文章编号:1004-0609(2007)05-0757-06

纳米CeO2p/Zn-4.5%Al复合材料的高能超声制备及其力学性能

周衡志,李子全,陈建康,胡孝昀

(南京航空航天大学 材料科学与技术学院,南京 210016)

摘 要:设计一套高能超声搅拌装置,并在氩气氛保护下,通过对纳米CeO2进行预处理及控制工艺参数,用该装置制备了CeO2质量分数分别为1%~6%的纳米CeO2p/Zn-4.5%Al复合材料。用SEM观察颗粒的分散情况,测试材料的室温拉伸性能。结果表明:所设计的装置结构合理、超声作用效果佳;纳米CeO2可以单粒分散入基体合金中;随着CeO2质量分数的增加,复合材料的抗拉强度和弹性模量明显高于基体合金,伸长率则降低;复合材料的断裂机制为脆性断裂。

关键词:金属基纳米复合材料;纳米CeO2;高能超声搅拌法;力学性能

中图分类号:TB 331 文献标识码:A

Preparation and mechanical properties of nano-CeO2p/Zn-4.5%Al composite materials by high-power ultrasonic technology

ZHOU Heng-zhi, LI Zi-quan, CHEN Jian-kang, HU Xiao-yun

(College of Materials Science and Technology, Nanjing University of Aeronautics & Astronautics,

Nanjing 210016, China)

Abstract:A suit of high-power ultrasonic stirring device was designed to prepare nano-CeO2p/Zn-4.5%Al composites with mass fraction from 1% to 6% through pretreating the reinforcement nano-CeO2 particulates and controlling proper process parameters. Reinforcement distribution was observed by SEM and tensile properties of the composites were tested at room temperature. The results show that the designed device has reasonable structure and well high-ultrasonic effect, and the nano-CeO2 can be homogenously mono-dispersed in the matrix. Compared with the matrix alloy, the tensile strength and elastic modulus of the composites increase obviously with the increment of mass fraction of particles, while the elongation decreases. The tensile fracture also shows that the damage mechanism of composites is brittle fracture.

Key words: metal matrix nanocomposites; nano-CeO2; high-power ultrasonic stirring technology; mechanical property

稀土改性锌基合金表现出优异的理化和力学性能,正成为材料科学领域内的研究热点[1-2]。研究表明,纳米CeO2的加入能显著提高Zn-Al热镀层合金的耐腐蚀性[3-7]。目前报道的制备纳米CeO2/Zn-Al复合材料的方法主要有高能球磨法和机械搅拌铸造法[8-10],纳米粉体很难均匀分散在合金中。与之相比,应用声空化和声流效应的高能超声搅拌法[11-14]能有效改善小粒径颗粒/熔体间的润湿性以及颗粒在基体中的分散性,对基体组织还具有除气、除渣作用[15],并具备高能、高效和高速的特点,是一种较为理想的制备金属基纳米复合材料(MMNC)方法[16-17]。

但是,该法制备MMNC尚处于实验阶段,主要困难在于:1) 纳米微粒在使用前就易团聚,进入金属基体液后的分散困难大;2) 变幅杆形成的能量场不均匀;3) 超声变幅杆端部易受应力腐蚀、高温腐蚀及空化腐蚀,既影响超声装置的正常使用,又污染了基体合金的成分,甚至产生不利于材料性能的化合物;4) 基体熔液表层氧化膜阻碍纳米增强相与金属液体间的浸润。

本文作者针对上述问题,首先开展纳米颗粒的表面预处理工艺研究,以改善其团聚状态;然后,设计了一套高能超声搅拌装置,并在氩气保护下采用高能超声搅拌法制备不同质量分数的纳米CeO2p/Zn- 4.5%Al复合材料,以提高基体合金的耐蚀和力学性能,并对其结构、颗粒分散性及室温拉伸性能进行表征。

1 实验

1.1 高能超声搅拌装置的设计

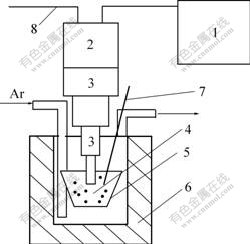

装置主要包括超声发生器、变幅杆施振器(带有循环冷却水系统)和加热保温装置,其结构如图1所示。熔体的加热保温由电阻加热炉、热电偶和控温仪自动完成,并采用氩气保护;换能器和变幅杆的上下移动由手柄摇动完成;变幅杆的施振方式采用直接浸入熔体的垂直振动方式,变幅杆小端尺寸略小于坩埚,保证作用能量场均匀,提高超声搅拌质量;超声发生器的功率在0~1 000 W连续可调,超声频率则由NFC- 1000C-1型多功能计数器测得。

