DOI:10.19476/j.ysxb.1004.0609.2017.11.02

晶粒尺寸及取向对AZ31合金板材室温拉伸塑性变形与断裂机制的影响

朱 涛1, 2,黄光杰1,曹玲飞1,谭文杰2,赵 飞2, 3

(1. 重庆大学 材料科学与工程学院,重庆 400081;

2. 贵州大学 材料与冶金学院,贵阳 550025;

3. 贵州省材料结构与强度重点实验室,贵阳 550025)

摘 要:对AZ31镁合金轧制态板材分别在473~673 K温度范围退火1 h以获得不同初始显微组织。通过金相显微镜、背散射电子衍射分析(EBSD)和力学试验机,研究晶粒尺寸和取向分布对合金板材室温单向静拉伸过程塑性变形和断裂机制的影响。结果表明,晶界取向角呈连续分布有利于晶粒协调塑性变形。随着晶粒尺寸的降低,晶界对室温塑性变形的贡献增大,晶界与位错滑移和孪生的交互作用增强。对于取向角均呈连续分布的473 K和573 K退火态板材,平均晶粒尺寸分别为3.6 μm和9.5 μm,塑性变形主导机制由晶界滑动和位错滑移转变为晶界滑动、位错滑移和孪生,断裂机制由微孔聚集型转变为微孔聚集型和解理型混合型断裂方式。673 K退火态板材的平均晶粒尺寸达22.9 μm,塑性变形主导机制为位错滑移和孪生。此时,由于晶界取向角呈离散分布,晶粒协调塑性变形能力差,断裂机制转变为解理断裂。

关键词:AZ31合金轧制板材;晶粒尺寸;取向;塑性变形;断裂机制

文章编号:1004-0609(2017)-11-2195-09 中图分类号:TG146.2 文献标志码:A

镁合金具有高的比强度和比刚度、良好的电磁屏蔽和阻尼性等优点,在交通运输、航空航天、电子等节能减重领域具有广泛应用前景[1-2]。然而,由于纯镁为密排六方结构,且轴比c/a接近1.63,室温下仅有两个独立的<a>滑移,孪生成为重要的室温塑性协调变形机制。因此其室温塑性变形能力差。另外,经过传统挤压或轧制等塑性加工后的镁合金通常具有强的基面织构,导致其力学各向异性增强,二次加工成形性恶化[3-4]。细化晶粒和弱化基面织构是改善镁合金室温塑性和力学各向异性的重要途径[5-7]。基于此,国内外学者广泛开展了合金化以及等径角挤压、异步轧制和累积叠轧等塑性加工技术及工艺对镁合金晶粒尺寸、基面织构、力学性能和成形性的研究[8-15]。然而,有研究表明,镁合金的室温塑性,特别是拉伸成形性并非晶粒越细小越好。晶粒尺寸和取向极大地影响镁合金室温塑性变形和断裂行为,从而对板材二次成形性产生重要影响。例如,HU等[16]采用不同轧制工艺制备了7~18 μm不同晶粒尺寸和基面织构的AZ31镁合金板材,研究其对力学性能和胀形性能的影响。结果表明,晶粒细化虽然提高板材的力学性能,但不利于提高板材的胀形性能。而基面织构减弱提高板材厚度方向变形能力和胀形性能。CHINO等[17]研究表明,镁合金板材中粗晶粒有利于在塑性变形过程中形成孪晶,有利于厚度方向的应变,从而提高其拉伸成形性。KOIKE等[18]采用等径角挤压结合退火制备了平均晶粒尺寸约6.5 μm的镁合金,研究其室温单向拉伸塑性变形行为。GUO等[19]研究了不同轧制方式制备的AZ31合金板材晶粒尺寸(5~24 μm)、基面织构和孪生对板材屈服强度和加工硬化行为的影响。LIU等[20]研究了取向对异常大晶粒AZ31合金板材室温塑性变形和宏观断裂形貌的影响。上述研究主要集中在晶粒尺寸和取向对塑性变形行为、机制[21]以及成形性的影响,而关于塑性变形机制和断裂机制的联系仍有待进一步研究。另外,目前制备5 μm以下的镁合金主要是采用挤压、等径角挤压或累积叠轧获得的,而通过传统轧制方式获得晶粒细小镁合金板材的报道并不多见。对轧制板材从细晶粒尺寸到粗大晶粒尺寸并结合取向分析对室温塑性变形和断裂机制影响及其变化规律研究的报道亦不多见。本文作者利用前期研究工作中获得的轧制工艺,结合退火处理获得了不同晶粒尺寸(3.6~22.9 μm)和初始织构的AZ31镁合金板材,研究其室温静拉伸过程的塑性变形机制和断裂机制,对镁合金轧制板材二次加工成形等方面具有重要的指导意义。

