DOI: 10.11817/j.issn.1672-7207.2017.01.016

冷轧带钢表面粗糙度影响因素及控制策略

徐冬1,张杰1,李洪波1,范庆国2,卢劲松2,董海龙2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 武汉钢铁(集团)公司,湖北 武汉,430083)

摘要:结合电火花毛化轧辊磨损形貌以及轧制界面油膜厚度的分布,建立真实表面接触的带钢表面粗糙度生成模型,研究轧辊全服役期内冷轧界面粗糙度的转印过程,并使用生产数据对模型进行验证。利用所建立的带钢表面粗糙度生成模型,确定不同磨损情况下油膜厚度与粗糙度Ra复印率的拟合关系,以此分析来料厚度、带钢屈服强度、压下率以及轧制速度对成品带钢表面粗糙度的影响。建立以调整成品机架压下率与轧制速度的冷轧带钢表面粗糙度控制策略。研究结果表明:压下率和轧制速度对表面粗糙度的转印行为有明显影响,能够成为调节带钢表面粗糙度复印率的主要手段。

关键词:冷轧;粗糙度;转印;控制策略

中图分类号:TG335.12 文献标志码:A 文章编号:1672-7207(2017)01-0112-07

Influence factors and control strategy of cold rolled strip surface roughness

XU dong1, ZHANG Jie1, LI Hongbo1, FAN Qingguo2, LU Jinsong2, DONG Hailong2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron & Steel (Group) Corp., Wuhan 430083, China)

Abstract: Based on the worn surface topography of EDT work roll and the distribution of lubrication oil at rolling interface, surface roughness generation model in cold rolling was established by finite element method. The proposed model was of well forecasting ability, and could accurately predict the surface roughness of cold rolled steel strip. The relationship between steel strip surface topography and the minimum lubrication oil thickness was analyzed by means of simulation results. In addition, according to the established relationship and the distribution of oil film thickness, the effect of rolling parameter on the generation of strip surface topography was obtained. Control strategy aiming at control the surface roughness of steel strip by adjusting the rolling speed and reduction ratio in S5 stand was proposed. The results show that reaction ratio and rolling speed have a significant impact on the process of surface roughness transfer.

Key words: cold rolling; surface roughness; transfer; control strategy

表面形貌是冷轧带钢最重要的表面质量指标之一,对高档汽车面板和家电面板的冲压性能[1-2]、润滑性能[3-5]、辊涂或喷涂后漆面与基体结合力[6]有重要影响。实际生产中,为了快速高效地测量带钢表面形貌,便于带钢表面质量控制,一般用算术平均粗糙度Ra对带钢表面形貌进行表征。算术平均粗糙度Ra是实际生产中最主要的表面形貌表征参数,也是冷连轧过程中带钢表面形貌最重要的被控对象。针对冷轧带钢表面形貌生成过程影响因素的问题,轧制试验、滑移线法和有限元仿真分析是主要的研究方法。MA等[7]通过轧制实验,对不同压下量、不同润滑条件下得到的冷轧带钢三维表面形貌进行了测量,并对轧制前后表面形貌特征参数的变化进行了分析,得到了压下量和润滑条件对表面形貌转印过程的影响规律。SHI等[8]用滑移线法分析了带有锯齿状粗糙峰轧辊的粗糙度转印问题,总结了具有锯齿状刚体压下并移开后带钢的表面特征。SHI等[9]在随后的研究中使用有限元软件仿真刚性锯齿作用在弹塑性表面之后的自由表面的轮廓变化,在此基础上利用滑移线方法分析平整过程粗糙度的转印问题。KIJIMA等[10-11]假设轧辊形貌为一系列半圆形微凸体,建立了形貌转印过程的有限元模型,总结了不同压力条件下表面粗糙度转印的规律。KIJIMA[12]通过转印过程有限元模型重点分析了轧辊半径对表面粗糙度转印过程的影响。在这些针对形貌转印过程的有限元模型中,轧辊的粗糙表面由理想微凸峰代替,这与毛化轧辊真实的表面形貌[13]存在较大差距,此外这些模型中并未考虑轧辊形貌的磨损,因此,不能分析轧辊整个服役期的粗糙度转印特点。针对带钢表面粗糙度的控制问题,一些学者[14-16]采用函数回归的方法研究了冷轧过程带钢表面粗糙度的生成规律,在此基础上建立了带钢粗糙度的控制模型,在工业现场取得了良好的效果,但由于预测模型是由测量数据回归分析得到的,一旦产品种类或轧制工艺发生改变,模型的精度不能得到保证,因此,通用性较差。本文作者将建立真实表面接触的带钢表面粗糙度生成模型,结合轧制界面油膜厚度的分布研究冷轧工艺参数对生成带钢表面粗糙度的影响,在此基础上提出带钢表面粗糙度的控制策略。