1—Ultrasonic power supply; 2—Ultrasonic transducer; 3—Waveguide; 4—Melts+particulates; 5—Crucible; 6—Resistance furnace; 7—Thermocouple; 8—Water-cooling pipe

图1 高能超声搅拌装置

Fig.1 Schematic diagram of MMNC fabricating device

超声变幅杆的主要作用是位移放大和聚能。当面积系数N相同时,阶梯形变幅杆的放大系数最大,其次是悬链线形、指数形,最小是圆锥形,而且阶梯形变幅杆的输入阻抗变化较小。因此,考虑到功率超声处理的负载为液体,研究采用阶梯形变幅杆,可以满足振幅尽可能放大的要求[18]。图1中设计的变幅杆大端面至小端面的直径依次90、50、39和16 mm。

1.2 复合材料样品的制备

纳米颗粒的预处理是制备MMNC不可缺的环节之一。实验中,将400 mL丙酮和10 mL表面活性剂A的混合溶液超声搅拌5 min,使其混合均匀,将平均粒径20 nm的 CeO2粉末烘干后慢慢加入混合液中,超声作用约1 h,静置沉淀,倒去上层清液后将剩余物置于烘箱中于80 ℃通风烘干,碾碎后立即加到合金液表面。

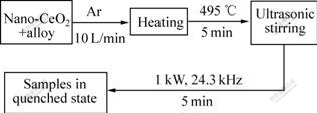

设计了CeO2质量分数为1%~6%的6个复合材料组分,经优化的工艺参数为:高能超声功率1 kW、频率24.3 kHz、屏极电流1 A,将量化的纳米颗粒加到熔融的基体合金液中,作用5 min后倒入不锈钢模具中,水淬,取样检测。

图2所示是制备复合材料的流程图。

图2 复合材料制备工艺流程

Fig.2 Fabrication process of MMNC

1.3 样品结构分析及性能检测方法

选择CeO2质量分数为6%的复合材料样品,抛光后在Bruker D8 Advance 型X 射线衍射仪上分析物相,Cu Kα靶,λ=0.154 18 nm,加速电压为30 kV,角度误差为±0.01°;在FEI-Sirion型场发射扫描电镜上观察纳米增强颗粒在基体中的分散性,加速电压为20.0 kV。

按照GB 6397—1986,用线切割机从待测复合材料样品上切取厚度为1 mm、宽度为10 mm、标距长度为15 mm的系列板状拉伸试样,然后在WD-10A型电子万能实验机上测试其室温拉伸性能,拉伸参数为:速度1 mm/s、温度25 ℃,并在扫描电镜下观察其断口形貌。

2 结果与讨论

2.1 超声参数

1) 变幅杆入射波振幅

振幅放大系数  ,初始超声振幅为2 μm,入射波振幅为

,初始超声振幅为2 μm,入射波振幅为 μm。

μm。

2) 熔体中变幅杆端面的振幅

超声波由钛制变幅杆进入基体合金溶液时,变幅杆端面的振幅和入射波的振幅满足下式:

(1)

(1)

式中 495 ℃时,钛制超声变幅杆的特征阻抗Z1=1.88×107 kg/(m2?s),熔体特征阻抗Z2=1/64×107 kg/(m2?s)。

所以

μm

μm

3) 熔体中变幅杆端面的声强

声波垂直入射条件下的声强透射系数 为:

为:

式中 It为透射波声强;Iλ为入射波声强,其值在超声功率1 kW、屏极电流1 A时为1.31×106 W/m2。由此,495 ℃时熔体中的超声声强为

熔体中的声压幅值pA和声强I的关系为:

式中 熔体密度ρ=6.7×103 kg/m3;声速C2=3 300 m/s。因此,pA=7.58 MPa。

计算的结果和实际的使用证明设计的超声搅拌装置结构合理、阻抗匹配,超声作用效果佳。

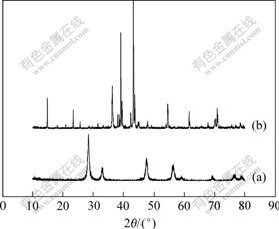

2.2 复合材料的物相

图3所示为复合材料样品的XRD谱。XRD分析结果表明,在复合材料中主要存在η(Zn)和α(Al)相,另外还有少量CeO2颗粒以及氧化物(ZnO、Al2O3)存在。纯CeO2粉的主要特征线(2θ=29°,33°,47.5°,56.5°)在图3中MMNC的谱线上都有相对应的衍射峰。这说明复合材料中存在有纳米CeO2粒子,但由于其相对含量低,所以衍射峰强度与基体相比显得略低。

