文章编号:1004-0609(2012)05-1262-08

高应变速率下AZ31镁合金的各向异性及拉压不对称性

毛萍莉,刘 正,王长义,王 峰

(沈阳工业大学 材料科学与工程学院,沈阳 110870)

摘 要:采用分离式霍普金森拉杆及压杆装置,研究挤压态AZ31镁合金高速变形下的各向异性及拉压不对称性,并从微观变形机制的角度探讨具有强烈初始基面织构的挤压态镁合金各向异性及拉压不对称性产生的原因。结果表明:在高速变形条件下,依据加载方向及应力状态挤压态AZ31镁合金的拉伸行为表现出很强的各向异性,但压缩行为的各向异性不明显;在挤压方向表现出很强的拉压不对称性,而在垂直于挤压方向的拉压不对称性很低。挤压态AZ31镁合金宏观上的各向异性及拉压不对称性是由于不同的微观变形机制所引起的。沿挤压方向拉伸的主要变形机制为柱面滑移,沿垂直于挤压方向拉伸及压缩的主要变形机制为锥面滑移;沿挤压方向压缩时初始变形机制为拉伸孪晶,当变形量为0.08(8%)左右时由于孪晶消耗殆尽,变形变而以滑移的方式进行。

关键词:镁合金;各向异性;拉压不对称性;变形机制;高应变速率

中图分类号:TG146.2 文献标志码:A

Anisotropy and asymmetry of as-extruded AZ31 magnesium alloy deformed under high strain rate

MAO Ping-li, LIU Zheng, WANG Chang-yi, WANG Feng

(School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China)

Abstract: The anisotropy and asymmetry of an as-extruded AZ31 magnesium alloy deformed under high strain rate were investigated by split Hopkison tension (SHTB) and pressure bar (SHPB). The reasons for the anisotropy and asymmetry were analyzed in terms of deformation mechanisms. The tension and compression were conducted along the extrusion direction and transverse direction, respectively. The results demonstrate that the as-extruded AZ31 magnesium alloy exhibits pronounced anisotropy in tension, but the anisotropic behavior is not obvious in compression according to the loading direction and stress state. The anisotropy is considerably apparent rather in tension than in compression and the asymmetry is more pronounced in extrusion direction than in transverse direction. The anisotropy and asymmetry of the as-extruded magnesium alloy are caused by the variety of the deformation mechanisms: the prismatic slip is the main activation system if tension stress is along the extrusion direction, while the pyramidal slip is the control deformation mechanism for tension and compression along the transverse direction. The initial deformation mechanism of compression along the extrusion direction is the tension twinning; when the strain is about 0.08 (8%) the tension twinning is exhausted. At this time the main deformation mechanism is changed to be slipping.

Key words: magnesium alloy; anisotropy; tension compression asymmetry; deformation mechanism; high strain rate

镁合金是目前工程应用中密度最低的金属结构材料,具有高比强度和比刚度、电磁屏蔽性能、阻尼性能等诸多优点[1-3]。但是,由于镁合金具有密排六方晶体结构,晶体的对称性较低,在挤压及板材轧制过程中易形成强烈的基面平行于挤压方向及轧制板面的初始织构,使其表现出明显的各向异性及拉压不对称性。对此,很多学者进行了较为充分的研究[4-11],只是相关的工作大多涉及准静态载荷条件,而对于高应变率条件下镁合金的各向异性及拉压不对称性的研究较 少[12-13]。YOKOYAMA[14]研究了应变率在1 000~2 000 s-1范围内AZ31B、AZ61A 及ZK60A镁合金的高应变率拉压不对称性, 发现在高应变率下挤压镁合金同样具有拉压不对称性。WATANABLE和ISHIKAWA[15]

发现在高应变速率下(约103 s-1)具有丝织构(á ?)

?)

的挤压态AZ31镁合金在所测试压缩温度下(室温至673 K)具有明显的各向异性:1) 对于纵向试样,其屈服应力与温度之间的依赖关系远小于横向试样的屈服强度对温度的依赖关系;2) 横向屈服应力小于纵向屈服应力;3) 纵向试样的流变曲线是下凸的。通过对压缩试样的外形分析、变形组织观察及滑移/孪晶启动的临界分切应力的计算,作者认为尽管初始织构不同,但是横向和纵向试样的变形机制在各个温度下都是相