1 冷轧带钢表面粗糙度生成过程建模

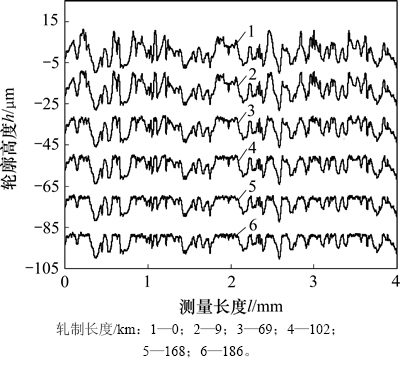

在轧制过程中,轧辊的硬度远远大于带钢的硬度,因此,在研究中把轧辊的形貌视为刚体,而带钢为塑性变形体。冷连轧机前4机架的工作辊表面经过磨床磨削,上机表面粗糙度在0.5 μm以下,带钢经过前4机架大压下率的轧制形成的粗糙度相对于5机架电火花毛化辊很小,因此,在建模中假设5机架入口处的带钢表面光滑。根据轧制界面润滑分析建立的轧辊表面磨损模型[17],电火花毛化工作辊在实际服役过程中轧制不同长度带钢的磨损预测形貌如图1所示。在带钢冷轧过程中,轧辊表面凸峰端部压入带钢表面,使带钢产生塑性变形,形成与凸峰具有相似形状的凹坑。同时,在凹坑的周围金属发生隆起,形成具有凸起特征的环形边缘,毛化轧辊的表面形貌在带钢表面的这种转印行为,是形成带钢表面形貌的主要过程。

图1 电火花毛化工作辊磨损形貌

Fig. 1 Worn surface topographies of electrical discharge textured surface

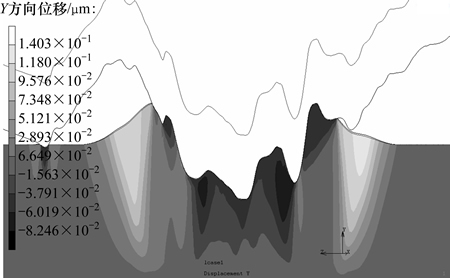

使用有限元Marc 软件建立真实表面接触的带钢表面粗糙度生成模型。建模时,根据磨损分析得到的毛化轧辊表面磨损形貌,在模型中依次建立形貌的特征点,连接成连续曲线代表轧辊轮廓。带钢的材料选用普通碳素钢,材料弹性模量E=200 GPa,泊松比 =0.3,为提高计算精度,采用网格重划分技术。计算终止条件为轧辊与带钢之间的平均间隙达到最小油膜厚度。图2所示为模型计算得到的带钢表层单元局部变形的结果,计算完成后提取带钢表面节点位置坐标即为轧制后的带钢表面形貌。

=0.3,为提高计算精度,采用网格重划分技术。计算终止条件为轧辊与带钢之间的平均间隙达到最小油膜厚度。图2所示为模型计算得到的带钢表层单元局部变形的结果,计算完成后提取带钢表面节点位置坐标即为轧制后的带钢表面形貌。

