不同约束条件下掺轻烧MgO混凝土的力学性能

李延波1, 2,邓敏1,莫立武1,唐明述1

(1. 南京工业大学 材料科学与工程学院,材料化学工程国家重点实验室,江苏 南京,210009;

2. 盐城工学院 材料工程学院,江苏 盐城,224051)

摘要:研究掺0%,5%,8%和12%(质量分数,下同)轻烧MgO混凝土的抗压强度、劈裂抗拉强度、极限拉伸值和轴拉强度随龄期的变化规律,并用扫描电子显微镜和光学显微镜对混凝土微观结构进行分析。结果表明:掺轻烧MgO混凝土在不同约束条件下力学性能都有不同程度的提高,3维约束对混凝土力学性能提高程度最明显。掺5%,8%和12% MgO混凝土3维约束试件360 d时抗压强度分别比自由试件高16.9%,22.0%和16.0%,180 d时劈拉强度分别比自由试件高32.93%,31.03%和33.33%。掺5%和8% MgO混凝土3维约束试件极限拉伸值比自由试件分别提高9.5%和3.1%,抗拉强度分别提高5.7%和6.9%。自由条件下,MgO掺量较大时,MgO水化膨胀使得混凝土内部结构松散,基体呈疏松、多孔状,骨料与界面黏接较弱;约束条件下,混凝土基体的致密性得到提高,基体和集料界面的黏接能力加强,从而提高了混凝土的力学性能。

关键词:约束条件;MgO混凝土;力学性能;微观结构

中图分类号:TU502 文献标志码:A 文章编号:1672-7207(2012)07-2534-08

Mechanical properties of concrete with light burnt MgO-based expansive additive under different restrained conditions

LI Yan-bo1, 2, DENG Min1, MO Li-wu1, TANG Ming-shu1

(1. State Key Laboratory of Materials-Oriented Chemical Engineering, College of Materials Science and Engineering,

Nanjing University of Technology, Nanjing 210009, China;

2. School of Materials Engineering, Yancheng Instituteof Technology, Yancheng 224051, Jiangsu)

Abstract: Compressive strength, split tensile strength, ultimate tensile strain and axial tensile strength of concrete with 0%, 5%, 8% and 12% light burnt MgO-based expansive agent were tested. By means of scanning electron microscope and optical microscope, the microstructure of concretes was examined. The results indicate that restraint may improve mechanical properties of concrete to some extent, and three-dimensionally restrained concrete shows best mechanical properties when concrete contains the same amount of MgO. Compressive strength of three-dimensionally restrained specimens with 5%, 8% and 12% MgO increases by 16.9%, 22.0% and 16.0% respectively at 360 d, and splitting tensile strength increases by 32.93%, 31.03% and 33.33% respectively at 180 d compared with unrestrained specimens. Ultimate tensile strain of three-dimensionally restrained specimens with 5% and 8% MgO increases by 9.5% and 3.1% respectively, and tensile strength increases by 5.7% and 6.9% respectively compared with unrestrained specimens. Under the free-curing condition, microstructure of expansive cement paste and concrete is loose, with cracks in the paste and matrix-aggregate interface. Restraint could improve the microstructure of expansive concrete with light burnt MgO, especially by densifying and intensifying the matrix-aggregate interface. As a result, the mechanical properties of concrete are improved.

Key words: restrained conditions; concrete with MgO-based expansive additive; mechanical properties; microstructure