同的,即基面滑移和(或) 拉伸孪晶。YANG

拉伸孪晶。YANG

等[16]分析了轧制态AZ31镁合金在应变速率为1 200 s-1时沿轧制方向、法向和45°方向的室温变形行为,结果表明,其高速压缩行为表现出各向异性:法向试样的流变应力最大,而轧制方向的流变应力最小,45°方向的流变应力介于两者之间。对于法向和45°方向试样,其变形机理为非基面滑移和基面滑移;对于轧制方向试样,其变形机理主要为孪晶。MATTHEW 等[17]采用SHPB试验研究了AZ31镁合金在应变速率大约为4×103 s-1和室温条件下3个方向(轧制、横向和法向)压缩变形行为的差别,同时与准静态的压缩变形行为进行了比较。ULACIA等[18]采用分离式霍普金森拉杆和压杆技术研究了AZ31镁合金在室温至400 ℃温度范围内、应变速率为103 s-1条件下3个方向(轧制、横向和法向)的压缩及拉伸变形行为,发现沿轧制方向压缩时的初始阶段拉伸孪晶是其主要的变形机制,即使温度升高到400 ℃也是如此;拉伸变形的主要变形机制为柱面滑移。目前,镁合金在诸多产品轻量化发展趋势中与高强钢、铝合金、塑料等材料形成了激烈竞争和互补的局势,为多样化应用提供了更多选择[19],正在被越来越多地选用到航空、航天、汽车和军工等领域[20]。在这些服役环境中,需要对镁合金材料在动态载荷作用下的力学行为及变形机制有更深入的了解。以中国、美国、加拿大的合作项目“镁质汽车前端研究与开发”为例[21],采用镁合金设计的GMX322 (2008 Cadillac CTS)车型前端,以新的镁合金结构替代原来的钢结构,可以将该车前端的质量减轻45%,这将改变以往汽车前重后轻的分布,使得前后部分的质量比由现在的55/45改变为50/50,从而在降低汽车燃油消耗、减少汽车尾气排放的同时,提高汽车在启动、运行和刹车过程中的平稳性。可是,目前有关镁合金材料在高速冲击载荷下的力学性能数据十分匮乏,对其变形各向异性及拉压不对称性机制的讨论十分有限,因此降低汽车前端零部件安全性设计的可靠性和准确性,限制镁合金在汽车等领域中应用需求的不断扩大。为此,本文作者采用分离式霍普金森压杆(Split Hopkinson pressure bar, SHPB)和拉杆(Split Hopkinson tension bar, SHTB)研究具有强烈初始基面织构的挤压态AZ31镁合金在高速变形条件下的各向异性及拉压不对称性,并从微观变形机制的角度探讨挤压态镁合金各向异性及拉压不对称性产生的原因。

1 实验

实验所用AZ31材料的化学成分如表1所列。在美国Timminco, Denver, Colorado进行热挤压,其挤压工艺如下:挤压温度360~382 ℃, 挤压比约为6, 挤压之后进行空冷。采用分离式Hopkinson压杆(SHPB)及拉杆(SHTB)进行高速冲击拉伸及压缩实验。采用D/max-A型X射线衍射仪测试挤压态AZ31镁合金的初始织构。实验所用挤压态AZ31材料以及试样切割方向、所用试样尺寸如图1所示。

表1 挤压态AZ31化学成分

Table 1 Chemical composition of AZ31 extrusion (mass fraction, %)

2 实验结果

2.1 挤压态AZ31镁合金的织构分析

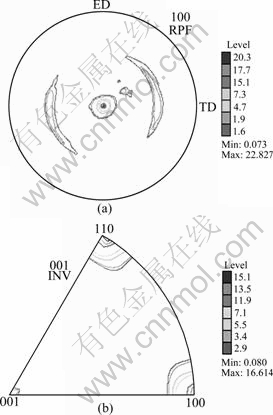

采用D/max-A型X射线衍射仪对挤压态AZ31镁合金的初始织构进行测试,其结果如图2所示。由图2可见,AZ31镁合金在挤压过程中形成了强烈的基面平行于挤压方向的初始织构。