1 实验

实验材料为AZ31镁合金热轧板坯,其主要成分(质量分数)如下:Al 3.1%,Zn 1.1%,Mn 0.3%,Mg余量。沿该热轧板坯轧向(RD)、横向(TD)和法向(ND)截取尺寸为60 mm×60 mm×4 mm的板坯。将板坯加热到673 K保温0.5 h,然后以5%~15%道次压下量进行轧制,获得总压下量约40%的轧制态板材。对该轧制板材分别在473、573 和673 K不同温度下退火 1 h,以获得不同初始晶粒尺寸和取向的退火态板材。在板材上线切割标距为15 mm×4 mm×1.5 mm (RD×TD×ND)的矩形拉伸试样。

采用GX51型Olympus金相显微镜进行金相显微组织观察。腐蚀剂为乙酸苦味酸酒精混合溶液。采用商用ACII溶液对退火态试样的RD×ND面以及拉伸试样断口附近TD×ND面进行电解抛光,抛光电压为20V,电流0.05 A,时间约60 s。然后采用配有HKL公司Channel 5电子背散射衍射系统的SUPRA40扫描电镜对试样中部区域附近进行微观形貌和取向分析,加速电压为20 kV,扫描步长0.5~1 μm。宏观织构采用型号为Rigaku D/max-2500PC的X射线衍射仪进行测试。室温单向拉伸力学性能在型号为CMT5205电子万能试验机上进行测试。拉伸方向与板材轧制方向(RD)一致,拉伸速率为0.5 mm/min。

2 结果与分析

2.1 初始显微组织和织构

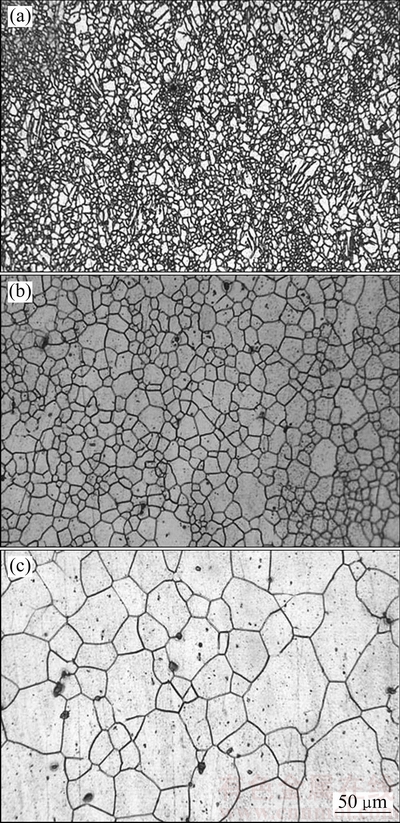

AZ31镁合金轧制板材经473、573和673 K不同温度退火1 h后的金相显微组织和宏观织构分别如图1和2所示。由图1(a)可见,473 K退火组织主要为细小的等轴状晶粒,同时仍存在少量形变长条状晶粒。这表明此时静态再结晶并未完全进行。这种形变长条状晶粒将可能导致板材力学各向异性增大。随着退火温度的升高,晶粒尺寸增大。采用截线法统计了其平均晶粒尺寸,分别为约3.6、9.5和22.9 μm。

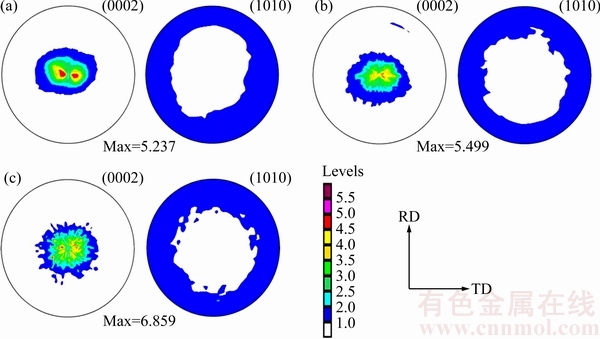

由图2的宏观织构可见,473 K退火态板材基面织构强度最低,为5.237。另外,基面织构沿TD方向呈双峰分布。文献[22]指出,孪晶是{0002}双峰织构的主要诱因。由此可见,本研究473 K退火态板材的基面织构分布特点与轧制工艺及其不完全静态再结晶退火有关。573 K退火态板材的基面织构强度较473 K退火态略有升高,为5.499。但基面织构双峰分布特征消失,主要沿TD方向以及与TD呈一定夹角的方向连续分布。而673K退火态板材,基面织构强度明显增大,达6.859,且呈不连续的弥散状分布。

图1 AZ31 镁合金板材不同退火态下的金相显微组织

Fig. 1 Optical microstructures of rolled AZ31 alloy sheets annealing at 473 K (a), 573 K (b) and 673 K (c) for 1 h

