文章编号:1004-0609(2011)12-3026-07

限制模压变形1060纯铝的组织演化与晶粒细化

杨开怀1,彭开萍2,陈文哲2, 3

(1. 福建船政交通职业技术学院 汽车运用与工程机械系,福州 350007;

2. 福州大学 材料科学与工程学院,福州 350108;

3. 福建工程学院 材料科学与工程系,福州 350108)

摘 要:设计平行模压变形、180°交叉模压变形、90°交叉模压变形对1060纯铝进行系列限制模压变形(CGP)试验,采用透射电镜研究该材料在不同变形工艺下的组织演化规律和晶粒细化速率。结果表明:变形工艺不影响组织的演化规律,但显著影响晶粒细化速率、晶粒细化效果以及大角度晶界的形成;90°交叉模压变形最优。在相同的变形温度、变形速率和应变累积条件下,所能达到的晶粒细化速率和大角度晶界的数量取决于剪切变形模式。

关键词:1060纯铝;限制模压变形;1060纯铝;组织演化;晶粒细化;细化机理

中图分类号:TG113;TG115 文献标志码:A

Microstructural evolution and grain refinement of 1060 pure Al processed by constrained groove pressing

YANG Kai-huai1, PENG Kai-ping2, CHEN Wen-zhe2, 3

(1. Department of Mechanical Engineering, Fujian Chuanzheng Communications College, Fuzhou 350007, China;

2. College of Materials Science and Engineering, Fuzhou University, Fuzhou 350108, China;

3. Department of Materials Science and Engineering, Fujian University of Technology, Fuzhou 350108, China)

Abstract: In order to well understand the role of the accumulative strain and the effects of shear strain plane in the grain refinement during constrained groove pressing (CGP), the microstructural evolution and the grain refinement rate of 1060 aluminum alloy processed by CGP, such as parallel CGP, 180° cross CGP and 90° cross CGP, were investigated by transmission electron microscopy. The results show that the microstructural evolution is independent of the pressing conditions. But the processing conditions significantly affect the grain refinement rate, final grain size and boundaries misorientation, and the 90° cross CGP is the most effective. It is reasonable to conclude that, in the same pressing temperature, strain rate and accumulative strain, the grain refinement rate, final grain size and boundaries misorientation are determined by the shear strain plane.

Key words: 1060 pure Al; constrained groove pressing; microstructure evolution; grain refinement; refinement mechanism

限制模压(Constrained groove pressing, CGP)变形法是新近开发的一种适用于制备大体积超细晶金属板材的剧烈塑性变形(Severe plastic deformation, SPD) 法[1]。与传统SPD法相比,CGP法有效克服了等径角挤压法、高压扭转法难以制备大体积板材试样的缺点,成功避免了叠轧合技术制备过程中对板材的叠合面、轧辊表面以及环境气氛等的苛刻要求,改进了反复褶皱压直法变形过程中对材料施加的类似于疲劳变形的弯曲变形方式,对材料施加的是剪切变形,更容易累积等效应变而达到细化晶粒的目的[2]。因此,CGP法迅速成为研究热点[3-8]。

然而,现有的相关研究仍主要集中于CGP变形等效应变量对材料晶粒细化的影响,所采用的变形方式与变形工艺路线较为单一[3, 5-8]。RAFIZADEH等[9]为了提高纯铜的CGP变形道次即等效应变量而改进晶粒细化效果提出了中间退火工艺,但效果并不理想。作者所在的课题组率先提出了180°交叉模压变形工艺,并用于细化两相Cu-Zn合金,发现在180°交叉模压变形方式下能够获得更好的晶粒细化速率和晶粒细化效果[10-11]。本文作者在此基础上,进一步提出90°交叉模压变形工艺并用于变形1060纯铝,采用透射电镜研究该材料在不同变形工艺下的组织演化规律和晶粒细化速率,以期明确CGP的晶粒细化机制与影响因素。