2.2 挤压态AZ31镁合金高速拉伸及压缩变形行为

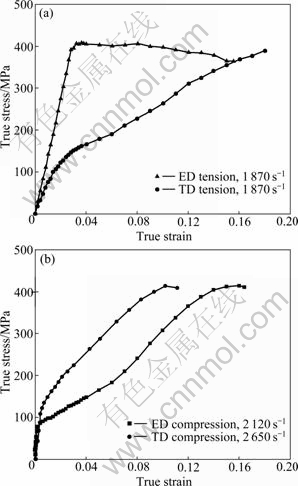

图3所示为室温下挤压态AZ31镁合金在挤压方向(ED)和垂直挤压方向(TD)的高速冲击拉伸测试结果。比较图3(a)和(b)可以看出:沿ED方向和TD方向拉伸时,变形行为的主要差别是:1) 屈服强度不同,沿ED方向拉伸的屈服强度明显高于沿TD方向的拉伸屈服强度;沿ED方向拉伸的屈服强度为350~450 MPa,而沿TD方向的屈服强度为100~150 MPa,沿ED方向拉伸的屈服强度达到了TD方向拉伸屈服强度的3倍。2) 加工硬化率不同,沿ED方向拉伸时AZ31镁合金在屈服之后呈现应变软化效应,即发生塑性失稳;而沿TD方向拉伸时AZ31镁合金在屈服之后呈现应变强化效应。另一方面,在图3(a)和(b)中不同方向的拉伸曲线上也存在相同点:都具有正的应变速率强化效应,即随着应变率的增加,应力逐渐增加。图4所示为挤压态AZ31镁合金沿挤压方向和横向压缩时的真应力—真应变曲线。从图4(a)可以看出:沿挤压方向压缩时,在应变速率分别为496、964和 2 120 s-1时的动态屈服应力分别为85、85和86 MPa,即应变速率从496 s-1到2 120 s-1增加了4倍,而材料的屈服强度几乎没有发生变化。此外,不仅不同应变速率的屈服强度相同,且真应力—真应变曲线也几乎重合,这说明挤压态AZ31镁合金在高速冲击载荷作用下沿ED方向压缩时的变形对应变速率不敏感。室温下挤压态AZ31横向实验结果如图4(b)所示。从图4(b)可以看出:沿ED方向压缩之后的屈服强度大约 在100 MPa,而TD方向压缩后合金的屈服强度大约为125 MPa。挤压态AZ31镁合金沿ED方向和TD 方向压缩屈服后的变形行为有非常明显的区别,即材料在屈服后的应变硬化率不同。沿ED方向压缩时材料屈服后应变曲线呈现非典型的下凸形状,在应变量为0.08左右时,应力—应变曲线存在拐点,即挤压态AZ31镁合金在应变量小于0.08时应变硬化率逐渐增加,当应变量大于0.08时应变硬化率逐渐降低;而沿TD压缩时材料屈服后的应力—应变曲线为典型的上凸形状。

图1 AZ31镁合金原始挤压试样、测试试样切割方案及试样尺寸

Fig. 1 Extrusion and orientation designation of as-received AZ31 magnesium alloy: (a) As-received AZ31 extrusion; (b) Sample cutting arrangement; (c) Geometry of tensile sample (mm); (d) Geometry of compression sample (mm)

图2 挤压态AZ31镁合金的极图及反极图

Fig. 2 Pole figure (a) and inverse pole figure (b) of as- extruded AZ31 magnesium alloy

图3 挤压态AZ31镁合金高速冲击拉伸时的真应力—真应变曲线

Fig. 3 Tension true stress—true strain curves of as-extruded AZ31 magnesium alloy at high strain rate: (a) Extrusion direction; (b) Transverse direction

2.3 挤压态AZ31镁合金高应变速率下的各向异性和拉压不对称性

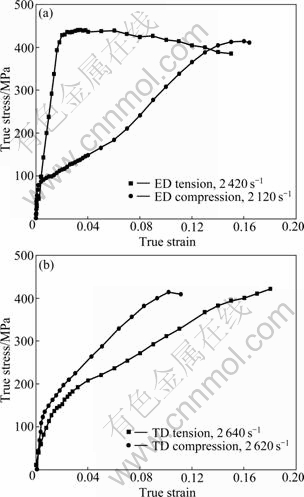

挤压态AZ31镁合金在ED方向和TD方向的高应变速率拉伸和压缩行为比较结果见图5。从拉伸行为的比较中可以看出:试样的取向对其高应变速率拉伸变形的影响很大(见图5(a)),当应变量小于0.15时,ED方向和TD方向的拉伸行为的差别很大,尤其是屈服强度。ED方向的屈服强度为400 MPa左右,而在横向,屈服强度大约为110 MPa。在挤压方向,当材料屈服后应变强化效应很小;而在TD方向,材料在屈服后应变强化效应非常明显。以上比较说明挤压态AZ31镁合金在拉伸时表现出强烈的各向异性。图5(b) 所示为挤压态AZ31镁合金在ED方向和TD方向压缩行为的比较。压缩变形行为在不同方向的差别不是很明显,而且在不同取向上的屈服强度比较接近;与拉伸行为不同的是,当应变量小于0.12时,TD方向的压缩应力大于ED方向的压缩应力,但是这种差别比较小,这说明挤压态AZ31镁合金在压缩时并没有表现出很明显的各向异性。图6所示为挤压态AZ31镁合金在高应变速率下拉伸及压缩行为在不同取向时的比较结果。图6(a)所示为ED方向的比较结果。从图6(a)可以看出,在ED方向拉压不对称性非常明显,压缩屈服应力大约为100 MPa,而拉伸的屈服应力为350~450 MPa。压缩的真应力—真应变曲线是下凸的,而拉伸的真应力—真应变曲线是上凸的。当应变量小于0.14时,拉伸应力大于压缩应力;但当应变量大于0.14后,压缩应力大于拉伸应力。图6(b)所示为TD方向的比较结果,在相同应变下TD方向压缩应力大于拉伸应力,但与沿ED方向相比,这种差异要小很多,也就是说,挤压态AZ31镁合金在TD方向的高速变形行为并没有表现出明显的拉压不对称性。