利用MgO膨胀剂的可调控膨胀特性补偿混凝土的收缩,提高了混凝土的抗裂能力,达到快速、优质浇筑大体积混凝土的目的。外掺轻烧MgO对混凝土力学性能的影响是工程界关心的问题之一,特别重视混凝土在膨胀过程中强度是否减低,其他物理力学有无变化,能否满足水工混凝土的特殊要求。长期研究证明,掺适量的轻烧MgO能够有效地补偿混凝土因温降、干燥等引起的收缩,其长期的体积变形与力学性能稳定,膨胀曲线均匀,且无倒缩现象[1]。膨胀混凝土的强度分为自由条件下和约束条件下2种强度[2]。李承木等[1, 3-4]研究表明,自由条件下,MgO掺量小于5%(质量分数,下同)时混凝土的抗压、抗折强度随着MgO掺量的增加略有提高。杨华全等[5]研究结论为:MgO掺量小于4%时,强度随MgO掺量增加而降低的趋势不明显,当掺量大于4%时,强度随MgO掺量的增加而显著降低。Hu等[6]研究了2维约束条件下掺10%UEA膨胀混凝土的抗压强度,7 d和28 d龄期的约束试件抗压强度比自由试件抗压强度分别高3.5 MPa和4.1 MPa。外掺MgO混凝土在2维约束条件下的抗压强度增加幅度约10%[7],还有部分文献[8-11]对外掺MgO混凝土在约束条件下的力学性能作探讨,但约束对外掺轻烧MgO混凝土力学性能的影响规律尚未阐明。研究约束条件下的膨胀混凝土的性能比自由条件下更能反映工程混凝土的实际情况,因为几乎所有的膨胀混凝土均处于约束条件之下,受到不同程度的各种限制作用,而且膨胀混凝土在有适当的约束作用时更有利于其功能的发挥[12]。因此,研究约束条件下掺轻烧MgO膨胀混凝土的力学性能具有实际意义。本文作者开展了约束条件下外掺轻烧MgO混凝土抗压强度、劈裂抗拉强度、极限拉伸值和轴拉强度的研究,探索约束条件下掺轻烧MgO混凝土力学性能变化规律,以期为掺轻烧MgO混凝土设计和工程应用提供参考。

1 实验

1.1 原材料与配合比

水泥为四川峨眉水泥厂生产的峨胜牌42.5低镁中热硅酸盐水泥,MgO含量为1.51%;粉煤灰(PFA)为宣威Ⅰ级灰;轻烧氧化镁由南京工业大学自行研制,80 μm方孔筛筛余量为3%,柠檬酸法测定MgO的活性指数为160 s;减水剂为江苏博特新材料有限公司生产的JM-B高效减水剂。粗集料为 5~20 mm和20~40 mm连续级配的玄武岩碎石;细集料为灰岩人工砂,细度模数为2.70。水泥、粉煤灰和粗、细集料均取自金沙江溪洛渡水电站工地。

混凝土基本配合比见表1,水胶质量比为0.41,氧化镁为外掺,掺量(质量分数)分别为胶凝材料总用量的0%,5%,8%和12%。

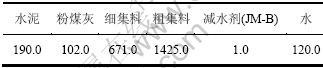

表1 混凝土基本配合比

Table 1 Mix proportion of concrete kg/m3

1.2 实验方法

混凝土试件参照DL/T 5150—2001《水工混凝土试验规程》相关方法成型。用于测试混凝土抗压强度和劈裂抗拉强度的试件尺寸(长×宽×高)为150 mm×150 mm×150 mm,混凝土成型用试模为3维密封型可拆卸铸铁试模。标养24 h后脱模养护的试件称为自由试件。试件成型后养护24 h卸去试模底盖保留试模侧面部分,使得试件处在2维约束条件下养护的试件称为2维约束试件。试件成型后将混凝土表面抹平,紧密安装好上盖,使得试模内混凝土处在3维约束状态下养护,待到预定龄期后拆模测试混凝土的性能,此混凝土试件称为3维约束试件。

用于测试混凝土自由膨胀率、轴心抗拉强度和极限拉伸值的试件尺寸(长×宽×高)为150 mm×150 mm×550 mm。脱模养护的试件称为自由试件。3维约束试件采用与抗压强度试件用试模相同材质的带盖铸铁试模成型,成型后将混凝土表面压实抹平,然后紧密装配好上盖,使得上盖与混凝土表面紧密接触,试模内混凝土处在3维约束条件下养护。所有试件成型后标养24 h,然后移入到30 ℃湿度大于90%的环境下养护。混凝土力学性能测试参照DL/T 5150—2001《水工混凝土试验规程》相关方法进行。

2 结果与讨论

2.1 混凝土在自由条件下的膨胀

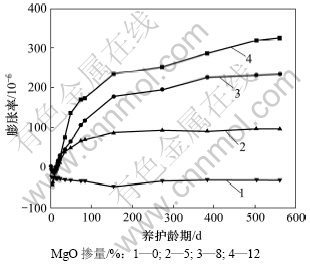

图1所示为掺0%,5%,8%,12% MgO混凝土试件在30 ℃、湿度大于90%的环境下养护时的自由膨胀情况。不掺MgO混凝土50 d时收缩趋于稳定。掺轻烧MgO的混凝土在90 d之前膨胀较快,90 d之后膨胀变缓慢。MgO掺量为5% 的混凝土150 d之后膨胀达到稳定,最大膨胀量分别为95×10-6。8% MgO掺量的混凝土在380 d之后膨胀趋于稳定,最大膨胀量为230×10-6;12% MgO掺量的混凝土在实验560 d的龄期内仍然呈膨胀趋势。总体来看,混凝土在养护龄期7 d内呈收缩状态,7 d之后开始膨胀;在21~90 d龄期内膨胀速率较快;90 d之后膨胀速率变慢。