图3 纯CeO2粉和CeO2p/Zn-4.5%Al复合材料的XRD谱

Fig.3 XRD patterns of pure CeO2 and CeO2p/Zn-4.5%Al: (a) Pure CeO2; (b) MMNC

2.3 复合材料中增强颗粒的分散性

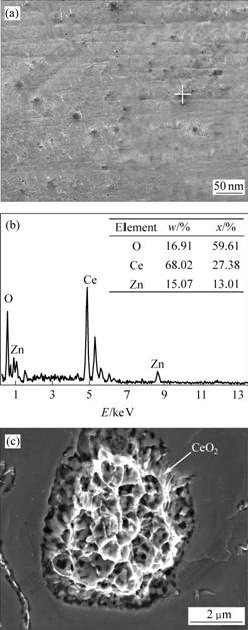

实验中发现,当CeO2质量分数逐渐增加时,熔液的粘度骤然增加,高质量分数的样品很难制备。图4(a)所示是颗粒含量为6%的复合材料水冷样的SEM图,其中的纳米CeO2增强粒子经过了预处理。从中可以看出,复合材料基体中较均匀地分散着20 nm左右的颗粒,且微粒呈单粒状分散;而图4(c)所示是选择不经预处理的CeO2颗粒作为增强相制备的复合材料的断口SEM图。从图中可以明显地看出:虽然在高能超声作用下,部分纳米微粒不经预处理可以就直接进入基体合金中,但其中的CeO2被基体液表面氧化皮包裹,分散性很差,大都呈团聚态,这将严重影响复合材料的各种性能,无法起增强作用。由此可见,经过有效的预处理工艺,在高能超声的作用下颗粒可以进入基体合金中,并且分散较均匀。图4(b)所示是图4(a)中十字交叉微区的能谱图。O元素的摩尔分数为59.61%,约为Ce元素摩尔分数27.38%的2倍,与CeO2结构式的摩尔比相同,没有过多的O出现,说明采用Ar保护措施是有效的,复合材料中的氧化现象不明显。

图4 复合材料SEM图

Fig.4 SEM morphologies of MMNC: (a) Nano-CeO2 pretreated before fabrication; (b) EDS results of crossing zone in Fig.4(a); (c) Nano-CeO2 unpretreated before fabrication

2.4 合金及复合材料的室温拉伸性能

2.4.1 抗拉强度

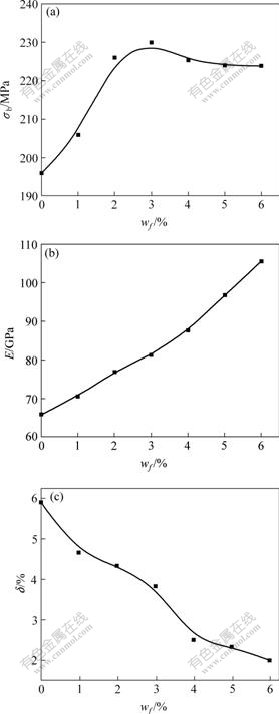

图5所示是CeO2p/Zn-4.5%Al复合材料的室温拉伸性能与CeO2质量分数(wf)的关系曲线。

图5 纳米CeO2p/Zn-4.5%Al拉伸性能与CeO2含量的关系

Fig.5 Relationships between tensile properties of CeO2p/Zn- 4.5%Al and mass fraction of nano-CeO2: (a) Curve of σb—wf; (b) Curve of E—wf; (c) Curve of δ—wf

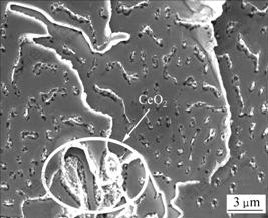

由图5(a)可知,由于纳米颗粒在基体中的弥散分布起到了强化作用,复合材料的抗拉强度σb明显高于基体合金的。当wf<3%时,σb随wf增加而急剧上升,当wf=3%时σb提高到229.9 MPa,较基体合金的196.0 MPa提高了17.3%;当wf>3%后,复合材料的σb略有平缓的下降,保持在225 MPa左右。其主要原因一方面是由于超细颗粒的加入引起了复合材料在液态时的粘度急骤变大,不易排出其中吸附的气体,在拉伸试样中形成微小的孔洞,使材料的σb降低;另一方面,当增强体颗粒的wf达到一定数量后,在基体中易形成内部结构疏松的脆性团聚体(见图6)。当复合材料受力时,外力就会由基体通过结合良好的界面传递给这些团聚体,并使之率先开裂,形成裂纹源,引起材料过早断裂,结果使复合材料的σb下降。