1 实验

1.1 试验模具与材料

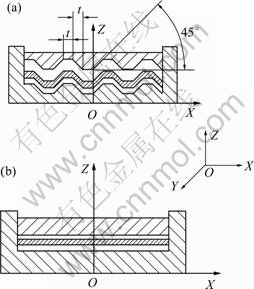

试验采用的CGP模具如图1所示,其中模具斜面角θ=45°,模具齿宽为t=4 mm,对应CGP变形试样尺寸为72 mm×72 mm×4 mm。

图1 模具结构示意图

Fig.1 Schematic illustration of die

试验材料为商业1060纯铝。首先将1060纯铝板材按尺寸要求切割成CGP变形试样,然后在X2-5-12型箱式电阻炉中500 ℃退火,保温2 h后空冷,以消除残余应力并获得均匀的组织结构。金相显微分析表明1060纯铝经退火后获得均匀的等轴晶粒组织,平均晶粒尺寸约为120 μm。

1.2 CGP变形试验

CGP变形在YB32-100型液压机上进行,变形速率为16 mm/s。在本研究中,设计了3种变形工艺,分别为平行模压变形、180°交叉模压变形和90°交叉模压变形。

1.2.1 平行模压变形

平行模压变形工艺流程如图2所示。每道次的平行模压变形包含5个步骤:1) 使用槽模对试样进行剪切变形,此时在试样中存在变形区和未变形区;2) 使用平模将试样压平,使得试样的变形区再次承受剪切变形,而未变形区仍然没有受到剪切变形;3) 将试样绕Z轴旋转180°;4) 再次使用槽模对试样进行剪切变形,此时步骤1)和2)中的未变形区承受剪切变形;5) 再次使用平模将试样压平。这样整个试样都获得等量等效应变,定义为变形1道次。重复上述步骤,直至完成所需的变形道次。

1.2.2 180°交叉模压变形

180°交叉模压变形工艺流程如图3所示。每一180°交叉模压变形循环包含3个步骤:1) 首先对试样进行1道次的平行模压变形;2) 将试样绕Z轴旋转90°;3) 再次进行1道次平行模压变形过程。如此,完成以上3个步骤后,整个试样获得相当于平行模压变形2道次的等量等效应变,同样定义为变形2道次。重复上述步骤,直至完成所需的变形道次。

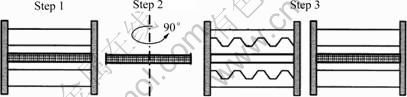

1.2.3 90°交叉模压变形

90°交叉模压变形工艺流程如图4所示。每一90°交叉模压变形循环包含5个步骤:1) 使用槽模对试样进行剪切变形;2) 使用平模将试样压平;3) 将试样绕Z轴逆时针旋转90°,重复步骤1)和2);4) 再将试样绕Z轴逆时针旋转90°,重复步骤1)和2);5) 再次将试样绕Z轴逆时针旋转90°,重复步骤1)和2);这样整个试样都获得等量等效应变。

图2 平行模压变形工艺流程

Fig.2 Schematic illustration of parallel CGP

图3 180°交叉模压变形工艺流程

Fig.3 Schematic illustration of 180° cross CGP

图4 90°交叉模压变形工艺流程

Fig.4 Schematic illustration of 90° cross CGP

90°交叉模压变形的实质是在变形2次(试样1次压弯1次压平)后,将试样绕Z轴旋转90°进行重复变形,且每次旋转的方向相同。在完成8次变形后,整个试样获得相当于平行模压变形2道次或180°交叉模压变形2道次的等量等效应变,同样定义为变形2道次。重复上述步骤,直至完成所需的变形道次。

1.3 电子显微分析方法

透射电镜薄膜样品制备按常规电镜试样的制备方法进行,先机械减薄至约70 μm,然后在MTP-1A型磁力驱动双喷电解减薄仪上进行电解双喷预减薄后(不穿孔),在Gatan Model 691 PIPS型离子减薄仪上进行减薄至透光。

金属薄膜样品的电子显微分析在JEM-2010EX型透射电镜(Transmission electron microscopy,TEM)上进行,加速电压200 kV。定量显微分析采用平均截距长度法[12]。