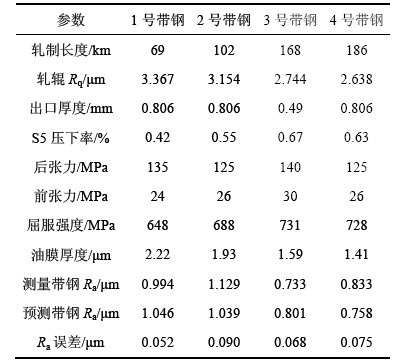

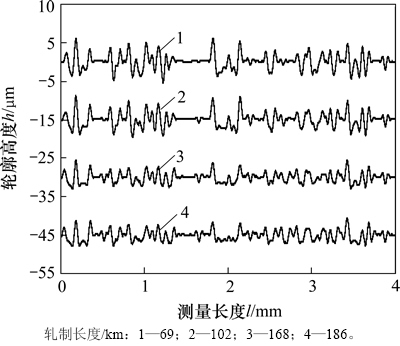

为了验证模型的准确性,对电火花毛化轧辊服役期内生产带钢表面粗糙度进行跟踪测量,记录测量带钢的生产工艺参数(如表1所示)。根据生产轧制工艺参数通过润滑模型[18]计算得到的轧制界面处最小油膜厚度,采用所建立的带钢表面粗糙度生成模型预测了轧制不同长度处带钢表面形貌,预测带钢表面的二维轮廓如图3所示。采用在德国马尔M1便携式粗糙度仪基础上进行二次开发所搭建的形貌测量分析系统对带钢形貌进行检测[19],为了减少测量的偶然误差,每次测量在展开钢卷尾部的2个不同断面进行,每个断面上分别在边部及中心位置进行3次测量,最终结果取6次测量的平均值,粗糙度的预测误差在0.1 μm以内,相对误差小于10%(如表1所示)。

图2 转印过程有限元分析结果

Fig. 2 Results after transfer action by finite element model

表1 轧辊服役期内部分带钢轧制工艺参数

Table 1 Rolling parameters of some strip during service cycles of roller

图3 预测带钢表面形貌

Fig. 3 Predicted strip surface topographies

2 轧制工况对带钢表面粗糙度的影响

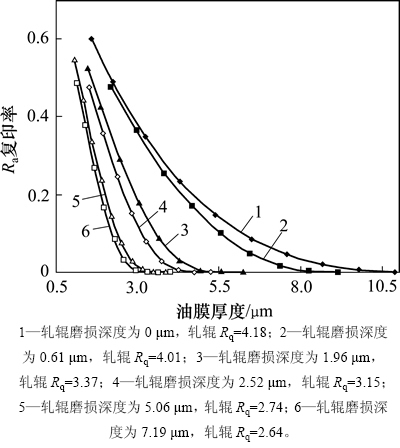

在轧制过程的某一时刻,轧制工况条件的变化会引起辊缝处的最小油膜厚度发生变化,而最小油膜厚度决定了此时表面粗糙度的复印率,因此,在研究轧制工况对转印关系的影响时,首先通过有限元仿真的结果,建立轧辊处于不同磨损情况下油膜厚度与Ra复印率的关系,如图4所示。

图4 轧辊表面不同磨损情况下油膜厚度与Ra复印率的关系

Fig. 4 Relationship between FRa and oil thickness under different wear conditions

采用四次多项式对数据点进行拟合,趋势线拟合程度R2均十分接近1,拟合结果如下:

(1)

(1)

其中:FRa为表面粗糙度复印率,是带钢与轧辊表面粗糙度的比值;h为最小油膜厚度;系数a0,a1,a2,a3和a4取值如表2所示。

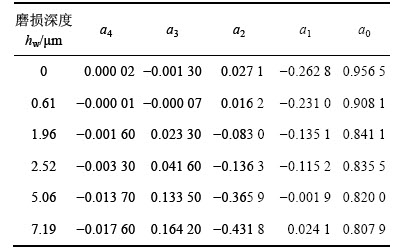

已知的磨损深度hw和Ra复印率与油膜厚度拟合关系式各项系数之间的关系如图5所示。由图5可知:各项系数的变化曲线较为平滑,因此,任意磨损深度的拟合关系式系数可采用插值的方法获得。