为进一步分析AZ31镁合金板材晶粒尺寸和取向对塑性变形和断裂机制的影响,图3给出了各退火态板材轧面微观区域的EBSD分析结果。可以看到,各退火态IPF图中大部分晶粒呈红色,表明晶粒的基面取向(c轴)与板材ND向平行,为镁合金板材典型的基面织构特征。

图2 AZ31镁合金板材不同退火态下的极图

Fig. 2 Pole figures of the AZ31 alloy sheets annealed at 473 K (a), 573 K (b) and 673 K (c) for 1 h

图3 AZ31镁合金板材不同退火态下的IPF(上图)、取向角分布和{0002}极图(下图)

Fig. 3 IPF maps (upper), misorientation distributions and (0002) pole figures (below) of AZ31 alloy sheets annealed at 473 K (a), 573 K (b) and 673 K (c)

对473 K退火态,IPF图(见图3(a))更清楚地显示了其不完全静态再结晶的组织特征,即除了细小等轴状再结晶晶粒外,还有少量的形变条带状晶粒。且形变条带状晶粒中分布着较多灰白色的小角度晶界 (<15°)。对应的晶界取向(差)角在<10°和~30°的位置呈峰值分布,且在5°~90°范围呈连续变化的特点。文献[23-25]指出:小角度晶界主要由于位错累积形成,表明材料含有较高的储存能;30°附近的峰与再结晶晶粒的晶界有关;86°附近的峰与{10 2}拉伸孪晶界面有关。由此可见,473 K退火态取向角分布进一步表明该组织为不完全静态再结晶态。

2}拉伸孪晶界面有关。由此可见,473 K退火态取向角分布进一步表明该组织为不完全静态再结晶态。

随退火温度升高,形变储存能不断减少,晶粒不断长大,对应的<10°的取向角不断减少,而~30°取向角则呈增加趋势。对573 K和673 K退火态,取向角仅在~30°处呈单峰分布。需要指出的是,573 K退火态的取向角总体呈连续变化的分布特点,而673 K退火态的取向角在<30°和>55°的分布范围急剧减少,呈不连续分布特征。

综上可见,微观取向角分布能在一定程度上反映显微组织的状态。结合文献[26]和本研究中显微组织及取向角分布特点可知,473、573和673 K退火态组织分别对应着不完全静态再结晶、完全静态再结晶和静态再结晶异常长大3种状态。另外,图3中微区的(0002)极图结果显示,基面织构强度随退火温度的变化趋势总体与宏观织构(见图2)的相一致。

2.2 力学性能

不同退火态板材的室温单向静拉伸工程应力-应变曲线如图4所示。为便于分析讨论,将各退火态下的平均晶粒尺寸、宏观基面织构强度及其力学性能(抗拉强度Rm和断后伸长率A)结果统计于表1中。可以看出,晶粒尺寸细小的473 K退火态板材流变应力高于573 K和673 K退火态板材。这主要是由于该板材显微组织晶粒尺寸细小、且位错密度较高所致。随着晶粒尺寸增大,板材的抗拉强度Rm呈降低的变化趋势,但断后伸长率A并非单调地增加或减小,而是在平均晶粒尺寸居中的9.5 μm时达到最大值。这进一步表明镁合金室温塑性变形能力并非晶粒越细小越好。值得指出的是,对于673 K退火态板材,由于基面织构强和取向角不连续分布,导致抗拉强度并未明显降低,而断裂伸长率降至最低。

图4 镁合金板材不同退火态下室温拉伸工程应力-应变曲线

Fig. 4 Tensile engineering stress-strain curves of AZ31 alloy sheets under different annealing states

表1 不同退火态下平均晶粒尺寸、基面织构及力学性能

Table 1 Average grain sizes, basal textures and mechanical properties of AZ31 alloy sheets under different annealing states

综上可见,板材基面织构强,呈离散分布时,对应的取向角不连续分布,晶粒协调塑性变形能力差,板材塑性差。在基面织构强度相对较弱且接近的情况下,尽管随着晶粒尺寸减小,晶界对室温塑性变形的贡献增强,但AZ31镁合金板材的室温塑性并非随晶粒细化而单调升高。因此有必要深入分析晶粒尺寸和取向分布对室温塑性变形机制和断裂机制的影响。