图6 复合材料断口形貌

Fig.6 SEM fractograph of MMNC

2.4.2 弹性模量

材料的弹性模量E是组织结构不敏感参数,复合材料的E基本符合混合定律,等于各组分E按其含量的加和。如图5(b)所示,复合材料的E与纳米CeO2的质量分数wf呈线性关系,随着wf的增加而逐渐线性增大,当wf=6%时E达到峰值105.5 GPa,比基体合金的65.8 GPa提高了60.3%。

2.4.3 伸长率

图5(c)所示是复合材料的伸长率δ随CeO2 wf变化的曲线。由图可见,δ随着wf的增加而降低。基体Zn-4.5%Al合金的塑性较差,其δ为5.9%。当复合材料受到拉伸时,分布在基体中的大量硬脆η(Zn)相(密排六方结构)极易发生脆性断裂,见图6中的白亮点。当wf从1%增加到6%时,复合材料的δ逐渐降低,直至最低的2.0%。这是因为在体积分数较高时,纳米CeO2易偏聚在复合材料中[17],在拉伸时易导致材料发生脆性断裂,断口形貌如图6所示。从图中的解理台阶也可以判断复合材料的断裂机制为脆性断裂。

3 结论

1) 设计的高能超声搅拌装置结构合理、阻抗匹配,熔体中变幅杆端面的振幅达到了53.41 μm,声强为1.30×106 W/m2,声压幅值为7.58 MPa。

2) 在熔液温度为495 ℃,功率为1 kW、频率为24.3 kHz的超声作用条件下,纳米CeO2经有效预处理后,可以呈单粒均匀分散在基体合金中;并且通氩气保护能够减少空气的卷入,有效地降低金属的氧化。

3) 与基体合金相比,纳米CeO2p/Zn-4.5%Al复合材料的抗拉强度和弹性模量明显增高,伸长率降低。随着纳米CeO2质量分数的增加,抗拉强度先急剧上升后平缓波动,弹性模量线性增大,而伸长率则逐渐下降。复合材料的断裂机制为脆性断裂。

REFERENCES

[1] 孟宪玲, 杨化滨, 王军红, 周作祥. 稀土氧化物对二次锌电极性能的影响[J]. 电化学, 2005, 11(1): 58-61.

MENG Xian-ling, YANG Hua-bin, WANG Jun-hong, ZHOU Zuo-xiang. Influence of Rare earth oxide on the performance of secondary zinc electrodes[J]. Electrochemistry, 2005, 11(1): 58-61.

[2] 李亚国, 朱奕庆, 薛 涛, 刘海林, 李 平. 铈对ZZn4-1锌合金性能和微观组织的影响[J]. 中国稀土学报, 1999, 17(4): 373-376.

LI Ya-guo, ZHU Yi-qing, XUE Tao, LIU Hai-lin, LI Ping. Effect of cerium on mechanical properties and morphology of ZZn4-1 alloy[J]. Journal of the Chinese Rare Earth Society, 1999, 17(4): 373-376.

[3] ZHANG X Y , WANG T W , JIANG W Q , WU D, LIU L, DUAN A H. Preparation and Characterization of three-dimensionally ordered crystalline macroporous CeO2[J]. Chinese Chemical Letters, 2005, 16(8): 1109-1112.

[4] 朱兆武, 龙志奇, 崔大立, 张顺利, 张国成. 超细CeO2粉体的制备及其紫外线吸收性能[J]. 中国有色金属学报, 2005, 15(3): 435-440.

ZHU Zhao-wu, LONG Zhi-qi, CUI Da-li, ZHANG Shun-li, ZHANG Guo-cheng. Preparation of ultra-fine particle-sized CeO2 powder and its UV absorbance[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 435-440.

[5] 郭广生, 李 铎, 王志华, 顾福博, 郭洪猷. 激光蒸凝法制备氧化铈纳米粒子[J]. 稀有金属材料与工程, 2005, 34(6): 928-931.

GUO Guang-sheng, LI Duo, WANG Zhi-hua, GU Fu-bo, GUO Hong-you. Preparation of CeO2 superfine powder by laser heating gas-evaporation method[J]. Rare Metal Materials and Engineering, 2005, 34(6): 928-931.