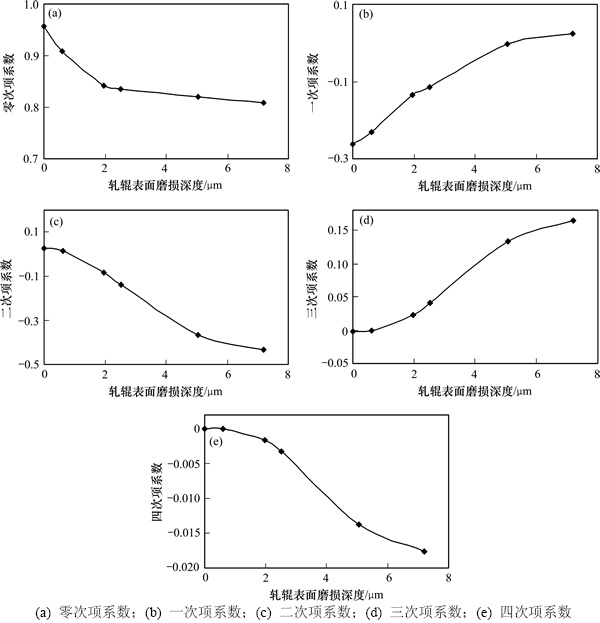

表2 轧辊不同磨损深度下的拟合系数

Table 2 Fitting coefficients under different hw

下面利用轧制界面润滑分析结果和Ra复印率与油膜厚度的关系分析轧辊表面处于不同磨损状态时,来料带钢特性和轧制工艺参数对成品带钢表面粗糙度的影响。

2.1 来料带钢对成品带钢粗糙度的影响

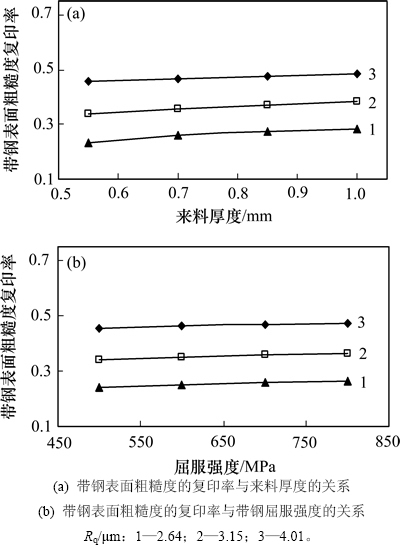

图6所示为使用电火花毛化工作辊情况下,来料带钢对成品带钢粗糙度复印率的影响,其中来料带钢影响因素包括入口带钢厚度和带钢屈服强度。

从图6可以发现:当轧辊处于不同磨损状态时,带钢表面粗糙度的复印率与来料厚度和带钢屈服强度的变化基本呈现线性关系。在相同工况条件下,随着入口带钢厚度的增加,出口带钢表面粗糙度的复印率逐渐增加;随着带钢屈服强度的增加,出口带钢表面粗糙度的复印率也逐渐增加。说明在相同情况下,来料厚度较大、屈服强度较高的带钢比较容易获得较大的粗糙度复印率。同时,随着轧辊表面的磨损,当轧辊表面Rq由4.01 μm降低到2.64 μm时,带钢表面粗糙度的复印率对来料厚度与带钢屈服强度的变化率分别从5.69×10-2 mm-1增大到1.16×10-1 mm-1和从5.19×10-5 MPa-1增大到8.32×10-5 MPa-1。总体来说,来料厚度以及带钢屈服强度对带钢表面粗糙度的转印行为的影响较小。