图4 挤压态AZ31镁合金高速冲击压缩真应力—真应变 曲线

Fig. 4 Compression true stress—true strain curves of as-extruded AZ31 magnesium alloy at high strain rate: (a) Extrusion direction; (b) Transverse direction

图5 挤压态AZ31镁合金的各向异性

Fig. 5 Anisotropy of as-extruded AZ31 magnesium alloy in extrusion direction and transverse direction: (a) Tension behavior; (b) Compression behavior

综合以上分析可知:在高应变速率下变形时,挤压态AZ31镁合金的各向异性与试样的加载方向有关,也就是与初始织构有关,试样在拉伸时表现出很强的各向异性,但在压缩时各相异性并不明显;拉压不对称性与加载方向有关,只有沿ED方向变形时才表现出明显的拉压不对称性,而沿TD方向变形时拉压不对称性并不明显。

3 讨论

在高速冲击载荷下,不同加载方向上挤压态 AZ31镁合金的各向异性以及不同试样取向上的拉压不对称性之间的差别与其结构和变形机制密切相关。基于晶格点阵结构,镁合金属于低对称性结构金属,虽然在{ }方向存在六次对称,但与c轴{0002}方向的性能存在很大的差异。与体心立方和面心立方晶格结构金属相比,密排六方晶体结构镁合金性能存在各向异性的倾向是很大的。经过热挤压后,多晶体镁合金由于织构的存在也表现为各向异性。对于镁晶体,其塑性变形主要有两种方式,即滑移和孪生。塑性变形过程中以滑移还是孪生的方式进行,取决于该种滑移或孪生启动的临界应力值以及外力与晶体的取向。由于镁晶体密排六方结构的特点,在常温变形时通常有3种滑移系,即基面滑移系{0002}á

}方向存在六次对称,但与c轴{0002}方向的性能存在很大的差异。与体心立方和面心立方晶格结构金属相比,密排六方晶体结构镁合金性能存在各向异性的倾向是很大的。经过热挤压后,多晶体镁合金由于织构的存在也表现为各向异性。对于镁晶体,其塑性变形主要有两种方式,即滑移和孪生。塑性变形过程中以滑移还是孪生的方式进行,取决于该种滑移或孪生启动的临界应力值以及外力与晶体的取向。由于镁晶体密排六方结构的特点,在常温变形时通常有3种滑移系,即基面滑移系{0002}á ?、柱面滑移系{

?、柱面滑移系{ }á

}á ?和锥面滑移系{

?和锥面滑移系{ }á

}á ?及{

?及{ }á

}á ?或{

?或{ }á

}á ?。由于柱面滑移和锥面滑移系在室温下的临界分切应力远大于基面滑移系的,因此,在一般情况下不易启动,但在基面滑移处于硬取向、高温或细晶的条件下,柱面滑移或锥面滑移也可能被激活。除滑移外,镁晶体的变形机制还有孪生,由此产生的孪晶主要有两种:拉伸孪晶{

?。由于柱面滑移和锥面滑移系在室温下的临界分切应力远大于基面滑移系的,因此,在一般情况下不易启动,但在基面滑移处于硬取向、高温或细晶的条件下,柱面滑移或锥面滑移也可能被激活。除滑移外,镁晶体的变形机制还有孪生,由此产生的孪晶主要有两种:拉伸孪晶{ }和压缩孪晶{