图1 混凝土自由膨胀变形曲线

Fig.1 Deformation curves of concrete under unrestrained condition

2.2 混凝土抗压强度

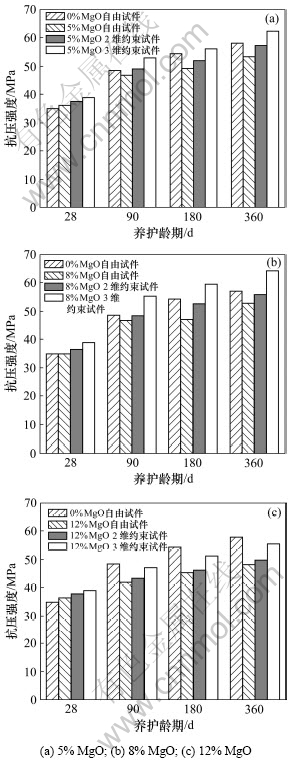

图2所示为不同掺量MgO混凝土在不同龄期时的抗压强度。28 d时,掺5% MgO混凝土自由试件、2维约束试件和3维约束试件的抗压强度均高于空白试件(0% MgO自由试件)。90 d时,自由试件抗压强度略低于空白试件,2维约束试件抗压强度与空白试件相当,3维约束试件抗压强度最高,为53.0 MPa。180和360 d龄期时,自由试件与2维约束试件抗压强度均低于空白试件,3维约束试件抗压强度仍然最高,分别为56.2和62.3 MPa,分别比自由试件提高了14.0%和16.9%。

MgO掺量为8%的自由试件28 d龄期时的抗压强度与空白试件相当,2维约束试件抗压强度略比前两者的高;自由试件90 d龄期后抗压强度均比空白试件的低,2维约束试件抗压强度与空白试件相差不大,但均高于自由试件的抗压强度,3维约束试件抗压强度在各龄期时均最高,28,90,180和360 d时分别为38.9,55.2,59.5和64.3 MPa。MgO掺量至12%时,自由试件、2维约束试件和3维约束试件强度均高于空白试件,且随约束维数的增加,强度增大。但90 d龄期及以后,自由试件、2维约束试件和3维约束试件的抗压强度均低于空白试件。

分析以上结果可以看出:混凝土强度随着养护龄期的延长而增加,MgO掺量和不同的约束条件对混凝土的强度均有一定的影响。相同掺量MgO混凝土试件在不同龄期时的抗压强度均呈如下规律:3维约束试件抗压强度>2维约束试件抗压强度>自由试件抗压强度。在约束条件下,与空白试件相比,适当的MgO掺量可以使得混凝土抗压强度有一定程度的提高,如掺8% MgO混凝土在3维约束条件下360 d龄期时抗压强度比空白试件和相同MgO掺量的自由试件分别提高了12.8%和22.0%。因此,在MgO微膨胀补偿收缩混凝土工程设计时,有必要分析具体工程所受的约束条件,结合MgO的掺量,找出最佳的切合点对提高工程混凝土的力学性能具有重要的意义。

图2 约束条件对MgO混凝土抗压强度的影响

Fig.2 Effects of restrained conditions on compressive strength of concretes with MgO

2.3 混凝土的劈拉强度

图3所示为不同掺量MgO混凝土的劈拉强度。MgO掺量为5%时,自由试件劈拉强度在各个龄期略高于空白试件(0% MgO),3维约束试件劈拉强度随着养护龄期的延长增长较快,28,90和180 d养护龄期时的劈拉强度分别为2.90,4.01和4.61 MPa,分别比相同MgO掺量的自由试件高7.41%,14.57%和15.25%,比空白试件高11.54%,21.51%和18.21%。

MgO掺量为8%时,自由试件在各个龄期时的劈拉强度均低于空白试件,3维约束试件劈拉强度则高于空白试件。3维约束试件在28,90和180 d时的劈拉强度分别为3.28,4.35和4.80MPa,比同龄期的自由试件分别高32.93%,31.03%和33.33%,比同龄期空白试件高20.73%,24.14%和18.75%。