2 结果与分析

2.1 平行模压变形1060纯铝的组织特征

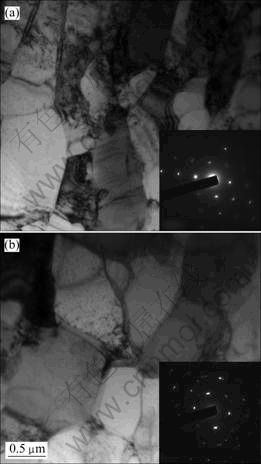

图5所示为商业1060纯铝CGP平行模压变形各道次试样的典型TEM像及其选区电子衍射花样。由图5可见,经CGP变形1道次后,试样中原始粗大晶粒被破碎成一系列具有小角度界面的亚晶,大部分亚晶界主要由几条甚至单条位错线构成,亚晶沿一定方向拉长成带状结构,同时在亚晶内部出现大量位错,位错在亚晶界处集结成条带状,或者在晶粒内部缠结到一起,或者在亚晶内部形成高密度的网格结构。说明CGP所引起的剧烈剪切变形在组织内部产生大应变,促使生成大量高密度位错。观察大量TEM像发现,经CGP变形1道次后,组织基本由带状亚晶构成,亚晶平均宽度约1 μm,平均长度约7 μm。

经CGP平行模压变形2道次后,亚晶内部的位错密度急剧增加,位错在应变作用下运动并发生反应,在条带状粗大亚晶内滑移,沿亚晶的横向缠结形成新的亚晶界,位错在亚晶界进一步塞积并开始形成锯齿状的亚晶界,条带状亚晶间夹有被剪切破碎成的细小亚晶粒,少数亚晶界上出现消光条纹,表明经CGP平行模压变形2道次后,试样开始形成非平衡组织。选区电子衍射斑点由分散的高亮斑点构成,表明选区内的亚晶基本上位于单个原始粗晶粒内,取向差很小,亚晶间主要仍以位错构成的小角度亚晶界连接。同时可以发现,衍射斑点呈被拉长状,这是由变形产生的位错等缺陷堆积造成的晶格弯曲带来的,说明晶粒畸变很严重。观察大量TEM像发现,经CGP平行模压变形2道次后,组织基本仍由具有明显方向性的条带状亚晶构成,亚晶平均宽度与变形1道次相比略有减小,但差别不大;亚晶平均长度减小到约4 μm。

经CGP平行模压变形4道次后,组织开始形成不规则形状的亚结构,其内部较为清晰,基本观察不到位错存在,表明随着变形道次的增加,高能量的位错在应力作用下运动并发生反应,逐渐在原始粗大亚晶带内滑移、缠结形成新的亚晶界,进而分割亚晶带而形成新的亚结构;同时,运动着的异号位错相遇而抵消,也会促使晶内位错密度降低。从图5中还可以发现,此时仍有少量亚晶带存在,亚晶带内部含有大量位错,亚晶带尺寸与前几道次变形试样相比差别不大。选区电子衍射斑点呈被拉长状,且已经开始形成极小的分散弧线,表明此时亚晶间主要仍以小角度的亚晶界连接,但已有少数亚晶具有较大的取向差。观察大量TEM像发现,经CGP平行模压变形4道次后,开始形成具有非平衡晶界的超细晶,晶粒明显细化,但组织基本由不规则状+条带状亚结构组成,仍具有一定的方向性。

图5 CGP平行模压变形试样TEM像及其选区电子衍射花样

Fig.5 TEM and corresponding selected area electron diffraction patterns of samples processed by parallel CGP: (a) 1 pass; (b) 2 passes; (c) 4 passes

2.2 180°交叉模压变形1060纯铝的组织特征

图6所示为商业1060纯铝CGP 180°交叉模压变形各道次试样的典型TEM像及其选区电子衍射花样。

图6 CGP 180°交叉模压变形试样TEM像及其选区电子衍射花样

Fig.6 TEM and corresponding selected area electron diffraction images of samples processed by 180° cross CGP: (a) 2 passes; (b) 4 passes

