文章编号:1004-0609(2010)S1-s0704-05

扩径推弯弯头的重要工艺参数

陈 军,杨海瑛,段文森

(西北有色金属研究院,西安 710016)

摘 要:介绍扩径推弯法成形原理以及影响弯头成形尺寸和形状的重要扩径推弯技术参数。技术参数的设定包括成形模羊角芯头的设计、芯头材料选择、感应加热圈的设计、扩径弯头温度和温度沿芯头的分布、扩径推弯速度和成品尺寸控制等。不同材质弯头由于物理特性和不同温度下的拉伸性能存在差异,可根据管坯材料特性,选择不同加工工艺参数,以保证弯头的形状、尺寸精度。

关键词:弯头;扩径推弯法;羊角芯头

中图分类号:TG 146.4 文献标志码:A

Important technology parameters of elbow made by

diameter-expanding and pushing

CHEN Jun, YANG Hai-ying, DUAN Wen-sen

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: The forming principle of elbow made by diameter-expanding and pushing and the important technology parameters affecting the elbow size and shape were introduced. The technology parameters include design of forming mould ram’s core, choice of core material, design of inductive heating loop, temperature of elbow made by diameter-expanding and pushing, temperature distribution along ram’s core, rate of diameter-expanding and pushing and the size control of finished size. Due to the difference of physical properties and tensile strength for the elbow of different materials at high temperature, different processing technology parameters should be chosen to assure the shape and dimensional accuracy of elbow according to the material characters.

Key words: elbow; method of diameter-expanding and pushing; ram’s core

在石化、电力、冶金、锅炉等工业生产装置中,为输送气体、液体或带固体颗粒的流体,大量地应用管道。管道由管子、管件和泵阀组成[1],其中:管子包括直管和弯管;管件是管子连接件的简称,管件有6个品种,即弯头、三通、异径管、四通、管帽和松套法兰接头(翻边)[1]。弯头是最重要的管件,弯头的用量占管件的84%;小曲率半径弯头可以使管道系统布置结构紧凑,占据空间小,节约费用,提高管道系统的运行质量。

对于小曲率半径弯头,弯曲半径越小,弯曲变形越大,弯头成形难度就越大。小曲率半径弯头的成形方法包括扩径推弯法、隧道挤压法、模压弯曲法、压片拼压法、凹槽轮滚压法、虾米腰弯头和超塑成形等方法。扩径推弯法与其他弯头成形方法相比,扩径推弯可生产不同材质的壁厚均匀的小曲率半径(R≈D)、薄壁(t/T≈0.015)、产品规格多(Dn=20~1 200)的多角度弯头(30°,60°,90°和180°),而且可以生产环形管(360°)或螺旋管,生产效率高,适合于批量生产。该方法不仅可以生产钢弯头,而且可以生产钛、锆、镍等其他金属材料的弯头或环形管。扩径推弯法生产效率高,并保证弯头外径圆度和壁厚均匀,这是其他弯管工艺所无法比拟的。

扩径推弯法生产弯头在钢、钛、锆、镍弯头的生产中得到了大量应用,影响推制磨头质量的工艺参数非常多,扩径推弯工艺参数不同,弯头推制后的形状、尺寸精度、表面光洁度、壁厚均匀性、椭圆度也不同。本文作者结合成形扩径推弯弯头的经验,阐述扩径推弯弯头中的重要工艺参数选择时所要注意的问题。