2.3 断口附近显微组织

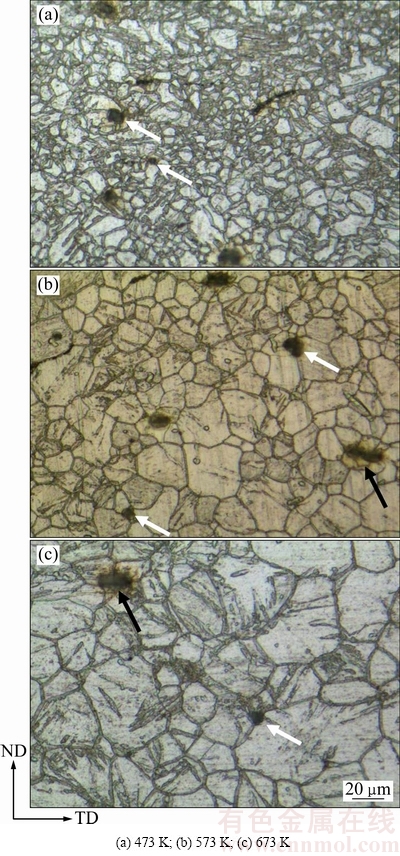

对不同退火态试样拉伸断口附近的金相显微组织进行观察,同时借助EBSD进行取向分析以探寻微观塑性变形机制,结果分别如图5和6所示。

由图5所示拉伸断口附近金相组织可以看出:对于473 K退火态板材,平均晶粒尺寸约为3.6 μm,断口附近显微组织主要为细小的等轴状晶粒和大小不一的黑色空洞(见图5(a)中白色箭头所示),空洞尺寸接近甚至远超过平均晶粒尺寸。仅在个别较粗大的晶粒中能观察到稀少的具有平直界面的孪晶。这表明,此细小晶粒尺寸条件下,孪生已不是协调室温塑性变形的主导机制。由文献[27]可知,空洞是金属蠕变断裂中较为常见的金相组织特点,是晶界滑动与晶內滑移交互作用的结果。另外,文献[18]的研究结果指出,细晶粒镁合金在室温单向静拉伸过程将激活非基面滑移。由此可以推断,473 K退火态板材的室温塑性变形主导机制为位错滑移和晶界滑动。关于空洞形成分析如下:对于该晶粒细小的退火态板材,在载荷作用下,将沿最大切应力方向产生晶界滑动,导致在三晶粒交界处形成应力集中。该应力集中极易通过激活滑动晶界前方晶粒的非基面滑移所松弛。随着非基面滑移的激活,晶內位错滑移和晶界(滑动)的交互作用不断增强,将在晶界产生交割,引起应力集中,成为空洞的萌生地。随着塑性变形的进行,空洞不断长大并连接,形成裂纹。

图5 不同退火态AZ31合金板材单向静拉伸断口附近的显微组织

Fig. 5 Microstructures near tensile fracture of AZ31 alloy sheets

图6 不同退火态合金板材单向静拉伸断口附近的IPF(上图)、{0002}极图(中图)和取向角分布(下图)

Fig. 6 IPF maps (upper), {0002} pole figures (middle) and misorientation distribution (below) in vicinity of tensile fracture of alloy sheets with different annealing states

对于573 K退火态板材,平均晶粒尺寸约为9.5 μm(见图5(b)),断口附近的金相显微组织中能较明显地观察到平直界面的孪晶,同时还能观察到黑色的微小孔洞(白色箭头所示)和平直小裂纹(黑色箭头所示)。这表明此时晶界、孪生和位错滑移都可能参与协调塑性变形。

当平均晶粒尺寸急剧增大到22.9 μm(见图5(c)),断口附近显微组织中的孪晶显著增多,同时空洞数量和尺寸(相对于晶粒尺寸而言)则明显减少。仍然存在黑色的平直裂纹(图5(c)中黑色箭头所示)。这表明孪生对塑性变形的贡献增大,而晶界协同塑性变形能力显著减弱。此时塑性变形初期产生的孪晶界因阻碍位错运动而导致位错塞积,将成为裂纹源的萌生地。这是图5(c)中平直裂纹形成原因。

综上可见,随着晶粒尺寸和取向的变化,断口附近金相显微组织中的孪晶、“空洞”和平直的微小“裂纹”均发生了变化。这表明AZ31镁合金板材在室温拉伸塑性变形过程中“激活”的位错、孪生和晶界及其交互作用发生改变,从而对塑性变形行为和断裂产生影响。这将进一步在断口附近的微观取向和断口形貌中进行分析验证。

由图6(a)可见,473 K退火态板材经室温单向静拉伸后,大量与RD向平行的绿色柱面取向晶粒偏转至ND向,但几乎未见基面取向~86°的大角度偏转。这表明晶粒取向偏转并非拉伸孪生所致。另外,不同取向的晶粒沿ND向至TD向呈准连续分布。这可能是晶粒协调塑性变形过程中沿此方向不断发生偏转的结果,与裂纹扩展的方向相对应。下文拉伸断口形貌(见图7(a))中主裂纹扩展方向与此相吻合。进一步结合取向角分布可见,取向角在<10°角度和~30°位置分别呈现峰值分布特点,而~86°取向角分布几乎可以忽略。这表明在此细小的晶粒尺寸下,板材室温拉伸塑性变形的主导机制为位错滑移和晶界滑动。由于位错滑移和晶界的交互作用导致<10°和~30°两取向峰之间的取向角呈连续分布。这进一步验证了上述断口附近金相组织分析中所获得的结论。