图5 拟合多项式各项系数随表面磨损深度的变化

Fig. 5 Change of fitting coefficients with hw

图6 来料带钢对成品带钢粗糙度复印率的影响

Fig. 6 Influence of coming strip on surface roughness transfer

2.2 工艺参数对成品带钢粗糙度的影响

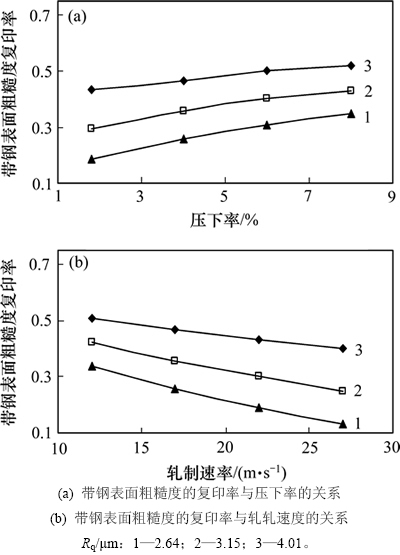

图7所示为使用电火花毛化工作辊情况下,轧制工艺参数对成品带钢粗糙度复印率的影响,轧制工艺参数影响因素包括压下率和轧制速度。

从图7可以发现:当轧辊处于不同磨损状态时,带钢表面粗糙度的复印率与压下率和轧制速度的变化也基本呈现线性关系;在相同工况条件下,随着压下率的增加,出口带钢表面粗糙度的复印率逐渐增加;随着轧制速度的增加,出口带钢表面粗糙度的复印率呈现下降趋势。其主要原因是随着压下率的减小或轧制速度的增加,辊缝处的润滑效果增强,平均油膜厚度增加,引起粗糙度复印率下降。并且压下率和轧制速度对带钢表面粗糙度的转印行为的影响较明显,能够成为调节带钢表面粗糙度复印率的主要手段。随着轧辊表面的磨损,当轧辊表面Rq由4.01 μm降低到2.64 μm时,带钢表面粗糙度的复印率对压下率和轧制速度的变化率分别从1.38×10-2 %-1增大到2.57× 10-2 %-1和从-7.18×10-3 s/m增大到-1.39×10-2 s/m。因此,为了获得较大的带钢表面粗糙度,只要在成品厚度及板形满足要求的前提下,在允许的范围内增加压下率、减小轧制速度即可。

图7 工艺参数对成品带钢粗糙度复印率的影响

Fig. 7 Influence of rolling parameter on surface roughness transfer

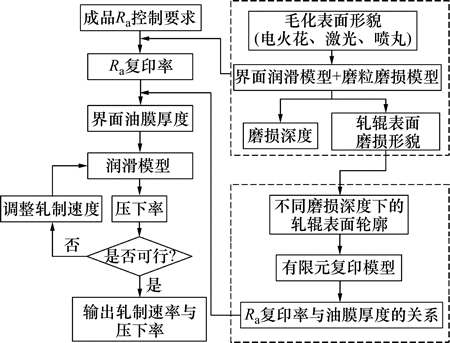

3 带钢表面粗糙度控制策略

对于冷连轧生产而言,建立成品带钢表面粗糙度生成模型的目的除了预报之外,更重要的在于根据用户对带材表面粗糙度的要求实时调整工艺参数来控制带钢表面粗糙度,满足用户的需求。在众多的影响带钢表面粗糙度生成的因素中,只有轧制速度与成品机架的压下率可以在线调整,完成带钢表面粗糙度的控制[20]。因此,本文在结合轧辊形貌磨损分析以及轧制界面润滑分析的基础上,通过带钢表面粗糙度生成模型,提出对成品带钢表面粗糙度的控制策略,控制策略的基本流程如图8所示,基本过程如下。

图8 冷轧成品带钢表面粗糙度控制策略流程图

Fig. 8 Flow chart of control strategy of cold rolled strip surface topography

1) 在轧辊上机之前,测量轧辊表面的原始二维轮廓,并以此为初始条件,在轧制过程中通过轧制界面润滑分析及轧辊表面形貌磨损分析确定此时轧辊的磨损深度及轧辊表面的磨损形貌。因为表面形貌具有随机性,测量同样具有随机性,为了避免不必要的测量误差以及提高计算效率,可以建立不同毛化手段、不同毛化工艺下的标准化表面形貌,在离线条件下求解不同磨损深度下的表面磨损轮廓,在控制过程中直接调取相关数据。