当MgO掺量至12%时,3维约束试件和空白试件劈拉强度强度相差不大。自由试件劈拉强度与3维约束试件和空白试件相比有明显的下降,其28,90和180 d时的劈拉强度分别比约束试件低16.9%,20.0%和20.0%。

以上分析可以看出,相同MgO掺量混凝土自由试件和约束试件劈拉强度都随着养护龄期的延长而增加。自由条件下,混凝土的劈拉强度随着MgO掺量由5%增加至12%而趋于降低,而约束条件下,混凝土的劈拉强度随着MgO掺量的增加是先增加后降低。这表明约束条件下,适当掺量MgO对混凝土劈拉强度的提高是有利的。

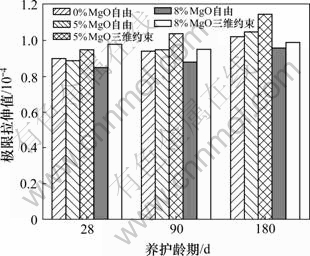

2.4 混凝土极拉值和轴拉强度

图4所示为30 ℃养护条件下,MgO掺量为0%,5%和8%的混凝土在不同龄期的极限拉伸值。从图4可以看出:在28 d龄期时,掺5% MgO混凝土的自由试件与空白试件(0% MgO)极限拉伸值相差不大,90和180 d时略高于空白试件;掺5% MgO约束试件各龄期的极限拉伸值则均高于相同MgO掺量的自由试件,28,90和180 d龄期时的极限拉伸值分别比相应龄期的自由试件极限拉伸值高6.74%,9.47%和9.52%。

当MgO掺量为8%时,自由试件在各个龄期的极限拉伸值均比相同龄期的空白试件和掺5% MgO的自由试件的低。掺8% MgO约束试件极限拉伸值在28 d时略高于5% MgO约束试件的极限拉伸值,90和 180 d龄期时则低于后者,且随着龄期的发展增长幅度不大,这可能是由于约束程度低引起的。

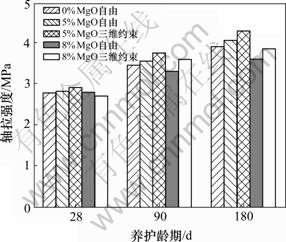

图5所示为30 ℃养护条件下,MgO掺量为0%,5%和8%的混凝土在不同龄期的轴拉强度。混凝土轴拉强度除了掺8% MgO约束试件在28 d龄期时略低于同MgO掺量的自由试件外,其他混凝土试件轴拉强度变化规律与极限拉伸值变化规律相似。

图3 约束条件对MgO混凝土劈裂抗拉强度的影响

Fig.3 Effects of restrained conditions on splitting tensile strength of concretes with MgO

图4 约束条件对MgO混凝土极限拉伸值的影响

Fig.4 Effects of restrained conditions on ultimate tensile elongation of concrete with MgO

图5 约束条件对MgO混凝土抗拉强度的影响

Fig.5 Effects of restrained conditions on tensile strength of concrete with MgO

极限拉伸值和轴拉强度是衡量混凝土抗裂能力的重要指标,极限拉伸值高能使混凝土更好地承受温度变化和干燥收缩等的变形[13],提高混凝土的极限拉伸值对混凝土抗裂能力的增强极为重要[14]。从上述结果可以看出,在其他条件相同的情况下,掺5% MgO混凝土在3维约束条件下养护能够获得较高的极限拉伸值和轴拉强度,这表明约束条件对掺适量MgO混凝土的极限拉伸值和轴拉强度提高是有利的,从而也将有助于提高混凝土的抗裂能力。

2.5 约束条件对掺轻烧MgO混凝土力学性能影响机理分析

图6(a)和(b)分别显示了约束条件下和自由条件下混凝土外掺轻烧MgO水化膨胀模型示意图。约束条件下,MgO的水化膨胀使受到试模的约束,在强约束条件下,可理想地认为混凝土宏观体积不变;自由条件下,混凝土不受约束,MgO的水化膨胀使得混凝土宏观体积增大。