1 扩径推弯原理

扩径推弯弯头是管坯套在芯杆上,芯杆锁定在固定牌坊等机架上,活动牌坊推动推制环、推制管和坯料顺芯杆前进从芯头外沿爬过而周向扩径、轴向弯曲变形成为弯头。

图1 所示为扩径推弯过程的网格变化,说明扩径推弯法原理是坯料外弧基本不变形,内弧轴向压缩、周向拉长、内弧侧厚度不变,扩径推弯是使比例变形,成为纯剪状[1-3]。在弯管成形过程中,各特征点的环向拉应变ef和轴向压应变eθ相等,径向应变et≈0。若将坯料表面等分成小网格, 扩径推制后弯头的外弧侧网格基本不变,则说明弯头外侧的金属没有参与变形,内侧的网格变化最剧烈,轴向产生压缩变形,网格缩短;径向产生拉伸变形,网格拉长,网格呈现等腰梯形状,从弯头外侧到内侧其变形程度逐步加剧。所以,在扩径推弯过程中,坯料受到的是拉压变形和微小弯曲变形,不产生剪切变形和扭转变形[4]。扩径推弯法可以避免传统弯管工艺成型时,外弧管壁受拉减薄,内弧管壁受压增厚而造成的壁厚不均匀现象,可保证外径的圆度和壁厚的均匀性。

图1 扩径推弯过程前后的网格变化[3]

Fig.1 Girding change before and after pushing bend by expanding diameter[3]

2 扩径推弯法要点

扩径推弯法的工艺参数非常多,包括:成形模羊角芯头的设计和制作、芯头材料选择、芯杆的尺寸选择和制作、加热方法的选择。若采用中频感应加热,则涉及加热圈的设计制作和加热圈的置放位置、中频加热的频率、成形模羊角芯头的预热温度和预热时间、坯料的变形温度和温度分布、推制速度、坯料内表面光洁度、芯头和芯杆的光洁度、润滑剂的选泽和使用方法等。工艺参数的选择均可影响弯头的成形质量。本文就扩径推弯过程中最重要的影响因素进行讨论。

2.1 成形模羊角芯头的设计和制作

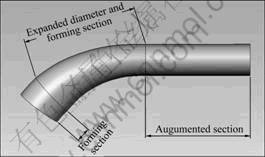

成形模羊角芯头的设计和制作是扩径推弯法的最重要技术。成形模羊角芯头由引伸段、扩径成形段和整形段组成,如图2所示。扩径成形段和整形段设计是成品弯头弯曲半径的决定因素。

图2 扩径推弯用成型模羊角芯头

Fig.2 Mould of ram’s core used by diameter-expanding and pushing method

引伸段是个直杆,其外径略小于坯料的内径,设计有一点锥度,有利于坯料越来越紧地抱箍在芯杆上,顺利地传递推制力。

扩径成形段的重要技术参数是中心线描述和型芯空间曲面形状描述。中心线设计有一段法、二段法、多段法和渐开线的变异,其中心思想是将坯料由无限大曲率半径逐渐减小到整形段的曲率半径R。随着扩径推弯技术的不断发展,芯头的设计趋向于采用数学曲线和椭圆截面结构[5],这样,可保证扩径推弯弯头的一次成型,无需后期整形,就可满足弯头的技术标准要求,大大提高了产品质量和生产效率。

扩径成形段中心线描述包括起始弯曲半径、弯曲角度。扩径成型段中心线长度与弯曲半径和弯曲角度相关,弯曲半径和弯曲角度越大,中心线长度越长。一般地,管坯材料的高温拉伸强度低、塑性好,比高温拉伸强度高、塑性差的材料其起始弯曲半径和弯曲角度小。

扩径成形段弯曲角度与弯曲中心线的长度是相互关联的参数。如果成形段大头外径为D2,成形段小头成形段外径为D3,扩径成形段长度为L1,成形段成形锥度β=(D3-D2)/L1,那么,扩径成形段存在一个最佳成形锥度β0。当β>β0时,造成扩径推弯速度太快,引起管坯对模具的正压力小于管坯摩擦力,致使轴向压力小,周向拉力大,容易造成管坯减薄;当β过大时,很容易造成管坯撕裂。但当β<β0时,一般可保证弯头壁厚均匀性,但β过小,会使羊角芯头成形段长度过长,一是造成加热圈长度增加,加热均匀性难以保证,二是造成管坯与羊角芯头接触面过大,总摩擦力增大,需要增加推制力。管坯所承受的轴向力过高也会造成管坯折叠、打皱,造成成形工作失败[6]。