由图6可见,经CGP 180°交叉模压变形2道次后,组织由具有一定方向性的亚晶构成,夹有被剪切破碎成的细小亚晶粒,亚晶内部具有高密度位错,晶界上出现了明暗相间的等厚条纹,且已经开始形成不规则形状的亚结构;选区电子衍射斑点由呈被拉长状的分散的高亮斑点构成,开始形成极小的分散弧线。与平行模压变形2道次试样相比,亚晶尺寸差别不大,但亚晶方向性较不明显,衍射斑点更为混乱。经CGP 180°交叉模压变形4道次后,试样组织特征与平行模压变形4道次试样相比有较大的差别,此时已经观察不到任何亚晶带,开始形成具有清晰晶界的等轴晶粒,但其晶界较宽,这是由于在剧烈的变形下,亚晶内部的位错不断运动而被亚晶界吸收,通过动态回复过程形成了清晰的、较宽的晶界。同时从图中还可以观察到仍然有部分晶粒内部含有位错,这部分晶粒的部分晶界仍然由高密度位错缠结而成,这是由于部分位错运动较为缓慢,未能完全形成清晰晶界的结果。其选区电子衍射斑点成环状,表明晶粒间具有较大的取向差,开始形成大角度界面。

2.3 90°交叉模压变形1060纯铝的组织特征

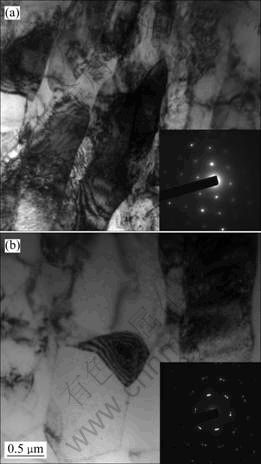

图7所示为商业1060纯铝CGP 90°交叉模压变形各道次试样的典型TEM像及其选区电子衍射花样。

图7 CGP 90°交叉模压变形试样TEM像及其选区电子衍射花样

Fig.7 TEM and corresponding selected area electron diffraction images of samples processed by 90° cross CGP: (a) 2 passes; (b) 4 passes

由图7可见,CGP 90°交叉模压变形2道次试样的组织由具有一定方向性的亚晶构成,夹有被剪切破碎成的细小亚晶粒,亚晶内部具有高密度位错,晶界上出现了明暗相间的消光条纹,且已经开始形成不规则形状的亚结构;选区电子衍射斑点由呈被拉长状的、分散的高亮斑点构成,开始形成极小的分散弧线。经CGP 90°交叉模压变形4道次后,试样内部观察不到任何亚晶带的存在,组织基本由具有清晰晶界的等轴晶粒组成,平均晶粒尺寸约0.8 μm。其选区电子衍射斑点成环状,表明晶粒间具有较大的取向差,形成大角度界面。与180°交叉模压变形4道次试样相比,90°交叉模压变形4道次试样所形成的等轴晶内部更为干净,晶界更为清晰,表明在90°交叉模压变形方式下,位错的运动与反应更为剧烈。

2.4 CGP变形晶粒细化机理及影响因素分析

目前,对SPD法影响晶粒细化效果的因素并没有统一的认识。一般认为,SPD过程中形成很大的应变积累是造成材料晶粒细化的主要原因。也有研究[13-16]表明,剪切变形方向、剪切面与织构以及晶体结构的相互作用是晶粒细化的主要原因,而应变的累积是晶粒细化的次要原因。张忠明等[17]则认为剪切变形方向和材料中较大应变量的累积同时起作用,只是在不同阶段的作用不同:在晶粒达到临界尺寸前,剪切变形方向对晶粒细化起主要作用,而应变累积起次要作用;当达到临界尺寸后,就应变量则对晶粒细化起主要作用。

1060纯铝的系列CGP试验结果表明,本研究所设计的3种变形方式均能有效细化晶粒,且变形方式的改变并没有影响试样组织演化的宏观规律;但是,变形方式的改变却显著影响晶粒细化速率与大角度晶界的形成。从图5~7中可以明显看出,交叉模压变形比平行模压变形具有更快的晶粒细化速率,更有利于促进等轴晶以及大角度晶界的形成,其中又以90°交叉模压变形最有利于促进等轴晶的形成。