图7 不同退火态 AZ31镁合金板材单向静拉伸断口形貌

Fig. 7 Morphologies of tensile fracture of AZ31 alloy sheets under different annealing states

对于573 K退火态板材经室温单向静拉伸后(见图6(b)),除了与RD向平行的绿色柱面取向晶粒外,与TD向平行的蓝色柱面取向晶粒也偏转至ND向,且主要沿RD向分布。其他取向晶粒在RD-TD面呈相对弥散的分布,各取向晶粒总体仍保持连续分布特点。此时,取向角除了在<10°和~30°位置呈峰值分布以外,~86°的取向角所占份数明显增大。这表明除了位错滑移、晶界滑动外,(拉伸)孪生也对室温拉伸塑性变形产生了贡献。拉伸孪晶因临界剪切应力较低,将在塑性变形初期优先产生。一方面,孪晶界和晶界均会在后续塑性变形过程阻碍位错运动,导致位错塞积,对应的<10°晶界取向角显著增多,呈强的峰值分布。另一方面,塑性变形初期产生的孪晶因改变晶粒取向,有利于激活新的滑移系,从而促进后续变形时位错、孪晶界和晶界三者之间的交互作用,导致裂纹扩展路径复杂。这将有利于提高室温拉伸塑性变形能力。这在力学性能结果(见图4)和拉伸断口形貌(见图7(b))中均得到证实。

对于673 K退火态板材经室温单向静拉伸后(见图6(c)),取向角在<10°和~86°位置的呈峰值分布,而~30°的取向角分布显著减少。这表明,位错滑移和(拉伸)孪生是该退火态板材室温塑性变形的主导机制。这也是常规镁合金室温塑性变形主导机制。由于该退火态板材基面织构强,当沿RD向进行单向拉伸时,伴随产生的TD向拉应力更容易激活拉伸孪晶,导致基面取向晶粒偏转~86°至TD方向,而柱面取向晶粒偏转至ND向(见图6(c)中(0002)极图所示)。由于此时晶界协调塑性变形能力急剧减弱,因此塑性变形初期产生的孪晶界以及晶界均会阻碍后续塑性变形时的位错运动,造成位错塞积,导致<10°的晶界取向角分布增至最大。需要指出的是,图6(c)IPF图与图5(c)相比,孪晶数量存在差异。这主要是由于图6(c)采集的区域较相对较小,而室温塑性变形时变形的不均匀可能导致孪晶在某些局部区域较多,而某些区域相对较少。

综上可见,晶粒尺寸和取向明显影响AZ31镁合金板材的室温塑性变形机制。随着晶粒尺寸减小,晶界协调塑性变形能力增强,塑性变形机制发生改变。本实验条件下,平均晶粒尺寸为9.5 μm的AZ31镁合金板材的综合力学性能较好。这是由于位错滑移、孪生和晶界滑动及其交互作用均对其室温塑性产生贡献。