}和压缩孪晶{ }。拉伸孪晶的切变量为0.131,而压缩孪晶的切变量为0.64。在镁合金中{

}。拉伸孪晶的切变量为0.131,而压缩孪晶的切变量为0.64。在镁合金中{ }á

}á ?孪生的切变量最小,也是镁合金中最容易发生的孪生。由于{

?孪生的切变量最小,也是镁合金中最容易发生的孪生。由于{ }孪晶只有在平行于c轴的方向存在拉力时才能形成[22-29];{

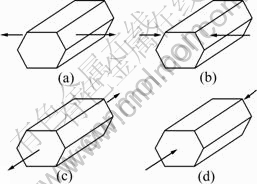

}孪晶只有在平行于c轴的方向存在拉力时才能形成[22-29];{ }孪晶只有在平行于c轴的方向存在压应力时才能形成[30],故前者称为拉伸孪晶,后者则称为压缩孪晶。依据Schmid定律,塑性变形的方式只取决于取向因子和临界分切应力大小。对于镁多晶体,不同变形机制临界分切应力(Critical resolved shear stress,CRSS)由小到大的排列顺序为基面、孪生、柱面、锥面[15]。一般认为,基面滑移与孪晶的临界分切应力和应变速率无关,而锥面滑移和柱面滑移的临界分切应力随着应变速率的增加而增 加[18]。从图2挤压态AZ31镁合金的初始织构测试结果可知,材料在热挤压过程中形成了强烈的初始织构,即形成了基面平行于挤压方向的织构。按照本研究提供的试样切割方案,试样在不同的加载方向时晶粒的受力方向与晶粒c轴的相对关系可用图7表示(图中箭头所指方向为载荷方向)。从图7(a)可以看出:沿挤压方向拉伸时,拉应力平行于基面而与c轴垂直,此时基面滑移不能启动,而取向因子对于柱面滑移和锥面滑移是相同的,因此,这两种滑移系处于竞争启动状态,但是最终哪个滑移系启动取决于滑移系的临界分切应力。由于AZ31镁合金柱面áa?滑移的临界分切应力小于锥面ác+a?滑移的临界分切应力[24, 28],因此,沿挤压方向拉伸时,启动的滑移系主要为柱面áa?滑 移[27]。沿横向拉伸时载荷方向与c轴的相对位置如图7(c)所示,从图7(c)可知:拉应力方向与c轴平行而与基面垂直,c轴受拉应力。当c轴受拉应力时,拉伸孪晶可以启动,但在直接拉应力状态下拉伸孪晶启动后无法形成孪晶-滑移的协调机制,而孪晶本身对塑性变形的贡献较小,所以孪晶启动后,由于自身不能协调变形而很快受到抑制。而此时锥面滑移处于有利位向,因此,锥面滑移启动。随着变形的进行,晶粒逐渐转动,原来不易启动的滑移系也开始启动,因此,变形量逐渐增大时挤压方向和横向的变形行为逐渐接近,在挤压方向拉伸和横向拉伸时启动的变形机制的不同致使它们具有很强的各向异性(见图5(a))。沿挤 压方向压缩时(见图7(b)),试样的受力方向与基面平行,与c轴方向垂直,晶格受压应力,c轴方向受张应力。在此种受力状态下,基面滑移不能启动。但此时c轴方向受间接拉力,拉伸孪晶的形成可以协调c轴的伸长,虽然拉伸孪晶的切变量较小(0.131),但是,大量的孪晶变形就可形成可观的宏观变形,因此,在这种受力条件下大量孪晶开始启动使材料屈服,由于拉伸孪晶的临界分切应力较小,因此,沿挤压方向压缩时的屈服点较低。在这种受力状态下,孪晶形成的速度非常快,对应变速率为496 s-1的变形组织进行观察发现其微观组织几乎全部是孪晶[31]。一般来说,当变形量达到0.08左右时,几乎全部晶粒被孪晶消 耗[32-33]。拉伸孪晶{