羊角芯头整形段的横截面为正圆形,扩径成形段的横截面为椭圆形,正圆形的圆心和椭圆形的中心点位于羊角芯头的中心弧线上,椭圆形的长轴和短轴均垂直于羊角芯棒的中心弧线,并且椭圆形的长轴垂直于羊角芯棒的中心弧线所做的平面。型芯空间曲面设计要求从坯料的外径d增大到弯头的外径D,直径的变化过程也是一个光滑、连续变化的过程。椭圆型芯可减少小曲率弯曲半径弯头推弯过程中的翘头现象。

整形段的形状基本等同于弯头的内腔,主要技术参数是总转角。合适的转角即可以使弯头实现完好的整形,又尽可能地减小推制摩擦阻力。

2.2 芯头材料的选择

因为芯头在工作时要承受相当大的推力和很高的温度,所以,芯头应选择高温强度大、耐磨性能好的材料。芯头材料可用1Cr18Ni9Ti,Cr25Ni20,Cr23Ni13, 2Cr23Ni18和4Cr14Ni14W2Mo等不锈耐热钢。

扩径推弯碳素钢弯头可采用1Cr18Ni9Ti和Cr22Ni8钢。由于碳钢的高温强度较低,为降低生产成本,可选用35CrMo铸钢。扩径推弯合金钢弯头可采用Cr25Ni3,Cr25Ni20和Cr32Ni5钢。

对于推制高温强度较高的钛合金、不锈钢及纯镍,为提高芯棒的耐热性、强度及伸长率,可采用1Cr18Ni9Ti,Cr25Ni20和Cr32Ni5钢。

2.3 扩径推弯的加热圈设计

扩径推弯时的加热方法形式多样,包括中频感应加热、高频感应加热和喷燃气火焰加热。中频加热法是最常用的加热方式。当材料室温强度较低、塑性特别好时,也可进行冷推弯。

中频感应加热法是局部加热工件、连续推进方式加热。采用这种方法,加热速度快,氧化情况好,可局部加热,生产环境清洁,有利于实现操作自动化或半自动化。加热圈采用紫铜管制作,紫铜管可为圆管或方管,绕制成螺旋状包围整个芯头的成形段和整形段,与芯头距离为30~60 mm,圈与圈距离为紫铜管直径的2~4倍。中频频率在600~1 800 Hz范围内。

中频感应线圈加热时,在交变磁场的作用下,管材内部产生涡流,将电能转变成热能,涡流渗透深度计算公式为

(1)

(1)

式中:ρ为电阻率;mr为磁导率;f为电流的频率。涡流的渗透能力与频率有关,频率低,则渗透能力大,加热温度高,速度快。

加热圈的一端应对准在引伸段和成形段的界面上,以保证温度升高和坯料扩径变形的协调性,确保管坯在非变形和小变形时材料有足够的强度承受推制力。

2.4 推制温度和温度分布

扩径推弯的坯料变形温度和温度分布是极其重要的。推弯过程中坯料的合适温度可以保证材料在合适的强度和塑性下顺利发生周向扩径、轴向弯曲变形。轴向也就是母线方向,在变形过程中承受受压缩变形,是推制力和摩擦力相向作用的结果。在坯料沿芯头前进过程中,由于芯头直径不断增大而造成周向拉长。

弯头扩径推制温度与管坯材质、壁厚、推扩速度及中频线圈有关。当壁厚一定时,低合金钢的加热温度高于碳素钢的加热温度,厚壁管的加热温度高于薄壁管的加热温度。由于材料材质不同,其高温力学性能差异大,弯头扩径推制温度也不同。一般地,纯金属的加热温度低于其合金的加热温度,碳钢和合金钢的室温和高温变形性能好,所以,推弯温度范围很大,如20号钢、45号钢的合适推弯温度为600~850 ℃。不锈钢的扩径推制温度为900~1 000 ℃,纯钛的推弯温度范围为650~750 ℃,钛合金的推弯温度为750~850 ℃,Ni-6合金在1 000 ℃以上高温下推弯变形性能较好。