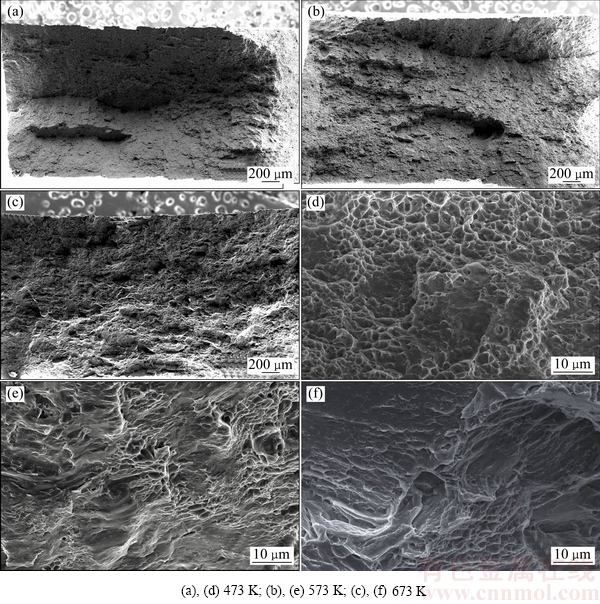

2.4 断口形貌

图7所示为不同退火态板材室温单向静拉伸试样的断口形貌。473 K退火态板材低倍下的宏观断口形貌(见图7(a))中有一条几乎贯穿TD向的主裂纹。高倍断口形貌中(见图7(d))可观察到许多几乎呈等轴状的“韧窝”。这是微孔聚集型断裂的典型微观断口特征,表明其断裂机制主要为微孔聚集型断裂。随着晶粒尺寸增大,573 K退火态板材宏观断口形貌中(见图7(b))除了和473K退火态类似的沿TD向的主裂纹外,还有“人字形”花样和“河流状”花样。这表明裂纹扩展路径变得更多也更复杂。高倍断口形貌(见图7(e))中除了有等轴状的韧窝外,还可以观察到舌状花样及解理台阶,说明此时不仅存在微孔聚集型断裂,还伴随有解理断裂。根据上文分析可知,这种混合型的断裂机制是其塑性变形过程位错滑移、晶界滑动和孪生及其交互作用的结果。673 K退火态板材断口形貌中,断口平齐,无明显主裂纹(见图7(c)),高倍下主要为许多不同高度的解理面和解理台阶(见图7(f)),是典型的解理断裂。文献[26]指出,密排六方点阵金属解理断裂的解理面为(0001)面。结合图6(c)中的微观取向分析结果可知,由于拉伸孪生导致基面取向由ND向偏转约90°至TD向。此时,发生拉伸孪生后的基面(0001)与板法向(ND向)平行。由此可以推测,解理断裂的解理面与拉伸孪晶中的(0001)面有关。这可能是由于晶粒协调塑性变形能力差且晶界对塑性变形贡献急剧减弱,随塑性变形的进行孪晶界及晶界处应力集中不断加剧,从而导致裂纹萌生,最后沿孪生晶粒(0001)面发生解理断裂。

3 结论

1) 随着AZ31镁合金板材平均晶粒尺寸由较粗大的22.9 μm减小到约3.6 μm,晶界对塑性变形贡献增强,室温塑性变形主导机制由常规的位错滑移和孪生转变为位错滑移和晶界滑动,断裂机制由解理断裂转变为微孔聚集形断裂。

2) 晶界取向角呈连续分布有利于晶粒协调塑性变形。本试验条件下,平均晶粒尺寸约为9.5 μm的板材室温塑性变形能力最大。此时晶粒尺寸和取向分布协同塑性变形能力最强,导致位错滑移、晶界滑动和孪生及其交互作用均对室温塑性变形产生贡献,断裂机制为微孔聚集型断裂和解理断裂共同存在的混合型断裂。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium: properties-applications- potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] 丁文江, 付彭怀, 彭立明, 蒋海燕, 王迎新, 吴国华, 董 杰, 郭兴伍. 先进镁合金材料及其在航空航天领域中的应用[J]. 航天器环境工程, 2011, 28(2): 103-109.

DING Wen-jiang, FU Peng-huai, PENG Li-ming, JIANG Hai-yan, WANG Ying-xin, WU Guo-hua, DONG Jie, GUO Xing-wu. Advanced magnesium alloys and their applications in aerospace[J]. Spacecraft Environment Engineering, 2011, 28(2): 103-109.

[3] 刘俊伟, 陈振华, 陈 鼎. 镁合金轧制板材低温变形行为与微观机制[J]. 中国有色金属学报, 2008, 18(9): 1577-1583.

LIU Jun-wei, CHEN Zhen-hua, CHEN Ding. Microstructure evolution and deformation behavior of hot-rolled Mg alloy at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1577-1583.

[4] 魏琳俊, 杨寿智, 夏伟军, 邓朝晖, 刘 灵. 镁合金板材特殊轧制技术的研究进展[J]. 机械工程材料, 2012, 36(11): 14-19.

WEI Lin-jun, YANG Shou-zhi, XIA Wei-jun, DENG Chao-hui, LIU Lin. Research progress for special rolling technology of magnesium alloy sheet[J]. Materials for Mechanical Engineering, 2012, 36(11): 14-19.

[5] 丁 茹, 王伯健, 王 成, 师晓莉. AZ31镁合金晶粒细化方法及机制研究现状[J]. 轻合金加工技术, 2010, 38(1): 23-26.

DING Ru, WANG Bo-jian, WANG Cheng, SHI Xiao-li. Research on grain refining methods and mechanisms of AZ31 magnesium alloy[J]. Light Alloy Fabrication Technology, 2010, 38(1): 23-26.

[6] 丁文江, 靳 丽, 吴文翔, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 21(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture optimization of wrought Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2371-2381.

[7] 宋 波, 辛仁龙, 孙立云, 陈 刚, 刘 庆. 镁合金拉伸压缩不对称性的影响因素及控制方法[J]. 中国有色金属学报, 2014, 24(8): 1941-1952.

SONG Bo, XIN Ren-long, SUN Li-yun, CHEN Gang, LIU Qing. Influencing factors and controlling methods of tension-compression asymmetry in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 1941-1952.