2) 利用轧辊表面的磨损轮廓,建立带钢表面粗糙度生成过程的有限元模型,计算Ra复印率与油膜厚度的关系。因为有限元模型的建立及计算时间较长,不能满足在线控制的要求,不同磨损形貌的Ra复印率与油膜厚度的关系可以使用本文中建立的多项式关系代替。

3) 针对成品带钢表面Ra的要求,以及过程1)中得到瞬时轧辊磨损形貌,可以计算此时需要达到的Ra复印率,并通过过程2)中建立的对应关系求得需要达到的最小油膜厚度。之后通过轧制润滑的分析确定压下率,若确定的压下率在可调控的范围内,则输出相应的轧制工况;若压下率过大或者过小,则不符合连轧机最后机架厚度及板形控制需求,对轧制速度进行调节,重新计算压下率直到满足需求为止。为了减少计算时间,可离线建立常见轧材及规格润滑状态表,在控制过程中,通过多维插值的方法确定压下率和轧制速度。

4 结论

1) 建立了真实表面接触的带钢表面粗糙度生成模型,结合轧辊形貌磨损和轧制界面油膜厚度的分布研究了轧辊全服役期内轧制界面粗糙度的转印过程,并使用生产数据对模型进行了验证。

2) 利用所建立的带钢表面粗糙度生成过程有限元模型,确定了不同磨损情况下油膜厚度与Ra复印率的拟合关系,结合界面润滑分析,研究了来料特征以及轧制工艺对成品带钢表面粗糙度的影响。发现压下率和轧制速度对带钢表面粗糙度的转印行为的影响较为明显,能够成为调节带钢表面粗糙度复印率的主要手段。

3) 结合润滑分析、轧辊形貌磨损分析以及所建立的带钢表面粗糙度生成模型,提出了以调整成品机架压下率与轧制速度的冷轧带钢表面粗糙度的控制策略,为冷轧带钢表面粗糙度的控制提供了依据。

参考文献:

[1]  M, PODGORNIK B,

M, PODGORNIK B,  J. Influence of surface preparation on roughness parameters, friction and wear[J]. Wear Tribology of Engineered Surfaces, 2009, 266(3/4): 482-487.

J. Influence of surface preparation on roughness parameters, friction and wear[J]. Wear Tribology of Engineered Surfaces, 2009, 266(3/4): 482-487.

[2] LIU Zhaobing, LIU Sheng, LI Yanle, et al. Modeling and optimization of surface roughness in incremental sheet forming using a multi-objective function[J]. Materials and Manufacturing Processes, 2014, 29(7): 808-818.

[3]  M, PODGORNIK B,

M, PODGORNIK B,  J. Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surfaces[J]. Tribology International, 2010, 48: 102-112.

J. Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surfaces[J]. Tribology International, 2010, 48: 102-112.

[4] XU Dong, ZHANG Jie, LI Hongbo, et al. Effect of surface spacing parameters on mixed lubrication condition[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2014, 228(5): 577-583.

[5] MASJEDI M, KHONSARI M M. On the effect of surface roughness in point-contact EHL: formulas for film thickness and asperity load[J]. Tribology International, 2015, 82: 228-244.

[6] SCHEERS J, VERMEULEN M, De MARE C, et al. Assessment of steel surface roughness and waviness in relation with paint appearance[J]. International Journal of Machine Tools and Manufacture, 1998, 38(5/6): 647-656.

[7] MA B, TIEU A K, LU C, et al. An experimental investigation of steel surface characteristic transfer by cold rolling[J]. Journal of Materials Processing Technology, 2002, 125(2): 657-663.

[8] SHI J Y, MCELWAIN D L S, DOMANTI S A. Some surface profiles of a strip after plane-strain indentation by rigid bodies with serrated surfaces[J]. Journal of Materials Processing Technology, 2002, 124(1/2): 227-237.

[9] SHI J Y, MCELWAIN D L S, DOMANTI S A. Some plastic deformation modes for indentation of half space by a rigid body with serrated surface as a model of roughness transfer in metal forming[J]. Journal of Engineering Materials and Technology, Transactions of the ASME, 2002, 124(2): 146-151.