}孪晶只有在平行于c轴的方向存在压应力时才能形成[30],故前者称为拉伸孪晶,后者则称为压缩孪晶。依据Schmid定律,塑性变形的方式只取决于取向因子和临界分切应力大小。对于镁多晶体,不同变形机制临界分切应力(Critical resolved shear stress,CRSS)由小到大的排列顺序为基面、孪生、柱面、锥面[15]。一般认为,基面滑移与孪晶的临界分切应力和应变速率无关,而锥面滑移和柱面滑移的临界分切应力随着应变速率的增加而增 加[18]。从图2挤压态AZ31镁合金的初始织构测试结果可知,材料在热挤压过程中形成了强烈的初始织构,即形成了基面平行于挤压方向的织构。按照本研究提供的试样切割方案,试样在不同的加载方向时晶粒的受力方向与晶粒c轴的相对关系可用图7表示(图中箭头所指方向为载荷方向)。从图7(a)可以看出:沿挤压方向拉伸时,拉应力平行于基面而与c轴垂直,此时基面滑移不能启动,而取向因子对于柱面滑移和锥面滑移是相同的,因此,这两种滑移系处于竞争启动状态,但是最终哪个滑移系启动取决于滑移系的临界分切应力。由于AZ31镁合金柱面áa?滑移的临界分切应力小于锥面ác+a?滑移的临界分切应力[24, 28],因此,沿挤压方向拉伸时,启动的滑移系主要为柱面áa?滑 移[27]。沿横向拉伸时载荷方向与c轴的相对位置如图7(c)所示,从图7(c)可知:拉应力方向与c轴平行而与基面垂直,c轴受拉应力。当c轴受拉应力时,拉伸孪晶可以启动,但在直接拉应力状态下拉伸孪晶启动后无法形成孪晶-滑移的协调机制,而孪晶本身对塑性变形的贡献较小,所以孪晶启动后,由于自身不能协调变形而很快受到抑制。而此时锥面滑移处于有利位向,因此,锥面滑移启动。随着变形的进行,晶粒逐渐转动,原来不易启动的滑移系也开始启动,因此,变形量逐渐增大时挤压方向和横向的变形行为逐渐接近,在挤压方向拉伸和横向拉伸时启动的变形机制的不同致使它们具有很强的各向异性(见图5(a))。沿挤 压方向压缩时(见图7(b)),试样的受力方向与基面平行,与c轴方向垂直,晶格受压应力,c轴方向受张应力。在此种受力状态下,基面滑移不能启动。但此时c轴方向受间接拉力,拉伸孪晶的形成可以协调c轴的伸长,虽然拉伸孪晶的切变量较小(0.131),但是,大量的孪晶变形就可形成可观的宏观变形,因此,在这种受力条件下大量孪晶开始启动使材料屈服,由于拉伸孪晶的临界分切应力较小,因此,沿挤压方向压缩时的屈服点较低。在这种受力状态下,孪晶形成的速度非常快,对应变速率为496 s-1的变形组织进行观察发现其微观组织几乎全部是孪晶[31]。一般来说,当变形量达到0.08左右时,几乎全部晶粒被孪晶消 耗[32-33]。拉伸孪晶{ }在变形过程中形成时会使基面转动86°[33],这种织构的重新定位使非基面滑移系启动参与变形,同时由于变形初期形成的孪晶界对于位错滑移来说是一种阻碍,位错与孪晶的交互作用表现在宏观应力—应变曲线上为加工硬化率的增加。沿挤压方向压缩且当微观变形机制由拉伸孪生为主变为滑移为主时,应力—应变曲线出现拐点,同时随着应变量的增加,加工硬化率逐渐降低。沿横向压缩时,试样的受力方向与c轴平行且c轴直接受压,如图7(d)所示。在此种受力状态下,受力方向与基面滑移系的滑移面成90°角,基面滑移不能启动。同时,沿c轴压缩时柱面滑移的取向因子为0,而锥面ác+a?滑移的 取向因子最大,因此,沿c轴压缩时启动的滑移系为锥面滑移。从上述分析可知:沿挤压方向压缩时首先启动的变形机制为拉伸孪晶,而沿横向压缩时启动的变形机制为锥面滑移,由于锥面滑移的临界分切应力大于孪生的,因此,沿挤压方向压缩的屈服强度小于横向压缩的屈服强度。由于沿挤压方向压缩变形且当变形量大于8%后,其主要的变形机制为非基面滑移,与横向压缩的变形机制趋于一致,因此,挤压态AZ31镁合金压缩时的各向异性不明显(见图5(b))。同时,从上述的分析中也可知:对于挤压态AZ31镁合金,沿挤压方向非常显著的拉压不对称性(见图6(a))也是由于不同的变形机制造成的,拉伸时的变形机制为柱面滑移,而压缩时的变形机制为拉伸孪晶。而对于横向变形,由于拉伸与压缩的主要变形机制均为锥面滑移,因此,挤压态AZ31镁合金横向的拉压不对称性就小得多(见图6(b))。

}在变形过程中形成时会使基面转动86°[33],这种织构的重新定位使非基面滑移系启动参与变形,同时由于变形初期形成的孪晶界对于位错滑移来说是一种阻碍,位错与孪晶的交互作用表现在宏观应力—应变曲线上为加工硬化率的增加。沿挤压方向压缩且当微观变形机制由拉伸孪生为主变为滑移为主时,应力—应变曲线出现拐点,同时随着应变量的增加,加工硬化率逐渐降低。沿横向压缩时,试样的受力方向与c轴平行且c轴直接受压,如图7(d)所示。在此种受力状态下,受力方向与基面滑移系的滑移面成90°角,基面滑移不能启动。同时,沿c轴压缩时柱面滑移的取向因子为0,而锥面ác+a?滑移的 取向因子最大,因此,沿c轴压缩时启动的滑移系为锥面滑移。从上述分析可知:沿挤压方向压缩时首先启动的变形机制为拉伸孪晶,而沿横向压缩时启动的变形机制为锥面滑移,由于锥面滑移的临界分切应力大于孪生的,因此,沿挤压方向压缩的屈服强度小于横向压缩的屈服强度。由于沿挤压方向压缩变形且当变形量大于8%后,其主要的变形机制为非基面滑移,与横向压缩的变形机制趋于一致,因此,挤压态AZ31镁合金压缩时的各向异性不明显(见图5(b))。同时,从上述的分析中也可知:对于挤压态AZ31镁合金,沿挤压方向非常显著的拉压不对称性(见图6(a))也是由于不同的变形机制造成的,拉伸时的变形机制为柱面滑移,而压缩时的变形机制为拉伸孪晶。而对于横向变形,由于拉伸与压缩的主要变形机制均为锥面滑移,因此,挤压态AZ31镁合金横向的拉压不对称性就小得多(见图6(b))。