[6] 骆心怡, 何建平, 朱正吼, 李顺林, 卢 翔. 纳米氧化铈颗粒对电沉积锌层耐蚀性的影响[J]. 材料保护, 2003, 36(1): 1-4.

LUO Xin-yi, HE Jian-ping, ZHU Zheng-hou, LI Shun-lin, LU Xiang. Effect of ceria nanoparticles on corrosion resistance of electrodeposited zinc coating[J]. Materiais Protection, 2003, 36(1): 1-4.

[7] 何建平, 骆心怡, 李顺林. 纳米氧化铈微粒对锌镀层结构和耐蚀性能的影响[J]. 稀土, 2003, 24(1): 24-27.

HE Jian-ping, LUO Xin-yi, LI Shun-lin. Effect of CeO2 nanoparticle on structure and properties of zinc electrodeposition[J]. Chinese Rare Earths, 2003, 24(1): 24-27.

[8] LUO X Y , HE J P , LI S L. CeO2/Zn nanacomposite coating by electrodeposition[J]. Transactions of Nanjing University of Aeronautics and Astronautics, 2002, 19(2): 161-165.

[9] 周衡志, 李子全, 杨继年. 纳米CeO2/Galfan 复合材料的制备工艺[J]. 南京航空航天大学学报, 2005, 35(5): 603-606.

ZHOU Heng-zhi, LI Zi-quan, YANG Ji-nian. Fabrication process of nano-CeO2 particulates/Galfan composites[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2005, 35(5): 603-606.

[10] 王武孝, 袁 森. 铸造法制备颗粒增强金属基复合材料的研究进展[J]. 铸造技术, 2001, 2: 42-45.

WANG Wu-xiao, YUAN Sen. Research and development of fabrication PRMMC by casting process[J]. Foundry Technology, 2001, 2: 42-45.

[11] LAN J , YANG Y , LI X C. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method[J]. Materials Science and Engineering A, 2004, A386: 284-290.

[12] SHI Gui-xia, LIU Zhen-gang, HAO Xiao-peng, et al. Preparation of GaP/RhB nanocomposite by ultrasonic irradiation[J]. Inorganic Chemistry Communications , 2003, 6(4): 349-351.

[13] 潘 蕾, 陈 锋, 吴申庆. 高能超声作用下SiCp/ZA27复合材料的制备及性能[J]. 铸造, 2003, 52(4):235-238.

PAN Lei, CHEN Feng, WU Shen-qing. Preparation of SiCp/ZA27 composites using high-intensity ultrasound and their properties[J]. Foundry, 2003, 52(4):235-238.

[14] 马立群, 陈 锋, 舒光冀. 用高能超声法制备微细颗粒增强金属基复合材料[J]. 材料研究学报, 1995, 9(4): 373-375.

MA Li-qun, CHEN Feng, SHU Guang-ji. Preparation of fine particulate metal-matrix composites by high intensity ultrasound[J]. Chinese Journal of Material Research, 1995, 9(4): 373-375.

[15] 陈 锋, 何德坪, 舒光冀. 振动干扰频谱对凝固组织形态的影响[J]. 东南大学学报, 1994, 24(4): 45-50.

CHEN Feng, HE De-ping, SHU Guang-ji. Influence of frequency spectrum of vibrational disturbances on solidification morphologies[J]. Journal of Southeast University, 1994, 24(4): 45-50.

[16] 龚荣洲, 沈 翔, 张 磊, 张 凌. 金属基纳米复合材料的研究现状和展望[J]. 中国有色金属学报, 2003, 13(5): 572-578.

GONG Rong-zhou, SHEN Xiang, ZHANG Lei, ZHANG Ling. Status and expectation of research on metal matrix nanocomposites [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 572-578.

[17] 贺春林, 刘常升, 孙旭东, 才庆魁. 纳米SiC颗粒增强铝基复合材料的拉伸性能[J]. 东北大学学报(自然科学版), 2005, 26(6):554-557.

HE Chun-lin, LIU Chang-sheng, SUN Xu-dong, CAI Qing-kui. Tensile properties of SiC nanoparticle reinforced pure aluminum matrix composites[J]. Journal of Northeastern University (Natural Science), 2005, 26(6): 554-557.

[18] 林仲茂. 超声变幅杆的原理和设计[M]. 北京: 科学出版社, 1987.

LIN Zhong-mao. The principle and design of ultrasonic transformer[M]. Beijing: Science Press, 1987.

收稿日期:2006-10-23;修订日期:2007-03-12

通讯作者:李子全,教授;电话:025-84892737;E-mail: ziquanli@nuaa.edu.cn

(编辑 何学锋)