较高,这是由于S3和P3的软化性能都较优,软化温度较高。炉料在1 150 ℃发生软化,改善了两者炉料间的接触条件,促使了炉料间反应的进行。而其他4种综合炉料结构的反应性指数都在1 050 ℃达到最高,且各炉料结构的炉料间反应性指数各不相同。从图2可以看出:其他4种炉料结构中都存在一种炉料在1 100 ℃以下就开始软化,如S1,S2,P1和L的软化温度都比较低,在1 050 ℃时,炉料间就开始发生反应;而3号和4号综合炉料结构的炉料间反应性指数都高,其高温软熔性能也较优,熔化区间较窄,软熔带透气性较好。

表8 综合炉料结构的炉料间反应性指数

Table 8 Reactivity index of mix burdens

综上可见:综合炉料的高温软熔性能与单一炉料的高温软熔性能之间也存在联系,但不是简单的叠加关系,高炉综合炉料的冶炼性能决定于单一炉料本身的冶炼特性与炉料间的反应程度。因此,在保证烧结矿、球团矿、块矿自身软熔性能的基础上,提高炉料间反应性,就成为提高综合炉料高温软熔性能的主要途径。

3 结论

(1) 烧结矿和球团矿的还原性比块矿的优,球团矿的低温还原粉化性能比烧结矿和块矿的优;烧结矿的软化开始温度较低,滴落温度较高,软熔区间较宽,透气性较差;2种含镁球团的软化开始温度较高,滴落温度较低,软熔区间较窄,透气性较好。

(2) 综合炉料的低温还原粉化性能和还原性具有叠加性,可以通过含铁炉料自身的冶金性能来预测综合炉料的冶金性能。含铁炉料高温软熔性不存在叠加性,炉料间存在相互反应。可通过不同炉料的搭配,改善综合炉料高温软熔性能,改善程度与炉料间的反应程度直接相关。

(3) 综合炉料结构30% S4+70% P2的高温软熔性能最优,熔化温度达到1 306 ℃;滴落温度较低,为 1 455 ℃;熔化区间为149 ℃,软熔带较窄,透气性较好。低温还原粉化性能和还原性能也较优,还原度和低温还原粉化指数分别达到81.00%和90.45%。

参考文献:

[1] 王丽娟. 关于钢铁工业发展循环经济规划目标的研究[J]. 冶金经济与管理, 2008(6): 10-12.

WANG Li-juan. Study on developing economic planning objectives in iron and steel industry[J]. Metallurgical Economics and Management, 2008(6): 10-12.

[2] 王维兴. 中国高炉炼铁技术进展[C]//洪及鄙. 中国钢铁年会论文集. 北京: 冶金工业出版社, 2007: 8-14.

WANG Wei-xing. Evolvement of ironmaking technology of blast furnace in China[C]//HONG Ji-bi. CSM Annual Meeting. Beijing: Metallurgical Industry Press, 2007: 8-14.

[3] 杨天钧. 中国高炉炼铁技术的进展[J]. 中国冶金, 2004, 14(6): 1-7.

YANG Tian-jun. Technology progress of blast furnace ironmaking in China[J]. China Metallurgy, 2004, 14(6): 1-7.

[4] 叶匡吾. 高炉炉料结构与精料[J]. 烧结球团, 2001, 26(5): 6-7.

YE Kuang-wu. BF burden composition and burden materials preparation[J]. Sintering and Pelletizing, 2001, 26(5): 6-7.

[5] 于强. 高炉精料与炉料结构[J]. 科技情报开发与经济, 2005, 15(1): 271-272.

YU Qiang. The beneficiated burden materials for the furnace and the structure of the burden[J]. Scientific and Technological Information for Development and Economy, 2005, 15(1): 271-272.

[6] 叶匡吾. 精料、炼铁和降低钢铁产品成本[J]. 烧结球团, 2003, 28(7): 1-3.

YE Kuang-wu. High quality burden, ironmaking and decreasing the cost of iron and steel products[J]. Sintering and Pelletizing, 2003, 28(7): 1-3.

[7] 王筱留. 钢铁冶金学: 炼铁部分[M]. 北京: 冶金工业出版社, 2000: 72-75.

WANG Xiao-liu. Iron and steel metallurgy: Iron part[M]. Beijing: Metallurgical Industry Press, 2000: 72-75.

[8] Volker J R, Heinrich A K. Reduction, softening and melting properties of pellets, sinters, lumpy ore and mixed blast furnace burden[C]//2th International Congress on the Science and Technology of Ironmaking and 57th Ironmaking Conference. Toronto, Canada, 1998: 1634-1654.

[9] 王海涛, 李光辉, 范晓慧, 等. 几种高炉炉料冶金性能的对比研究[J]. 钢铁, 2006, 41(1): 23-27.

WANG Hai-tao, LI Guang-hui, FAN Xiao-hui, et al. Comparative study on metallurgical properties of blast furnace burdens[J]. Iron and Steel, 2006, 41(1): 23-27.

[10] 周传典. 高炉炼铁生产技术手册[M]. 北京: 冶金工业出版社, 2002: 10-13.

ZHOU Chuan-dian. Technical manual of blast furnace production[M]. Beijing: Metallurgical Industry Press, 2002: 10-13.

[11] 朱德庆, 王志远, 潘建, 等. 巴西某镜铁精粉的烧结特性及强化工艺[J]. 中南大学学报: 自然科学版, 2006, 37(5): 878-883.

ZHU De-qing, WANG Zhi-yuan, PAN Jian, et al. Sintering behaviors of Brazilian hematite concentrate and its improvements[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 878-883.

[12] Yamaoka Y, Hotta H, Kajikawa S. Testing method of high-temperature properties of blast furnace burdens[J]. Transactions ISIJ, 1982, 22: 164-172.

[13] Kaushik P, Fruehan R J. Mixed burden softening and melting phenomena in blast furnace operation (Part 1): X-ray observation of ferrous burden[J]. Ironmaking and Steelmaking, 2006, 33(6): 507-520.

[14] Kaushik P, Fruehan R J. Mixed burden softening and melting phenomena in blast furnace operation (Part 3): Mechanism of burden interaction and melt exudation phenomenon[J]. Ironmaking and Steelmaking, 2007, 34(1): 10-23.

[15] 吴胜利, 汪国俊, 姜伟忠, 等. 高炉内天然块矿与烧结矿高温交互反应研究[J]. 钢铁, 2007, 42(3): 10-13.

WU Sheng-li, WANG Guo-jun, JIANG Wei-zhong, et al. Interaction between lump ore and sinter in BF[J]. Iron and Steel, 2007, 42(3): 10-13.

(编辑 陈灿华)

收稿日期:2009-12-15;修回日期:2010-03-08

基金项目:教育部新世纪优秀人才支持计划项目(NCET-05-0630)

通信作者:范晓慧(1969-),女,河北昌黎人,教授、博士生导师,从事钢铁冶金理论与新技术研究;电话:0731-88830542;E-mail:csufanxiaohui@126.com