图6 挤压态AZ31镁合金的拉压不对称性

Fig. 6 Asymmetry of as-extruded AZ31 magnesium alloy: (a) Tension and compression behavior in extrusion direction; (b) Tension and compression behavior in transverse direction

图7 挤压态AZ31镁合金高速冲击拉伸及压缩载荷方向与晶粒c轴的相对关系

Fig. 7 Specimens orientations with respect to AZ31 magnesium extrusion (Arrow direction is loading direction): (a) Extrusion direction tension; (b) Extrusion direction compression; (c) Transverse direction tension; (d) Transverse direction compression

4 结论

1) 挤压态AZ31镁合金在高应变速率变形条件下根据加载方向及应力状态的不同,各向异性及拉压不对称性不同,其拉伸行为表现出很强的各向异性,但是压缩行为的各向异性不明显;挤压态AZ31镁合金在挤压方向表现出很强的拉压不对称性,而在横向拉压不对称性很低。

2) 挤压态AZ31镁合金宏观上的各向异性及拉压不对称性是由于不同的微观变形机制引起的。当挤压态AZ31镁合金沿挤压方向拉伸时其主要的变形机制为柱面滑移;沿横向拉伸时主要的变形方式为锥面滑移;而沿挤压方向压缩时初始变形机制为拉伸孪晶,当变形量为0.008左右时,由于孪晶消耗殆尽,变形转变为以滑移的方式进行;沿横向压缩时其主要的变形机制为锥面滑移。

3) 挤压态AZ31镁合金在不同加载方向变形机制的不同是其强烈的初始基面织构所引起的。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium: Properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] AGHION E, BRONFIN B. Magnesium alloys development towards the 21st century [J]. Materials Science Forum, 2000, 350/351: 19-23.

[3] VANFLETEREN R. Magnesium for automotive applications [J]. Advanced Materials and Processes, 1996(5): 33-34.

[4] YI S, BOHLEN J, HEINEMANN F, LETZIG D. Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets [J]. Acta Materialia, 2010, 58(2): 592- 605.

[5] AGNEW S R, DUYGULU ?. Materials modeling and simulation of isothermal forging of rolled AZ31B magnesium alloy: Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

[6] KLEINER S, UGGOWITZER P J. Mechanical anisotropy of extruded Mg-6%Al-1%Zn alloy [J]. Materials Science and Engineering A, 2004, 379(1/2): 258-263.

[7] BOHLEN J, N?RNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium-zinc- rare earth alloy sheets [J]. Acta Materialia, 2007, 55(6): 2101- 2112.

[8] YIN S M, WANG C H, DIAO Y D, WU S D, LI S X. Influence of grain size and texture on the yield asymmetry of Mg-3Al-1Zn alloy [J]. Journal of Materials Science and Technology, 2011, 27(1): 29-34.

[9] LEE M G, WAGONER R H, LEE J K, CHUNG K, KIM H Y. Constitutive modeling for anisotropic/asymmetric hardening behavior of magnesium alloy sheets [J]. International Journal of Plasticity, 2008, 24(4): 545-582.

[10] YIN De-liang, WANG Jing-tao, LIU Jin-qiang, ZHAO Xiang. On tension-compression yield asymmetry in an extruded Mg-3Al-1Zn alloy [J]. Journal of Alloys and Compounds, 2009, 478(1/2): 789-795.

[11] BALL E A, PRANGNELL P B. Tensile-compressive yield asymmetries in high strength wrought magnesium alloys [J]. Scripta Metallurgica et Materialia, 1994, 31(2): 111-116.

[12] WU Yuan-yuan, TAN Cheng-wen, YANG Yong-biao, WANG Fu-chi, CAI Hong-nian. Research on the anisotropy of hot rolled AZ31B alloy at high strain rates [J]. Rare Metal Materials and Engineering, 2009, 38(3): 404-408.