平行模压变形与交叉模压变形每道次施加的等效应变量是相等的,区别在于是否改变了变形循环间的剪切变形方向。如图1所示,在CGP变形下,试样沿XOZ面发生剪切变形;在压弯变形过程中,试样虽然承受了方向相反的真实应变,但其剪切方向仍然平行于XOZ平面。因此,在平行模压变形方式下,试样虽然可以通过多次反复变形累积较大的等效应变,但其每一变形循环的剪切变形方向相同,均平行于XOZ平面。单一的剪切变形方向只能开动处于最有利取向的滑移系统,且由于CGP压弯与压平过程的真实应变方向相反,压弯变形过程中产生的位错如果没有被有效锁定,则在压平变形过程中可能会被湮灭[11],这就降低了变形试样位错的增殖速率,进而降低晶粒细化速率。在180°交叉模压变形下,试样首先经受1道次完整的平行模压变形循环,而后旋转90°继续变形,这也就直接改变了剪切变形方向,使得相邻变形道次间试样的剪切变形方向相互垂直;在90°交叉模压变形下,试样每经受1次压弯压平变形循环后即旋转90°再继续变形,这就使得每一压弯压平变形循环间试样的剪切变形方向均相互垂直。剪切变形方向的改变有利于开动多个滑移系,从而抑制位错的湮灭速率,有效提高位错密度,提高位错与晶界以及位错本身的交互作用,使得位错更容易穿过初始形成的粗大拉长带状亚晶形成横向亚晶界而分割带状亚晶粒;且剪切变形方向的改变有利于促进亚晶的旋转与转动,进而促进高角度晶界的形成。因此,可以认为在CGP法的晶粒细化过程中,剪切变形方向对晶粒细化速率和大角度晶界的形成起主要作用。

同时,应变量的累积对CGP法晶粒细化的作用同样十分重要。在平行模压变形中,虽然每一变形循环间的剪切变形方向始终相同,但经平行模压变形4道次后,变形试样同样开始形成具有非平衡晶界的超细晶,晶粒明显细化。可见应变量的累积对晶粒细化所起的作用同样十分重要。

因此,在CGP法的晶粒细化过程中,剪切变形方向和应变量累积二者作用是缺一不可的,同时二者也是密切相关的,且二者的这种相关性不同于张忠明 等[17]的研究过程中发现的剪切变形方向和应变量累积在晶粒细化的不同阶段所起的不同作用,二者的相互作用贯穿于CGP变形的整个晶粒细化过程。在相同的变形温度、变形速率和应变累积条件下,剪切变形方向的改变对晶粒细化速率以及大角度晶界的形成起主要作用,也就是说所能达到的晶粒细化速率和大角度晶界的数量取决于剪切变形模式。

3 结论

1) 平均晶粒尺寸约120 μm的1060纯铝经CGP变形1道次后,晶粒被破碎成一系列具有小角度晶界的、沿一定方向拉长成带状结构的亚晶。平行模压变形4道次后,组织基本由不规则状和具有一定的方向性的条带状亚晶组成。180°交叉模压变形4道次后,观察不到任何亚晶带,开始形成晶内不含位错的具有清晰晶界的等轴晶粒。90°交叉模压变形4道次后,组织基本由具有清晰晶界的等轴晶粒组成,平均晶粒尺寸约为0.8 μm。

2) 变形方式对1060纯铝组织演化宏观规律的影响不大,但是显著影响晶粒细化速率、晶粒细化效果以及大角度晶界的形成,3种变形方式中以90°交叉模压变形最优。

3) CGP法的晶粒细化过程中,剪切变形方向和应变量累积二者是缺一不可密切相关的,且二者的相互作用贯穿于CGP变形的整个晶粒细化过程。在相同的变形温度、变形速率和应变累积条件下,所能达到的晶粒细化速率和大角度晶界的数量取决于剪切变形 模式。

REFERENCES

[1] SHIN D H, PARK J J, KIM Y S, PARK K T. Constrained groove pressing and its application to grain refinement of aluminum[J]. Materials Science & Engineering A, 2002, 328: 98-103.

[2] 杨开怀, 陈文哲. 大体积超细晶金属材料的剧烈塑性变形法制备技术[J]. 塑性工程学报, 2010, 17(2): 124-131.

YANG Kai-huai, CHEN Wen-zhe. Producing bulk ultrafine-grained materials by severe plastic deformation[J]. Journal of Plasticity Engineering, 2010, 17(2): 124-131.