在推弯过程中,温度分布是比温度更重要的工艺参数,温度分布要求内侧和外侧均匀,整形段温度等于或高于成形段温度。推弯过程是温度渐变增加的过程,不允许温度降低和局部温度过高,否则将发生弯头局部减薄甚至破裂。当扩径推弯的推制温度不均匀时,会造成成品壁厚不均匀,甚至破裂。

当扩径推弯的管坯加热温度过高、时间过长时,会使材料晶粒长大,减弱晶粒之间的结合力,从而降低管体机械性能,过热严重会使材料发生氧化或熔化,造成过烧。加热温度也不能过低,因为温度过低不但减小扩径推弯速度,而且增加液压推力和芯头磨损量。

材料的磁导率、比热容、热导率和电阻率均影响坯料的加热效应。钢是铁磁性材料,在居里点以下时 (Fe的居里点为770 ℃),其磁化率c非常大,比顺磁性材料的磁化率高几百至几千倍,在中频加热时具有很高的加热效应。不锈钢、铝、钛和锆是顺磁材料,磁化率c为10-4左右,加热效应较低,需要较高的加热功率,推制前芯头的预热显得尤为重要。镍的居里点为358 ℃,所以,它在推弯情况下是顺磁材料。铜是抗磁材料,应考虑用喷燃气火焰加热。不锈钢的推弯也常用喷燃气火焰加热,热导率低和电阻大的材料有利于加热效应。因此,管坯加热温度必须选择合适。

2.5 扩径推制速度

弯头扩径推弯推制速度与扩径比、加热温度、摩擦力、设备能力有关。扩径推弯急弯弯头时扩径量大,摩擦阻力大,推制速度小;相反,长半径弯头扩径推弯扩径比小,摩擦阻力小,推制速度大。管坯加热温度越高,变形抗力越小,弯头的扩径推弯推制速度就越快,生产效率越高;相反,温度越低,变形抗力越大,推制速度就越小,生产效率越低[7]。

为减小管坯和芯头之间的摩擦阻力,首先要提高芯头的表面光洁度,另外,清除管坯内壁的切屑等杂质,然后均匀涂敷优质润滑剂——石墨。此外,设备的推力非常重要,若液压机有足够大的推力,则中频柜有足够大的调控能力,推制速度可快些。

2.6 成品尺寸控制

弯头弯曲半径主要取决于成形模羊角芯头的弯曲半径,但弯头弯曲半径与推弯温度有一定关系。当扩径推弯温度较低时,会造成成品弯曲半径R偏大,反之,推制温度高,会造成成品弯曲半径R偏小[6]。

材料的热膨胀系数不同也会影响成品的尺寸。模具和坯料的膨胀系数不同,推弯在较高温度下进行,冷却后其尺寸收缩是不一致的,所以,设计模具时应考虑被加工材料的热胀性。

扩径推制弯头一般在600~1 000 ℃的温度范围内进行。由于不同材质弯头的热膨胀系数不同,扩径推弯温度不同以及芯头模具和管坯的热膨胀系数不同,材料由推弯弯度冷却至室温,由于热胀冷缩致使弯头成品尺寸收缩量不一样。所以,设计模具时,应充分考虑被加工材料的热胀性特性。其中,芯头模具中的整形段直径设计最关键,直接影响成品弯头的直径精度。考虑到芯头、管坯热胀冷和扩径推弯温度因素,整形段最大直径Dm 的计算公式如下:

(2)

(2)

(3)

(3)

(4)

(4)