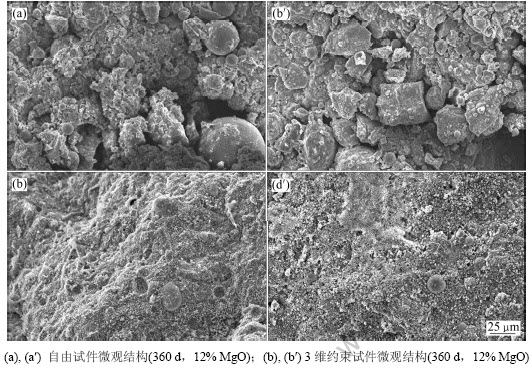

MgO水化固相体积增加,研究表明[15]:氧化镁膨胀剂中方镁石水化生成水镁石固相体积增大为原来的212.6%。水泥浆体具有黏弹性性能,在MgO水化产生的膨胀力作用下将产生黏性流动。在有外部约束下黏性流动不能使得整体混凝土产生膨胀,只能使得水泥浆体受到挤压而密实,从而提高了混凝土基体的密实性。图7所示为掺12% MgO混凝土自由试件和3维约束试件90 d时的电镜照片,3维约束试件基体结构致密,自由试件结构松散、呈多孔状,密实性差。图8所示为掺12% MgO混凝土自由试件和3维约束试件360 d龄期时的电镜照片,可以看出,自由试件随着MgO水化膨胀的进一步发展,内部结构比90 d时更加松散,而3维约束试件变化则不明显。这是导致MgO混凝土自由试件和3维约束试件力学性能随着龄期发展相差变大的主要原因。

图6 外掺MgO混凝土约束膨胀与自由膨胀示意图

Fig.6 Schematic of restrained and free expansion of concrete with MgO

另外在MgO水化膨胀力的作用下同时也推动水泥浆体向混凝土骨料界面处移动,在外部约束作用下使得混凝土基体和骨料界面结合紧密,图9(a)和(b)所示为掺12% MgO混凝土3维约束试件和自由试件360 d时骨料与基体界面结构的光学显微图像,图中显示自由试件混凝土骨料与基体之间的界面结构清晰,界面黏接相对较弱,局部还观察到有微裂纹产生;3维约束试件混凝土骨料与基体界面黏接密实,界面结合紧密,界面处为砂浆基体或水泥水化产物充分填充。

图7 90 d时自由试件与3维约束试件的微观结构

Fig.7 Microstructures of concretes under restrained and unrestrained conditions at 90 d

图8 360 d时自由试件与3维约束试件的微观结构

Fig.8 Microstructures of concretes under restrained and unrestrained conditions at 360 d

混凝土的力学性能与混凝土基体密实程度和界面结构有着密切关系,通过以上分析,相比于自由条件下,约束条件下外掺轻烧MgO混凝土基体密实度增强,混凝土界面结构紧密,在一定程度上提高了混凝土的力学性能。

图9 混凝土骨料与基体界面结构光学显微图像

Fig.9 Optical microscopy images of interface between aggregate and matrix in concrete

3 结论

(1) 掺轻烧MgO混凝土在不同约束条件下力学性能都有不同程度的提高,尤其是3维约束对混凝土力学性能提高比较明显,掺5%,8%和12% MgO混凝土3维约束试件抗压强度360 d龄期时分别比自由试件高16.9%,22.0%和16.0%,劈拉强度180 d龄期时分别自由试件高32.93%,31.03%和33.33%。掺5%和8% MgO混凝土3维约束试件极限拉伸值比自由试件分别提高9.5%和3.1%,抗拉强度分别提高5.7%和6.9%。

(2) 自由条件下,MgO掺量较大时,水化膨胀使得混凝土基体结构呈疏松、多孔状,骨料与界面黏接较弱,局部有微裂纹存在;约束条件下,混凝土基体的致密性得到提高,基体和集料界面的黏接能力较强,从而提高了混凝土的力学性能。

参考文献:

[1] 李承木. 外掺MgO混凝土的基本力学与长期耐久性能[J]. 水利水电科技进展, 2000, 20(5): 30-35.

LI Cheng-mu. Basic mechanics and long term durability of concrete mixed with MgO[J]. Advances in Science and Technology of Water Resources, 2000, 20(5): 30-35.

[2] 赵顺增, 游宝坤. 补偿收缩混凝土裂渗控制技术及其应用[M]. 北京: 中国建筑工业出版社, 2010: 136-138.

ZHAO Shun-zeng, YOU Bao-kun. Anti-cracking and leakage control technology compensation shrinkage concrete and its application[M]. Beijing: China Architecture and Building Press, 2010: 136-138.