[10] KIJIMA H, NIELS B. Skin-pass rolling Ⅰ: studies on roughness transfer and elongation under pure normal loading[J]. International Journal of Machine Tools and Manufacture, 2008, 48(12/13): 1313-1317.

[11] KIJIMA H, BAY N. Skin-pass rolling Ⅱ-Studies of roughness transfer under combined normal and tangential loading[J]. International Journal of Machine Tools and Manufacture, 2008, 48(12/13): 1308-1312.

[12] KIJIMA H. Influence of roll radius on roughness transfer in skin-pass rolling of steel strip[J]. Journal of Materials Processing Technology, 2014, 214(5): 1111-1119.

[13] 徐冬, 李洪波, 张杰, 等. 冷轧平整机毛化辊表面形貌特征多参数对比分析[J]. 中南大学学报(自然科学版), 2014, 45(3): 734-741.

XU Dong, LI Hongbo, ZHANG Jie, et al. Surface topography multi-parameter analysis of textured rolls in cold temper mill[J]. Journal of Central South University (Science and Technology), 2014, 45(3): 734-741.

[14] 周庆田, 白振华, 王骏飞. 冷连轧过程板面粗糙度模型及其应用的研究[J]. 中国机械工程, 2007, 18(14): 1743-1746.

ZHOU Qingtian, BAI Zhenhua, WANG Junfei. Research and application of strip surface roughness model about tandem cold mill[J]. China Mechanical Engineering, 2007, 18(14): 1743-1746.

[15] 陈金山, 李长生. 不锈钢冷连轧板带的表面粗糙度建模[J]. 东北大学学报(自然科学版), 2013, 34(8): 1123-1127.

CHEN Jinshan, LI Changsheng. Modeling for surface roughness of stainless steel strip in tandem cold rolling[J]. Journal of Northeastern University (Natural Science), 2013, 34(8): 1123-1127.

[16] 张晓峰, 李瑞, 张勃洋, 等. 平整轧制过程中带钢表面形貌的生成模型[J]. 机械工程学报, 2013, 49(14): 38-44.

ZHANG Xiaofeng, LI Rui, ZHANG Boyang, et al. Model for the generation of surface topography in steel strip temper rolling[J]. Journal of Mechanical Engineering, 2013, 49(14): 38-44.

[17] XU Dong, ZHANG Jie, LI Hongbo, et al. Research on surface topography wear of textured work roll in cold rolling[J]. Industrial Lubrication and Tribology, 2015, 67(3): 269-275.

[18] SHEU S, WILSON W R D. Mixed lubrication of strip rolling[J]. Tribology Transactions, 1994, 37(3): 483-493.

[19] XU Dong, ZHANG Jie, LI Hongbo, et al. Design of 3-D functional characteristic parameters of rolling interface measurement system[C]// 2nd International Conference on Recent Trends in Materials and Mechanical Engineering. Singapore, 2013: 56-61

[20] 白振华,王骏飞. 冷连轧机成品板面粗糙度控制技术的研究[J]. 钢铁, 2006, 41(11): 46-49.

BAI Zhenhua, WANG Junfei. Control technique for surface roughness of strip in cold tandem rolling[J]. Iron and Steel, 2006, 41(11): 46-49.

(编辑 杨幼平)

收稿日期:2016-01-20;修回日期:2016-03-12

基金项目(Foundation item):国家自然科学基金资助项目(51404023, 51604024);中央高校基本科研业务费专项资金资助项目(FRF-TP-15-001A1);中国博士后科学基金资助项目(2016M590042);国家科技支撑计划项目(2015BAF30B01) (Projects(51404023, 51604024) supported by the National Natural Science Foundation of China; Project (FRF-TP-15-001A1) supported by Fundamental Research Funds for the Central Universities; Project(2016M590042) supported by China Postdoctoral Science Foundation; Project(2015BAF30B01) supported by National Key Technology Support Program)

通信作者:徐冬,博士,从事板带轧制过程板形与表面形貌控制研究;E-mail: xudong@ustb.edu.cn