[13] WAN G, WU B L, ZHANG G Y, ESLING C. Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2010, 527(12): 2915-2924.

[14] YOKOYAMA T. Tensile and compressive properties of wrought magnesium alloy at high rates of strain [J]. Journal de Physique, 2003, 110(4): 69-74.

[15] WATANABE H, ISHIKAWA K. Effect of texture on high temperature deformation behavior at high strain rates in a Mg-3Al-1Zn alloy [J]. Materials Science and Engineering A, 2009, 523(1/2): 304-311.

[16] YANG Yong-biao, WANG Fu-chi, TAN Cheng-wen, WU Yuan-yuan, CAI Hong-nian. Plastic deformation mechanisms of AZ31 magnesium alloy under high strain rate compression [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1043-1046.

[17] MATTHEW T T, MARK F H, PHILLIP M G, HAITHAM E K, WILBURN R W. Anisotropic effects on the strain rate dependence of a wrought magnesium alloy [J]. Scripta Materialia, 2009, 60: 182-185.

[18] ULACIA I, DUDAMELLB N V, G?LVEZC F, YID S, P?REZ-PRADOB M T, HURTADO I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates [J]. Acta Materialia, 2010, 58(8): 2988-2998.

[19] 刘 正, 史文方, 毛萍莉. 镁、铝合金及塑料轻量化竞争与挑战[J]. 中国金属通报, 2009, 39: 17-19.

LIU Zheng, SHI Wen-fang, MAO Ping-li. The competition and challenge among magnesium, aluminum and plastic in the application of lightweight [J]. Bulletin of China Metal, 2009, 39: 17-19.

[20] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002: 35-36.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. The theory and application of magnesium based lightweight alloy [M]. Beijing: Mechanical Industry Press, 2002: 35-36.

[21] LIU Zheng, MAO Ping-li. A Canada-China-USA collaborative research and development project: Magnesium front end research and development 2008 annual report [R]. 2008: 14-32.

[22] YOO M H. Slip, twin, and fracture in hexagonal close-packed metals [J]. Metall Trans A, 1981, 12(3): 409-418.

[23] WAN Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy [J]. Acta Materialia, 2007, 897-905.

[24] AGNEW S R, DUYGULU O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

[25] BARNETT M R. Twinning and the ductility of magnesium alloys. Part I: “Tension” twins [J]. Materials Science and Engineering A, 2007, 464: 1-7.

[26] YOO M H, LEE J K. Deformation twinning in hcp metals and alloys [J]. Philosophical Magazine A, 1991, 63(5): 987-1000.

[27] SAMMANA T A, LIA X, CHOWDHURYB S G. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy [J]. Materials Science and Engineering A, 2010, 527: 3450-3463.

[28] GEHRMANNA R, MATTHIAS M F, GOTTSTEIN G. Texture effects on plastic deformation of magnesium [J]. Materials Science and Engineering A, 2005, 395: 338-349.

[29] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52: 5093-5103.

[30] BARNETT M R. Twinning and the ductility of magnesium alloys. Part II: “Contraction” twins [J]. Materials Science and Engineering A, 2007, 464: 8-16.

[31] 毛萍莉, 刘 正, 王长义, 金 鑫, 王 峰, 郭全英, 孙 晶. 高应变速率下AZ31B镁合金的压缩变形组织[J]. 中国有色金属学报, 2009, 19(5): 816-820.

MAO Ping-li, LIU Zheng, WANG Chang-yi, JING Xin, WANG Feng, GUO Quan-ying, SUN Jing. Deformation microstructure of AZ31B magnesium alloy under high strain rate compression [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 816-820.

[32] JIANG L, JONAS J, LUO A A, SACHDEV A K, GODET S. Influence of { } extension twinning on the flow behavior of AZ31 Mg alloy [J]. Materials Science and Engineering A, 2007, 445/446: 302-309.

} extension twinning on the flow behavior of AZ31 Mg alloy [J]. Materials Science and Engineering A, 2007, 445/446: 302-309.

[33] BROWN D W, AGNEW S R, BOURKE M A M, HOLDEN T M, VOGEL S C, TOME C N. Internal strain and texture evolution during deformation twinning in magnesium [J]. Materials Science and Engineering A, 2005, 399: 1-12.

(编辑 陈卫萍)

基金项目:国家“十二五”科技支撑计划资助项目(2011BAE22B00)

收稿日期:2011-04-11;修订日期:2011-08-02

通信作者:毛萍莉,教授,博士;电话:024-25497131;传真:024-25496768;E-mail: pinglimao@yahoo.com