[3] HOSSEINI E, KAZEMINEZHAD M, MANI A, RAFIZADEH E. On the evolution of flow stress during constrained groove pressing of pure copper sheet[J]. Computational Materials Science, 2009, 45: 855-859.

[4] YANG Kai-huai, CHEN Wen-zhe. Tensile properties of 1060 Al alloy subjected to constrained groove pressing[J]. Advanced Materials Research, 2010, 129/131: 65-69.

[5] HOSSEINI E, KAZEMINEZHAD M. Nanostructure and mechanical properties of 0-7 strained aluminum by CGP: XRD, TEM and tensile test[J]. Materials Science and Engineering A, 2009, 526: 219-224.

[6] ZRNIK J, KOVARIK T, NOVY Z, CIESLAR M. Ultrafine- grained structure development and deformation behavior of aluminium processed by constrained groove pressing[J]. Materials Science and Engineering A, 2009, 503: 126-129.

[7] 杨开怀, 吴永泉, 陈文哲. 限制模压变形三维有限元模拟[J]. 中国机械工程, 2010, 21(23): 2877-2881.

YANG Kai-huai, WU Yong-quan, CHEN Wen-zhe. Three-dimensional finite element simulation of constrained groove pressing[J]. China Mechanical Engineering, 2010, 21(23): 2877-2881.

[8] PENG Kai-ping, SU Li-feng, SHAW L L, QIAN Kuang-wu. Grain refinement and crack prevention in constrained groove pressing of two-phase Cu-Zn alloys[J]. Scripta Materialia, 2007, 56: 987-990.

[9] RAFIZADEH E, MANI A, KAZEMINEZHAD M. The effects of intermediate and post-annealing phenomena on the mechanical properties and microstructure of constrained groove pressed copper sheet[J]. Materials Science and Engineering A, 2009, 515: 162-168.

[10] 张萤, 彭开萍, 林雪慧. 形变方式对模压形变H62黄铜组织性能的影响[J]. 材料热处理学报, 2009, 30(4): 114-119.

ZHANG Ying, PENG Kai-ping, LIN Xue-hui. Influence of groove pressing mode on microstructure of H62 brass after the groove pressing[J]. Transactions of Materials and Heat Treatment, 2009, 30(4): 114-119.

[11] PENG Kai-ping, ZHANG Ying, SHAW L L, QIAN Kuang-wu. Microstructure dependence of a Cu-38Zn alloy on processing condition of constrained groove pressing[J]. Acta Materialia, 2009, 57: 5543-5553.

[12] 汪守朴. 金相分析基础[M]. 北京: 机械工业出版社, 1986.

WANG Shou-pu. Foundation of metallographic analysis[M]. Beijing: China Machine Press, 1986.

[13] ZHU Y T, LOWE T C. Observations and issues on mechanisms of grain refinement during ECAP process[J]. Materials Science and Engineering A, 2000, 291: 46-53.

[14] SEGAL V M. Equal channel angular extrusion: From macromechanics to structure formation[J]. Materials Science and Engineering A, 1999, 271: 322-333.

[15] IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON T G. The process of grain refinement in equal-channel angular pressing[J]. Acta Materialia, 1998, 46: 3317-3331.

[16] CHOLINIA A, PRANGNELL P B, MARKUSHEV M V. The effect of strain path on the development of deformation structures in severely deformed aluminium alloys processed by ECAE[J]. Acta Materialia, 2000, 48: 1115-1130.

[17] 张忠明, 徐春杰, 田景来, 王锦程, 郭学锋. ECAP挤压L2纯铝的微观组织演化规律[J]. 西安理工大学学报, 2005, 21(3): 227-231.

ZHANG Zhong-ming, XU Chun-jie, TIAN Jing-lai, WANG Jin-cheng, GUO Xue-feng. Microstructure evolution laws of pure Al L2 during equal channel angular pressing[J]. Journal of Xi’an University of Technology, 2005, 21(3): 227-231.

(编辑 李艳红)

基金项目:福建省科技厅重点项目(2009H0023);福建省教育厅资助项目(JB07027)

收稿日期:2010-04-07;修订日期:2011-07-20

通信作者:陈文哲,教授,博士;电话:0591-22863009;E-mail: chenwz@fzu.edu.cn