式中:D0、s0分别为实际原料直径、壁厚的平均值;D1、s1分别为实际成品直径、壁厚的平均值;T1为扩径推弯温度;T0为常温;αg 为芯头线膨胀系数;αf为管材线膨胀系数。

不同的弯头品种、材质、温度、速度、扩径比,其?s,αg和αf不同,采用式(2)进行计算。要精确地控制成品外径尺寸,必须精确地控制成品外径尺寸,精确修正羊角芯头的整形段外径Dm。用不同材质制造羊角芯头,可以使成品的外径尺寸相差达0.2 mm[7]。

3 结论

1) 扩径推弯弯头是一个周向扩径、轴向弯曲变形的过程,弯头壁厚均匀,生产效率高。具有足够塑性和一定强度的金属材料都可以用扩径推弯法制造标准弯头。

2) 要成功地推弯金属弯头,必须掌握好芯头的设计和制作、加热圈的设计、扩径推弯温度和温度场分布、推弯速度以及成品尺寸控制等工艺参数。推制温度、推制速度和扩径比之间是相互关联的。

3) 由于材料高低温拉伸性能以及热导率、电阻率、比热容和热膨胀系数等物理参数不同,扩径推弯不同材质弯头,可根据管坯材料特性,选择不同加工工艺参数,方可保证弯头的形状、尺寸精度。

REFERENCES

[1] 鹿晓阳, 史宝军, 鹿晓力. 分析热推弯管成形过程的实验解析法[J]. 锻压机械, 1997(4): 10-13.

LU Xiao-yang, SHI Bao-jun, LU Xiao-li. Experimental analysis for axis-thust tube bending[J]. Metal Forming Machine, 1997(4): 10-13.

[2] 鹿晓阳, 徐秉业, 岑韦志, 史宝军. 牛角芯棒热推弯管成形过程受力变形特点[J]. 力学与实践, 1998, 20(6): 15-17.

LU Xiao-yang, XU Bing-ye, CEN Wei-zhi, SHI Bao-jun. The characteristics of force and deformation in forming process of heated pushing curved tubes through ox-core[J]. Mechanics and Engineering, 1998, 20(6): 15-17.

[3] 段文森, 戴红卫. 三种钛制对焊用无缝管件的开发研究[C]//第一届全国管道学术交流会议. 北戴河, 1997: 79-86.

DUAN Wen-sen, DAI Hong-wei. Development and investigation of three butt-welded seamless pipe fittings of titanium alloy[C]//The 1st Academic Symposia Processing of Chinese Pipeline. Beidaihe: 1997: 79-86.

[4] 李 奎. 中频热推弯管新工艺及试验研究[J]. 施工技术(吉林), 1994(2): 32-38.

LI Kui. New technique and experimental investigation of axis-thrust tube bending by inductive heating[J]. Construction Technology (Jilin), 1994(2): 32-38.

[5] 马 力. 弯头扩径推弯过程中推杆几何形状设计[J]. 管道技术与设备, 1998(4): 18-22.

MA Li. Geometric analysis of pushing bar during axis-thrust tube bending[J]. Pipeline Technique and Equipment, 1998(4): 18-22.

[6] 段文森. 钛及钛合金弯头成形工艺改进[J]. 金属学报, 2002, 38(Sup 1): 422-424.

DUAN Wen-sen. Improvement of elbow forming technology of titanium and its alloys[J]. Acta Metallurgica Sinica, 2002, 38(Sup.1): 422-424.

[7] 张永兰. 推制式热扩管工艺的实践及研究[J]. 钢管, 2004, 33(1): 9-12.

ZHANG Yong-lan. Practice and research of push-type tube hot-expanding process[J]. Steel Pipe, 2004, 33(1): 9-12.

(编辑 陈灿华)

基金项目:国家重点基础研究发展计划资助项目(2007CB613807);国家支撑计划资助项目(2007BAE07B03)

通信作者:陈 军;电话:029-86231078;E-mail: christinchenjun@163.com