[8] LUO Jun, YAN Hong, CHEN Rong-shi, HAN En-hou. Effects of Gd concentration on microstructure, texture and tensile properties of Mg-Zn-Gd alloys subjected to large strain hot rolling[J]. Materials Science and Engineering A, 2014, 614: 88-95.

[9] ZHAN Mei-yan, ZHANG Wei-wen, ZHANG Da-tong. Production of Mg-Al-Zn magnesium alloy sheets with ultrafine-grain microstructure by accumulative roll-bonding[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 991-997.

[10] CHANG L L, KANG S B, CHO J H. Influence of strain path on the microstructure evolution and mechanical properties in AM31 magnesium alloy sheets processed by differential speed rolling[J]. Material and Design, 2013, 44: 144-148.

[11] 赵东清, 周吉学, 刘运腾, 董旭光, 王 晶, 杨院生. 低温挤压Mg-4Zn-2Al-2Sn合金的组织和力学性能研究[J]. 金属学报, 2014, 50(1): 41-48.

ZHAO Dong-qing, ZHOU Ji-xue, LIU Yun-teng, DONG Xu-guang, WANG Jing, YANG Yuan-sheng. Microstructure and mechanical properties of Mg-4Zn-2Al-2Sn Alloys extruded at low temperatures[J]. Acta Metallurgica Sinica, 2014, 50(1): 41-48.

[12] TANG W Q , HUANG S Y , LI D Y , PENG Y H. Mechanical anisotropy and deep drawing behaviors of AZ31 magnesium alloy sheets produced by unidirectional and cross rolling[J]. Journal of Materials Processing Technology, 2015, 215: 320-326.

[13] 李瑞红, 蒋 斌, 陈志军, 潘复生. 超轻Mg-Li-Al系变形镁合金挤压板材的组织及性能[J]. 中国有色金属学报, 2016, 26(1): 31-36.

LI Rui-hong, JIANG Bin, CHEN Zhi-jun, PAN Fu-sheng. Microstructure and mechanical properties of as-extruded ultra-light Mg-Li-Al sheet[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 31-36.

[14] YU Kun, XIONG Han-qing, DAI Yi-long, TENG Fei, FAN Su-feng, QIAO Xue-yan, WEN Li. Mechanical properties and formability of ultrasonic treated twin roll casting magnesium alloy sheet[J]. Rare Metal Materials and Engineering, 2017, 46(3): 622-626.

[15] 张 会, 王同乐, 刘文义, 王永善, 夏鹏举. 等通道转角挤压对镁铝硅合金组织性能的影响研究[J]. 塑性工程学报, 2017, 24(1): 36-40.

ZHANG Hui, WANG Tong-hui, LIU Wen-yi, WANG Yong-san, XIA Peng-ju. Effect of equal channel angular pressing on microstructure and mechanical properties of Mg-Al-Si alloy[J]. Journal of Plasticity Engineering, 2017, 24(1): 36-40.

[16] 胡水平, 王 哲. 织构和晶粒尺寸对AZ31镁合金薄板成形性能的影响[J]. 中国有色金属学报, 2012, 22(9): 2244-2249.

HU Shui-ping, WANG Zhe. Effect of texture and grain size on press formability of AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2244-2249.

[17] CHINO Y, KIMURA K, MABUCHI M. Deformation Characteristics at room temperature under biaxial tensile stress in textured AZ31 Mg alloy sheets[J]. Acta Materialia, 2009, 57: 1476-1485.

[18] KOIKE J, KOBAYASHI T, MUKAI T, WATANABE H, SUZUKI M, MARUYAMA K, HIGASHI K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Materialia, 2003, 51(7): 2055-2065

[19] GUO Li-li, CHEN Zhong-chun, GAO Li. Effects of grain size, texture and twinning on mechanical properties and work-hardening behavior of AZ31 magnesium alloys[J]. Materials Science and Engineering A, 2011, 528: 8537-8545.

[20] LIU Pei, XIN Yun-chang, LIU Qin. Plastic anisotropy and fracture behavior of AZ31 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 880-884.

[21] 宋 波, 辛仁龙, 郭 宁, 刘婷婷, 杨青山. 变形镁合金室温应变硬化行为的研究进展[J]. 中国有色金属学报, 2014, 24(11): 2699-2710.

SONG Bo, XIN Ren-long, GUO Ning, LIU Ting-ting, YANG Qing-shan. Research progress of strain hardening behavior at room temperature in wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2699-2710.

[22] 孟 强, 蔡庆伍, 江海涛, 胡水平. AZ31镁合金单轴拉伸过程中的{0002}双峰织构观察[J]. 稀有金属, 2011, 35(2): 159-163.