[3] 李承木, 陈学茂. 外掺MgO混凝土基本力学性能的温度效应[J]. 水力发电, 2006, 32(8): 31-33, 37.

LI Cheng-mu, CHEN Xue-mao. Temperature effect test of mechanics property of concrete mixed with MgO[J]. Water Power, 2006, 32(8): 31-33, 37.

[4] 陈理达, 谢立国, 李红彦, 等. 不同恒温条件外掺MgO砼基本力学性能的进一步研究[J]. 广东水利水电, 2003(2): 11-13.

CHEN Li-da, XIE Li-guo, LI Hong-yan, et al. Further study on basic mechanical of concrete mixed with MgO under different temperature conditions[J]. Guangdong Water Resources and Hydropower, 2003(2): 11-13.

[5] 杨华全, 周守贤. 掺氧化镁混凝土力学性能试验研究[J]. 人民长江, 1993(4): 49-54.

YANG Hua-quan, ZHOU Shou-xian. Study on mechanical properties of concrete with MgO[J]. Yangtze River, 1993(4): 49-54.

[6] HU Shu-guang, LI Yue. Research on the hydration, hardening mechanism, and microstructure of high performance expansion concrete[J]. Cement and Concrete Research, 1999, 29(7): 1013-1017.

[7] 曹泽生, 徐锦华. 氧化镁混凝土筑坝技术[M]. 北京: 中国电力出版社, 2003: 109-111.

CAO Ze-sheng, XU Jin-hua. Construction technology of MgO concrete dam[M]. Beijing: China Electric Power Press, 2003: 109-111.

[8] 张国新, 陈显明. 掺氧化镁混凝土的膨胀效果分析[J]. 水利学报, 2005, 36(2): 185-189.

ZHANG Guo-xin, CHEN Xian-ming. Analysis of expansion effect of magnesium oxide (MgO) in mass concrete[J]. Journal of Hydraulic Engineering, 2005, 36(2): 0185-0189.

[9] Nagatakki S, Gomi H. Expansive admixtures (mainly ettringite)[J]. Construction and Building Materials, 2007, 21(2): 428-435.

[10] 李家正, 陈霞. 外掺氧化镁混凝土性能研究综述[J]. 膨胀剂与膨胀混凝土, 2010(1): 10-14.

LI Jia-zheng, CHEN Xia. Survey of the properties of concrete mixed with MgO[J]. Expansive Agents & Expansive Concrete, 2010(1): 10-14.

[11] 莫立武. MgO膨胀剂的微观结构与性能[D]. 南京: 南京工业大学材料科学与工程学院, 2008: 102-106.

MO Li-wu. Microstructure and properties of MgO-based expansive agent[D]. Nanjing: Nanjing University of Technology. College of Materials Science and Engineering, 2008: 102-106.

[12] 吴中伟, 张鸿直. 膨胀混凝土[M]. 北京: 中国铁道出版社, 1990: 66-71.

WU Zhong-wei, ZHANG Hong-zhi. Expansive concrete[M]. Beijing: China Railway Publishing House, 1990: 66-71.

[13] 美国内务部垦务局著. 混凝土手册[M]. 王圣培, 译. 北京: 水利电力出版社, 1999: 23-26.

US Department of Interior Bureau of Reclamation. Concrete manual[M]. WANG Sheng-pei, trans. Beijing: Water Conservancy and Electric Power Press, 1999: 23-26.

[14] 刘数华, 方坤河. 混凝土的极限拉伸值研究综述[J]. 福建建材, 2007(1): 14-16.

LIU Shu-hua,FANG Kun-he. Summarization of research on ultimate tension of concrete[J]. Fujian Building Materials, 2007(1): 14-16.

[15] 方坤河. 过烧氧化镁的水化及其对混凝土自生体积变形的影响[J]. 水利发电学报, 2004, 23(4): 45-49.

FANG Kun-he. Hydration of excessively combusted magnesium oxide and its influence on autogenous volume change of concrete[J]. Journal of Hydroelectric Engineering, 2004, 23(4): 45-49.

(编辑 陈爱华)

收稿日期:2011-09-20;修回日期:2011-12-15

基金项目:国家重点基础研究发展计划(“973”计划)项目(2009CB623105);江苏省新型环保重点实验室开放基金资助项目(AE201046)

通信作者:邓敏(1965-),男,江西横峰人,教授,博导,从事混凝土材料科学研究;电话:025-83172110;E-mail: dengmin@njut.edu.cn