MENG Qiang, CAI Qing-wu, JIANG Hai-tao, HU Shui-ping. {0002} double peak texture of AZ31 Magnesium alloy during uniaxial tension[J]. Chinese Journal of Rare Metals, 2011, 35(2): 159-163.

[23] WANG Bing-shu, XIN Ren-long, HUANG Guang-jie, LIU Qing. Effect of crystal orientation on the mechanical properties and strain hardening behavior of magnesium alloy AZ31 during uniaxial compression[J]. Materials Science and Engineering A, 2012, 534: 588-593.

[24] 卢立伟, 赵 俊, 刘龙飞, 王 尧, 刘天模. 冷锻及再结晶退火对挤压态AZ31镁合金组织的影响[J]. 中国有色金属学报, 2014, 24(12): 2969-2977.

LU Li-wei, ZHAO Jun, LIU Long-fei, WANG Yao, LIU Tian-mo. Influence of cold forging and recrystallization annealing on microstructure of extruded AZ31 magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 2969-2977.

[25] 宋广胜, 陈强强, 徐 勇, 张士宏. AZ31镁合金压缩过程中织构对微观变形机制的影响[J]. 稀有金属材料与工程, 2016, 45(12): 3186-3191.

SONG Guang-sheng, CHEN Qiang-qiang, XU Yong, ZHANG Shi-hong. Effect of texture on micro-mechanism of AZ31 magnesium alloy during compression[J]. Rare Metal Materials and Engineering, 2016, 45(12): 3186-3191.

[26] 彭伟平, 刘 腾, 何良菊, 李培杰, 曾 攀. 中间退火对镁合金板材组织和性能的影响[J]. 材料热处理学报, 2007, 28(3): 58-62.

PENG Wei-ping, LIU Teng, HE Liang-ju, LI Pei-jie, ZENG Pan. Influence of intermediate annealing on microstructure and mechanical property of magnesium alloy sheet[J]. Transactions of Materials and Heat Treatment, 2007, 28(3): 58-62.

[27] 时海芳, 任 鑫. 材料力学性能[M]. 北京: 北京大学出版社, 2010: 223.

SHI Hai-fang, REN Xin. Mechanical properties of materials[M]. Beijing: PekingUniversityPress, 2010: 223.

Influence of grain size and misorientation of AZ31 alloy sheets on plastic deformation and fracture mechanisms during tensile test at room temperature

ZHU Tao1, 2, HUANG Guang-jie1, CAO Ling-fei1, TAN Wen-jie2, ZHAO Fei2, 3

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400081, China;

2. School of Materials and Metallurgy, Guizhou University, Guiyang 550025, China;

3. The Key Laboratory for Mechanical behavior and Microstructure of Materials, Guiyang 550025, China)

Abstract: Different initial grain sizes and misorientation of AZ31 alloy sheets were obtained by different annealing temperatures of 473-673 K for 1 h, respectively. The mechanisms of plastic deformation and fracture were investigated by optical microscope, EBSD and tensile test with strain rate of 1×10-3 s-1 at room temperature. The results show that the continuous distribution of grain boundary misorientation angle(GBMA) inclines to improve the ability of grain coordination plastic deformation. With decreasing grain sizes, the contribution of grain boundary on plastic deformation at room temperature increases for improving the interaction between grain boundary sliding(GBS) and dislocation slipping(DS) as well as twinning. As for the alloy sheets annealed at 473 K and 573 K, which present the mean grain sizes of about 3.6 μm and 9.5 μm with continuous distribution of GBMA in both, the mechanism of plastic deformation transforms from the domination of interaction of GBS and DS to that of GBS, DS and twinning. And the fracture mechanism transforms from the micropore aggregation fracture to the mixture fracture, combining with micropore aggregation and cleavage. While as for the sheet annealed at 673 K, characterized by the average grain size of about 22.9 μm and disperse distribution of GBMA, the mechanism of plastic deformation is dominated by DS and twinning, and the fracture mechanism changes into cleavage fracture for the poor ability of grain coordination plastic deformation.

Key words: as rolled AZ31 alloy sheet; grain size; misorientation; plastic deformation; fracture mechanism

Foundation item: Project(QKH LH[2015]7651) supported by the Joint Fund of Science and Technology Department of Guizhou Province, China

Received date: 2016-10-25; Accepted date: 2017-07-21

Corresponding author: HUANG Guang-jie; Tel: +86-23-65112334; E-mail: gjhuang@cqu.edu.cn

(编辑 何学锋)

基金项目:贵州省联合基金项目(黔科合LH字[2015]7651号)

收稿日期:2016-10-25;修订日期:2017-07-21

通信作者:黄光杰,教授,博士;电话:023-65112334;E-mail:gjhuang@cqu.edu.cn